Everyone knows that every day millions of people pass the roads of our country. different cars However, few people know that every fourth vehicle has shock absorbers in need of replacement. In our article, we will talk about the most common reasons for shock absorbers to fail and try to figure out which shock absorbers are better to put on vehicle in case of their forced replacement.

First you need to find out what a shock absorber is and why you need it. Speaking in simple language, then the shock absorber is an important unit of any car, which is entrusted with a responsible task: to constantly ensure the smooth movement of the vehicle and to promote maximum adhesion of its wheels to the road surface. In other words, the shock absorbers absorb the shock that the body of the car receives while driving on uneven roads, and do not allow the car to swing and roll to the sides as a result of hitting any bumps in the road.

Shock absorber structure

The basis of the shock absorber is a cylinder with a piston inside it. There is hydraulic fluid in the cylinder, through which the piston is forced to pass by the springs that support the car body. Hydraulic fluid cannot be compressed or stretched at all. As a result, the movement of the piston is possible only if there are nozzles, small holes through which liquid can flow into the inner cavity of the cylinder.

Breakdown reasons

Modern technologies do not stand still, therefore shock absorber manufacturers are producing more and more reliable and high-quality products. However, the condition of the roadbed in our country is often not at the highest level, so even the most high-tech and expensive shock absorbers can fail quite quickly. There are two main reasons for their breakdowns:

- Strong shocks that shock absorbers take when a car wheel hits a large hole in the road. In most cases, the consequence of such an incident is either a strongly bent stem (in hard shock absorbers) or a knocked-out valve of the working chamber (in soft shock absorbers). In either case, the damaged unit must be replaced immediately.

- The penetration of road dust and dirt into the shock absorbers is also quite often the cause of the violation of the integrity of their structure, leading over time to their deterioration. Usually, the boot is the first to wear out, which is a protective cover for the rod coming out of the shock absorber working chamber. After that, dust particles begin to freely penetrate directly into the working chamber, scratching the stem and violating the tightness of the stuffing box, provoking oil leakage. Shock absorbers with such damage are practically beyond repair, therefore, as in the first case, they must be immediately replaced with new ones.

Views

If you are faced with the need to replace shock absorbers, then this issue must be approached with all responsibility and caution. The fact is that the behavior of the car after installing new shock absorbers can change a lot.

First of all, you need to decide which indicator you give priority to: vehicle handling, or comfort while traveling on it. Unfortunately, with an increase in one of these indicators, the value of the other invariably decreases.

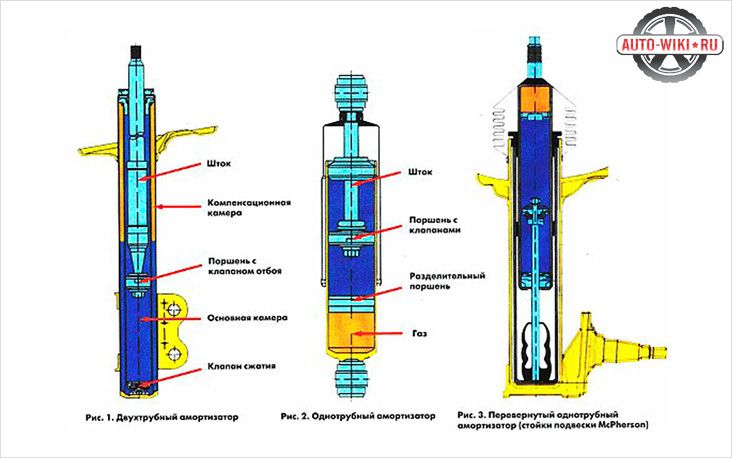

According to the type of construction, shock absorbers are divided into two-tube and one-tube, according to the composition of the working substance - into gas, oil and gas-oil.

Each type of shock absorber has both positive and negative sides, which should be discussed in more detail.

- The oil shock absorbers (double-tube) are characterized by a simple design, which guarantees their stable operation. However, one cannot fail to mention their main drawback, which is the high probability of foaming of the working substance (oil) during rapid movement on a poor quality roadway. In other words, this can be explained as follows: the increased work of the piston while driving on bumpy roads leads to the formation of cavitation bubbles in the oil, causing it to foam and reduce the throughput of the valves through which it passes. As a result, shock absorbers almost completely cease to perform their functions to stabilize the car body during its movement.

