Through two pedals in the Ford T planetary transmission, which consisted of two stages, gears were changed (one pedal included the highest and low gear, and the second reverse), and in order to do it smoothly and in a timely manner, certain skills were needed. But nevertheless, even then they significantly simplified the work, especially in comparison with the traditional boxes used at that time without synchronizers.

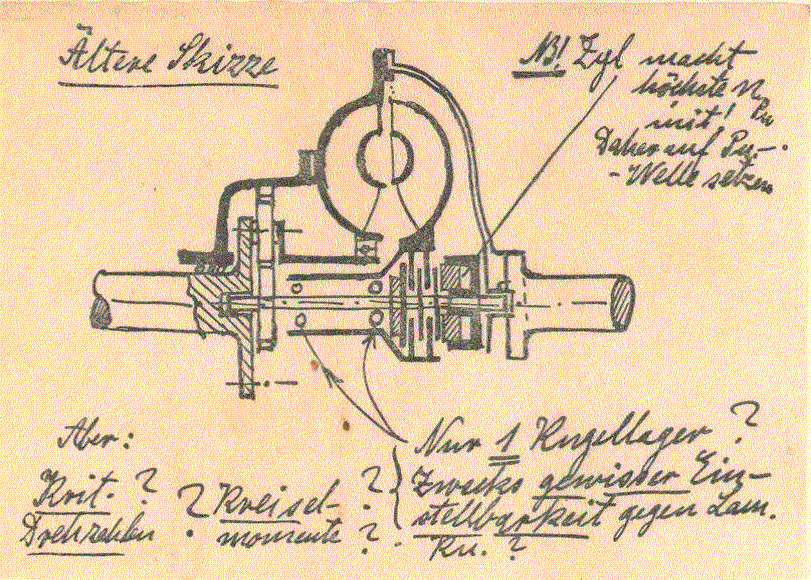

The subsequent direction of development in this area included work on the creation of semi-automatic transmissions, in which gear shifting was partially automated, later from all this, an automatic transmission appeared in the form in which we know it. So, for example, two companies in America (General Motors and Reo) in the thirties of the last century literally at the same time presented the development of semi-automatic transmissions. It is worth noting the development of General Motors as the most interesting, since it (like modern automatic transmissions) used a planetary mechanism controlled by hydraulics, taking into account the speed of the car. The downside of such designs was their absolute unreliability, moreover, they continued to use the clutch when changing gears to temporarily disconnect the transmission from the engine.

Vacamatic and Simplimatic

In the third line of development, a hydraulic element was introduced into the transmission. Chrysler has become the undoubted leader in this direction. Although the development began in the thirties, the widespread use of such a transmission on its cars, the company began only in the pre- and post-war years. A distinctive feature of this design was not only a fluid coupling, which was later replaced by a torque converter, but how can an overdrive (overdrive ratio less than one) be referred to as features, which automatically switched on, which worked in parallel with a conventional two-stage mech. box. So the semiautomatic device declared by the manufacturer was in fact an ordinary mechanic with an overdrive and a hydraulic element.

She had the designation M4 ( Vacamatic or Simplimatic- these are commercial designations of the pre-war period) and M6 ( Presto-Matic, Fluidmatic, Tip-Toe Shift, Gyro-Torque and Gyro-Matic- commercial designations of the post-war period) at the beginning it was a symbiosis of three units - a traditional two-stage mechanical gearbox, a fluid coupling and an automatically engaging overdrive (with a vacuum drive on the M4 and electric on the M6).

Each block of such a transmission has its own purpose:

Starting off makes the fluid coupling softer, it allows, without disengaging the clutch or gear, to stop "dropping the clutch". Over time, it was replaced by a more functional turbine transformer, it more improved car dynamics and increased the torque, in contrast to the fluid coupling, which worsened the acceleration dynamics.

A manual gearbox was generally responsible for the choice of the operating mode of the transmission. There were three such ranges - High, Low and Reverse. Each of these bands had two transmissions.

When the car exceeded the set speed, overdrive was automatically turned on, shifting gears within the effective range.

The lever used to switch the operating ranges was located on the steering column. Later, such switches, as it were, imitated automatic transmissions and could even have a quadrant range indicator at the lever, but the gear shifting process itself remained unchanged. The existing clutch pedal was painted red as it was only intended for range selection. Start moving with normal road conditions It was recommended in the High-range, that is, in the second stage of the manual transmission of two-speed and third gear of the transmission - this was done by the multi-liter six- and eight-cylinder Chrysler engines with their high torque. When driving on muddy areas, as well as when lifting, it was necessary to start driving from the first gear, that is, in the Low range.

