It is difficult to overestimate the importance of vehicle maintenance. It allows you to significantly extend the service life and maintains maximum performance for a long time.

Attention! The main difference between maintenance and repair is the preventive component.

Timely Maintenance prevents many breakdowns and increases the safety of the machine. Repair, in turn, is a forced measure, without which the normal operation of the car is simply impossible.

Why cars need maintenance

With every day of operation, the condition of the car is only getting worse. Even with the most careful use, the running of time cannot be completely eliminated. But there is a whole range of preventive measures that can help slow it down.

Attention! The main reason for the failure of the majority internal mechanisms auto parts wear. It occurs as a result of friction between the elements of the system.

In the process of friction, the parameters of the parts change, their size decreases, in some cases serious deformation occurs. The result of the changes is an increase in clearances.

When the clearances increase, the parts working with each other cannot perform their functions normally. In this case, the driver usually hears a knock or some kind of beating. This is all due to the fact that the threaded mount is weakening. As a result, the lack of vehicle maintenance develops into such destructive phenomena as:

- decrease in engine power;

- breakage of parts;

- increased fuel consumption.

Naturally, against the background of all these factors, the overall reliability decreases. vehicle... This is why timely maintenance is so essential. This is a whole complex of actions aimed at preserving the system.

A properly organized maintenance process allows you to keep the system in good working order for a long time. THAT greatly helps to reduce the wear rate of the internal components of the car. Moreover, it is an excellent prevention of malfunctions.

Attention! THAT allows you not only to keep the internal state of the car in order, but also the external one.

The video shows how the maintenance is carried out:

Maintenance features

A car is a complex system that is quite difficult to maintain. It is not surprising that there are many types of maintenance that serve as a preventive measure for certain destructive processes.

Modern maintenance includes the following types of work:

- washing;

- lubricating;

- harvesting;

- filling stations;

- control;

- adjusting;

- fasteners.

Each species has its own specifics. Moreover, their frequency is also different. Maintenance is not only a prophylaxis against possible breakdowns and helps to maintain high productivity engine and other systems, as well as detect this or that malfunction in order to make repairs on time.

Maintenance is mandatory and carried out regularly. It is usually best to do this procedure once a month. It happens as follows:

- a plan is drawn up for a certain period;

- the plan prescribes the types of vehicle maintenance;

- a list of planned operations is drawn up.

This is a classic scheme that works in our country and in most European countries. It has long been proven effective and does not require unnecessary recommendations. Its name is planned preventive.

Types of scheduled maintenance and their frequency

The fundamentals of a maintenance system have been developed for quite some time. Back in 1962, a document appeared that was the first collection of standards. Since then, it has been redesigned many times to meet the current needs of motorists.

Taking this set of standards as a basis, all vehicle maintenance can be divided into the following types:

- daily;

- first;

- second;

- seasonal.

Each type of maintenance has its own characteristics. Take the maintenance that needs to be done every day as an example. At first glance, this may seem excessive, but in reality there is nothing wrong with it. In addition, the procedures of this complex do not present any complexity and take a minimum of time.

Daily maintenance starts with external control. In most cases, a simple inspection before starting a trip is enough to prevent a dangerous situation on the road even before leaving.

Attention! Refueling the machine and adding oil and water are also daily maintenance.

Maintenance of the first and second points is a much more serious procedure. It includes the following types of work:

- lubricating;

- fasteners;

- adjusting;

- control.

If necessary, this list can be supplemented. But it depends on the availability of a specific need. The first TO is considered relatively simple. There is no need to open the components of the structure or remove any parts. It all starts with a routine inspection. Then all the work described above is carried out.

Attention! During TO-1, special attention is paid to the inspection of the engine and control system.

Exactly these assemblies need to be inspected in detail. Such scrupulousness will allow you to get one hundred percent confidence in the performance and safety of the vehicle. By the way, these details are checked on the fly.