- Gas-oil shock absorbers (two-tube) have a more complex structure, consisting of a pair of cylinders, one of which is located inside the other. Due to the presence of nitrogen in them, pumped under pressure, usually not exceeding 5-6 atm., Gas-oil shock absorbers allow the car to move on bumpy roads at significant speed without severe loss of directional stability. At the same time, the probability of oil foaming in them is practically excluded.

- Gas shock absorbers have only one cylinder, which is divided into two parts by a piston inside it. The bottom of the cylinder is full working fluid, the upper part is a compensation chamber into which gas is pumped under high pressure (23-25 atm.). Such shock absorbers successfully dampen high-frequency vibrations due to good cooling and zero probability of foaming of the working substance. The disadvantage of such shock absorbers is a complete loss of performance in the event of a gas leak, as well as excessive rigidity, which manifests itself when driving on poor quality road surfaces.

Shock Absorber Selection Process

When choosing shock absorbers, you can be guided by personal preferences based on driving style, or trust the numerous reviews on the global Internet regarding a particular manufacturer. Fans of driving on flat roads and autobahns are happy to put more rigid shock absorbers on their vehicles. Drivers who often have to travel on rough roads prefer soft shock absorbers. However, practice shows that the most correct solution in this case would be to purchase exactly those shock absorbers that the manufacturer of your car recommends to install. Only then can you be sure that the shock absorbers will be able to provide the necessary drag force, which is the basis of their long and stable operation.

Non-standard shock absorbers often have very different shock absorbers from "native" ones. specifications which, instead of improving the ride behavior of the suspension, can significantly degrade its performance.

Video

More details about shock absorbers can be found below:

Before considering the question of which shock absorbers are better to choose for your car, let's answer the question - what unites shock absorbers of all types and types and all companies producing shock absorbers. Quite right! And you don't even need to think a lot. All shock absorbers are united by their main task in the design of the car - the creation of safe and comfortable conditions for the movement of the car.

Choice of shock absorbers. What to look for

As soon as we remembered the shock absorber companies, let's remember their brands. It is the focus on these brands that is the first principle in choosing shock absorbers. So, the world brands of car shock absorbers: Kayba, Boge, Sachs, Monroe. Without a doubt, there are other, no less prestigious brands, but here is the first thing that came to mind.

You can argue about which shock absorbers are better endlessly. Let's look at the main factors affecting the choice of shock absorbers, and which ones can be better said only after their long and intensive use.

Advertising is theory, and practice destroys all stereotypes. So, the time has come, you spent and came to the conclusion that it takes. Or after the warranty period has passed, and they will no longer endure the second repair.

The question of which shock absorbers to choose is a painful "nail" spinning in my head. After all, the task is not just to choose shock absorbers, but having spent a lot of money, to be sure that they will serve as expected - for a long time, and will ensure safety.

Shock Absorber Selection Criteria

- We focus on your standard shock absorbers. We are orienting ourselves, but not really hoping. The fact is that the manufacturer produces them based on average operating conditions. It is in this place that you must remember how long the shock absorbers served you, how the car behaved, and conclude to buy exactly the same ones, or opt for another manufacturer or type of shock absorbers.

- Shock absorber types. In this part, there is also a constant struggle between manufacturers. Oil and gas-oil (gas) shock absorbers are compared and incorrectly indicate their mutual disadvantages. Here, ignore the banner ad battles. Any model of shock absorbers, even of the same brand, is designed for operation in certain modes. And in practice, no one will prove to you why this or that type of shock absorber is better. It all depends on the following factors on our list.

- When choosing shock absorbers, do not forget to consider design features shock absorbers and the car so that you do not have problems when replacing the shock absorbers.

- Your riding style. If you are a fan of aggressive drive, then you want shock absorbers with increased rebound and compression ratios, but you will have to sacrifice comfort. And if you calmly move from point to point, and in point from point to point, then stop your choice on ordinary standard ones. Their cost is much less than advanced shock absorbers, and they perform their functions no worse.

- ... If you have all four gas shock absorbers, but you want to change, for example, the front shock absorbers for oil, then we strongly advise you to do full replacement all shock absorbers for one type. The difference in the characteristics of different types of shock absorbers on different axles will be significantly noticeable in both the comfort and handling of the car. Not fatal, but noticeable.

