Today, V-belts are widely used not only in the automotive industry, but also in many other areas of activity. Why are they so in demand among manufacturers? What are their characteristics and how do they differ in size? We will discuss this in detail below.

Description

First, let's look at the description of these elements.

Concept

As practice shows, the wedge transmission is more reliable than the flat belt and allows for better grip of the strap with the shaft. Such adhesion makes it possible to reduce the level of belt tension and, accordingly, the threshold of the force that acts on the pulleys and bearings. If necessary, in the case of a V-belt, it is quite possible to reduce the angle of engagement of the shaft or use higher gear ratios.

Currently, V-belts, regardless of their marking and type, are widely used in modern equipment and technology. As a result of this, manufacturers of straps have long increased the range of their products, in the domestic market you can find many different types... are the most popular not only among consumers, but also among companies engaged in the production Vehicle... Such elements allow performing the main function of transferring torque from the motor pulley to all kinds of auxiliary devices.

In fact, such products are considered innovative in the belt-driven segment. The straps were originally designed to transfer torque from the pulley to the motor. Currently, for the production of these products, manufacturers use all kinds of modern multicomponent materials. In addition, the assortment itself includes dozens of different types.

Application

V-belts are currently used in many areas of national economic activity.

This is about:

- First of all, about the production of vehicles. Today straps are used literally everywhere by many car manufacturers... In this case, we are also talking about the industrial automotive industry, in particular, construction cranes.

- Operated in various drives for agricultural vehicles. We are talking about combines, tractors and so on.

- V-belts are used to equip drives of all kinds of industrial and production equipment. In many modern factories and enterprises, machine tools in workshops and other equipment are equipped with such elements.

- In addition, manufacturers also use wedge products in the design and manufacture of modern ventilation equipment.

- Often the straps are used in various drives of compressor devices.

- Recently, such components are increasingly being equipped with Various types models of household appliances.

- Among other things, V-belts have also come to be used in conveyor belts.

Regardless of the area of use, such components are used to transfer torque from the motor shaft of the motor to other accessories and units.

Characteristics of V-belts

If everything is clear with the field of application, we suggest that you dwell in more detail on technical characteristics... It should be noted right away that such elements differ in size, designation, profile, type and design. We will consider these aspects in more detail below.

Types

Let's start with the types - today there are five of them:

- drive products with normal standard cross-section are one of the most common;

- diversified products;

- wide drive straps, mostly used in designs automatic transmissions, in particular - variators;

- straps for the production of fan products;

- narrow belts of small width.

Design and geometrical parameters

Let's move on to the design of the elements. Regardless of the type, any V-belt will have an isosceles trapezoid section. It should be noted that the lateral planes of the element are its working surfaces. These components function in special grooves of several shafts (from two or more), and the profile of these pulleys is also made in the form of a trapezoid. The transfer of torque from one shaft to the second or the other occurs as a result of the frictional force between the lateral planes of the element and the sides of the grooves.

The angular part of the wedge allows for optimal wedging of the belt into the groove of the shaft, as a result of which its free exit from there is also achieved. Typically, this angle is about 40 degrees.