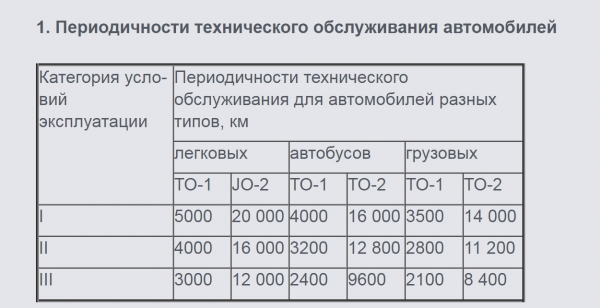

TO-2 is carried out much later than TO-1. You can find out the exact dates from the table above. As you can see, the periods for different types of vehicles differ significantly. Little of, the conditions in which the car was operated are of great importance.

The main feature of the second maintenance is a deep and thorough inspection. It needs to be done every 12,000 kilometers at least. Provided that the car had more soft conditions use, this figure can grow to 20,000.

During the second maintenance, parts and devices are removed if necessary during inspection. For this procedure, special stands and sophisticated diagnostic equipment are used.

But the second maintenance is not limited to this. It also adjusts, lubricates and secures certain system elements. Checking the operation of the units is of particular importance. This is done on the fly, of course.

Seasonal maintenance should be performed at least twice a year. It is necessary in order to prepare the vehicle for changing climatic conditions and make driving safe both in warm and cold seasons.

As an example, consider the transition of a car to winter mode. It all starts with replacing summer tires with winter tires. It is also necessary to change the oil. Otherwise, the engine will not start in cold weather.

Attention! Anti-corrosion treatment of the body will be useful when preparing a car for winter. It will protect your car from rust in any weather.

Legal aspect

Car maintenance guarantees safety not only for you, but also for all other participants road traffic... For example, if you get into an accident due to the fact that the integrity was violated hydraulic drive brake system, you will bear the full brunt of the punishment.

Attention! This malfunction is easily detected by a daily check.

Maintenance helps to avoid accidents on the road. In addition, it greatly extends the service life of the machine. The main thing is to carry out each type of maintenance in a timely manner.

Another video on how maintenance and repair of a car is carried out:

For car during the working period, the TO system includes ETO, TO-1, TO-2, STO and TO in special operating conditions.

For TR vehicles is of an application nature.

Overhaul of KR cars is carried out through the established mileage standards (in kilometers), depending on the category road conditions operation and natural and climatic zones.

Daily Maintenance (EO) includes:

Checking the vehicle arriving from the line and released on the line;

External care and refueling operations.

To check cars, the enterprise creates a control and technical point (KTP) with an inspection ditch or lifts and a set of necessary tools, fixtures and equipment. Checking cars is the responsibility of the driver and the employees of the technical control department.

When checking a car arriving from the line, the following are established:

Arrival time;

Readings of the counter of the distance traveled and the remaining fuel in the car's tank;

Completeness;

The presence of malfunctions, breakdowns, damage;

Need in current repair.

If necessary an application for current repairs is drawn up with a list of malfunctions to be eliminated, and an act of damage to the rolling stock, indicating the nature, causes of the breakdown and the persons responsible for it.

When the car is released to the line, its appearance, completeness and technical condition are checked, as well as the performance of the service or repair assigned to it the day before (according to the external inspection and accounting documentation).

The check is carried out according to a certain list of operations drawn up at the enterprise, taking into account the design and conditions of its operation. The list should provide for a mandatory check of the serviceability of systems, assemblies, assemblies and parts that affect traffic safety, including steering, brakes, suspension, wheels and tires, body and cab, outdoor lighting devices, light and sound alarms, windshield wipers.

When changing drivers on the line, the technical condition of the car at the time of its transfer is checked by the driver who finished the shift, together with the driver who starts work. Serviceability is confirmed by the signatures of the drivers in waybill with indication of transmission time and speedometer readings.

To perform external care operations, which include cleaning the body and the cab, washing and wiping or drying, posts or external care lines with washing installations and other necessary equipment are created in a motor transport company.

