The need to modernize the braking system of a car may be needed in two cases. Firstly, attention will have to be paid to the braking system when the vehicle is being prepared for extreme high-speed driving. We are talking about the "full pumping" of the car, which is planned to participate in the races.

In addition, if the owner of the car, although he does not plan to take part in the races, nevertheless decided to subject his car to significant tuning, there will also be no escape from modernizing the braking system. As you know, tuning any car is bringing its basic qualities to the level required by a specific car owner. That is why the cases of tuning of already serious cars with a "hot character" obtained at the factory are so widespread. In this case, changing one system entails altering the second, followed by the third, and as a result, a major overhaul of the entire car is obtained. There is nothing strange in this - almost all systems and components in the car are interconnected with each other. So, increasing the power power unit without fail will require an increase in the efficiency of the braking system. After all, standard brakes are designed for effective braking of a car with standard factory characteristics, and it will be very difficult to stop a car with a tuned engine and suspension at high speed with conventional brakes.

The second common reason for the modernization of the braking system of cars is insufficient work. standard system... And although for modern cars such a problem is quite rare, in the case of owners of a used car, especially Russian production, the revision of the brakes may not be superfluous.

Starting small

As statistics show, a significant number of road accidents occur due to insufficient efficiency of the braking system. The brakes simply do not work at the right time, due to a sharp increase in the load on the system. This problem is especially acute in domestic cars, which do not have the anti-lock braking system familiar to most foreign cars.

It must be borne in mind that the artisanal modernization of the vehicle's braking system is a prohibited procedure. It is very dangerous to interfere with the braking system of a car in the "garage conditions of an auto-cooperative". Independent, unprofessional intervention in the braking system of a car in the overwhelming majority of cases puts an end to the honest passage of a technical inspection of the car, and the effectiveness of such intervention is often very doubtful.

However, if you take the necessary steps accurately and correctly, you can greatly improve the performance of your vehicle's brakes. Moreover, this will be relevant both for domestic "Ladas" of different years of production, and for many foreign cars. Moreover, small alterations are within the power of everyone who understands at least a little about the device of the car. So, on many foreign cars, as well as on modern domestic cars, it is quite easy to install ventilated brake discs, replace brake calipers and pads. Today, many well-known companies produce special tuning car brake pads with an increased coefficient of friction relative to standard pads. Such products do not lose their effectiveness, even at a very high temperature of the working surface, while possessing a significant indicator of thermomechanical strength.

As for tuning brake discs, in most cases they are made of high quality cast iron. As a rule, tuning brake discs are made ventilated and have perforations. The ventilated brake disc resembles a pump rotor and serves the function of creating additional air discharge for greater cooling. Perforation is also used to speed up the cooling of the disk. In addition, the perforated disc is good at removing carbon deposits that form on the pads when they come into contact with the discs. It is not surprising that even tuning pads, working with such brake discs, wear out much faster than with standard brake discs. And this state of affairs can be inconvenient for the daily operation of the car.

Further more

The next step in modernizing car brakes is to install a more powerful, vacuum booster... The essence of replacing a vacuum booster is to reduce the time required for the brakes to apply. After all, the more powerful the amplifier is, the less time it will take to apply the brakes after pressing the pedal. In addition, if you are going to install tuning brake pads and discs on your car, replacing the amplifier with a more powerful one is simply a must.

In case of modernization of the brake system domestic car choosing the right amplifier is easy. In any serious auto parts store, you can find a more powerful unit for almost any domestic model. Owners of foreign-made cars, especially heavily used ones, may find a part from a more powerful car suitable. For many modern models of foreign cars, you can find a vacuum brake booster in which the main brake cylinder made with an increased diameter and, as a result, with increased productivity. Installing such an amplifier will make the pedal travel shorter, reducing the effort applied to it. In this case, the braking force will increase.

The hardest part is the rear brakes

The more complex procedure is usually the rear brake upgrade. On many cars produced today, not to mention the cars of yesteryear, the rear pair of wheels are equipped with drum brakes. Rear brakes are modernized by replacing drum brakes with disc brakes. There is no point in arguing about the advantages of disc brakes. As the temperature rises, functional characteristics disc brakes remain stable, while the efficiency of drum brakes is significantly reduced.