And the last, important recommendation. Taking into account the peculiarities of the domestic directions of movement, which are proudly called "roads", look under your feet. In the sense that even if you put yourself super fancy Monroes, they will not withstand the required resource when you literally "fly" into the pits, in the hope of the brand name of your shock absorbers.

As you know, almost every car has shock absorbers. What are they for? After all, not everyone is installed, so you can do without them. It's not that simple. Shock absorbers are designed to damp vibrations of the vehicle and suspension elements in the vertical plane. Now in more detail. Have you ever seen a ball dropped by a basketball player?

It bounces off the surface and bounces for a long time, but with each jump, the amplitude decreases. Much the same would happen with a car without shock absorbers. Of course, he would not jump very high, but the wheels would come off the road surface, and that's for sure. Well, let them come off, some will say. And here is the most important thing. The more time the wheel is on the road surface, the more controllable the car becomes, and as a result, the safety when driving it increases.

If you accelerate the car, for example, by dirt road between the two villages and direct it to a small springboard. The car will bounce. At the time of flight, you turn the steering wheel to the right, to the left, at least twist, the car will fly to where it was going until the wheels were off the road. Imagine that at this moment a local burenka crosses the road. You cannot do anything, neither turn to the side, nor stop, the brakes in the air do not work ... Maybe this is not a very good example, but I think everyone understands the meaning. On potholes and bumps, the same thing would happen, only at this moment the car would move almost without hesitation, but its wheels would jump like balls.

And so, shock absorbers are needed in the suspension of a car to increase the safety of the driver and his passengers while driving. There are some exceptions, but that's another topic.

What shock absorbers are

What types of shock absorbers are there and how are they classified? What kind of shock absorbers and what kind of cars can be installed? All shock absorbers are divided into two-tube and one-tube. Both those and others can be oil, gas-oil and gas. But here you can make a reservation.

These three types are most likely a marketing ploy of shock absorber manufacturers, or just the convenience of somehow distinguishing them. Each of them contains some amount of oil or other liquid (manufacturers do not stand still), which serves as a working fluid. But the gas, it is mainly nitrogen (or another inert gas), is present in the latter two. Let's figure out how they differ.

The structure and operation of shock absorbers

Let's start with two-pipe. From the name you can immediately understand that we are talking about some two pipes. Exactly. One of the pipes, this is the body of the shock absorber, what we see from the outside. The second pipe, slightly smaller in diameter, is located inside the body. This tube contains a piston. The piston is attached to the end of the rod that protrudes from the top of the shock absorber (a shiny rod with a diameter of about 10-14 mm). In the upper part, the shock absorber housing is usually rolled, welded or closed with a screw nut.

The shock absorber is filled with a certain amount of oil. There are precisely calibrated holes at the bottom of the inner tube. Let's consider the principle of the shock absorber. During the downward movement of the rod and, accordingly, the piston, oil flows through the holes from the cavity of the small pipe and fills the cavity of the large one, that is, the body. The air at the top of the housing is compressed. When the piston moves up, the oil flows back into the cavity of the small pipe.

It is the viscosity of the oil and the diameter of the calibrated holes that affect the deceleration of the piston and, accordingly, the rod. For example, try drawing water into a syringe through a needle. It won't work quickly. Thus, abrupt up and down movements, that is, fluctuations, are slowed down. Everything works fine, but there is a fly in the ointment in this well-oiled mechanism. With intensive operation of the shock absorber, for example, when driving on a "comb", the oil in the shock absorber heats up and its viscosity decreases, that is, the oil liquefies.

Liquid oil, when quickly flowing through small calibrated holes, begins to foam. A large number of small air bubbles appear in the oil. The density of the liquid decreases and it is easier for it to pass through the holes. As a result, the effectiveness of shock absorbers drops significantly. The engineers decided to correct this flaw. A certain volume of gas was pumped into the upper part of the shock absorber body under low pressure (3-5 atmospheres). Thereby reducing the foaming effect. The gas presses on the oil and prevents it from foaming. The result is gas-oil shock absorbers.

Gas-oil shock absorbers are more susceptible to aggressive driving over bumps, however, they also have disadvantages. Pressurized gas is located at the top of the shock absorber. And to keep it inside requires very high manufacturing precision and quality of the seal between the stem and the top (nut or cover) of the shock absorber.