Exceeding a certain speed by automatic switching on overdrive was switched to second gear, while the manual transmission itself remained in first gear. Switching to the upper range as needed, the fourth gear was often included (this is due to the fact that the overdrive was turned on to get the second gear) - it had a gear ratio of 1: 1. In practical driving, it was virtually impossible to go through all of the four gears, while formally the transmission was considered a four-speed. Two gears included the rear range and turned on, as a rule, after the car came to a complete stop. Driving a car with such a transmission for the driver was similar to driving a car with a two-speed automatic transmission, the difference is that when switching, the clutch pedal is activated.

Exceeding a certain speed by automatic switching on overdrive was switched to second gear, while the manual transmission itself remained in first gear. Switching to the upper range as needed, the fourth gear was often included (this is due to the fact that the overdrive was turned on to get the second gear) - it had a gear ratio of 1: 1. In practical driving, it was virtually impossible to go through all of the four gears, while formally the transmission was considered a four-speed. Two gears included the rear range and turned on, as a rule, after the car came to a complete stop. Driving a car with such a transmission for the driver was similar to driving a car with a two-speed automatic transmission, the difference is that when switching, the clutch pedal is activated.

Such a transmission in the forties - fifties of the last century was installed at the plant as an option on Chrysler cars in all their divisions. After the automatic two stepped boxes , as well as three-stage automatic machines TorqueFlite, semiautomatic devices Fluid-Drive, interfering with sales of fully automatic transmissions, had to be removed from production. The last Chrysler brand car to be fitted with a transmission was Plymouth in 1954. In fact, this transmission became a kind of transitional link from conventional "mechanics" to hydrodynamic automatic gearboxes and was a kind of "run-in" for their technical solutions, which was used in the future.

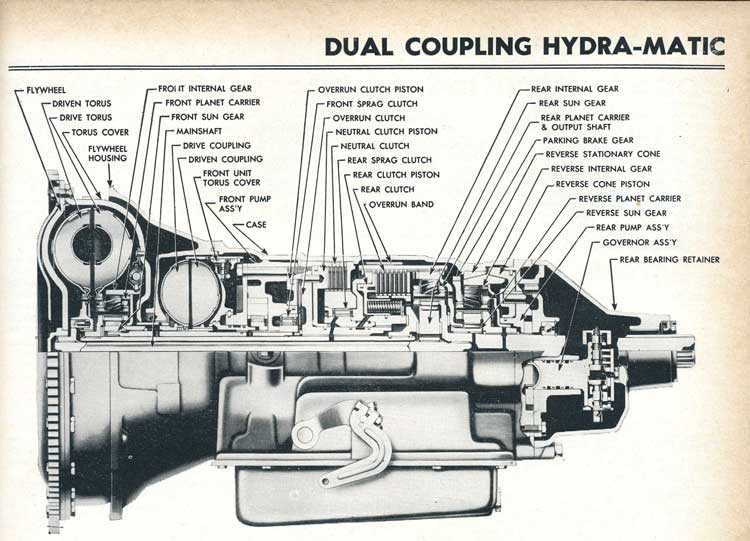

The transmission, which also existed in the forties of the last century, consisted of three stages and was designated as - Slushomatic, the first gear was conventional here, the second gear was part of a single range along with the third automatically engaging. However, the firm that pioneered the fully automatic gearbox was General Motors. In one thousand nine hundred and fortieth, such an automatic transmission became available optionally on Oldsmobile cars, after a while on - Cadillac, and even later on - Pontiac. Its commercial designation was Hydra-Matic, a combination of a hydraulically controlled three-speed planetary gearbox and fluid clutch. Adding the reverse gear here, such a transmission could be considered four-speed. Vehicle speed and position throttle taken into account by the transmission control system. The Hydra-Matic automatic transmission, in addition to GM cars, was also used by such firms as Rolls-Royse, Bentley, Nash, Hudson and Kaiser, and it was also used in military equipment. From one thousand nine hundred and fifty-four to one thousand nine hundred and fifty-four, the Hydra-Matic transmission was used in Lincoln vehicles. Over time, Mercedes-Benz developed its four-speed automatic transmission based on the Hydra-Matic transmission, which has its own design features... General Motors in 1956 developed an improved Jetaway automatic transmission, in which, unlike the Hydra-Matic, two fluid couplings were used, rather than one. All this led to smoother gear changes, but significantly reduced efficiency. Among other things, the parking mode P has been added here, in this mode the automatic transmission is blocked by a special stopper. The Hydra-Matic was locked in reverse mode R.

