Fishermen, hunters and hobbyists winter species sports use snowmobiles to travel to the best recreational areas. Even inexpensive models of such equipment cost about a hundred thousand rubles, more often more. Those who want to save money can assemble a homemade snowmobile on tracks in an ordinary garage workshop. The cost of parts for construction does not exceed 40 thousand rubles.

Snowmobile device

Homemade snowmobiles are settling on caterpillar... The tracks are driven by the engine internal combustion mounted on a rigid metal frame. Supported in working position by wheels and special rollers. Basic execution options:

- With a solid or breakable frame.

- With rigid or shock-absorbed suspension.

- With an engine from a walk-behind tractor or from a motorized carriage.

Short skis are used for steering. Lightweight snowmobiles (weighing up to 100 kg), designed for movement with maximum speed up to 15 km / h, do not require mandatory equipment braking system... They stop easily when the engine speed drops. Make a homemade snowmobile on tracks you can use the algorithm:

- Engine selection, frame and chassis calculation.

- Spot-welded frame assembly.

- Steering device.

- Installation of the engine in the design position for a temporary attachment.

- Checking the structure for resistance to overturning.

- Upon successful check - major welding of the frame, installation of the engine.

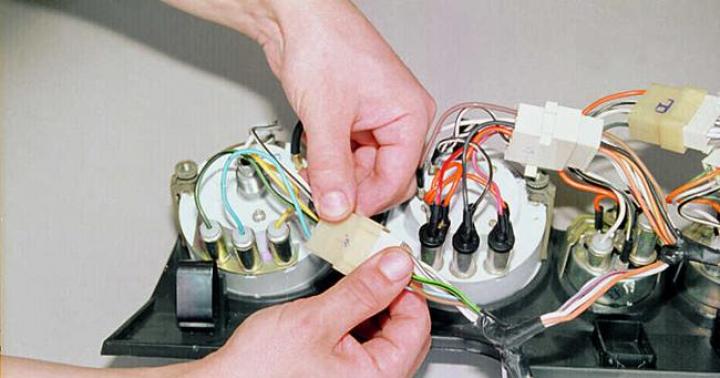

- Installation of drive system, bridges.

- Assembling and installing tracks.

- Body parts assembly.

After that, the final tests are carried out. If the snowmobile runs normally and does not tip over, then it is driven into the garage and disassembled. The frame is cleaned of rust, painted in 2 layers, the remaining elements are finished, after which they assemble a homemade snowmobile on tracks with their own hands.

Engine selection

Are applied gasoline engines for motoblocks or sidecars. The engine speed is controlled by the throttle stick placed on the rudder grip. To make a homemade tracked snowmobile with your own hands, the easiest way is use ready-made small-volume engines for walk-behind tractors with pre-installed:

- Fuel tank.

- Ignition system.

- Reduction gear with a ratio of 1: 2.

- Centrifugal clutch that automatically engages when revving up.

The power of these motors does not exceed 10 Horse power, but they are easy to install: the master does not need to separately assemble the ignition system, supply fuel pipes, adjust the clutch, etc. There are different options on the market:

| Brand | Model | Power, hp with. | Volume, cm3 | Weight, kg | Approximate price, thousand rubles |

| Kipor | KG160S | 4,1 | 163 | 15,5 | 20−25 |

| Sadko | GE- 200 R | 6,5 | 196 | 15,7 | 15−20 |

| Lifan | 168 FD-R | 5,5 | 196 | 18,0 | 15−20 |

| Zongshen | ZS168FB4 | 6,5 | 196 | 16,0 | 10−15 |

| Nomad | NT200R | 6,5 | 196 | 20,1 | 10−15 |

| Brait | BR-177F-2R | 9,0 | 270 | 30,0 | 10−15 |

| Honda | GX - 270 | 9,0 | 270 | 25,0 | 45−50 |

If it is not possible to purchase a ready-made engine from a walk-behind tractor, then you can use an engine from a motorized carriage. Such engines are more powerful by 10-15 horsepower, but require self-assembly. The system includes:

- Engine.

- Clutch.

- Reducer.

- Gas tank (volume 5-10 liters).

- Muffler.

- Generator.

- Switch and coil electronic ignition.

Some of the elements will fit from old motorcycles (Minsk, Vostok, Java, Ural). The gas tank is positioned as close to the carburetor as possible to shorten the length of the pipes.