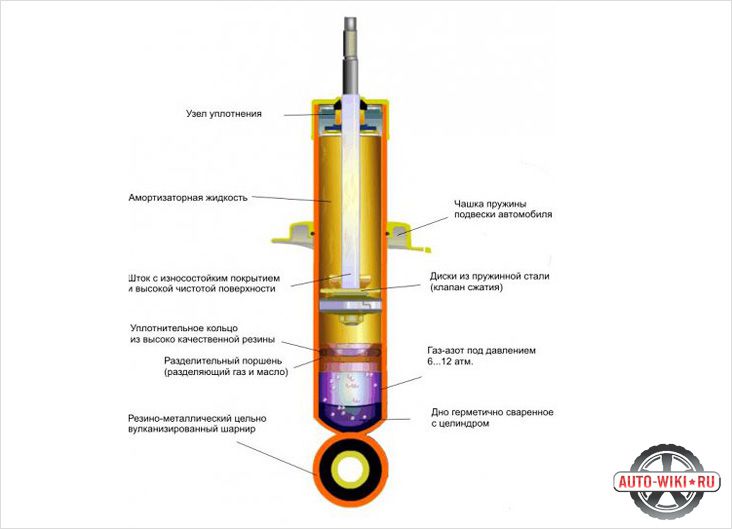

As soon as the seal is worn out and the gas bursts out, the gas-oil shock absorber turns into a regular oil shock absorber with its previous disadvantages. Single tube or gas shock absorbers high pressure slightly different from their counterparts. They simply do not have an inner pipe.

The piston with the rod moves in the shock absorber housing itself. The calibrated holes are located directly in the piston. Oil flows down from above the piston cavity and vice versa. At the bottom of the shock absorber, under the piston, there is another piston or membrane. She can also move up and down.

Gas is pumped under high pressure (over 15 atmospheres) under the membrane in the lower part of the shock absorber, and oil or other liquid is above the membrane. The membrane acts as a separator between oil and gas, but the gas still presses on the oil through the membrane. In this case, the gas is isolated from the outlet to the outside by two seals - this is the membrane and the upper cover of the shock absorber.

Reliability is improved, but there are still drawbacks to these shock absorbers. If the oil or gas-oil shock absorber is slightly crushed, for example, against a stone or a branch on a country road, then they will continue to work without any changes in their characteristics. Gas shock absorbers won't survive this. If the body deforms, the shock absorber will simply jam in one position.

Comfort and safety

The price for all types of shock absorbers is also different. The cheapest are oil, slightly more expensive gas-oil. The latter, however, may exceed the price of the former by several times. Some manufacturers make their own changes to the design of shock absorbers, increasing their performance and reliability, but the principle of operation does not globally differ from those described above. There are new developments in shock absorbers with variable stiffness, which are already being used on modern cars... Such shock absorbers can be installed on jeeps.

When driving off-road, the hard mode is activated. This is necessary in order not to damage the suspension elements when passing difficult sections. These can be stones, deep ditches and ditches, crossing over fallen trees. On smooth asphalt, you can turn on the comfortable soft mode.

The load on the suspension is minimal, and there is no need for a driver with passengers to go as on a stool. At factories, cars are equipped with shock absorbers with average characteristics. So that it is comfortable to move on the asphalt, and on a country road not to be afraid of a breakdown of the suspension on bumps and pits. These are, as a rule, oil or gas-oil shock absorbers.

Gas-oil ones are slightly tougher than their oil counterparts due to the presence of gas, but they work much better. Gas ones are used very rarely, mainly in sports cars, where the most important criterion is handling at high speeds and very high suspension loads. High pressure gas shock absorbers are very rigid, therefore Everyday life on cars are not used.

Breakage

Even good shock absorbers fail. How do you know when it's time to change a shock absorber? There are several symptoms of shock absorber breakage. Shock absorber knocking when the vehicle rolls. A knock can occur if the internal elements of the shock absorber are destroyed. For example, the piston unscrewed from the stem, the valve assembly collapsed (calibrated holes have valves).

A knock can also be emitted by a destroyed silent block, through which the shock absorber is attached to the suspension elements. But there may be no knocking at all, and the shock absorber still needs to be changed. A visual inspection shows oil leaks in the area of the stem exit. This indicates a worn stem seal through which gas can escape and expel oil. This is due to the wear of this seal. Sometimes there are no smudges and everything is dry, but you swing the car with your hands, it continues to swing and stops for a long time compared to a working shock absorber.