On Buick cars (owned by the same General Motors), from one thousand nine hundred and forty-eight, a two-stage Dynaflow automatic transmission began to be adopted, in which a torque converter was used instead of a fluid coupling. Over time, such transmissions appeared on cars of such brands as (1949) Packard and (1950) Chevrolet. As conceived by the engineers, the lack of third gear was compensated for by means of a torque converter with its ability to increase torque. Further in the fifties, Borg-Warner introduced a completely new three-stage. Varieties of such automatic transmissions were used by such car manufacturers as Ford, Studebaker, American Motors, etc., both in the United States of America itself and in other countries from such manufacturers as Volvo, International Harvester and Jaguar. In the Union of Soviet Socialist Republics, their ideas were also used in the development of automatic transmissions at the Gorky Automobile Plant, which were subsequently installed on the Chaika and Volga cars.

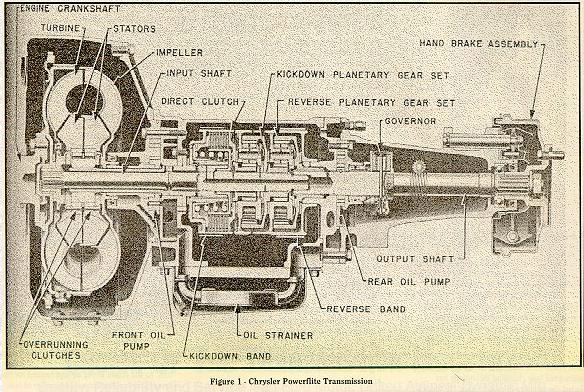

Chrysler introduced the two-speed automatic transmission PowerFlite in 1953. And since 1956 it has been supplemented by the TorqueFlite with three steps. Of all the early-design automatic transmissions, it is Chrysler's transmissions that are reasonably considered the most successful. The shift pattern of the P-R-N-D-L automatic transmission in the United States of America was finally established in the mid-sixties. Old-style transmissions that do not have a parking lock and outdated pushbuttonsMode switches are a thing of the past. At the end of the 60s of the last century, the early models of two- and four-stage in the United States completely fell out of use, their place was taken by three-stage automatic gearboxes with a torque converter. In the same period, a modification of the fluid for automatic transmissions took place and synthetic fluid came to replace the very scarce whale blubber.

The increased demand for efficiency in cars in the 80s was the reason for the return to transmissions with four gears, it was the fourth gear that had a gear ratio of less than one (OverDrive). Torque converters, which lock at high speed, have become widespread; they have significantly increased the efficiency of automatic transmissions by reducing losses in the hydraulic element. Finally, in the 80s and 90s, computerization took place in engine management systems. The same systems have become ubiquitous in the control of automatic transmissions. In previous control systems, only fur was used. valves and hydraulics, now computer controlled solenoids control flows transmission fluid... Thanks to this, the shifting has become more comfortable and smoother, the economy has improved due to the increase in the efficiency of the automatic transmission. Later, "sports" began to appear and manual control of an automatic gearbox (tiptronic) becomes possible. Then there was an automatic transmission with five steps. Expendable materials improved, which allows you to avoid such a procedure as changing the oil in the automatic transmission because the oil service life is equal. Further chronologically:

2002 - BMW creates a six-speed automatic transmission ZF, used in the BMW of the seventh series;

2003 - Mercedes Benz creates the 7G-Tronic seven-speed automatic transmission;

2007 - Toyota creates an eight-step automatic transmission, applied on the Lexus LS460.

Ten years ago, all drivers, before buying a car, always decided without any problems and confusion with which gearbox to buy a car. The choice was not difficult. Today it is much more difficult to make such a choice. If there are no problems with the mechanical box, then any buyer may have difficulties, since at the moment there are several types of automatic boxes on the market, which differ not only in their design, but also have different principle work.

Provides an explanation as to what automatic transmission better, and how they differ from each other.

After reading our material, you will find out how the CTV variator differs from a box with double clutch... We have put together a material for you to help you understand the variety of automatic transmissions these days. You can also choose with which type of gearbox to purchase a car.