Frame and body

It is recommended to draw up a drawing of the frame before work. The structure is welded from a 25 x 25 mm square tube with a wall thickness of 2 mm. At payload over 150 kg, the section size is increased to 30 x 25 mm. The loading area and body elements are sheathed with plywood. Seats are matched with a hydrophobic coating.

A hinge is located in the center of the fracture frame, allowing rotation around a vertical axis. The maximum angle of rotation is limited by welding metal plates. The front half is used for steering and the engine is placed on the rear frame.

The one-piece frame is welded in the form of a rectangle, inside which bridges and tracks are located. The engine is placed in front on a special platform, rigidly welded to the rest of the frame. In both cases, the motor is placed in the transverse direction (the shaft extends to the end).

Drive system

A small diameter drive sprocket is installed on the motor output shaft. From it, the torque is transmitted through the chain to the driven shaft located under the engine seat. On the driven shaft there are:

- Large diameter driven sprocket.

- Cogwheels that drive the tracks.

- Track guides.

The driven shaft is mounted on the frame with bearings. The cogwheels push the tracks, propelling the tracks. The chain and sprockets are removed from one device. Old motorcycles and snowmobiles ("Buran") are suitable for the role of a donor. The cogwheels for tracks can only be removed from other tracked vehicles.

The idler rollers rotate with the shaft, are attached next to the gear wheels and serve to tension the belt. They are made of wood or plastic and have a layer of soft rubber at the ends. The rubber prevents damage to the track. It is easy to make such rollers yourself by fixing the edging with a furniture stapler.

Calculation and assembly of the caterpillar

The caterpillar is a tape on the outer surface of which the tracks are fixed. Tracks are rigid lugs installed along the entire length of the tracks. Track options:

- Made of 3 mm thick conveyor belt.

- From a car tire.

- From V-belts.

- Factory-made ready-made caterpillars.

The conveyor belt must be looped back. Its durability is only sufficient for light snowmobiles with engines no more powerful than 10 hp. with. Car tires are stronger than tape and are suitable for powerful motors. One-piece tires do not need to be looped back, so the chance of rupture is minimal. A tire of the right length is more difficult to find than a tape.

Ready tracks are removed from other similar equipment (snowmobiles "Buran", "Sherkhan"). Grousers are installed on them from the factory. The products are not suitable for use with low-power motors from walk-behind tractors. Self-made snowmobiles made from "Buran" tracks must have toothed wheels from the same "donor".

The size of the track is selected according to the required driving characteristics: the wider the width, the lower the controllability, but the higher the cross-country ability. The minimum area of the contact patch from a snowmobile (skis and tracks) should be such that the pressure from the equipped vehicle does not exceed 0.4 kg / cm 2 of the surface. In light snowmobiles, a conveyor belt 300 mm wide is used, cut lengthwise into 2 strips of 150 mm.

Preparing the ribbon

The tracks are attached to homemade caterpillars M6 bolts with a wide head. The bolts are fixed with a nut, a washer and a grover are used. Before fastening, leading holes with a diameter of 6 mm are drilled in the tape and tracks. When drilling, a jig and wood drills with a special sharpening are used.

The conveyor belt is also looped back with M6 bolts. To do this, the edges of the tape overlap each other with an overlap of 3-5 cm, the connection contains 1-2 rows of bolts. For track width 150 mm withstand the following distances:

- From the edge of the tape 15-20 mm.

- Between the bolts on the tracks 100-120 mm.

- Between the bolts when ringing 25-30 mm.

Just one track requires 2 bolts, one tape connection - 5-10 bolts, depending on the number of rows. When using car tires, only the treadmill is left, and the sidewalls are removed with a shoe knife.

The tracks are made of a polyethylene pipe with a diameter of 40 mm with a wall thickness of 5 mm, sawn in half in the longitudinal direction. An entire section of the lug is adhered to the belt. In light snowmobiles, one track connects the track pair. With a track width of 150 mm, the track length is 450-500 mm.

The lugs are cut with a circular saw into wood. A special machine is used with two guides (metal and wood), rigidly fixed on a fixed tabletop. The pipe walls are sawn in turn.

The distance between the tracks depends on the parameters gear wheels on the drive shaft. Usually it is 5-7 cm. The specified distance is maintained with an error of no more than 3 mm. Otherwise, the operation of the drive is disrupted: the lugs "run over" the teeth of the driving wheels, the caterpillar begins to slip and fly off the rollers.