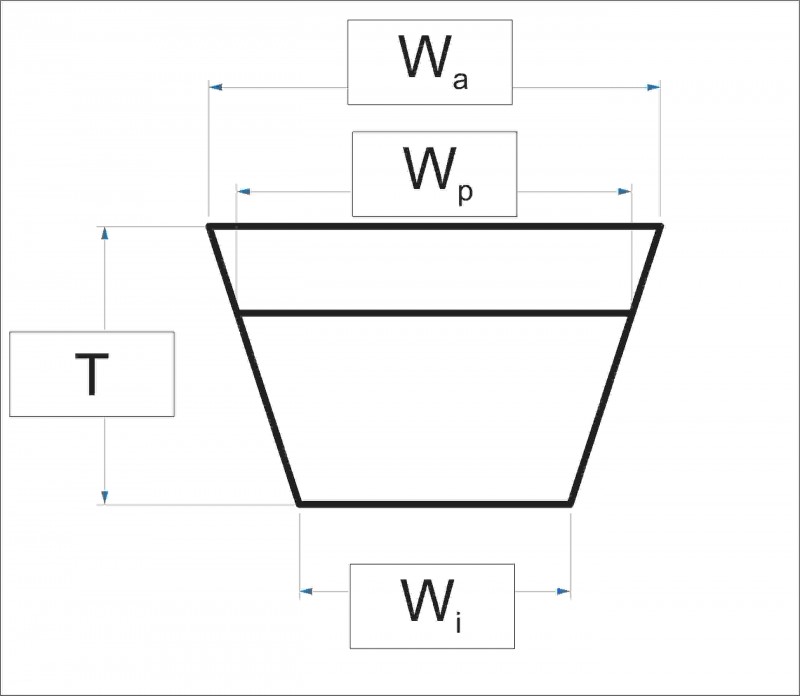

Let's go directly to the geometric parameters in accordance with the component diagram:

- Wa is a parameter that determines the width along the larger base;

- Wp - this parameter determines the calculated length, which corresponds to the width factor;

- T is a parameter that determines the height;

- Wі is an indicator that determines the value of the angle.

As for the geometric parameters, we have finished, now we will consider which layers, and there are several of them, any V-belt consists of:

- first of all, it is the main, bearing layer of the component;

- the second layer is a stretch layer;

- the third, no less important layer is compression;

- well, the wrapper itself.

The traction layer can be made of several materials. Depending on this, the design can be cord-fabric or cord-cord. In the case of cord fabric belts, cracks often develop in the compression layer over time, which as a result propagate to the entire element. Cord-fabric elements require more energy to transmit torque, which contributes to a decrease in service life. If we compare with cord-cord products, cord-fabric straps work on average twice less.

In the cord components, the traction layer contains the cord material, which consists of turns of the corresponding cord. It is known to those skilled in the art that this cord is negatively affected by the compression effect, and accordingly the traction layer is usually a stretch layer. Compared to cord fabric belts, their service life is slightly higher.

Marking

Now for the markings and markings that you can see on the V-belt design.

Let's consider all these notations in a nutshell:

- the name of the manufacturer of the product or its trademark is applied to the structures, which makes it possible to identify the manufacturer;

- the belt will indicate the parameters of the cross-section, as well as the indicator of the calculated length;

- the exact date of production or the mark of the quarter and year when the product was produced;

- GOST 1284-89 indicating the type of motor (four-, eight- or sixteen-valve engine);

- strap class mark;

- and, of course, the very purpose of the element, where it should be used.

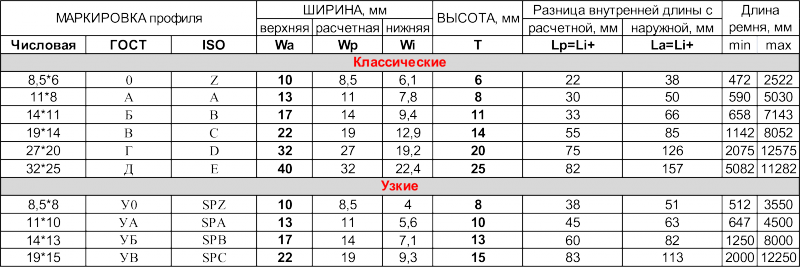

Dimensions (edit)

Let's move on to the dimensions of the components. As stated above, V-belts can be used in a wide variety of applications. Accordingly, they can have different sizes depending on the application. We suggest you familiarize yourself with this nuance in more detail. The size chart is shown below.

Correct operation

In order for the V-belt to work out its service life as much as possible, it is necessary to comply with certain requirements regarding its installation and use.

They are listed below:

- First of all, remember that belts are mounted on shafts in a relaxed state. This is done manually, without the use of tools.

- The angle of the groove of the shaft on which the strap is installed must coincide with the angle of the wedge of its side. Please note that the side of the strap should be evenly against the walls of the V-shaft groove. If this requirement is not met, then the stress on the strap will fall unevenly, as a result, this will significantly reduce its service life.

- The shafts of the pulleys on which the belt is put on must be installed parallel to each other. And the grooves should be located opposite each other. If the shafts are not parallel, then this will also lead to deformation of the elements. The same goes for grooves. As you can imagine, this will reduce the belt life.

- The grooves of the shafts in which the belt is mounted must not be dirty or contain debris. The same goes for any grease or solvents - it just shouldn't get on them. In addition, the grooves do not need to be painted, as this may alter their surface albeit slightly, but change their surface.