The discs have a higher temperature resistance, also due to more efficient cooling. Disc brakes are lighter and less bulky, in addition, they increase the sensitivity of the brakes, the efficiency of the braking function increases, and the stopping distance becomes shorter. Disc brakes are simpler and easier to maintain - it is not difficult to replace worn-out pads yourself, while replacing pads on drum brakes is best done in service center... Measurements have shown that about 70% of the vehicle's energy during braking is extinguished with the help of the front brakes, the rear pair only provides a decrease in the load on the front discs.

As a rule, if the car being upgraded is front-wheel drive, the procedure for replacing drum brakes with disc brakes is relatively easy. Difficulties can only be caused by reworking the hand brake. When installed on rear wheels disc brakes, you will need to replace the hubs, install the calipers, the tubes are changed to flexible brake hoses, the brake disc itself and the pads are installed, and it will also be necessary to reconfigure the pressure regulator.

It is much more difficult to remodel the braking system on rear wheel drive cars. In this case, you will have to change rear axle... Usually the bridge is picked up from another car. In any case, the procedure for modernizing the rear axle brakes on rear-wheel drive cars is only possible in an equipped car service, and therefore it is not recommended to undertake such alterations on your own.

An extremely large number of accidents happen due to loss of vehicle control. Better brakes are vital when increasing engine power and loving speed.

What is the first step to improving the braking system?

First, it is recommended to study the braking system and its design. It is worth starting by changing the pads and discs to sports options. Pads are best purchased with a reinforced compound designed for our purposes. While they may not perform so well in quiet driving due to pre-heating requirements, they maintain their properties perfectly during heavy braking. During dynamic driving with regular and rather sharp brakes, such pads are not subject to overheating and demonstrate reliability.

The situation is similar with disks. If you have factory ones, you need to purchase ventilated discs with holes. When braked, they are not subject to overheating, which will prolong their performance. For better efficiency, it is recommended to use discs from another car with larger dimensions. Braking will be better as the contact area between disc and pad increases.

The purchase of expensive ventilated discs, for example, on the site http://superbrakes.ru and, at the same time, saving on pads, quickly leads to the destruction of discs. Experts advise sticking to one manufacturer in this matter, because the material will be of the same type and balanced according to its data (minimum wear at the maximum coefficient of friction).

Our next step will be the installation of a more powerful vacuum amplifier. The more powerful it is, the faster the brake response will be. Options in this matter would be buying a modified large vacuum booster or using it from another car. The installation of such equipment is important when improving the braking system and when braking at high speed, its performance is noticeable. The effectiveness of the brakes will require less pedal effort.

It's time to start changing our drum brakes to disc brakes. The advantages are:

With a rise in temperature, the indicators are quite stable.

The temperature resistance of the discs is higher, as is the improved cooling capacity.

Braking is more effective, which results in a shorter braking time.

Smaller dimensions and weight

Increased inhibitory sensitivity.

Decreased response over time.

About seventy percent of the energy of a moving car is canceled out by the front brakes. In the same time, rear brakes give a decrease in the load on the front.

Basically, if you have a car not with rear wheel drive the process is quite simple. The disadvantage is the search for a solution to modernize the handbrake. We'll have to change the hub, install the caliper, install hoses instead of tubes, mount the disc and adjust the pressure sensor. A rear-wheel drive car imposes some difficulties - the bridge needs to be replaced. It is much easier to find a suitable bridge from any vehicle.

Improving the brakes only with discs cannot be limited. Interestingly, rubber hoses are susceptible to stretching or swelling. Since they "walk" a little, the efficiency of the braking system is an order of magnitude less, and the gas pedal has to be depressed. To avoid such consequences, reinforced type hoses are used.

The next step of improvement is the replacement of additional components. This refers to the mounting of multi-piston mechanisms. The process requires significant changes, but in the end there is a completely replaced brake mechanism, which will clearly affect the result.

Warning: interfering with the work of the factory brakes is PROHIBITED. After such shenanigans, you will have to forget about an honest technical inspection. Do not forget that tuning can be life-threatening as well.