Chassis

Lightweight snowmobiles designed for riding on loose snow are equipped with an articulated suspension made of an extended M16 nut. It is a lightweight construction with simple device, which does not provide comfortable driving characteristics of homemade products.

Snowmobiles on tracks, designed for driving on packed snow, must provide shock absorbers (from a motorcycle or moped). Shock absorbers are installed at the points of attachment of skis and bridges to the frame. The suspension travel is selected so that the moving parts do not touch the snowmobile body during operation.

Steering wheel and skis

The steering is displayed on two front skis according to a scheme structurally similar to the suspension. It is made of a threaded stud installed in an elongated M16 nut, rigidly welded to the frame. The steering wheel from a moped or motorcycle ("Minsk") is used.

In total, the design uses 3 plastic skis from a children's scooter (or homemade from plywood 3 mm thick). A pair of front skis are used for taxiing. Skis up to 1 meter long are used, if necessary, reinforced with a steel pipe and plate.

The third ski is supporting, serves to maintain the belt in working order. It is shorter than the others and is located between bridges (in the center). A T-beam is attached to the support ski, rigidly welded to the frame. On top of the beam are freely rotating track rollers. Installation of this design is unnecessary if the track does not sag.

Construction of bridges

The bridges are located under the loading dock. One bridge has 2 inflatable wheels from the garden cart and a metal rod. The wheels rotate freely and are not driven. In snowmobiles, built on the basis of motors from motoblocks, the wheels are half inflated. Clamps are welded to the outer ends of the wheels, with the help of which the axles are attached to the frame.

The front axle is stationary, its clips are rigidly welded to the frame. Rear axle must move freely along the frame, as it serves to tension the track. Its locks provide for frictional tightening of M10 bolts, securing the bridge in the working position.

With the onset winter period two-wheeled vehicles are losing their relevance. Using a car to overcome short distances with high snow cover is not particularly practical, and in most cases - impossible process. The snowmobile copes with this task much better.

Winter mechanical vehicle in most cases is equipped with a caterpillar rear wheel drive and front steering skis. High cross-country ability, versatility and ease of use make the snowmobile by far the most popular means of transportation in the winter season.

Features of homemade snowmobiles

Nowadays, you can buy a snowmobile in any motorcycle showroom, both in a large metropolis and in a small city, but the prices of this equipment force many amateurs winter ride make a homemade snowmobile on tracks with your own hands.

There are four important advantages of a self-made vehicle over a factory one:

- Price is the most important factor for most. The cost of some units of the leading manufacturers of motor vehicles can exceed the cost of those assembled from scrap materials by 5-10 times.

- Parameters - the ability to assemble a vehicle of the desired configuration. It concerns how appearance, and power reserve, type of chassis, etc.

- Reliability is the point that even well-known manufacturers do not always boast of. When self-manufacturing, a person uses the highest quality materials and pays special attention to the most important parts of the mechanism.

- Benefit - the ability to use materials, parts and accessories from other devices lying around in garages and backrooms.

At the same time, homemade snowmobiles are used both on the streets of settlements and on roadless areas of suburban expanses and ski resorts.

Homemade snowmobile on tracks with your own hands: where to start?

1 - back light, 2 - hitch, 3 - body (plywood, s16), 4 - side reflectors, 5 - rear shock absorber (from motorcycle -171, Dnepr-187, 2 pcs.), 6 - gas tank (from the launcher of the T-150 tractor), 7 - seat, 8 - main frame, 9 - switch (from motorcycle -171, Voskhod-187,), 10 - ignition coil (from motorcycle -171, Voskhod-187,), 11 - power point(from a motorized carriage, 14 HP), 12 - a muffler (from a motorized carriage), 13 - steering column, 14 - steering joint in a leather case filled with grease (hinge from -171, UAZ-187,), 15 - limiter for vertical movement of the steering ski (chain), 16 - steering ski rotation limiter, 17 - steering ski, 18 - side ski (2 pcs.), 19 - generator, 20 - clutch lever (from a motorcycle), 21 - drive chain guard, 22 - footboard, 23 - drive shaft drive chain, 24 - track drive shaft, 25 - lower track chain guide (polyethylene , s10, 2 pcs.), 26 - track chain (from the header of the forage harvester, 2 pcs.), 27, 31 - upper front and rear chain guides (polyethylene s10, 2 pcs.), 28 - shock absorber hinge frame mover (shortened rear shock absorbers motorcycle -171, Dnepr-187, 2 comp.), 29 - support ski, 30 - rear spacer frame, 32 - rear axle.