- With regard to tension, this indicator should be monitored from time to time. The tension will need to be adjusted if necessary. Especially you need to pay attention to this indicator during the first 48 hours of operation.

- If you are dealing with various production machines or equipment, then during its transportation, the tension of the belts will need to be loosened.

- If the strap breaks or has already exhausted its service life, then you need to dismantle the entire set along with rollers and other straps.

Truck V-Belts Video

For a detailed description, see the video.

GOST 1284.1 - 89

Energy in mechanisms and machines can be transmitted using mechanical, pneumatic, hydraulic and some other devices.

In technology mechanical transmission- these are such mechanisms by means of which the kinematic transfer of energy from a machine, called an engine, to a machine, called a tool, is carried out in such a way that during this process there is a transformation of moments, speeds, and in a number of cases, types of motion (for example, rotational into reciprocating) and even its laws.

In mechanics, using a transmission, a shaft is connected, which has an energy source (engine) with the shafts with which its consumers are equipped. The latter are most often the working bodies of various machines (for example, the driving wheels of a road or rail transport).

|

Wp- estimated belt width, mm W- the width of the larger base of the belt, ( mm); T- belt height, ( mm); α - belt wedge angle equal to ( 40 ± 1)° |

|||||

| Dimensions and tolerances of V-belts | |||||

| V-belt section designation | W p deviation | W (ref.) | T (nominal) | Limit deviation | |

| nominal | ultimate | ||||

| Z (O) | 8.5 | +0.4; -0,3 | 10 | 6.0 | ± 0.3 |

| A | 11.0 | +0.6; -0.4 | 13 | 8.0 | ± 0.4 |

| B (B) | 14.0 | +0.7; -0.5 | 17 | 11 (10.5) | ± 0.5 |

| C (B) | 19.0 | +0.8; -0.5 | 22 | 14(13.5) | ± 0.5 |

| D (D) | 27.0 | +0.9; -0.6 | 32 | 19.0 (20) | ± 0.6 |

| E (D) | 32.0 | +1.0; -0.7 | 38 | 23.5(25) | ± 0.7 |

V-belt A – 1800 , where:

A- section of the belt;

1800 - nominal estimated length of the belt ( mm).