EO refueling operations include refueling cars with fuel, adding oil to the engine crankcase and coolant to the radiator, they are produced by drivers at the expense of their working hours, provided for by their mode of operation. Refueling is carried out, as a rule, at gas stations according to coupons, oil and water are topped up at the enterprise.

The timing of the SW is determined by the mileage per working day.

The first maintenance (TO-1) includes control, fastening, adjusting, lubrication operations, performed, as a rule, without removing or partially disassembling (opening) the serviced devices, assemblies and mechanisms.

TO-1 is performed during the period between work shifts (in between shifts).

The second maintenance (TO-2) includes all operations of TO-1, performed in an extended volume, and, if necessary, the serviced devices, assemblies and mechanisms are opened or removed.

To carry out TO-2, the vehicle can be removed from service.

Maintenance of TO-1 and TO-2 is performed after a certain mileage, set depending on the operating conditions, presented in table 7.1.

Table 7.1 - Types and frequency of vehicle maintenance for category I operating conditions

Seasonal maintenance (SO) is carried out 2 times a year. It is the preparation of the car for operation in the cold and warm seasons, mainly combined with TO-2 with a corresponding increase in the labor intensity of the work.

Each motor transport enterprise should draw up monthly schedules for the implementation of TO-1 and TO-2, taking into account the frequency of these types of services and planning the average daily runs of the rolling stock. The terms of setting the rolling stock into service can be indicated in the schedules or total mileage from the beginning of operation according to the readings of the counter of the distance traveled, or in calendar days.

Maintenance is designed to eliminate the resulting failures and malfunctions of the vehicle and units (trailers and semitrailers) and should contribute to the fulfillment of the established mileage standards before overhaul with minimal downtime. Current repairs are carried out by carrying out disassembly and assembly, fitting and fitting and other necessary work with replacement: the unit has separate worn out or damaged parts, except for the base (body) parts; at a car (trailer, semitrailer) of individual components and assemblies requiring current or major repairs.

The need for routine repairs is identified during the work on the line and during the next maintenance.

Overhaul is designed to restore the performance of cars and units and ensure mileage before subsequent overhaul or write-off of at least 80% of the norm for new cars or units. At overhaul complete disassembly of the units for parts and repair of basic parts is mandatory.

The basic (body) parts of the car include the cylinder block, gearbox housing, pipes cardan shaft, drive axle housing, beam front axle or cross member at independent suspension, steering and power steering housing, cab frame, frame longitudinal beams.

Any vehicle needs regular maintenance - a set of measures aimed at maintaining efficiency and performance characteristics of all components and assemblies of the vehicle. Regular maintenance is very important for trucks, as they are constantly exposed to severe stress, and if maintenance is not done on time, the truck's life will be drastically reduced. So maintenance is an important event that affects the efficiency of the vehicle, the cost of operating and repairing it.

Maintenance of trucks is different from servicing other types of vehicles, it has its own characteristics that every truck owner should be aware of. And here the brand, model and manufacturer of the car does not matter - both domestic and foreign trucks of all classes need maintenance equally. Therefore, here we will look at how the maintenance of trucks is carried out without reference to their types, brands and models.

Truck Maintenance Standards and Requirements

Few of the car owners know that the frequency of routine maintenance and a number of other aspects of vehicle maintenance is not a whim of automakers and dealers, but a measure regulated by a state standard. In particular, in Russia today the standard GOST 21624-81 “System of maintenance and repair of automobile equipment. Requirements for the operational manufacturability and maintainability of products ", which, among other things, sets the timing of maintenance, and also prescribes a number of requirements for the design of vehicles and their maintenance.

However, no one prevents car manufacturers from setting their own terms and requirements for maintenance, but, as practice shows, the standard reflects well the actual state of affairs and the terms of routine maintenance and the requirements set by it are fully consistent with the terms and requirements of automakers.

Scheduled maintenance intervals

The GOST 21624-81 standard establishes three types of vehicle maintenance:

Daily Maintenance (EO);

First TO (TO-1);

Second TO (TO-2).