Every year it is more and more difficult for the owners of old cars of category N 1 to "cure" their diseases and drive in the same stream with modern, more dynamic models. Components and assemblies from machines of later release and alteration of systems according to their model help to solve these problems.

Improving the efficiency of the brakes in these cars will help drivers feel more confident on the road, prevent dangerous situations arising from a longer braking distance than other cars.

The most affordable and reliable way to improve this system is to use the currently produced hydraulic vacuum booster 4, separator 5 and brake alarm 7, as shown in Figure 2.17 (this option is coordinated with the traffic police). Tubes with a diameter of 6 mm are used, with a wall thickness of 1 mm, with the same flaring and union nuts as in old cars. We fix the new units on the body in any way, but reliably enough.

Figure 2.17 - Diagram of the hydraulic brake drive: 1 - front wheel brakes; 2 - tee; 3 - a hose with a diameter connected to the engine intake manifold; 4 - hydraulic vacuum amplifier; 5 - brake separator;

6 - control lamp; 7 - alarm indicator; 8 - the main brake cylinder; 9 - rear wheel brakes

As a design development, a signaling device 7 is proposed, which is designed so that in the event of failure of one of the circuits of the separate drive under the influence of a pressure difference, at the first pressing of the brake pedal on the instrument panel, the lamp of the faulty circuit is lit, which in turn increases the braking efficiency ...

After assembling the system, pour the BSK fluid into the main brake cylinder 8 and, turning the valve in the brake separator by 2 ... 2.5 turns, pump alternately the brakes of the rear and front wheels, then the hydraulic vacuum booster.

We wrap the separator bleed valve with the brake pedal released.

As always, doing this work, add fluid to the master brake cylinder so that air does not enter the system.

If all brakes and their drive are correctly adjusted and there is no air in the system, the brake pedal, when pressed with your foot, should not go down more than half its travel, and the warning lamp should not light up when the ignition is on.

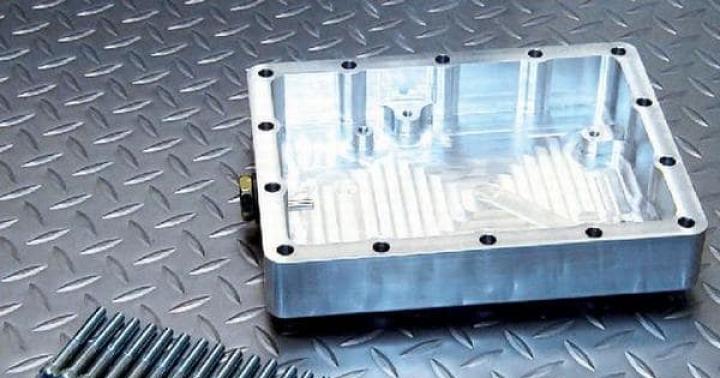

To increase the braking efficiency on sports cars, “sports brakes” have been developed and are being installed today; a set of such brakes can be represented in the form of Figure 2.18.

Figure 2.18 - Set of brakes of a sports car

Let us dwell on each of the elements of Figure 2.18 in more detail. The task of the brake disc is to absorb the kinetic energy of a moving car and dissipate it into the environment, that is, the kinetic energy goes into thermal energy, and the thermal energy from the disc goes into the environment, so it is clear that it heats up during braking, and when the car accelerates, it cooling. Consequently, the thicker the disk and the larger its diameter, the higher its heat capacity, the more energy it is able to accumulate. However, an increase in the size of the brake disc also leads to an increase in its weight, which increases the unsprung mass of the car, and its thickness is not used rationally. Therefore, ventilated brake discs are used in motorsport. They have two washers connected by jumpers in such a way that channels are formed inside it through which cooling air circulates, i.e. during the rotation of the wheel, it works as a centrifugal pump (Figure 2.19). This solution leads to both a decrease in the mass of the disk and an improvement in its heat transfer.