| Sizes of sections and lengths of V-belts | |||||

| Z (O) | A | B (B) | C (B) | D (D) | E (D) |

| 500 | 500 | 630 | 1180 | 1900 | 4000 |

| 530 | 530 | 710 | 1400 | 2000 | 4500 |

| 560 | 560 | 750 | 1500 | 2120 | 4750 |

| 600 | 600 | 800 | 1600 | 2240 | 5000 |

| 630 | 630 | 850 | 1700 | 2360 | 5300 |

| 670 | 670 | 900 | 1800 | 2500 | 5600 |

| 710 | 710 | 950 | 1900 | 2650 | 6000 |

| 750 | 750 | 1000 | 2000 | 2800 | 6300 |

| 800 | 800 | 1060 | 2120 | 3000 | 6700 |

| 850 | 850 | 1080 | 2240 | 3150 | 7100 |

| 900 | 900 | 1120 | 2360 | 3350 | 7500 |

| 950 | 950 | 1150 | 2500 | 3475 | 8000 |

| 1000 | 1000 | 1180 | 2650 | 3550 | 8500 |

| 1060 | 1060 | 1200 | 2800 | 3750 | 9000 |

| 1120 | 1120 | 1250 | 3000 | 4000 | 9500 |

| 1150 | 1180 | 1320 | 3150 | 4250 | 10 000 |

| 1180 | 1213 | 1400 | 3350 | 4500 | 10 600 |

| 1213 | 1250 | 1450 | 3550 | 4750 | 11 200 |

| 1250 | 1280 | 1500 | 3585 | 5000 | 11 800 |

| 1320 | 1320 | 1600 | 3750 | 5300 | 12 500 |

| 1400 | 1350 | 1650 | 4000 | 5600 | 13 200 |

| 1500 | 1400 | 1700 | 4250 | 6000 | 14 000 |

| 1600 | 1450 | 1800 | 4350 | 6300 | |

| 1700 | 1500 | 1900 | 4500 | 6500 | |

| 1800 | 1550 | 2000 | 4750 | 6700 | |

| 1900 | 1600 | 2120 | 5000 | 7100 | |

| 2000 | 1650 | 2240 | 5300 | 7500 | |

| 2120 | 1700 | 2360 | 5600 | 8000 | |

| 2240 | 1750 | 2500 | 6000 | 8500 | |

| 2360 | 1800 | 2650 | 6300 | 9000 | |

| 2500 | 1900 | 2800 | 7100 | 9500 | |

| 2000 | 3000 | 7500 | 10 000 | ||

| 2120 | 3150 | 8000 | 10 600 | ||

| 2240 | 3350 | 8500 | 11 200 | ||

| 2360 | 3550 | 9000 | 11 800 | ||

| 2500 | 3750 | 9500 | 12 500 | ||

| 2650 | 4000 | ||||

| 2800 | 4250 | ||||

| 3000 | 4500 | ||||

| 3150 | 4750 | ||||

| 3350 | 5000 | ||||

| 3550 | 5300 | ||||

| 3750 | 5600 | ||||

| 4000 | 6000 | ||||

| 4500 | 6300 | ||||

History mechanical transmission goes back centuries. They became known to people even when technology was just in its infancy, and now, having passed a long and thorny path of development, they are extremely widespread. In order to correctly operate mechanical transmissions, it is necessary to know the methods on the basis of which they are calculated and designed.

As practice shows, the most common of the transmissions is such a method of transmitting mechanical energy, in which it is transmitted by means of the frictional force arising between the contacting surfaces of the pulley and the belt. A similar mechanical transmission called belt.

It consists of main parts, like pulleys (leading and driven), which are located at some distance from each other, as well as a drive belt that bends around them and fits snugly enough to the surfaces of both.

Belt transmission have a number of undoubted advantages, the main of which are the following:

Low cost and simplicity of design;

Unstressed work and smooth running;

Easy to operate and maintain;

The ability to broadcast torque over long distances.

At the same time belt drives are not devoid of some shortcomings. They cannot be used in high-speed mechanisms, since at high revolutions of the drive pulley, the drive belt slips. Besides, belt drives rather heavily load the bearings of the supports and the shafts themselves. Another very significant disadvantage is the possibility of a belt breaking or jumping off, and in order to prevent this from happening, such transmissions require periodic monitoring.

V-belt transmission belongs to the category of those characterized by a flexible connection between the driving and driven shafts. They are most often used in general mechanical engineering and are for it one of the most typical methods for transmitting mechanical energy.

For example, V-belt transmission are used in almost all metal and woodworking machines, in drives of water pumps, generators, fans, compressors, construction equipment, etc.

Those V-belts, which have a standard cross-section, are capable of operating at temperatures from -30 ° C before +60 ° C.

Standard cross-section V-belt means that its profile has the shape of a trapezoid with an angle 40 °... Compared to a flat belt, such a belt has a higher traction force, but significantly lower Efficiency.

Absolutely any drive belt- this is a traction element, and therefore it must have sufficient strength, wear resistance, durability. It is also important that it is inexpensive and has good adhesion to the pulley surface. Concerning V-belts, then it is most rational to use them when the gear ratios are quite large.

V-belts dimensions table. Tolerances for V-belts. 5.00 / 5 (100.00%) 2 votes

V-belts dimensions table.

The V-belt is used to transmit torque from the driving gear to the driven gear. The shape of one wedge resembles an isosceles trapezoid. Belt dimensions will vary depending on the profile. Table 1 below shows the main dimensions of the V-belt.

Figure 1. Main dimensions of the V-belt.

Table 1. Dimensions of the V-belt.

| Belt profile | a | a * p | Δ a p | h | Δ h |

| O | 10 | 8,5 | +0,4; -0,3 | 6 | ± 0.3 |

| A | 13 | 11 | +0,6; -0,4 | 8 | ± 0.4 |

| B | 17 | 14 | +0,7; -0,5 | 10,5 | ± 0.5 |

| V | 22 | 19 | +0,8; -0,5 | 13,5 | ± 0.5 |

| G | 32 | 27 | +0,9; -0,6 | 19 | ± 0.6 |

| D | 38 | 32 | +1; -0,7 | 23,5 | ± 0.7 |

| E | 50 | 42 | +1; -0,8 | 30 | ± 0.8 |

and p is the estimated belt width, mm.