The oil has leaked out long ago, everything was washed off by autumn rains and the shock absorber is dry. Perhaps the oil did not leak out, but tore off the tip of the rod from the piston, the piston fell to the bottom. There will be no knocks or smudges. During visual inspection, you should also pay attention to the bump stop and the stem boot. If torn parts are replaced in time, the shock absorber can serve for a long time.

What shock absorbers to put on a car

A huge number of companies that produce shock absorbers are represented on the modern market. It will take a lot of space and time to tell about everyone. Consider a few manufacturers that have proven themselves well in the market.

- Sachs is a German manufacturer of shock absorbers. Delivers to Audi factories, BMW, SAAB, VW, Volvo.

- Sachs Touring is a gas-oil or oil shock absorber for a relaxed driving style.

- Sachs Advantage is a gas-oil shock absorber, slightly stiffer than the top one.

- Sachs Unlimited is a self-adjusting lift or shock absorber that can handle high rebound loads.

- Bilstein are also German shock absorbers. Installed on BMW, Ferrari, MB, Porsche.

- Bilstein Sport - sports shock absorbers (not for sports, but for road use).

- The Bilstein Sprint is the same as the Sport, but designed for shorter springs.

- Bilstein Rally - for sports use, put on cars participating in rallies.

- Kayaba are Japanese shock absorbers. Highly big choice, are installed on both Japanese and European cars.

- KYB Premium - oil shock absorbers, blue box.

- KYB Super - two-tube gas shock absorbers, red box.

- KYB Gas-A-Just are white single-tube gas shock absorbers.

- KYB Ultra SR - sport gas shock absorbers in golden metallic color.

- Tokico - Japanese shock absorbers. They are supplied mainly to the factories of Japanese car manufacturers. The markings are similar to the Kayaba shocks.

- Monroe is a Belgian supplier of shock absorbers. It supplies its products to assembly lines of some plants of Porsche, Volkswagen Group, Volvo.

- Radial-matic oil shock absorber.

- Gas-Matic is a double-tube gas-oil shock absorber.

- Van-Magnum are oil-filled shock absorbers for SUVs and minibuses.

- Sensa-Trac is a two-tube gas-oil shock absorber.

- Koni - Dutch shock absorbers.

- Koni Special - soft shock absorbers for a comfortable ride.

- Koni Sport - stiffer shock absorbers for aggressive driving (for some car models, these shock absorbers have the ability to adjust the rebound force without removing from the car).

- Koni Sport kit is a set of shortened springs and shock absorbers designed for use with short springs. You cannot put such on a jeep, they are intended for the preparation of passenger cars.

- Koni Load-a-Juster - a spring is wound on the shock absorber, which prevents the car from sagging under a heavy load.

- Boge is a German manufacturer of shock absorbers. Delivers its products to factories Audi, VW, BMW, Volvo, Alfa Romeo.

- Boge Pro-gas - gas shock absorber (two-pipe gas-oil), designed for comfortable driving (for this it has a special groove in the zone of low strokes of the shock absorber, which affects their softness)

- Boge Turbo-gas - As the name suggests, something aggressive for a sporty ride.

- Boge Nivomat - special shock absorber, can support a given ground clearance... Used on station wagons, where subsidence is possible at high load.

- The Boge Turbo24 is a monotube shock absorber for off-road riders.

There is a small nuance. Shock absorbers from one brand can work fine for a long time on one car and have bad reviews when used on another. And vice versa.

Owners of Japanese SUVs are lucky in this regard. The main suppliers to the Toyota and Mitsubishi plants are Kayaba and Tokico. Shock absorbers Kayaba and Tokico have quite high quality and an attractive price. If in the store you are offered to choose the original or the presented brands, you definitely need to take the latter. They differ in packaging and price differences. The original is usually more expensive.

On the original, there may be a stamp of the car manufacturer, that is, Toyota or Mitsubissi confirms the quality of the shock absorbers with their logo. That's the whole difference. This applies to many manufacturers. For cars of German brands, there are several options for shock absorbers. Some famous German manufacturers shock absorbers are so popular that they are often counterfeited.