Figure 2.19 - Brake disc with spiral channels

The brake pad must provide a high coefficient of friction (braking efficiency directly depends on its value) in the entire range of speeds, pressures in the brake drive and temperatures of the brake disc. It consists of a metal frame to which a friction material is molded (Figure 2.20).

Despite the need to reduce the mass of the brake mechanism, the metal frame is made, as a rule, massive in order to more evenly distribute the pressures on the friction material.

Figure 2.20 - Pads of a sports car

Friction material is a complex composition containing 50 or more components. This is due to the complexity of the physical and chemical processes occurring during braking. The brake lining must provide reliable braking at temperatures up to 600 ... 700 ° C. At the same time, it should not collapse, providing the necessary resource, and also firmly adhere to the metal frame. It should also be remembered that as the temperature rises, the friction material becomes softer, i.e. it shrinks harder.

From all that has been said, it is clear that "sports" driving in order to ensure reliable braking of the car at any speed requires a more careful approach to the choice of brake system components than usual on public roads. However, the achievement of this goal, as a rule, leads to an increase in its value.

The following are accepted as indicators of braking properties: braking distance when braking a car with maximum efficiency; stopping distance, taking into account the distance traveled by the car during the driver's reaction time, and the response time of the brake drive; the amount of vehicle deceleration.

The influence of tires on the braking properties of a car is very great and is especially noticeable on wet and slippery roads. The braking properties of one and the same car on some tires may be insufficient, while on others they may well meet the necessary requirements to ensure braking efficiency.

The braking properties of a car are mainly dependent on the grip of the tires. The coefficient of adhesion depends on many factors and, first of all, on the type of surface and condition of the road, construction and materials of the tire, air pressure, wheel load, driving speed, heating temperature and braking mode. Wheel grip on a dry, hard road practically does not depend on the degree of wear of the tread pattern, but it is of decisive importance on wet and especially covered with a layer of water or mud roads, when the magnitude of the friction force in the plane of contact of the tire with the road decreases sharply. As the wear of the tread pattern increases, the depth and volume of the drainage grooves between the protrusions of the tread pattern decreases, as a result of which the drainage of water from the contact zone sharply worsens and the adhesion of the tires to the road drops sharply.

Car tuning starts with large wheels and big brakes. This outwardly adds style to any car, more than any bumpers, and in technical terms it is simply irreplaceable. Powerful foreign cars are equipped with large brake discs in combination with ABS. Large discs allow quick braking at high speeds, and ABS prevents the wheels from locking and skidding on wet and slippery surfaces.

VAZ cars have a huge potential for tuning, that is, improvements and improvements in design. The more budget car model, the more the desire comes to do everything in it as it should be. All over the world, tuners with a sense of humor make from inexpensive cars, sports cars, which in their parameters are not inferior to expensive and powerful brothers.

For VAZ car the best option are forged wheels with a diameter of 15 inches, and tires 55 / 205R15. Various variations on this theme are possible. Some manage to "shove" 16, 17 inch wheels into the basin. But one thing is obvious - 13 inch wheels do not allow installing normal brakes and have poor grip, they are completely unsuitable for active driving.

When the "correct" wheels are installed on the car, small, unsightly front brake discs appear, and the rear drums of the nineteenth century design that do not fit into the appearance of a sports car in any way.

Unfortunately, the statement that everything at the factory is ideally designed for the car does not always find confirmation. Tests "Lada Kalina", conducted by the German magazine "AutoBild" showed that the brake system needs to be replaced, quote:

But the real crime begins when braking: "Kalina" gets up after 59.4 m! This is the stone age of motorization and is deadly for both riders and everyone around you! Red card for Kalina. It cannot be released on our roads, unless asked to return to the plant as soon as possible.

Of course, German journalists spoiled by test drives of expensive and sports cars, have already forgotten that there are cars with 13 inch wheels, on which you need to drive carefully and calmly, not to accelerate more than 100 km / h when the standard brakes stop working. However, for lovers of more dynamic driving standard equipment turns out to be rather weak.

Front braking system When braking, the weight of the car is transferred to the front, and therefore the load on the front brakes is 60-70%. At high speeds, the front brake discs become very hot, even to reddening during very active driving, and may deform slightly (beating on the pedal). When the disc is very hot, the wear of the pads is accelerated.