V-belts when transmitting torque have the highest efficiency rates, this is due to the special design of the belt in the form of a trapezoid. The advantages of such belts include:

- relatively low heating with a high area of contact with the pulleys;

- resistance to tensile deformations;

- high adhesion to the pulley surface;

- smooth and quiet operation;

- minimum vibrations during intermittent operation.

V-belts are made on the basis of rubberized construction materials; they can also include elastic fabric, nylon cable or steel cord. When manufacturing belts, use the table of permissible deviations along the length of the belt.

Tolerances for V-belts.

Table 2. Permissible deviations along the length of the belt, mm

| Belt length, mm | Permissible deviation | Maximum difference between the lengths of belts in one set |

| ≤950 | +14; -8 | 2 |

| 1000-1250 | +15; -9 | 3 |

| 1320-1600 | +18; -12 | 3 |

| 1700-2000 | +25; -15 | 5 |

| 2120-2500 | +30; -15 | 7,5 |

| 2650-4500 | +40; -20 | 10 |

| 4750-7100 | +50; -25 | 12,5 |

| 7500-11200 | +60; -30 | 15 |

| 11800-18000 | +90; -50 |

V-belts have a long service life. By GOST 1284-68 they must remain functional at temperatures from -30 to +60 ° C

Was the article helpful ?! Share with your friends on social networks !!!

V-BELTS

(GOST 1284.1-89)

The description applies to endless rubber-fabric (cord-fabric and cord-cord) drive V-belts of normal cross-sections, intended for drives of machine tools, industrial plants and agricultural machines operating at ambient temperatures:

from -30

before +60 o C- for temperate and tropical climates;

from -60

before +40 o С- for cold and very cold climates and sets their dimensions and control methods.

BELT SECTION DIMENSIONS

MAIN DIMENSIONS

| Section designation | W p | W reference | T | α | |||

| Nominal. | limit deviation | Nominal. | limit deviation | Nominal. | limit deviation | ||

| Z (0) | 8,5 | + 0,4 - 0,3 | 10 | 6.00 | + 0,3 - 0,3 | 40 ° | ± 1 ° |

| A | 11,0 | + 0,6 - 0,4 | 13 | 8,00 | + 0,4 - 0,4 |

||

| B (B) | 14,0 | + 0,7 - 0,5 | 17 | 11 (10,5) | + 0,5 - 0,5 |

||

| C (B) | 19,0 | + 0,8 - 0,8 | 22 | 14 (13,5) | + 0,5 - 0,5 |

||

| D (D) | 27,0 | + 0,9 - 0,6 | 32 | 20 (19,0) | + 0,6 - 0,6 |

||

| E (D) | 32,0 | + 1,0 - 0,7 | 38 (40) | 25 (23,5) | + 0,7 - 0,7 |

||

| E0 (E) | 42,0 | + 1,0 - 0,8 | 50 | 30,0 | + 0,8 - 0,8 |

||

| 40x20 | 35,0 | + 1,0 - 0,7 | 40 | 20,0 | + 0,7 - 0,7 |

||

| 1. Do not use EO (E) and 40x20 belts for newly designed drives! 2. Belts with dimensions in brackets were manufactured before 01.01.1995. 3. Limit deviations of the dimensions of the cross-sections of the belts are given only for the design of technological equipment and measuring pulleys. |

|||||||

The calculated width W p is taken as the width of the cross-section of the belt under tension at the level of the neutral line.

SYMBOL

Belt of section C (B) with an estimated length of 2500, IV class, operated in areas with a temperate climate:

Belt C (B) - 2500 GOST 1284.1-89

The same for transmissions of increased accuracy of moving agricultural machines:

Belt С (В) - 2500 IV ПСх GOST 1284-89

The same in areas with cold and very cold climates:

Belt C (V) - 2500 IV PSh HL GOST 1284-89

DESIGNED BELT LENGTHS

MEASURED UNDER TENSION

| Estimated belt length L p | Belt section GOST 1284.1-89 | ||||||

| Z (0) | A | B (B) | C (B) | D (D) | E (D) | E0 (E) | |

| 400, (425), 450, (475), 500 | |||||||

| (530), 560, (600) | |||||||

| 630, (670), 710, (750), 800, (850), 900, (950), 1000, (1060), 1120, (1180), 1250, (1320), 1400, (1500), 1600, (1700) | |||||||

| 1800, (1900), 2000, (2120) | |||||||

| 2240, (2360), 2500, (2650), 2800, (3000), 3150 | |||||||

| (3350), 3550, (3750) | |||||||

| 4000, (4250), 4500 | |||||||

| (4750), 5000, (5300), 5600, (6000) | |||||||

| 6300, (6700) | |||||||

| 7100, (7500), 8000, (8500), 9000, (9500), 10000, (10600) | |||||||

| 11200, (11800), (13200), 14000 | |||||||

| (15000) | |||||||

| 16000, (17000), 18000 | |||||||

| Difference between calculated and internal belt length | 25 | 33 | 40 | 59 | 76 | 95 | 120 |