As you know, such shock absorbers do not shine with quality. There are several companies that specialize in shock absorbers for the preparation of sports cars. These are, for example, Ironman, Tough Dog. Shock absorbers from these manufacturers are very expensive and are designed to be installed on vehicles that are competing in sporting events. They are not suitable for everyday use, they are very tough (the shock absorbers are filled with gas under high pressure).

Output

It doesn't matter what kind of car you have, a subcompact or minivan, an executive limousine or an SUV, the choice of shock absorbers depends on the driving style and the fullness of your wallet. There is also no consensus about what is better, what is better. You can kill high-quality shock absorbers for a quiet comfortable ride in one day on off-road rides. Or buy expensive high-pressure gas shock absorbers and then tell everyone that they are bad because of their rigidity. You just need to competently approach the choice.

So, drivers, read the article above and approach the choice of shock absorbers for your iron horse competently ...

Time passes and you remember with sadness the time when it was quiet and comfortable in the car, and the car obediently performed any maneuvers on the road.

Gradually, there were extraneous noises, knocks, the car began to obey the steering wheel poorly, what could have happened over time?

The answer is simple - you have defective shock absorbers and it's time to replace them.

What gives the serviceability of the shock absorbers.

Firstly, you will not feel the shaking and vibration caused by uneven road surfaces, and there will be less noise in the car.

Secondly, improved comfort conditions, increased safety when driving in a car, but this is not the main thing in this case.

Technical condition shock absorbers have an impact on everything related to the car.

Irregularities in the road surface cause the wheel to vibrate and shake more intensely. Especially the so-called waves on asphalt concrete, which resemble a washboard, and of course paving stones, cobblestone pavements, concrete pavement slabs, etc., help in this.

If the shock absorbers of the car are in poor condition, then the wheel easily gets into resonance and pushes high above the road surface.

Conclusion - do not fly at high speeds on tram tracks and other bumps on the road.

Another source of incorrect wheel vibrations and the overall suspension of the car in general is poor wheel balancing.

Or, suppose the wheel itself is well balanced, but the car vibrates due to the disturbed shape of the disc after hitting an obstacle, "hernia" on the tire, rupture of the tire cord, adhered dirt on the wheel ...

There can be only one conclusion here: bad shock absorbers are also heavy acceleration of the car, smoothness of the car, problems during braking, safe cornering and overcoming ups and downs - in general, all the reasons that can lead to an accident due to increased slippage due to increased vibration wheels.

And yet, not all motorists pay due attention to shock absorbers. Many of them wind hundreds of kilometers on dead shock absorbers, completely oblivious to loud knocks and rattling in front or behind the car.

Some are just too lazy to go to a car service. And by the way, it is very easy to independently check the serviceability of the shock absorbers.

A simple inspection is enough to determine if there are any oil leaks on the shock absorber housings, and then shake the car in turn for each of it

the shock absorber by swinging the fender or bumper three or four times.

After such an impact, the body should not make more than one "return" movement to the initial level.

If the car will swing longer, or if you hear obvious knocks, then the shock absorbers can be considered faulty and must be urgently replaced.

In our time, shock absorbers of two types are most widely used - hydraulic and gas-hydraulic (they are often also called gas-filled or simply gas).

In shock absorbers of a hydraulic type, damping of vibrations of elastic suspension elements is obtained by moving fluid in the shock absorber (this is a special shock absorber oil - it is chosen because of its high viscosity) from one cavity of the shock absorber to another and back through a system of built-in valves.

In gas-filled ones, there is also a liquid, but it is preliminarily "compressed" with the help of a small volume of gas under pressure, which, unlike a liquid, can be compressed.

By the way, gas-filled shock absorbers have one big drawback, which is especially pronounced on our bad roads.

In the event of imminent vibration, the air in the shock absorber will foam the oil and create “air dips” when the shock absorbers are operating.

Intense vibration creates gas bubbles low pressure, and this will not only reduce the efficiency of the shock absorbers, but also very quickly lead to their malfunction.

Here the effect of cavitation is triggered and then small gas bubbles simply eat up the walls and other units of the shock absorber.

V front wheel drive vehicles which are very popular today, two completely different types of shock absorbers are installed - the rear classic type and the front struts, such as McPherson.

McPherson is a type of shock absorber with a telescopic hydraulic front strut and a somewhat complex design.

Currently, the spare parts market has a very large selection of types of shock absorbers from various manufacturers.

At the same time, manufacturers are trying to expand their assortment of shock absorbers for as many car models as possible, as well as for different driving styles, dividing, for example, into "sports" and "comfortable" driving styles.

