Contact ignition system in modern cars practically not used and gave way to contactless and electronic systems. Nevertheless, our car owners have a lot of old cars (in our case, this is the VAZ-2106), for which we would like to improve the performance of their engines. As a rule, two options are selected for this: installation of an injection power unit or a modern ignition system.

What is contactless and electronic ignition

It is necessary to immediately distinguish between the concepts of "electronic" and "contactless" ignition, since these are fundamentally different systems. Electronic ignition has a position sensor crankshaft and is controlled with its help through an ECU (electronic engine control unit). For contactless ignition to work, such difficulties are not needed.

How does it work? In the non-contact type ignition distributor, instead of open contacts, an induction coil is installed, which gives a high voltage current, which is then supplied to the candles. And then, as usual, the fuel in the cylinders ignites.

The advantages of using the system on a VAZ 2106

- Lack of breakable contacts that often burn out.

- No additional adjustments required.

- The wear of the spark plugs is significantly reduced.

- Fast "cold" engine start in winter.

- Smoother motor operation.

- There is no need to clean and change contacts.

DIY installation and connection diagram

So, having decided on the choice, we suggest that you familiarize yourself with the necessary tools, the procedure for replacing them and video instructions.

Tool

From the tool you will need:

- Key for 13 - remove and put the distributor

- Screwdriver - tighten the screws.

- Drill with a drill for metal, diameter for self-tapping screws

- Two self-tapping screws - screw on the switch.

- Keys 10 and 8 - remove and install the coil.

How to install step by step

- Disconnect the negative battery.

Before starting work on the ignition system, disconnect the negative terminal of the battery

- Remove the distributor cover with high voltage wires.

Removing the ignition distributor cover

Removing the ignition distributor cover - Disconnect the high voltage wire on the coil.

Disconnecting the wire from the ignition coil

Disconnecting the wire from the ignition coil - Set the ignition distributor slider perpendicular to the engine with short starts of the starter.

This is how the distributor should be installed relative to the motor.

This is how the distributor should be installed relative to the motor. - Mark the position of the distributor with a marker on the engine.

Installing the ignition distributor slider

Installing the ignition distributor slider - Unscrew the nut holding the distributor with a 13 key. Disconnect the wire connecting the device to the coil.

Before removing the ignition distributor, disconnect the wire that goes to it from the coil

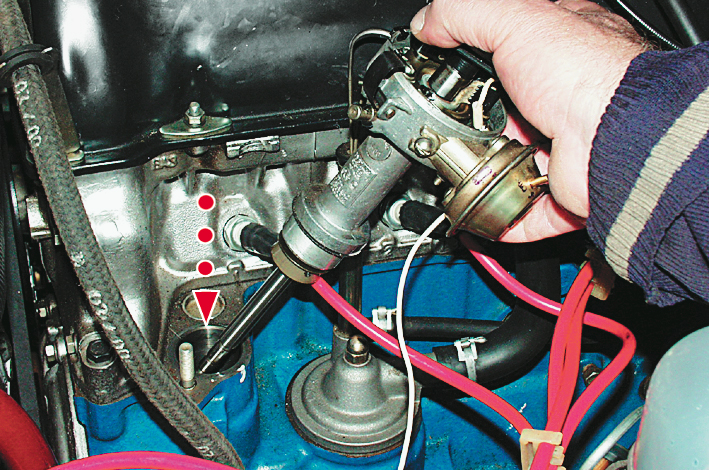

Before removing the ignition distributor, disconnect the wire that goes to it from the coil - Insert the new ignition distributor into the engine by removing the cover from it.

The ignition distributor must be inserted into the standard socket

The ignition distributor must be inserted into the standard socket - Rotate the trembler body so that the middle mark on it aligns with the mark you put on the motor earlier.

- Tighten the nut securing the new ignition distributor.

The ignition distributor mount is held in place by the nut

The ignition distributor mount is held in place by the nut - Put on the distributor cover and connect the wires to it.

This is how the cover is installed on the distributor.

This is how the cover is installed on the distributor. - Replace the ignition coil with a new one.

A new system needs a new coil

A new system needs a new coil - Connect the original and new wires to the coil. To connect everything correctly, use the diagram.