Note: The calculated belt lengths indicated in parentheses are used in technically justified cases. By agreement between the manufacturer and the consumer, belts of other lengths may be used for imported equipment.

A full description of these belts can be found in GOST 1284.1-89 "Driving V-belts of normal cross-sections. Basic dimensions and control methods".

PULLEYS FOR V-BELT DRIVE

(GOST 20889-88)

PULLEY GROOVE PROFILE

MAIN DIMENSIONS

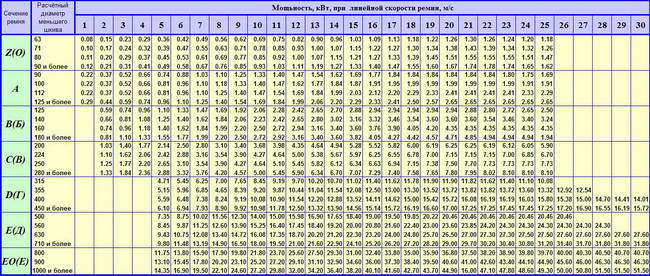

RATED POWER TRANSFER

Note: This table corresponds to one of the methods for determining the transmitted power! (Anuryev V.I. 1978). In Anuryev V.I. for 1999, tables are given taking into account the speed of the smaller pulley and the length of the belt.

Each pulley operating at speeds exceeding 5 m / s must be balanced. Static balancing accuracy standards are given in GOST 20889-88.

Today, many types of V-belts from various manufacturers are used in our country. Mostly V-belts are used according to the Russian GOST standard and according to European DIN. For example: classic section (Z, A, B, C, D, E), narrow reinforced (SPZ, SPA, SPB, SPC), narrow reinforced with molded tooth (XPZ, XPA, XPB, XPC), double-sided V-belts (AA , BB, CC, DD), poly V-belts (PJ, PK, PL, PM), polyurethane V-belts (3M, 5M, 7M, 11M), multi-ribbed V-belts (SPB, SPC, 9J, 15J, 3VX, 5VX), variator , polyurethane V-belts with steel cord (Ferropan). Many belt manufacturers produce belts according to both GOST and DIN standards. Most types of V-belts are interchangeable by these standards.

INTERCHANGEABLE V-BELTS

WORLD LEADING MANUFACTURERS

| Type of belt brand |

ContiTech | Optibelt | Gates | Megadyne | Fenner | Goodyear | Bando |

Classic profile with wrapper |

Conti-V® |

Hi-Power® |

Fenner® Classic PBV-Belts |

Classical |

|||

Narrow profile with wrap |

Conti-V® |

Optibelt SK |

Super HC® |

Fenner® PowerPlus® wedgebelt |

Narrow SP |

||

|

Conti-V® |

Optibelt |

Jnea X |

Fenner® CRE PLUS® wedge belt Fenner® |

Torque Flex® |

Power Ace® Cog |

|

Narrow profile with molded tooth |

Advance FO® |

Optibelt |

Quad-Power® III |

Linea X |

Fenner® Quattro PLUS® belt |

||

Classic Wrapped Belts |

Conti-V® |

Hi-Power® |

Hy-T® Torque |

Power King® |

|||

|

Conti-V® |

Optibelt KB |

Super HC® |

Fenner® Concord Plus® |

Hy-T® Torque |

Power Ace® |

|

Narrow Wrapped Belts |

Quad-Power® |

Hy-T® Torque |

Power Ace® |

||||

Classic profile with wrapper. |

|||||||

Narrow profile with wrapper. |

CONTI®-V |

Optibelt |

|||||

Wrapped narrow section banded belts. Premium class. (SPBP, SPCP, 9JP, 15JP, 8VP - aramid cord) |