The drawing of a homemade snowmobile is critical stage at the preparatory stage of manufacturing. Here to help engineering skills come in handy... and in the absence of such, superficial sketches are made, creating a general image of the future mechanism.

Before creating a drawing, it is necessary to determine the list of required components. The basis of the standard configuration of the snowmobile is:

- Frame - depending on the complexity of the design, it can be borrowed from an ATV, motor scooter, scooter, motorcycle, etc. If they are not available, the part is usually cooked from thin-walled metal pipes with a diameter of about 40 mm.

- Seat - given the difficult operating conditions of the equipment, the material of this element must have a high moisture-repellent ability.

- Engine - is selected with the calculation of the required speed and the total weight of the vehicle. The most commonly used motors are motoblocks, scooters, motorcycles, etc.

- Tank - 10-15 liter metal / plastic container will fully provide carefree trips over relatively long distances and will not take up much space on the unit.

- Skis - in the absence of ready-made options, for self-made it is recommended to use nine / ten-ply plywood sheets with a thickness of about 3 mm.

- Steering wheel - chosen with the calculation of convenience and practicality. Similar to the frame, engine and seat, it is removed from the specified two-wheeled units.

- Drive - a part that transfers rotary motion from the engine to the track. It performs this function well.

- The caterpillar is the most complex and important element... Their types and methods of self-production will be discussed further.

How to make homemade caterpillars?

One of the most common materials for the manufacture of a propulsion unit is car tire... A homemade caterpillar from a car tire has one over other options important advantage- it is made in the form of a closed loop, which significantly reduces the likelihood of rupture.

The beads are separated from the tire using a boot knife, leaving a flexible treadmill. The lugs are attached to the driving blade - plastic pipes sawn along with a diameter of about 40 mm and a thickness of about 5 mm. Cut to fit the width of the tire, half-pipes are attached to the canvas with bolts (M6, etc.) at intervals of 5-7 cm.

Homemade caterpillars are made in the same way. from conveyor belt... Their main advantage is the ability to choose the length of the propeller. After cutting to the required length, special attention should be paid to the hitch. The ends of the tape overlap each other by 3-5 cm, and are fixed across the entire width with the same bolts as the lugs.

Handmade tracks are often made with materials at hand, such as V-belts. Fastened in width by means of lugs, they make up a full-fledged caterpillar track with hollows for the gear already existing on the inside.

Note that the wider the track, the better the snowmobile's flotation, but the poorer handling. Factory options have three patterns in widths of canvas in inches: 15 - standard, 20 - wide, 24 - extra wide.

Let's go to practice

A frame made of pipes or corners is primarily equipped with a steering gear. Having chosen the height and angle of inclination, weld the element with spot welding. Install and secure the motor according to the drawing, taking care not to tilt too much. The snowmobile should not have a long fuel line so try to position the tank closer to the carburetor.

The next step is to install the track. Attach the driven axle with the belt fitted to the rear of the frame (on a fork, suspension, shock absorber, etc., depending on the type of construction), the leading axle in the middle of the snowmobile (most often under the driver's seat), in the shortest possible hitch with the engine. The gears of both axles are pre-engaged.

Homemade snowmobile from a walk-behind tractor

This transformation is especially popular today. The walk-behind tractor can be used, either partially or completely. In the first case, a supporting frame with a rear axle is added to the unit (engine with steering fork and wheels). The most difficult stage in this case is the transformation of the working shaft of the walk-behind tractor into a drive gear.

Homemade snowmobile from a walk-behind tractor with partial use of parts is more versatile. In this case, only the engine and the steering fork are removed from the "donor", to the bottom of which the skis are attached. The motor itself can be located at the rear of the structure.

It should be noted that the engines of the main part of the motoblocks are designed for the weight and pressure of the wheels, which is several times less than the tracked one. Therefore, in order to avoid increased wear of parts and fuel consumption, it is better to equip such a snowmobile with wheels. low pressure.

AMAZING AND UNUSUAL DIY DIY 1 ***

Description:

A selection of the coolest and most unusual homemade products made!