Traditional automatic transmission

Like most models BMW latest the generation of the 5-series is also equipped with an 8-speed classic automatic transmission

Like most models BMW latest the generation of the 5-series is also equipped with an 8-speed classic automatic transmission

Still available on many models. For example, you can find ordinary automatic transmissions on cars, and. Basically, many models of these brands use an 8-speed automatic transmission.

However, on some of the more expensive models, automakers have also started installing new 9-speed gearboxes, which in a few years are likely to appear on cheaper cars as well.

Conventional automatic transmissions use a torque converter in their design, which does the same job as the clutch in a manual transmission. But unlike mechanics, the torque converter is not activated when the clutch pedal is pressed, but automatically.

This is done with hydraulic system, in which the oil passes through special channels and enters certain sections of the box, creating pressure in the system, according to which the computer determines what speed should be turned on.

Thanks to the hydraulic interface, the modern automatic transmission shifts gears very smoothly. , since for the first time in the car market automatic transmissions appeared in 1940.

Since that time, the classic gearbox has improved in its characteristics, but, nevertheless, the principle of operation and the structure of the gearbox have practically not changed.

However, even modern automatic transmissions change gears more slowly than, for example, an automatic transmission with two clutches, which primarily affects fuel consumption.

Therefore, a car with a conventional gearbox consumes more fuel than a similar car with a gearbox with two clutches.

Designations of automatic transmissions on, and: ZF 8HP; ZF 9HP; Tiptronic

Dual-clutch automatic transmission

The PDK gearbox, which is installed on cars, is one of the best in the world

The PDK gearbox, which is installed on cars, is one of the best in the world

The dual clutch box, as its name suggests, has two clutches in its design. This does not mean, of course, that a car with such a gearbox has two clutch pedals.

Of course, the whole process of the dual-clutch box is electronically controlled without driver intervention (no need to press the clutch pedal and shift gears yourself).

For example, one clutch controls the odd gears and the other the even gears. The moment you go in one gear, increasing the engine speed, torque begins to be transmitted to the other shaft (automatic gear shifting) with almost no delay, since the second clutch is already ready to shift the clutch to transmit torque.

As a result of these actions, the gear shifting process is faster than an experienced driver manually shifting gears on a manual transmission.

In addition, some dual-clutch transmission systems are more economical than mechanical boxes... That is, some cars with a dual-clutch transmission consume much less fuel than cars equipped with automatic and manual transmissions.

However, there is one drawback. This is the process when the vehicle starts moving. At first, the box can pause in order to engage the clutch on the shaft, where the first gear is located. This is also felt when maneuvering at low engine speeds. For example, you may feel the twitching of a car.

It is worth noting that the design of a dual-clutch transmission is very complex and due to the fact that this type of transmission has appeared on the market quite recently, it is still premature to talk about its reliability. It takes about 10 years for experts and car manufacturers to understand how similar type of transmission racks are before long car operation.

The most famous designations for dual-clutch gearboxes are: DSG, PDK, M-DCT and Powershift.

Automated manual transmission

Despite the fact that the Up is a small compact car, during acceleration, gear changes are jerky due to the automated manual transmission

Despite the fact that the Up is a small compact car, during acceleration, gear changes are jerky due to the automated manual transmission

With the introduction of the dual-clutch transmission, automated manual transmissions are becoming a rarity in the global automotive market, but nevertheless, some companies still continue to install this type of transmission on many vehicles.

A car that uses this type of gearbox, as well as a dual-clutch gearbox, does not have a clutch pedal, but there is a gearshift knob, as on traditional mechanics.

By shifting the speed, the box turns off the transmission of torque from the engine to the box, transfers the transmission of torque to the desired shaft, and then turns on the transfer of energy from the engine to the box again. And all this without the participation of the driver.

At first it may seem that this type of transmission has an advantage over conventional automatic transmissions, many of which do not allow drivers to change gears on their own, but in fact there are disadvantages that are in the operation of an automated manual transmission.

So there are problems with the speed and smoothness of the transmission. The problem is that these gearboxes take time to do the necessary steps in the correct order to change gear without the clutch. Therefore, the whole process is too slow so as not to cause discomfort for passengers and the driver.

But, despite this, many drivers often note that cars with such boxes accelerate very slowly, which is associated with huge delays between gear changes.