The standard also establishes the frequency of routine maintenance (or service interval), it is measured in kilometers of vehicle mileage. Speaking specifically about trucks, the frequency different types THAT is the following:

EO - every day (once a day);

TO-1 - at least 4000 km;

TO-2 - at least 16,000 km.

It should be noted right away that the standard does not stipulate the frequency of maintenance, which should be carried out during the break-in period of the car - here the manufacturer is responsible for everything. However, for trucks, run-in lasts on average 1000 km, and many manufacturers, upon reaching such mileage, recommend replacing the engine, and sometimes transmission oil... A number of manufacturers recommend performing the first maintenance only with a mileage of 4000 km, however, this is recommended only to those drivers who fully followed the recommendations for running the car, otherwise the engine and transmission resource will be sharply reduced, which is fraught with serious costs in the future. So for greater reliability and safety, it is better to do some maintenance work with a mileage of 1000 - 1500 km.

Also, the standard does not establish another type of maintenance that is actually present in Russia - seasonal maintenance (or service station). It is held every six months in spring and summer, and is necessary to prepare the car for the upcoming seasonal changes climatic conditions.

However, there are exceptions to any rule. For example, many current models of European and American trucks, including Iveco, have an extended service interval, which can reach 40-60 thousand km. We are talking about TO-2, in which the engine oil is changed and other measures are taken. And immediately it should be noted that this does not contradict the requirements of the standard, since it indicates the minimum mileage between TO-2, and nothing is said about the maximum.

Although this is not the limit. Many trucks and mainline tractors have an service interval of 80 - 100 thousand km, but there is one "but" here - such an interval is set only for vehicles operated in Europe, for Russia it is completely unacceptable. In our country, trucks are faced with a number of negative factors that lead to increased wear of the engine and other units - low-quality fuel, poor road conditions, finally, poor-quality service, etc. And if for the same Iveco Eurocargo or Trakker to be guided by European standards for the frequency of maintenance, then the truck simply will not "live" until the next MOT, and if it does "live", it will require large repair costs.

Here the question is pertinent, with what frequency is it best to carry out maintenance of the car? It all depends on the age of the car and some other factors. If the truck is new and is still under warranty, then the service must be visited within the timeframe set by the dealer. For old cars, the service interval is chosen by the owners themselves, but in this case it is worth adhering to either the dealer's terms, or the manufacturer's recommendations, or the above standard.

Approximate scope of work for EO, TO-1, TO-2 and STO

So what is included in the maintenance work? It all depends on the mileage, that is, on the type of maintenance.

Daily service. With EO, the car is inspected for the integrity of individual mechanisms and for the presence of breakdowns, the performance of the brake system, lighting devices and other mechanisms is checked, the tire pressure is measured, and the car is washed and refueled (if necessary). That is, the EO is aimed at ensuring that the car embarks without any problems and fulfills the assigned tasks.

First THAT. With TO-1, the level of all technical fluids (oils, coolant, etc.) is checked, as well as the adjustment of various mechanisms - steering, clutch drive, brake pedal free play and others. Finally, with TO-1, the lubrication of the components, assemblies and mechanisms that require it is carried out. Lubrication work is carried out according to the map, which must be in the car or in the service of an authorized dealer.

Second MOT... With TO-2, the same work is carried out as with TO-1, as well as a number of other activities. First of all, changing the engine oil. Often, it is during TO-2 that some units are disassembled and repaired, which were simply adjusted and lubricated during TO-1. Typically, the service interval specified for this particular vehicle corresponds to the time between maintenance-2.

Seasonal maintenance. Workshop activities depend on the time of its holding. So, in the fall, during the service station, it is necessary to prepare the car for operation in the cold season (that is, at negative air temperatures). For this, antifreeze is poured into the cooling system (although in most modern cars water is practically not used anymore), an anti-freeze liquid is in the washer reservoir, and oil of a low viscosity is in the engine (although this is by no means always required). It is also mandatory to check and, if necessary, adjust the density of the electrolyte of the batteries. Finally, in the fall, it is necessary to drain the condensate from the receivers of the pneumatic system and replace the dryers (in the future, when frost sets in, it is recommended to drain the condensate at least once a week). In the spring, the amount of maintenance work is less, since trucks are much better suited for operation in the warm season than in the cold one.