All episodes of "DIY homemade" see the playlist https: //www.youtube.com/playlist? List ...

homemade all-terrain vehicles

homemade cars

snowmobiles homemade

homemade tracks

auto homemade

homemade tractor

homemade all-terrain vehicle

Many people dream of having a car on their farm that could get anywhere, off-road, and even in winter. You can and buy an all-terrain vehicle (snowmobile)- but not everyone can afford it. The proposed design homemade all-terrain vehicle

also knows how to swim - an amphibian. The design is designed from the outset to maximize the use of standard, readily available assemblies, while minimizing the cost of purchased parts. Homemade all-terrain vehicle passed all tests and is successfully operated.

The basis of the all-terrain vehicle is an open rectangular body. Self-made vertical sides made of plywood 7-10 mm thick. On the upper edge of the sides, peculiar wings are attached, forming a single plane, a small bevel is made in front. The suspension is three-axle. In plan, the body is rectangular with a slightly narrowed front part.

The body is divided by vertical transverse partitions; in front of the trunk, further in the expanding part of the cab with the driver's seat and steering wheel, behind it on the sides are two boxes adapted for the seats for passengers and at the same time - an additional trunk.

Below are the drawings and description of the triaxial homemade snowmobile, all-terrain vehicle, amphibians on low-pressure pneumatics designed by G. Vidyakin

Side view

Frontal view

Description of positions: 1 - support front axle, 2 - bumper, 3 - steering gear, 4 - rear wheel balancer, 5 - chain drive to the rear wheel, 6 - fuel tank, 7 - footboard, 8 - wheel disc. 9 - wheel hub, 10 - front axle, 11 - chamber, 12 - valve, 13 - detachable rim, 14 - rear axle wheel shaft.

The next compartment is the transmission compartment. By the way, the transmission is covered with a horizontal cover that is flush with the passenger seats.

All-terrain vehicle body

Description of positions: 1 - trunk, 2 - windshield, 3 - driver's seat, 4 - box, 5 - space for passengers and luggage, 6 - window covered with rubberized fabric, 7 - engine cover, 8 - mud flaps, 9 - side , 10 - side members of the power frame of the engine and transmission, 11 - rear wheel balancers niche, 12 - front axle niche.

And the last compartment homemade snowmobile- power, closed with a horizontal cover, slightly raised above the seats, in which the engine is mounted. On the cover there is an additional box-type casing for the engine. Hinged covers for boxes, transmission and engine hood provide easy access to the units.

Frame for engine and transmission

Description of positions: 1 - middle spars (corner 40 x 40 mm), 2 - cross members (square tube 40 x 40 mm), 3 - side spars (corner 40 x 40 mm), 4 - cross member (corner 30 x 30 mm), 5 - a support bracket for the balance beam (angle 40 x 40 mm).

Fenders, partitions, covers - plywood, connected to the body with duralumin corners, the floor - made of duralumin sheet, duralumin corners are riveted from below for rigidity. In the front part of the body, under the trunk partition, a small transverse niche is made for the front axle. In the rear part of the body under the seat boxes and further to the engine compartment, on both sides, there are longitudinal niches for the rear wheel balancers. By the way, rear wheels as close as possible to each other, the front ones are somewhat forward - the turning radius of the all-terrain vehicle depends on this distance.

Above the fenders at the front of the body homemade all-terrain vehicle obliquely installed windshield and two side windows. Under the fenders, between the rear wheels, gas tanks are mounted on both sides, the cross-section of which has the shape of a trapezoid tapering downward. Above all the wheels in the horizontal parts of the wings, rectangular cutouts are made, covered with a rubberized fabric: when hitting an obstacle, this allows the wheels to rise above the level of the wings and not brake against them.

Engine and transmission units homemade all-terrain vehicle mounted on a frame that is integral with the body. It consists of four side members made of 40X40 mm steel angles and cross members made of square steel tubes. Outside, along the sides, there are small brackets from a 40 x 40 mm corner for attaching the rear wheel balancers. Wherever possible, the longitudinal member flanges have been trimmed to reduce weight and drilled into them.