CONTI®-V |

Optibelt |

Predator® |

||||

Reversible V-belts |

Hi-Power® |

||||||

Premium Drive Belts |

CONTI®-V |

||||||

Polyurethane V-belts (60 °) |

|||||||

Wrapped polyurethane V-belts (60 °) (3M-JB, 5 M-J B, 7M-JB, 11M-JB) |

Banflex® |

||||||

V-ribbed |

Multirib® |

Fenner® Poly Drive Ribbed belts |

|||||

Variator |

Varispeed® |

Optibelt |

Related documents:

V-ribbed belts

an example of a drawing of a detail of a V-belt pulley

GOST 1284.2-89 - "Driving V-belts of normal cross-sections. Specifications"

GOST 1284.3-80 - "Driving V-belts of normal cross-sections. Transmitted power"

GOST 1284.3-96 - "Driving V-belts of normal cross-sections. Transmitted power"

GOST 23831-79 - "Flat driving rubber-fabric belts. Specifications"

GOST 24848.1-81 - "Variator V-belts for industrial equipment... The main dimensions and methods of their control "

According to Russian standards, the length of the belt indicated on the belt in the designation, regardless of the profile, is always the calculated length! Imported belts may have an ID or OD length.

For imported V-belts, the following abbreviations are adopted:

Li = length of the V-belt in inner diameterLa = Outside diameter V-belt length

Lp (or Lw) = estimated belt length (length of the tensioned belt along the neutral line).

The difference between the calculated and internal lengths, the designation of imported belts and their Russian counterparts, the minimum pulley diameter and the weight of the belts are shown in the table:

| Belt type designation according to European standard | Belt type designation according to GOST | Min. pulley diameter, mm. | The difference between the calculated and internal length (Lp - Li), mm. | Belt weight kg / m. |

| Z | Z (0) | 50 | 25 | 0.06 |

| A | A | 71 | 33 | 0.115 |

| B | B (B) | 71 | 40 | 0.19 |

| 20 | No analogue | 112 | - | 0.27 |

| C | C (B) | 160 | 59 | 0.31 |

| 25 | No analogue | 180 | - | 0.40 |

| D | D (D) | 250 | 76 | 0.65 |

| 38 | No analogue | 355 | - | 1.06 |

| E | E (D) | 500 | 95 | 1.07 |

An example of import marking of a V-belt and selection of a Russian analogue:

B-2460 LiAccording to the table above, for profile B, the difference between the design length (Lp) and the length along the inner diameter (Li) is 40 mm. In this example, the ID length is 2460 mm. Accordingly, the calculated length will be equal to 2460 + 40 = 2500 mm.

Thus, we get the Russian analogue of this belt: B-2500

Other marking of the belt according to the European standard is also possible: instead of the letter indicating the belt profile, the dimensions (in mm) of the width of the large belt base (W), the height of the belt (T) and the length of the belt according to the inner diameter (Li) can be indicated.

For example, for B-2460 Li the following designation is possible: 17x11-2460 Li.

Table of maximum permissible deviations in the dimensions of the calculated length of belts according to GOST.

| Estimated belt length Lp, mm | limit deviation, mm | |

| for agricultural machines | for machine tools | |

| up to 850 | +8/ -4 | +14/ -8 |

| 900-1180 | +10/ -6 | +14/ -10 |

| 1250-1400 | +12/ -8 | +16/-12 |

| 1500-1900 | +16/-12 | +24/ -12 |

| 1950-3150 | +20/ -12 | +28/ -12 |

| 3200-4250 | +26/-14 | +36/-14 |

| 4350-5000 | +30/ -18 | +42/ -18 |

| 5300-6700 | +24/-24 | +48/ -24 |

| 7100-10000 | +32/-32 | +64/ -32 |

| 10600-18000 | +48/-48 | +96/ -48 |

Depending on the materials used and manufacturing technology, belts are produced in 4 classes.

P / p No. |

Class |

Operating time from gears. capacity (million cycles) |

Elongation with power transmission (%) |

Prfil |

Operating time without power transfer (million cycles) |

Elongation without power transmission (%) |

Z (O), A, B (B), |

C (B), D (D) E (D) |

|||||

1.8 - for machine tools and equipment 2.5 - for moving agricultural machines |

||||||

C (B), C (C), D (D) |

All profiles |

|||||

All profiles |

All profiles |