Thus, during the year the owner truck conducts several different types of maintenance. As practice shows, the average annual mileage of trucks in Russia ranges from 40,000 km (with moderate operation) to 250,000 km (with active operation without downtime), and the average annual mileage is about 100,000 km. This means that, on average, a truck passes MOT-2 two, and sometimes three times a year, which requires corresponding costs. However, this cannot be avoided - without maintenance, the car will quickly deplete its resource and will require even higher costs.

Car maintenance is a series of preventive measures, these measures are carried out according to a plan or seasonally, as well as after a certain interval of mileage.

Another season is coming to an end, so the car needs to be prepared for the next one. A seasoned car enthusiast knows that regular maintenance checks will greatly extend the life of a vehicle. But not everyone knows what is meant by seasonal maintenance.

Maintenance types

Car service can be safely divided into:

- maintenance (TO-1, TO-2);

- seasonal maintenance (SO);

- daily maintenance (EO).

Any technical inspection must be carried out depending on the operating conditions of the car, as well as on its brand.

Daily maintenance

EO is the daily maintenance of the car, in most cases this is a routine inspection that needs to be carried out before leaving, but most often it is done once a week, much less often once a month, it all depends on the owner this car... The EO includes a suspension inspection, a tire pressure check, and a car body inspection for damage. paintwork(chips, scratches), it is also necessary to inspect the instrument panel of the car.

Do not forget to regularly clean and wash the car, this will protect the metal of the body from the unwanted effects of chemical compounds, as well as salt and dirt, in addition, it is advisable not to be lazy and monitor the oil level and its condition in the engine and gearbox. It is also worth checking the coolant level.

It's also worth remembering about the little furry assholes - cats that can hide under the hood or in the wheel arch. In order not to harm the animal and not get a possible breakdown, it is worth making sure that there are no extra "passengers".

During the operation of the car, as a result of exposure to a number of factors (exposure to loads, vibrations, moisture, air currents, abrasive particles, when dust and dirt hits the car, temperature effects, etc.), its irreversible deterioration occurs. technical condition associated with wear and damage to its parts, as well as a change in a number of their properties (elasticity, plasticity, etc.).

A change in the technical condition of a car is due to the operation of its components and mechanisms, the impact of external conditions and storage of the car, as well as random factors. Random factors include hidden defects in vehicle parts, structural overloads, etc.

For prevention and elimination possible problems perform daily vehicle maintenance.

Daily Maintenance (EO) performed daily before leaving the line and after the return of the car from the line in between shifts and includes: control and inspection work on mechanisms and systems that ensure traffic safety, as well as on the body, cab, lighting devices; cleaning and washing and drying and wiping operations, refueling the car with fuel, oil, compressed air and coolant. Car wash is carried out on demand, depending on weather, climatic conditions and sanitary requirements, as well as on the requirements for outward appearance car.

Control work carried out at the EO. First, you need to inspect the car (trailer, semitrailer), identify external damage and check its completeness, check the condition of the doors, cab, platform, glass, rear-view mirrors, sun visors, plumage, license plates, door mechanisms, the locking mechanism of the tilting cab, constipation sides of the platform, hood, trunk lid, tailgate of a dump truck, springs, wheels, tires, fifth wheel (towing) devices, road wheels (semi-trailer), make sure that the trailer is connected, etc.

The executive part of maintenance operations is performed as needed, based on the results of their control part. These lists are generic; are specified for specific car models and their modifications in the second part of the Regulations. On the basis of the lists of the main operations, measures are developed for the organization and technology of monitoring (diagnosing) the technical condition of the rolling stock, for performing other maintenance work. Maintenance of special vehicle equipment (pumps, refrigeration units, etc.) is carried out in accordance with the manufacturer's instructions.