Location of engine and transmission

Description of positions: 1 - elastic coupling, 2 - middle spar, 3 - cross member, 4 - side spar, 5 - bulkhead, 6 - differential lock thrust, 7 - reverse gear engaging thrust, 8 - reverse gear, 9 - angular gear , 10 - partition, 11 - intermediate shaft, 12 - cross member for fastening the support of the intermediate shaft sprocket, 13 - Gear selector rod, 14 - air filter, 15 - tailgate, 16 - generator, 17 - engine, 18 - left side, 19 - muffler, 20 - starter, 21 - battery, 22 - chain drive to the rear wheels, 23 - rear wheel balancer support, 24 - rear wheel balancer trunnions, 25 - brake drum, 26 - chain drive, 27 - differential lock unit.

The engine from the SZD motorized carriage is mounted in the rear part of the body on intermediate supports, which, in turn, are fixed to the side members through four damping rubber pads from the Moskvich engine. A cross member with an intermediate sprocket is also installed on the intermediate supports, connected by a vertical chain drive to the output sprocket of the engine. The intermediate sprocket shaft through the intermediate roller with elastic couplings (the elastic element is a flat disc drive belt 10 mm thick) is connected to a bevel gearbox mounted on a cross member. An asterisk is installed on the output shaft of the gearbox, connected by a chain drive to the input shaft of the main gear (from the motorized carriage), fixed on two crossbars.

The kinematic diagram of the all-terrain vehicle.

Latin letters indicate: z is the number of teeth of the sprockets, t is the pitch of the roller sleeve chains, b is the width of the sleeve roller chains.

The output shafts of the main drive through elastic couplings (from the same drive belt) are connected to intermediate shafts with sprockets, which transmit rotation to the wheels through a chain drive. The output shafts of the main gear, intermediate shafts and balancer trunnions are located coaxially, as shown in Figure 3. It also shows that the trunnions are fixed in bearings on bearings, while the intermediate shaft bearings are pressed into the trunks. The inner trunnion is hollow; an intermediate shaft passes through it. At the inner ends of the intermediate shafts, brake drums from the wheels of the Tulitsa scooter are mounted, on which toothed rims are installed; through chain drives, they are connected to the rollers of the differential lock. The latter is a sliding splined sleeve connecting the rollers.

The axles of all transmission mechanisms are located practically in the same plane. Tensioning of chain drives: transmissions - by means of spacers, gears to wheels - by pressure screws.

All bearing assemblies are protected from dirt by seals from the Volga car or have protective washers.

Front axle all-terrain vehicle- from a steel pipe 0 60X3 mm, reinforced in the middle with a welded pad from the same pipe. Along the axis of symmetry of the bridge, a horizontal axis is welded in perpendicular to it, the ends of which are fixed in bearing supports installed in the niche of the front part of the body. Stands with pivots and pivots from the Volga car are welded to the flattened ends of the pipes. Rubber bumpers installed along the edges of the niche limit axle swinging in the vertical plane.

Front axle of all-terrain vehicle

Steering, as required by the rules of the traffic police, factory-made, from a motorized carriage. The crankcase with the rack is installed under the body floor on the bracket, the steering wheel shaft is connected to the pinion shaft through cardan joint, the second (upper) rudder shaft support is a ball bearing attached to the bracket. Since the steering wheel is located in the plane of symmetry of the body, the joints of the steering rods on the rack are displaced to one side and the rods differ significantly in length, this leads to the fact that the swing of the cross member is accompanied by a noticeable leash of the near wheel.

Steering device and support of the front axle of a homemade all-terrain vehicle

Description of positions: 1 - front axle support, 2 - steering rod hinge, 3 - rack and pinion steering, 4 - body floor. 5 - hinge, 6 - steering column, 7 - steering rod.

Rear wheel balancers homemade all-terrain vehicle-snowmobile are symmetrical frames welded from two rectangular pipes 40X20 mm, connected by cross members from the same pipes. The central support of the balancer pivots in trunnions - bushings welded to the plates fixed to the frame. The wheel shaft supports at the ends of the balancers are of a similar design. The frame of the balancer is somewhat bent, the balancer trunnions are located on top, and the wheel shaft supports are below, so the wheel axles are 180 mm below the balancer joints. The rigidity of the balancers is low, under load they are somewhat deformed, just like the engine and transmission frame, however, the presence of elastic couplings and the possibility of skewing the chain drives compensate for this disadvantage.

Transmission device

Description of positions: 1 - chain drive, 2 - balancer frame, 3 - trunnion, 4 - balancer support, 5 - bracket, 6 - side, 7 - final drive, 8 - elastic coupling, 9 - brake drum, 10 - chain ring gear differential lock transmission, 11 - brake lever, 12 - intermediate shaft, 13 - wheel shaft.