All connections must correspond to the diagram

All connections must correspond to the diagram

Each owner of the legendary classic model VAZ 2106 is well aware of all the problems associated with the operation of this car, since in most cases he eliminates them on his own. Such problems also include malfunctions of the contact (cam) ignition system of the VAZ 2106. Constantly burning contacts required cleaning and adjustment, because of the backlash of the bearing and the distributor bushing, the engine operation resembled a "shake", especially at idle. The system is designed to solve all these emerging problems. electronic ignition.Electronic ignition for six

Scheme

Diagram of a contactless ignition system VAZ 2106:

1 - ignition distributor sensor; 2 - spark plugs; 3 - screen; 4 - non-contact sensor; 5 - ignition coil; 6 - generator; 7 - ignition switch; eight - accumulator battery; 9 - switch

Installation

first of all, it is necessary to set the TDC - 4 cylinders (we look at the position of the slider), this must be done by turning the crankshaft ratchet to the mark on the pulley, we combine marks 4 and 3 in the figure);

dismantle the distributor, candles and the coil (remembering the color of the wires suitable for the ignition coil);

we lay new wiring;

install a new high-voltage ignition coil;

we put the distributor exactly as the old one was (the installation of electronic ignition of vaz 2106,2103, 2107 with engines of 1.5 and 1.6 liters is slightly different from other models. These engines have different cylinder block heights and, accordingly, different length of the distributor drive shaft);

we fix the switch (it is advisable to find a place on the shield of the engine compartment);

we screw in the candles and put on high voltage wires (operating procedure 1-3-4-2);

we connect the wiring as in the diagram:

How to expose

For work you will need a 12-volt control light, a 13 key and a crankshaft key:

It is necessary to set the ignition on the idle engine, with the "negative" terminal of the battery disconnected.

Set the piston of the first cylinder of the internal combustion engine to the ignition position. To do this, you need to unscrew the spark plug from it. We plug the spark plug hole with our finger and at the same time turn the crankshaft clockwise with a wrench.

When there is a compression stroke, the air under pressure will begin to push the finger strongly - this is what you need.

Now it is important to clearly align the mark on the pulley with the second one, which you are looking for on the timing cover. The mark in the middle means that the ignition advance is set by 5 degrees.

It happens that some people cannot find their tags. But in fact, there are always labels. Just wipe the surfaces well with a metal brush, add light.

After setting the marks, you can remove the key. Wrap the removed plug back and connect the armor wire.

The next stage of work will be determination of ignition timing:

Before starting, connect the negative terminal of the battery.

Using a 13 key, slightly loosen the mounting nut of the ignition distributor.

Here you will need a prepared control light with two wires. We connect one terminal to ground, the other to the low-voltage ignition coil.

Turn on the ignition by turning the key to the "I" position.

It is necessary to carefully turn the ignition distributor housing clockwise until the control lamp goes out.

After that, it is necessary to smoothly turn the distributor rotor counterclockwise - until the contact is open and the light turns on again.

Now you need to tighten the mount and check the behavior of the machine on the go.

Adjustment

Closed contact angle correction

The ignition adjustment of the VAZ 2106 begins with the simplest operation of removing the distributor cover, then the crankshaft turns until the maximum distance between it and the distributor is reached. Following this, they begin to unscrew the screws that fix contact group on the bearing plate and between the contacts, a probe is inserted to determine and select the optimal position for the group. Ideally, everything is determined by the applied force to move the stylus, which should be minimal, after finding a section that meets this requirement, the position of the group is fixed by tightening the screws. The size of the gap is also important for its determination, the thickness of the probe should be 0.44 millimeters. It is the adjustment of the gap that provides the required value of the angle of closed contacts, its optimal value is 55 ± 3 °.

If the parameters correspond to the norm, then you can proceed to the second stage, which consists in adjusting the advancing ignition angle. To begin with, we will determine that the distributor breaker in the type of engine under consideration needs to implement the opening moment simultaneously with the spark in the first cylinder. This provides for the advance of the top dead center of the piston stroke for the first cylinder by 0 ± 1 °.

Correction of the lead angle using a stroboscope

There are several ways to adjust this indicator, on which the correct ignition adjustment of the VAZ 2106 as a whole largely depends. The most efficient way to cope with this task is the method involving the use of a stroboscope. The device must be connected to the automotive electrical network, while it is necessary to dismantle and plug the vacuum correction hose from the distributor. Following this, the engine is warmed up, until it holds idle speed with the subsequent loosening of the bolt responsible for fixing the distributor body.