Although, of course, each manufacturer has a certain specificity peculiar only to them.

So, which companies are the main manufacturers in the shock absorber production market today?

In the European Union, consumers of the Kayaba concern from Japan are such well-known car manufacturers as Ford, Renault, Peugeot, Seat and many others.

This manufacturer has more than seven thousand employees in different countries.

Largely due to its high quality operational characteristics and relatively low cost, Kayaba shock absorbers firmly entrenched themselves on the roads of the CIS countries.

Ultra SR gas-filled shock absorbers are especially popular in our country. Among the new products present in the Ultra SR shock absorbers are increased damping properties, these properties allow stabilizing the grip of the wheel with the road and vehicle handling, good quality characteristics in the case of using tires with low profile tread, and also there is no damping.

The stands are designed for active drivers who love a sporty driving style that places very strict demands on the car's handling.

The basis of the company's specialization was and is the production of shock absorbers for cars.

The basis of the company's specialization was and is the production of shock absorbers for cars.

In many respects, shock absorbers made by this company differ from products manufactured by other manufacturers.

The main differences are the ability to adjust the characteristics of shock absorbers.

The difference between the "initial" position of the shock absorber when delivered from the factory conveyor and the adjustable "max" position is 100%.

The provided adjustment stock can be used to adapt the shock absorbers to various road surfaces in accordance with the personal wishes of the car owner.

The shock absorbers produced by this company are adapted for almost any type of car, for any driving style and for wide operating conditions.

The company produces more than 2500 models of shock absorbers annually, but the designers do not like any one design type: the types of shock absorbers are selected depending on the suspension design and the specified conditions in which the car will be used.

The Belgian company Monroe (a very well-known name in the market) makes deliveries of shock absorbers for many types of cars every year.

The Belgian company Monroe (a very well-known name in the market) makes deliveries of shock absorbers for many types of cars every year.

The Sensatrac shock absorber is the latest in its wide range of shock absorbers.

Only one Monroe company can offer such a service as custom-made shock absorbers for 99% of cars.

Monroe Sensatrac shock absorbers are developed on the well-proven gas pressure technologies that were implemented in the Gazmatic model.

The new Monroe systems build on a wealth of experience in the gas shock absorber segment, which can provide precise and responsive ride response.

Sensatrac incorporates all of these benefits and adds many new benefits to shock performance: adaptability to all driving conditions, improved vehicle handling, and improved responsiveness during sharp maneuvers.

More than half a century has passed since the SACHS company entered the production of shock absorbers and is now one of the leading brands in the world, a manufacturer of shock absorbers.

More than half a century has passed since the SACHS company entered the production of shock absorbers and is now one of the leading brands in the world, a manufacturer of shock absorbers.

Using many years of experience in new developments, applying Newest technologies and materials, originally solving design problems, all this makes it possible for shock absorbers made by SACHS to become serial components on assembly lines of such giants in the automotive industry as Alfa Romeo, Audi, BMW, Mercedes, Lada, Jaguar, Lancia, Peugeot, Saab, Skoda and many others.

In conventional shock absorbers, with an increase in the load on the shock absorber, the speed of movement of the shock absorber rod will proportionally increase.

The work of SACHS shock absorbers is provided to small details - with an increase in the load, the speed of movement of the rod will smoothly increase up to a certain moment, and then it becomes stable.

That's where the durability and reliability, ride comfort and safety of these shock absorbers come from. SACHS provides a one-year warranty for all of its shock absorbers, regardless of the vehicle's mileage.

The production of these shock absorbers is located in Germany and these shock absorbers are mainly equipped with cars made in Germany.

The production of these shock absorbers is located in Germany and these shock absorbers are mainly equipped with cars made in Germany.

Their sales outside Europe are somewhat limited.

However, they have a very good reputation among specialists (after the merger of the Boge and Sachs concerns, the Boge trademark passed to the latter, and now Sachs produces its shock absorbers under two trademarks.

Shock absorbers Boge and Sachs do not differ in quality, since they combine all the technologies and years of experience of both companies).

The manufacturer of these shock absorbers is a Dutch manufacturing company car parts.

The manufacturer of these shock absorbers is a Dutch manufacturing company car parts.

This company specializes in - the development and implementation of the highest quality standards for the production of auto parts and the adaptation of manufactured products to state standards of different countries of the world.