How can you avoid severe overheating of the front brakes? Increase the brake disc diameter and pad area. Naturally, the front brake discs must be ventilated, that is, there are ribs inside the disc that are cooled by the ambient air. On some VAZ cars, non-ventilated discs are used in front, the braking efficiency with them is extremely low.

Most VAZ models use 13-inch wheels, and 239 mm front discs (called 13-inch). It is dangerous to drive at high speeds with such a braking system, and the service life of such front brakes is short.

On VAZ 2112 and Priora cars, 14-inch wheels are used, and ventilated front brake discs 260 mm (called 14-inch). The efficiency of such front brakes is noticeably higher, but insufficient for active driving or racing.

There are also tuning options for a VAZ 15-inch brake disc with a size of 286 mm, it is used with wheels of 15 inches or more.

The caliper remains standard enlarged with the help of special brackets designed for this disc. In this case, the brake pads remain standard, VAZ ones. The area of these pads is small, and therefore does not allow the use of such a disc fully efficiently.

The best use of such a disc would be to install a larger caliper with increased pad area. The most effective and inexpensive is the GAZ caliper (Volga 3110, Gazelle, Sobol), it is the same on all these machines.

GAZ calipers are installed on the front axle of the VAZ using special adapters. The adapters are screwed with two screws to steering knuckle... Then the GAZ caliper is screwed to the adapters with two bolts.

For comparison, VAZ and GAZ pads are shown. They are made by various manufacturers, the price and quality depend on the brand.

The same pads for VAZ and GAZ, and for comparison, the pads that are used on a car with a 436 mm brake disc. Guess which is more effective?

This table shows the heating temperature of three types of VAZ brake discs with repeated braking at a speed of 100 km / h to 50 km / h. You can see how the temperature rises depending on the number of brakes.

Let's take a look at the graphs. The heating dynamics of each disc during the braking cycle provides a clear indication of the benefits of ventilated brakes. The worst of the three, obviously, is 2108. In 25 brakes, it warmed up to 440 ° C. For many brake pads, operation in this mode will prove fatal (see ZR, 1998, No. 7). The same size, but ventilated, the 2110 reached 300 ° C. A lot too? Compared to the previous one, sheer trifles - 140 ° C colder. And most importantly, the heating dynamics showed that if for the "eighth" disks, a continuation in the same spirit will allow reaching astronomical temperatures, then the "tenths" are unlikely to exceed 350 ° С. And here is the champion - disc 2112. This one is 21 mm larger in diameter and also with ventilation. Its temperature was 70 ° C lower, reaching 230 ° C. The graph shows: no matter how much you continue testing in the selected mode, it will be difficult to heat this disk by more than another 10-20 degrees.

The magazine "Behind the wheel"

Rear disc brakes

If earlier the rear disc brakes seemed to be an expensive pleasure, today their installation on a VAZ car of front-wheel drive models starts from 3000 rubles.

The main advantages of disc brakes over drum brakes:

1.The braking and cooling performance of the brakes is greatly improved.

2.Easy to replace pads and visual control of their wear.

3. Of course, the appearance: a car with drum systems cannot pretend to be a sports car.

Consider the design of the rear disc brakes of a front-wheel drive VAZ. A hub is attached to the rear beam of the car on each side, on which there is a brake disc and a wheel rotates. Also, a hydraulic brake caliper with pads is attached to the beam by means of an adapter faceplate. The caliper can be with or without a built-in mechanical parking brake. Hydraulic options available parking brake... In motorsport cars, the handbrake is often missing.

Rear brake discs should preferably be 1-2 inches smaller than the front to avoid overbraking the rear axle.

Three main elements for tuning the VAZ rear brake system:

Brake disc VAZ 13-14 inches. Used on front-wheel drive VAZ models

as a front brake disc. There are three types:

13 inches unventilated (model 2108),

13 inches vented (model 2110) and

14 inches vented (model 2112).

The average price is 300-600 rubles 1 piece.

The caliper also comes in three types, depending on the disc with which it is used.

Sold complete with pads and hose.