Some drivers, to smooth the shifting process, slightly lower the gas pedal before changing to a different speed. But cars with traditional automatic and dual-clutch transmissions accelerate cars much faster and shift gears more smoothly.

The most famous designations for automated manual transmissions: Unofficially, this type of transmission is called semiautomatic, ASG, EGC and ETG.

Continuously Variable Transmission (CVT) - CVT

The new generation is equipped with a variator, which allows the car to dynamically pick up speed, but the owners pay for this with a loud engine sound.

The new generation is equipped with a variator, which allows the car to dynamically pick up speed, but the owners pay for this with a loud engine sound.

The continuously variable transmission is not similar in design to any other transmission. In the variator, you will not find more than one spare part that is used in other types of gearboxes. The CVT uses two pairs of metal cones, each with pointed ends.

One set of cones are attached to the engine and the other two are attached to the wheels vehicle... A belt is stretched between these pairs of cones. The cones move towards each other, usually under the control of a computer.

In modern variators, the design of the box allows using a computer to change the angle of the belt located between the two cones, which ultimately allows you to change the gear ratios of the gears.

It sounds strange, but in fact such a design of the box allows you to constantly change the gear ratios, instead of using the fixed values set at the factory.

This means that the gear ratios can be adjusted infinitely, which allows the engine to run more efficiently when accelerating. In fact, there is no gear change when picking up speed, which creates the effect that the car accelerates without delay.

But as well as, in the operation of the variator there are also disadvantages.

For example, there is an annoying loud engine sound that is constantly running at high revs. That is, if your car is equipped with a variator, during acceleration, the engine speed will not fall, as it happens, for example, on automatic or manual transmissions (when changing to another gear, the engine speed decreases).

The most famous designations for continuously variable transmissions: E-CVT, CTV and Multitronic.

Definition

Automatic gearbox(Automatic transmission, automatic transmission) - one of the types of gearboxes, the main difference from mechanical gearbox is that in the automatic transmission gear shifting is ensured automatically (i.e., the direct participation of the operator (driver) is not required). The choice of gear ratio corresponds to the current driving conditions, and also depends on many other factors. Also, if a mechanical drive is used in traditional gearboxes, then in an automatic gearbox there is a different principle of movement of the mechanical part, namely, a hydromechanical drive or a planetary mechanism is involved. There are designs in which a two-shaft or three-shaft gearbox works together with a torque converter. This combination was used on LiAZ-677 buses and in the products of ZF Friedrichshafen AG.

In recent years, automated manual transmissions with electronic control and electro-pneumatic or electromechanical actuators.

Background

No wonder they say that laziness is the engine of progress, so the desire for comfort and a simpler, more convenient life has given rise to many interesting things and inventions. In the automotive industry, such an invention can be considered an automatic gearbox.

Although the design of the automatic transmission is quite complex and became popular only at the end of the 20th century, it was first installed in a Swedish Lisholm-Smith bus from 1928. In mass production, the automatic transmission came only 20 years later, namely, in 1947 in a Buick Roadmaster car. The basis of this transmission was the invention of the German professor Fettinger, who patented the first torque converter in 1903.

The photos show the same Buick Roadmaster - the first production car with automatic transmission.