Wheels homemade all-terrain vehicle made of a wide-profile tire tube 1120 x 450 x380. Tubular rims, central disc and cradles for supporting the caster are made of aluminum alloy. The lodges are connected to the rims by welding, to the disc - by means of riveted corners. The lodges are split, so that the outer rim is detachable; it is bolted to the disc. The disc in the central part is reinforced with a riveted pad, bolted to the hub. The valves have been moved to the side surface, which allows the chambers to rotate on the rims. Drive and steer wheels are interchangeable.

In the design of the all-terrain vehicle, several nodes are used, which can be attributed to those that have turned up under the arm. One of them is a bevel gearbox. It can be dispensed with by placing the motor in the longitudinal direction. When assembling the transmission and installing the engine, all fasteners were fabricated and fitted in place. At the same time, all possible measures were taken to reduce the size and weight of standard units; for example, the protrusions of the main gear mounting, motorized carriages were cut, a small-sized muffler for the engine was made.

Control systems.

Control a do-it-yourself all-terrain vehicle, and the alarm system is completely copy the car. Control drives: throttle- cable, clutch and brakes - hydraulic, gear shifting, engaging reverse- rods and handles located on board the all-terrain vehicle to the right of the driver; there is also mounted the differential lock control handle (through the rods). All hydraulic cylinders are from the front wheel brakes of the motorcycle.

The power supply system is somewhat different from that adopted on a motorized carriage: a car generator is installed on four legs along the axis of the crankshaft and the engine fan alternating current connected to the crankshaft by an elastic coupling.

To heat the windshield, warm air is supplied from the engine cylinder through the air intake and corrugated sleeve by two automobile fans - at the inlet and outlet.

You can modify some of the nodes to fit your existing ones, adhering to the main scheme and everything will work out for you. Good luck.

How to make a snowmobile on tracks with your own hands?

With the onset of the winter period, two-wheeled vehicles are losing their relevance. Using a car to overcome short distances with high snow cover is not particularly practical, and in most cases - impossible process. The snowmobile copes with this task much better.

A winter motor vehicle is in most cases equipped with a rear-wheel drive track and front steering skis. High cross-country ability, versatility and ease of use make the snowmobile by far the most popular means of transportation in the winter season.

Features of homemade snowmobiles

Nowadays, you can buy a snowmobile in any motorcycle dealership, both in a large metropolis and in a small city, but the prices of this equipment force many winter driving enthusiasts to make a homemade snowmobile on tracks with their own hands.

There are four important advantages of a self-made vehicle over a factory one:

- Price is the most important factor for most. The cost of some units of the leading manufacturers of motor vehicles can exceed the cost of those assembled from scrap materials by 5-10 times.

- Parameters - the ability to assemble a vehicle of the desired configuration. This applies to both the appearance and the power reserve, the type of chassis, etc.

- Reliability is the point that even well-known manufacturers do not always boast of. When self-manufacturing, a person uses the highest quality materials and pays special attention to the most important parts of the mechanism.

- Benefit - the ability to use materials, parts and accessories from other devices lying around in garages and backrooms.

At the same time, homemade snowmobiles are used both on the streets of settlements and on roadless areas of suburban expanses and ski resorts.

Homemade snowmobile on tracks with your own hands: where to start?

1 - rear light; 2 - hitch; 3 - body (plywood, s16); 4 - side reflectors; 5 - rear shock absorber (from the Dnepr motorcycle, 2 pcs.); 6 - gas tank (from the launcher of the T-150 tractor); 7 - seat; 8 - main frame; 9 - electronic ignition switch (from the Voskhod motorcycle); 10 - ignition coil (from the Voskhod motorcycle); 11 - power plant (from a motorized carriage, 14 hp); 12 - muffler (from motorized carriages); 13 - steering column; 14 - steering joint in a leather case filled with grease (joint from "UAZ"); 15 - limiter for vertical movement of the steering ski (chain); 16 - steering ski turn limiter; 17 - steering ski; 18 - side ski (2 pcs.); 19 - generator; 20 - clutch lever (from a motorized carriage); 21 - drive chain shield; 22 - footboard; 23 - drive shaft drive chain; 24 - the drive shaft of the caterpillar; 25 - lower track chain guide (polyethylene, s10, 2 pcs.); 26 - caterpillar chain (from the header of the forage harvester, 2 pcs.); 27, 31 - upper front and rear chain guides (polyethylene s10, 2 pcs.); 28 - shock absorber of the propeller hinge frame (shortened rear shock absorbers of the Dnepr motorcycle, 2 sets); 29 - support ski; 30 - rear spacer frame; 32 - rear axle.