The light emitted by the stroboscope is directed to the crankshaft pulley, the rotation of the distributor housing will allow to achieve a position that ensures that the visible position of the mark on the pulley is opposite the corresponding marks applied to the timing cover. In this position, the distributor body is fixed by tightening it with bolts. The presence of revolutions is of decisive importance. idle move power unit during adjustment. If the revolutions are higher, a centrifugal regulator will take part in the work, which will distort the adjustment results.

Malfunctions

|

Cause of malfunction |

Remedy |

|

Engine won't start |

|

| The switch does not receive voltage pulses from the contactless sensor: |

Do the following: |

| - open circuit in the wires between the ignition distributor sensor and switch |

|

| - the contactless sensor is faulty | - check the sensor using an adapter connector and a voltmeter; faulty replace the sensor |

| No current pulses are received on the primary winding of the ignition coil: | Do the following: |

| - open circuit in the wires connecting the switch with the switch or with ignition coil |

- check the wires and their connections; replace damaged wires |

| - the switch is faulty | - check the switch with an oscilloscope; Replace defective switch |

| - the ignition switch does not work | - check, replace the faulty contact part of the ignition switch |

| No high voltage applied to spark plugs: | Do the following: |

| - loosely seated in sockets, tips torn off or oxidized high voltage wires; the wires are heavily dirty or damaged insulation |

- check and restore connections, clean or replace wires |

| - wear or damage to the contact coal, its hanging in the cover of the ignition distributor |

- check and, if necessary, replace the contact angle |

| - current leakage through cracks or burnouts in the lid or rotor ignition distributor sensor, through carbon deposits or moisture on the inner surface cover |

- check, clean the lid from moisture and carbon deposits, replace the lid and rotor, if they have cracks |

| - burnout of the resistor in the rotor of the ignition distributor | - replace the resistor |

| - damaged ignition coil | - replace the ignition coil |

| Spark plug electrodes or the gap between them are oiled does not correspond to the norm |

Clean the spark plugs and adjust the electrode gap |

| Damaged spark plugs (cracked insulator) | Replace candles with new ones |

| The order of connecting high voltage wires is violated to the terminals of the ignition distributor sensor cover |

Connect wires in ignition order 1-3-4-2 |

|

The engine runs erratically or |

|

| Too much early ignition in engine cylinders | Check, adjust the ignition timing |

| Large gap between spark plug electrodes | Check, adjust the gap between the electrodes |

|

Engine is uneven and unstable |

|

| The springs of the weights of the ignition timing regulator in the distributor sensor have weakened ignition |

Replace the springs, check the operation of the centrifugal regulator on the bench |

|

Engine interruptions at all |

|

| The wires in the ignition system are damaged, the fastening is loose wires or their tips are oxidized |

Check the wires and their connections. Replace damaged wires |

| Worn electrodes or oily spark plugs, significant carbon deposits; cracked plug insulator |

Check plugs, adjust electrode gap, damaged plugs replace |

| Worn or damaged contact carbon in the cover of the distributor sensor ignition |

Replace contact angle |

| Strong burning of the central contact of the rotor of the sensor-distributor ignition |

Strip the center pin |

| Cracks, dirt or burnouts in the rotor or cover of the distributor sensor ignition |

Check, replace rotor or cover |

|

Engine does not develop full power |

|

| Incorrect ignition timing | Check, adjust the ignition timing |

| Jamming of weights of the ignition timing regulator, weakening springs of weights |

Check, replace damaged parts |

| The switch is faulty - the shape of the pulses on the primary winding the ignition coil is not correct |

Check the switch with an oscilloscope, replace the faulty switch |

Although progress has stepped far forward, there are still many adherents of the classic VAZ models. Such cars include an old penny, which has long been discontinued, and more modern, but also no longer produced, 2104 models. This article will focus on how contact ignition is to contactless (electronic) and is there really a use for such a replacement.

Why do you need a replacement?