During the SW process, the following activities must be performed:

Check the correctness and integrity of the sealing of the speedometer and taximeter, the operation of lighting and light alarms, a sound signal, windshield wipers, washers for the windshield and headlights, the heating and heating system (in the cold season), ventilation systems;

Check the condition of the power steering by visual inspection, check the backlash of the steering wheel, the condition of the limiters of the maximum steering angles;

Check the tightness of the power steering, brake drive and clutch release mechanism, power supply, lubrication and cooling systems, hydraulic system of the platform lifting mechanism of a dump truck, check the condition and tension of the drive belts;

Check the operation of units, assemblies, systems, speedometer, taximeter and other control and measuring instruments of the car on the move. Stop the engine and check the operation of the centrifugal oil filter by ear.

Cleaning and washing work carried out under the EO. Cleaning work is performed, as a rule, at the beginning or at the end of a shift.

When cleaning, debris, dust, dirt are removed manually or mechanically. To organize the mechanized method, electric vacuum cleaners and dust extraction plants are used.

Cleaning and washing works are performed before each maintenance and repair. After cleaning, the machine is washed in order to remove various contaminants from its surface. The difficulty in removing contaminants depends on their composition.

In the process of cleaning and washing work, the following measures must be taken:

Clean the cab (body) and platform;

Wash and dry the vehicle (trailer, semitrailer), and in necessary cases sanitize it;

Wipe off the rear-view mirrors, headlights, sidelights, direction indicators, taillights and brake light, cockpit glass, and license plates.

The performance of the machine depends on the quality of the wash. It is important to exclude the concentration of dirt and moisture in the metal structures of box-section machines and the ingress of moisture into electrical appliances and devices.

Lubrication, cleaning and filling work carried out with EO. Refueling works of machines are organized depending on their location. Refueling of cars returning to the base every day is carried out at the refueling points of the enterprise or refueling stations equipped with high-performance automatic dispensers. Refueling of cars at the site is carried out by mechanized units installed on trailers or on mobile equipment.

Refueling of cars should be carried out with the least quantitative and qualitative losses of fuel and lubricants... To avoid quantitative fuel losses, it is important to have a valve on the tip of the filling devices that turns off the fuel supply when the tank is full, as well as reliable devices for accurately determining the volume of fuel.

Changing the engine oil is planned after a certain amount of time. However, the intensity of aging largely depends on the technical condition of the engine. Therefore, it is advisable to evaluate the performance of the engine oil during the operation of the machine and to replace it when the limiting state is reached. Replenishment of the lubrication system engine oil it is also desirable to produce it in a mechanized way with the ability to control the volume to be poured. To reduce the loss of lubricants and working fluids, it is necessary to ensure the tightness of the filling and control plugs, as well as the serviceability of the air filters.

Before sending the car to the line, it is necessary to check the oil level in the crankcases of the engine and hydromechanical transmission. On vehicles with a diesel engine, check the oil level in fuel pump high pressure (high pressure fuel pump) and speed regulator crankshaft engine. Check the fluid level of the hydraulic brake and clutch release mechanism in the cooling system.

When parking the car, drain the condensate from the water separator, air cylinders of the pneumatic brake actuator, sediment from the fuel filters, fuel tank(for cars with diesel engines during the cold season). In case of garage-free storage in the cold season, drain the water from the engine cooling system and the starting heater, and before starting the engine, fill the cooling system with hot water or connect the engine to the heating system. Refuel the vehicle. Fill the windscreen and headlight washer tanks with water.

Specific work on the daily maintenance of gas vehicles.

When the engine is running on liquefied gas. Before leaving the car on the line, you must:

Check by external inspection the fastening of the gas cylinder to the brackets, the condition of the gas equipment, gas pipelines and the tightness of the connections of the entire gas system;

Check the ease of starting and the operation of the engine on gas for Idling at different speeds of the crankshaft;

Check and, if necessary, adjust the CO content in the engine exhaust gases;

Check the condition, fastening and tightness of the devices of the petrol power supply system of the engine;

Lubricate the threads of the stems of the main, filling and supply valves; remove, clean and reinstall the filter element of the main filter and the strainer gas reducer;

Check the internal tightness of the flow valves and the external tightness of the gas fittings. If the gas cylinder fittings are not tight, the vehicle cannot be admitted to the maintenance post (line) until the identified malfunctions are eliminated.