The average price is 800 rubles 1 piece.

An adapter plate is required to attach the caliper to the rear beam of the vehicle.

Universally fits 13 '' and 14 '' brakes.

The average price is 350 rubles 1 piece.

Installation of rear disc brakes on VAZ 2108-2115 cars,

adjustment of braking forces on the rear axle.

We turn off the drum brake system (this process is described in detail in the Articles section). Remove the hub by unscrewing 4 bolts. Unscrew brake pipe from the cylinder.

We fasten the hub by placing the corresponding faceplate (right, left) between it, the protrusions on the adapter faceplate should look outward. The grover indicated by the arrow is not placed under the bolt; it will interfere with the installation of the caliper.

The bolts for fastening the hub are needed 5mm longer than the previous ones. That is, M10 * 30 * 1.25 instead of M10 * 25 * 1.25. The standard bolts are too short. You will need six of them on each side. That is, four pieces for mounting the hubs and two pieces for mounting the calipers, 12 pieces in total. If you have not found suitable bolts, then they can be made from longer ones by cutting them with a "grinder". Only the thread should be no more than 13mm from the head.

The angle of the beam, shown in the figure, is crushed with a hammer, if necessary, it is slightly modified with a "grinder". The operation is simple as the metal is soft. This is done so that the caliper does not touch the beam. This operation is not required for 14-inch rear discs and calipers. But if you put the brakes in the back 14 ", the front should be at least 15".

The hub has a 1mm lug in a circle, marked in red. This protrusion interferes with the seating of our standard VAZ disc. The disc has an internal hole of 58mm, the hub, in principle, also has the same diameter, but in the place of this protrusion the diameter is 60mm. What to do?

If you happen to not have a lathe at hand, it doesn’t matter. We again take the wonderful tool "grinder" and carefully grind this protrusion from the hub without removing it from the car. The hub will rotate to provide even metal removal. Just do not get carried away with this process, constantly try on the brake disc so that it does not dangle and press tightly against the hub.

We choose one of three types of VAZ discs (13 "unventilated, 13" ventilated, 14 "ventilated). Remember that the disc comes out 1 to 2 inches less than the front brakes. We put the disc on the hub, fix it with guide bolts.

We attach a caliper corresponding to the size of the given disc, connect the brake pipe with a hose. We pump the brakes.

The modern rhythm of life requires constant acceleration from humanity. This is significantly reflected in the technological evolution of vehicles. Manufacturers produce cars with improved powerful engines, which requires improvement and modernization of the braking system of the machine. This is the main unit that is responsible for road safety.

Brake tuning can help make your ride safer and your braking distance shorter.

Today, the most important issue for motorists is tuning the brake system. This aspect is of interest to both drivers of vehicles with uprated engines and owners of ordinary cars who are prone to high-speed driving. Consider in this article, the brakes to get the most positive result.

Features of the choice of brake units for tuning the brake system of a car

Tuning brakes is used by motorists to reduce the braking distance of the vehicle, as well as more effective braking when driving at high speeds. Before proceeding with the modernization, it is important to understand that the parts that need to be purchased are of a high price category. To get an excellent result, you need to put on the car new and improved modern parts.

Components such as brake discs and calipers, hoses and pads are responsible for the effectiveness of a car's brakes. In order to carry out a complete tuning of the brakes, it is desirable to simultaneously replace all parts of the system. Let us consider in more detail what the elements of the vehicle's braking system are needed for.

Brake discs and calipers

The main part of the car's braking system is the discs. From a technological point of view, braking is the transformation of mechanical action into thermal energy due to friction, which is characterized by high temperature indicators. Basically, the discs are made of cast iron, which is resistant to high temperatures, has a high hardness, which provides protection against deformation and guarantees a long service life of parts. And also the design features of the disks affect the quality of heat energy removal.

Tuning brake discs are of different types:

- Ventilated, which outwardly resemble two disks glued together. This design allows air to pass between the discs, which increases the cooling rate of the part. They are characterized by high strength.

- Perforated discs have transverse slots. They have not worked very well, as they often show cracks and breaks near the drilled holes.