A drawing of a homemade snowmobile is an essential step in the preparatory stage of manufacturing. Here to help engineering skills come in handy... and in the absence of such, superficial sketches are made, creating a general image of the future mechanism.

Before creating a drawing, it is necessary to determine the list of required components. The basis of the standard configuration of the snowmobile is:

- Frame - depending on the complexity of the design, it can be borrowed from an ATV, motor scooter, scooter, motorcycle, etc. If they are not available, the part is usually cooked from thin-walled metal pipes with a diameter of about 40 mm.

- Seat - given the difficult operating conditions of the equipment, the material of this element must have a high moisture-repellent ability.

- Engine - is selected with the calculation of the required speed and the total weight of the vehicle. The most commonly used motors are motoblocks, scooters, motorcycles, etc.

- Tank - 10-15 liter metal / plastic container will fully provide carefree trips over relatively long distances and will not take up much space on the unit.

- Skis - in the absence of ready-made options, it is recommended to use nine / ten-layer plywood sheets with a thickness of about 3 mm for self-production.

- Steering wheel - chosen with the calculation of convenience and practicality. Similar to the frame, engine and seat, it is removed from the specified two-wheeled units.

- Drive - a part that transfers rotary motion from the engine to the track. A motorcycle chain performs this function well.

- The caterpillar is the most complex and important element. Their types and methods of self-production will be discussed further.

How to make homemade caterpillars?

One of the most common materials for making a propulsion unit at home is car tire... A homemade snowmobile track from a car tire has one important advantage over other options - it is made in the form of a closed loop, which significantly reduces the likelihood of rupture.

The beads are separated from the tire using a boot knife, leaving a flexible treadmill. The lugs are attached to the driving blade - plastic pipes sawn along with a diameter of about 40 mm and a thickness of about 5 mm. Cut to fit the width of the tire, half-pipes are attached to the canvas with bolts (M6, etc.) at intervals of 5-7 cm.

Homemade caterpillars are made in the same way. from conveyor belt... Their main advantage is the ability to choose the length of the propeller. After cutting to the required length, special attention should be paid to the hitch. The ends of the tape overlap each other by 3-5 cm, and are fixed across the entire width with the same bolts as the lugs.

Handmade tracks are often made with materials at hand, such as V-belts. Fastened in width by means of lugs, they make up a full-fledged caterpillar track with hollows for the gear already existing on the inside.

Note that the wider the track, the better the snowmobile's flotation, but the poorer handling. Factory options have three samples of canvas widths in inches: 15 - standard; 20 - wide; 24 - extra wide.

Let's go to practice

A frame made of pipes or corners is primarily equipped with a steering gear. Having chosen the height and angle of inclination, weld the element with spot welding. Install and secure the motor according to the drawing, taking care not to tilt too much. The snowmobile should not have a long fuel line, so try to position the tank closer to the carburetor.

The next step is to install the track. Attach the driven axle with the belt fitted to the rear of the frame (on a fork, suspension, shock absorber, etc., depending on the type of construction), the leading axle in the middle of the snowmobile (most often under the driver's seat), in the shortest possible hitch with the engine. The gears of both axles are pre-engaged.

Homemade snowmobile from a walk-behind tractor

This transformation is especially popular today. The walk-behind tractor can be used, either partially or completely. In the first case, a supporting frame with a rear axle is added to the unit (engine with steering fork and wheels). The most difficult stage in this case is the transformation of the working shaft of the walk-behind tractor into a drive gear.

A homemade snowmobile from a walk-behind tractor with partial use of parts is more versatile. In this case, only the engine and the steering fork are removed from the "donor", to the lower part of which skis are attached instead of wheels. The motor itself can be located at the rear of the structure.

It should be noted that the engines of the main part of the motoblocks are designed for the weight and pressure of the wheels, which is several times less than the tracked one. Therefore, in order to avoid increased wear of parts and fuel consumption, it is better to equip such a snowmobile with low pressure wheels.

http://motoholder.ru