On the web, in various automotive forums, owners have a multi-page debate about the benefits. contactless ignition... And these advantages are really enough. After installing the contactless ignition, the work becomes smooth and soft. There are no dips during sudden acceleration of the car. Starting is much easier, especially in cold weather. And of course, noticeable fuel economy.

The device and principle of operation of contactless ignition.

Essentially, the device contactless ignition not much different from the system contact ignition... The only differences are the absence of a distributor and the presence of a pulse sensor with a transistor switch unit.

Installation of a contactless ignition system at a VAZ

First you need to purchase a kit contactless ignition for . We strongly recommend buying contactless ignition from trusted retail outlets. It should be noted that the kit must correspond to the characteristics of the engine of your car, and the length of the distributor shaft should not differ from the length of the shaft that is currently on the unit.

The contactless ignition kit should include:

- distributor

- coil

- switching unit

- connecting wires

- set of high voltage wires

- four spark plugs marked DVRM

To replace contactless ignition system passed successfully, the correct sequence of work must be followed. First you need to remove the negative. Then we disconnect the wires from the ignition coil and the central high-voltage wire, after which we remove the distributor cover. Now we set the slider to the position as shown in the figure so as not to knock off the ignition settings. You also need to make a mark on the block in order to correctly set the new contactless ignition distributor. Please note that we put the mark in the middle of the five slots on the lower part of the distributor body. Now you can unscrew the nut and remove the old distributor contact ignition system.

Before installing the contactless ignition, open the cover of the new distributor and put the slider in the same position as on the old one, perpendicular to the engine. And only then we insert it into the hole in the cylinder block. Then we combine the mark that we made previously, and clamp the body with a nut.

Then we make the assembly: put on the lid, connect high voltage wires.

Then we disconnect and remove the old ignition coil and put a new one in its place. We connect the other end of the central high-voltage wire to it, but the brown wire that went from the coil to the distributor is no longer useful to us and can be safely postponed.

We connect all high-voltage wires to their places. We connect two brown wires to the new ignition coil to the “K” contact, and two blue ones to the “B” contact.

Now we determine the place for the switch (it is possible in the area of the washer reservoir) and fix it with self-tapping screws. We connect the connector, and we twist all the wires with electrical tape.

After the operations done, start the engine and, if necessary, correct the operation of the contactless ignition.

Contact ignition is no longer available on modern cars. There are many reasons for this, including due to the large number of mechanical systems in the composition of such an ignition. What should the owners of old cars do? Sometimes they ask themselves the question, is it possible to convert the contact distributor to a contactless one?

Advantages of BSZ (contactless system)

ATTENTION! Found a completely simple way to reduce fuel consumption! Don't believe me? An auto mechanic with 15 years of experience also did not believe until he tried it. And now he saves 35,000 rubles a year on gasoline!

So, on the old-style distributor, due to the presence of a huge number of mechanical components, backlashes and gaps appear over time. The energy of the spark is not provided as needed, and the quality of the contacts themselves is highly questioned.

The installation of a contactless ignition system or BSZ can solve all the previous difficulties, since one hall sensor can replace a group of various mechanical elements at once. Progress is a good thing, you can't argue with that.

Hall Sensor

Since we are talking about the hall sensor, then we will consider those moments due to which it is considered significantly better mechanics, and is even capable of replacing several of them.

Note. It is interesting that up to a certain point this sensor could not be considered as an analogue of the mechanical component of the distributor.

However, over time, in the course of technological progress and obvious shortcomings of mechanical components, such as constant pollution, lack of contacts, etc., the hall sensor began to displace old systems. And today it is even installed on scooters, playing the function of an integral part of the ignition regulator.

Essentially, a hall sensor is a thin semiconductor sheet. In the course of a pulse hitting it, a current with a weak voltage appears. An increase in voltage is only possible if a magnetic field passes across the semiconductor. This property of the material was adopted by physics.

The element consists of a semiconductor material (plate), a chip (microcircuit), a magnet and a metal shield with slots. It is through the last component that the magnetic field is passed, which is why energy arises. The metal shield, of course, does not allow the magnetic field to pass through, but when the slots are opened, a low voltage pulse is generated.

An interesting point. When this device is combined with a distributor, a single unit is obtained called a distributor, which performs the standard functions of an ignition distributor with great efficiency.