CV joints and clutch baskets, crosspieces for cardan shafts and thrust bearings, wiper blades, brake pads, air, oil and fuel filters, high voltage wires and spark plugs, here is a small list of their products that is constantly expanding.

By the beginning of 2011, auto parts produced by HOLA can be selected for more than 2700 brands, models and modifications of cars.

HOLA products were originally designed and developed specifically for Russian climatic and road conditions.

Shock absorber fluids will ensure normal operation of shock absorbers in the temperature range from -35 to +120 degrees.

The shock absorbers supplied by HOLA are designed for a mileage of at least 70,000 km, which they successfully withstand.

These shock absorbers are manufactured in the USA, and of course they are installed mainly on American-assembled cars.

These shock absorbers are manufactured in the USA, and of course they are installed mainly on American-assembled cars.

Therefore, only a few of them end up in retail sale, mainly their consumers are assembly lines of car factories.

These shock absorbers are famous for their very high quality indicators, but according to many experts, they are absolutely not designed for our roads.

They need highways with ideal road surfaces.

And in conclusion of the article, you can add the following: in recent years, in Turkey and Poland, they have established the production of not very expensive inserts for the "cartridges" of the front struts for front-wheel drive car models.

Of course, you can argue about their quality for a long time, but the savings in the family budget are obvious, and the price makes such a purchase very tempting.

This article does not provide a complete list of all companies involved in the production of shock absorbers, I will write about the rest in another article, or in addition to this one.

In the meantime, I wish you all a good road and trips.

The topic of choosing a shock absorber design does not apply to all motorists. Many people clearly know that they need gas shock absorbers, others - oil, and still others - only gas-oil. The rest do not know at all what types of car shock absorbers are.

Shock absorbers for cars are installed on each support point (wheel). Usually four wheels are four shock absorbers. Their main purpose is to damp vibrations after passing uneven sections of the road. Therefore, the question of how to choose the right shock absorbers is easily solved. Much more difficult .

A spring always works in tandem with each shock absorber. When the wheel hits a bump, the spring begins to compress, extinguishing the impact. Accordingly, after this, the opposite action occurs - unclenching. The task of the shock absorber is to smoothly extinguish the expansion of the spring. This contributes to a shorter return of the fulcrum (wheel) to its original state, in which the car is as stable as possible.

Which type of shock absorber is best? Gas or oil?

The work of the shock absorber can be supported by a special design, which is made as follows: a piston with holes, valves of different diameters and directions moves inside the cylinder, passing oil or gas. Accordingly, under compression, the throughput of the holes and valves is several times greater than under tension.

In the production of shock absorbers, along with oil, air damping chambers are used. One of the main distinguishing qualities of the gas medium in shock absorbers is the increase in stiffness when accelerating the movement of the rod. The same cannot be said about oil shock absorbers. But their characteristics also depend on the manufacturer, so it would be useful to ask the seller a question about which company to choose shock absorbers for your transport.

Gas-oil shock absorbers are the same gas shock absorbers. Since there are no purely gas shock absorbers. There is always a mixture of gas and oil in the structure.

The result is the following. Oil, as a more saturated medium, has a lower compression ratio than gas. Therefore, oil dampers are more rigid than gas dampers. In normal operation, gas shock absorbers are more flexible than oil shock absorbers. But when you change the speed of movement of the rod, gas shock absorbers become much more rigid in contrast to oil. In practice, oil dampers are softer than gas dampers. The point here is in the settings that the manufacturers equip the shock absorbers with.

So that the owner does not think about how to choose shock absorbers for the car, the manufacturer, after special calculations, pre-installs the necessary shock absorbers on the car. Many factors are taken into account - first of all, the weight of the car and the design of the suspension. Therefore, you cannot experiment with shock absorbers on your own. For each car model, the manufacturer manufactures both oil and gas shock absorbers. And therefore, use gas shocks for smoother roads, as they are stiff, and oily ones for uneven ones. They pass bumps and irregularities softer.

The production of gas shock absorbers is more complicated and more expensive than oil shock absorbers. Since additional damping chambers and special sealing materials are used. Durability depends on the quality of the workmanship. A gas shock absorber is more complex in its design. Therefore, an oil shock absorber is more reliable, since its design is simpler. The price of gas shock absorbers is higher.