- Notched discs are in great demand among motorists. Self-cleaning well from dirt and carbon deposits due to design features... However, they are noisier when braking.

Modern discs are made of wear-resistant ceramic or carbon. Parts that are produced using such technologies are distinguished by a high level of heat energy removal and service life, however, the cost of goods has a high price threshold. If you are the owner of a sports car, then the most practical solution would be to choose carbon fiber products, they are resistant to high temperatures. For ordinary cars, experts advise not to buy them, since for effective braking they need to warm up well. For owners of standard vehicles, ceramic discs are more suitable. They are lightweight and cope with their tasks under different temperature conditions.

Brake pads

Tuning a car's brake system cannot be complete without replacing conventional brake pads with special ones, which are characterized by a higher coefficient of friction. However, it is necessary to take into account the fact that the pads, which are designed for more powerful vehicles, begin to work effectively only when heated to a certain temperature. There are special pads that are made of a softer material than conventional pads and do not require very high temperature regimes for correct work. It is important to compare the parameters of the product and your driving style before buying in order to find a compromise solution to the issue.

Brake Upgrade Options

After purchasing all the necessary units, it is necessary to proceed to replacing the standard brake products with tuning ones. And at this stage of work, problematic moments arise. Brake discs may not fit in the mounting holes or new calipers in the standard seats.

In order not to face such problems when installing parts, when choosing products, you can pay attention to special tuning kits that are now sold for most brands and models of cars.

With the installation of special kits, absolutely no questions arise, all standard fasteners completely coincide with the fasteners of the tuning parts. You can handle the replacement of parts yourself without the help of specialists. However, the kits generally have a brake disc of the same size as the standard one or slightly larger than the previous one. Previously, it was agreed that the diameter of the brake disc proportionally affects the braking distance of the vehicle. Retrofitting the brakes with tuning kits will dramatically improve brake performance. If you want to redesign and improve the brakes as much as possible, you can take advantage of more complex tuning options that require some rework.

The first method involves replacing standard disks on products bigger size... Accordingly, in order to install them on the car, it is necessary to drill additional holes in the hubs, which will coincide with the fasteners of the tuning parts. It may also require the manufacture of adapter plates to install the calipers over the larger discs. Mounting larger discs will entail purchasing larger and wider wheels.

The second tuning method is to replace the standard product with a ventilated disc or a disc with notches of the same size. In this case, you will not need to purchase a new set of tires for the vehicle. It is possible to increase the efficiency of the brakes by installing an additional caliper on each disc of the vehicle. In this case, it is important to make reliable fasteners for complementary calipers. This tuning increases the braking efficiency by about two times.

The choice of tuning method depends on your preferences and financial capabilities. The first method is more costly in terms of money, the second option will be more economical, however, it depends on the equipment of your workshop and your capabilities.

And one more important point. New car models are equipped from the factory with standard disc brakes on the front and rear wheels. If you have an old car, you will need to replace the rear drum brakes with modern disc brakes. In this case, serious alterations of the wheel hubs and fixtures for mounting the calipers will be required. If you have the technical ability, then you can redo the fasteners yourself, otherwise, in the absence necessary tools, it is better to seek help from professionals.

- Before starting work, remember that unsuccessful tuning of the body kits of the car or its interior will subsequently affect only its appearance... Poorly tuned braking systems can cost you your life.

- Brake system directly responsible for the safety of the vehicle on the road. Changes in the braking system of a vehicle are prohibited by law. Therefore, before tuning the brakes, think about how you will undergo regular technical inspections.

- Retrofitting the braking system is very expensive. Full tuning is essential for racing and sports cars. For conventional vehicles, it is often enough to replace the brake elements with special tuning kits, which are easier to install and more efficient to use.

- If, nevertheless, you decide to upgrade, choose only products from well-known manufacturers that have passed certification.

conclusions

There are different ways to upgrade the vehicle's braking system. You can install special tuning brake kits or radically change the brake system by increasing the size of the discs. It all depends on your wishes and financial capabilities. The main thing is to be extremely attentive and careful, consult a specialist. The braking system of the car is the guarantee of your safety on the road.