Other benefits

The commissioning of BSZ has become one of the major innovations in the automotive industry. This innovation allowed not only to increase the power power plant, but also to reduce fuel consumption several times. Moreover, thanks to new system the amount of harmful substances emitted into the atmosphere was also reduced.

KSZ or a contact system did not justify the hopes of the designers, after all, it was not possible to increase the energy quantity in the spark, and even in the process of switching to more powerful engines, such a distributor no longer justified itself.

In a word, high-precision ignition control with KSZ is impossible, the engine constantly experiences interruptions in operation, fuel consumption and CO2 emissions increase.

Obviously, many experts consider the supply of relatively more energy to the candles to be almost the main advantage of the BSZ. Due to this, the spark, which is so necessary for the complete combustion of gasoline, increases. And this, in turn, leads to an improvement in the vehicle's maneuverability on the road.

BSZ distributor is both a general improvement, as well as pulse stability. On all ranges of operation of the internal combustion engine, recoil is significantly improved. The hall sensor in this case plays a much larger role, completely replacing the archaic contact system.

Finally, another indisputable advantage of BSZ is its simplicity and low maintenance requirement. Such a distributor will require adjustment only once, and not like KSZ - constantly.

Alteration of the KSZ in the BSZ will not take more than 1 hour, if you follow the correct instructions for carrying out. This applies, of course, to a person who is versed in an auto electrician and who knows what difficulties he can expect along the way.

Any operation, whether it is repair or modernization, begins with the preparation of the workplace.

- Decide where to install the switch. Many put it on the left mudguard, where it is fixed with two self-tapping screws to the body. However, you should be careful and make sure that the contact of the radiator of the device with the metal part of the car frame is as much as possible. Thus, better heat dissipation is ensured.

- Install the ignition tag on the 4th cylinder.

- Purchase a new set of SZ that would fit the BSZ. The gap in such candles should be set to 0.8 mm.

- Purchase and replace a coil.

It remains to change the distributor to an electronic one, install a hall sensor.

Arm yourself, of course, with the necessary tools:

- A set of different keys.

- A set of screwdrivers.

- Self-tapping screws.

- Drill with a set of different drills.

So, here's how the distributor changes:

- The cover is removed to provide access to the rotor.

- Set the slider rotor to a position that can be easily repeated when installing a new BSZ distributor. Mark on ICE.

- Unscrew the distributor retainer completely and remove the device.

- Take out the main armor wire, integrating the coil and distributor.

- Set the slider of the new distributor in accordance with the old one.

- Place the body according to the marks set in advance and marked on the body of the internal combustion engine.

- Insert a new cover, connect the wires.

The coil is also being updated:

- With an eight-key, we unscrew the nut-wiring contacts.

- The ten-key loosens the fixation of the coil itself.

- Install a new coil.

Attention. In the process of installing a new coil, be sure to focus on the location of the contacts. It is better to put everything as it was done on the old scheme.

- The new device is fixed.

- The wires are connected to the contacts.

Advice. It is better not to remove the wires from the old coil for now, but to do this after installing a new one. Thus, it will be possible to re-flip the wiring without making mistakes.

- The main armor wire is threaded, connecting the distributor to the coil.

One of essential elements BSZ is a switch. As it was written above, its location is chosen in advance. It is put as follows:

- The switch leans against the body to mark the drilling locations.

- The device is screwed on with self-tapping screws.

Attention. Under one of the self-tapping screws, a black ground cable is inserted from the connection block.

In fact, in some cases, the secret of the alteration comes down to replacing the distributor stem. On the old one it is shorter. If you manage to rearrange this very stem from some new type of distributor, then as a result you can save a lot on buying a new distributor.

As for setting up the BSZ distributor, it is carried out only once. UOZ can be set without any devices. This is done on an internal combustion engine heated to 85 degrees, while driving at an average speed. The gearbox switches to 4th speed, the accelerator pedal is pressed into the floor. If a short-term detonation occurs, after which the engine picks up speed again, then the BSZ is set correctly. On the contrary, if a knocking occurs during this, you must stop. The ignition is set incorrectly. And here's what to do:

- Rotate and distribute clockwise 1 degree.

- Repeat driving with a sharp change of speed.

A similar operation is repeated until the correct ignition is set.

That's all there is to it. Good luck on the road with the new distributor!