After returning the car to the transport company, you must:

By visual inspection, check the tightness of the fittings, gas cylinder and supply valves;

Check for gasoline leaks at the fuel line connections. Clean the outside and, if necessary, wash the fittings of the gas cylinder and devices of the gas and petrol power supply system.

When parking the car, it is necessary to close the flow valves to exhaust all the gas in the system; drain the sediment from the gas reducer, and in the cold season, drain the water from the evaporator cavity (when filling the engine cooling system with water).

When the engine is running on compressed gas.

Before leaving the car on the line, you must:

Check by external inspection the attachment of the gas cylinders to the brackets, and the brackets to the longitudinal beams of the platform;

Check by external examination the condition of gas equipment, gas pipelines;

Check the condition and fastening of the supply and main valves, as well as gas pipelines;

Check the condition and fastening of the high and low pressure, carburetor mixer, heater and gas supply lines;

Lubricate the threads of the stems of the main, filling and supply valves;

Check the tightness of the gas system with compressed air (nitrogen);

Check the tightness of the petrol power supply system by inspection;

Check the operation of solenoid shut-off valves on gas and petrol;

Check and, if necessary, adjust the CO content in the exhaust gases when the engine is running on gas, and then on gasoline. Before checking the operation of the engine on gasoline, it is necessary to close the supply valves, exhaust gas from the power supply system (before stopping the engine) and close the main valve. Open the valves of the front and rear group of cylinders, open the main valve. Check (by ear) the tightness of the gas system connections;

Check the ease of starting and the operation of the engine on gas at idle speed and at different speeds of the crankshaft. Check the operation of the engine on gasoline.

After returning the car to the transport company, it is necessary to clean the valves of the cylinders and gas equipment from dust and dirt and, if necessary, wash. Check the tightness of high pressure pipelines and gas cylinder connections; tightness of main and supply valves of gas cylinders. Check for leaks of gasoline in the connections of the fuel lines, the solenoid valve-filter. Close the supply valves of the front and rear groups of cylinders and exhaust gas from the system; close the main valve. Drain sediment from the low pressure gas regulator.

Additional work on dump trucks and tractors.

When carrying out SW on dump trucks and tractors, together with the main operations, it is necessary:

Check the condition of the subframe, subframe beams and articulated joints of the platform lifting device, fifth wheel and towing devices;

Check the condition and tightness of the oil pipelines and hoses connections, the operation of the platform lifting device, the condition of the platform safety stop;

Check the condition of the tailgate and the operation of its locking device;

Inspect by inspection the condition and attachment of the power take-off, the dumping platform axle covers, the connections of the rod and cylinder of the platform lifting device;

Check the oil level in the reservoir of the platform lift mechanism: if necessary, top up or replace it (according to the schedule).

Specific work on buses.

When carrying out an SW on buses, together with the main operations, it is necessary:

Check by inspection the condition of the frame, floor, seat upholstery, locks of windows and hatches, handrails, brackets;

Check the condition, attachment and operation of the side lights, route indicator and route number lamps;

Check the condition of the doors and their opening mechanisms by inspection; check the operation of power windows, door locks, hood, trunk lid; check the condition of the instrument panel, body upholstery (for passenger cars); check the action of the alarm from the passenger compartment to the driver;

Check the serviceability of the air suspension and the operation of the body position regulators;

Check the condition of the trusses, side members of the body base by inspection;

Check the condition and fastening of the composters and accumulation cash registers, as well as the serviceability of the ticket feeder.

Determination of the technical condition of the units is especially necessary when the unit or unit has failed. According to individual, practically established signs, you can find an interface or a node where the performance is impaired.

To maintain the rolling stock road transport in a technically sound condition necessary for normal operation, a planned preventive maintenance and repair system has been adopted, it also includes daily maintenance (EO), which, by checking and eliminating some technical problems helps to prevent serious (severe) malfunctions.