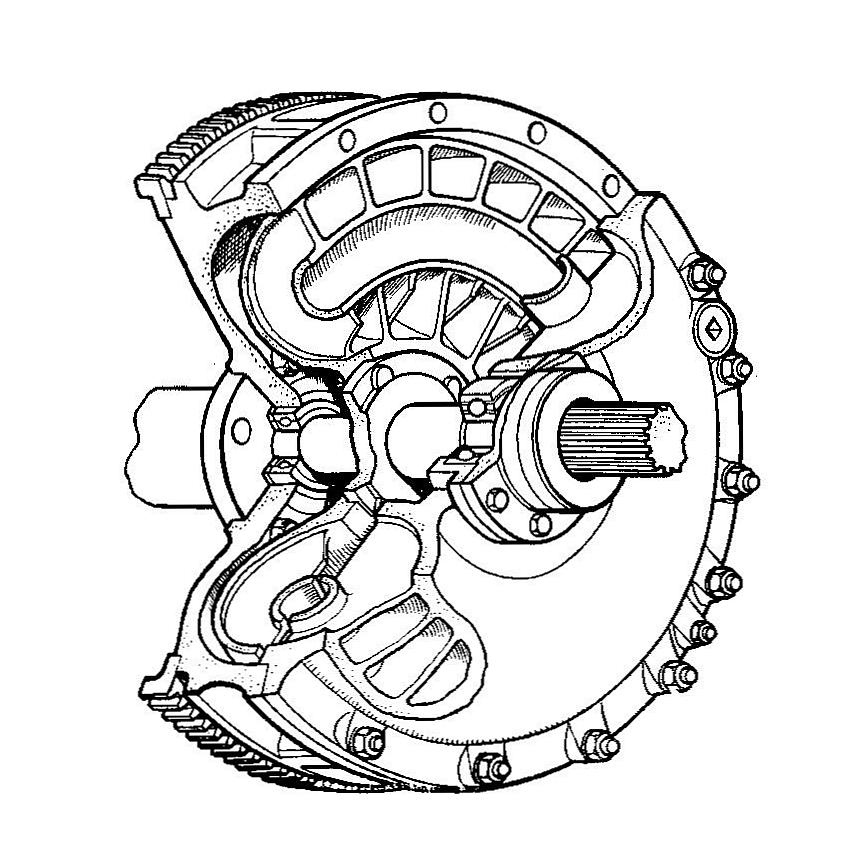

V automatic transmission the clutch is played by a torque converter, which transmits torque to the gearbox from the engine. The torque converter itself consists of a centripetal turbine and a centrifugal pump, between which a guide vane (reactor) is located. All of them are located on the same axis and in the same housing, together with the hydraulic working fluid.

Closer to the present

The middle of the 60s of the 20th century was marked by the final consolidation and approval in the United States of the modern automatic transmission switching scheme - P-R-N-D-L... Where:

"P" (Parking) - "Parking"- The neutral mode is on, in which the output shaft of the box is mechanically blocked, so that the car does not move.

"R" (Reverse) - "Reverse"- Enabling reverse gear (reverse gear).

"N" (Neutral) - "Neutral"- There is no connection between the gearbox output and input shafts. But at the same time, the output shaft is not blocked, and the car can move.

"D" (Drive) - "Main mode" - Automatic switching in a full circle.

"L" (Low) - Driving only in 1st gear. Only 1st gear is used. The hydrospreader is locked.

Increasing demands on the efficiency of cars led to the return in the 1980s of four-speed transmissions, in which the fourth gear had a gear ratio of less than one ("overdrive"). Also, torque converters that lock at high speed became widespread, which made it possible to increase the efficiency of the transmission by reducing the losses arising in the hydraulic element.

In the period from 1980-1990, the computerization of engine control systems took place. Similar control systems were used in automatic transmissions. Now control over the flow of hydraulic fluid was regulated by solenoids connected to the computer. As a result, gear shifting became smoother and more comfortable, and economy and work efficiency increased again. In the same years, it becomes possible to manually control the gearbox ("Tiptronic" or similar). The first five-speed gearbox is invented. There is no need to change the oil in the gearbox, since the resource already poured into it is comparable to the resource of the gearbox.

Design

Traditionally, automatic gearboxes consist of planetary gearboxes, torque converters, friction and freewheel clutches, connecting drums and shafts. Sometimes a brake band is used, which slows down one of the drums relative to the automatic transmission housing when one of the gears is switched on.

The role of the torque converter consists in the transmission of moment with slippage when starting off. On high revs engine (3-4 gear), the torque converter is blocked by a friction clutch, which prevents it from slipping. Structurally, it is installed in the same way as the clutch on transmissions with manual transmissions - between the automatic transmission and the engine itself. The converter housing and drive turbine are attached to the engine flywheel, as is the clutch basket.

The torque converter itself consists of three turbines - a stator, input (part of the body) and output. Usually, the stator is deafly braked on the automatic transmission case, however, in some cases, the stator braking is activated by a friction clutch to maximize the use of the torque converter over the entire speed range.

Friction clutches("package") connecting and disconnecting the elements of the automatic transmission - the output and input shafts and the elements of planetary gearboxes, and braking them on the automatic transmission housing, the gear changes are carried out. The clutch consists of a drum and a hub. The drum has large rectangular grooves on the inside, and the hub has large rectangular teeth on the outside. The space between the drum and the hub is filled with annular friction discs, some of which are plastic with internal cutouts, where the teeth of the hub enter, and the other part is made of metal and has protrusions on the outside that enter the grooves of the drum.

The disc pack is hydraulically compressed by the annular piston, the friction clutch communicates. Oil is supplied to the cylinder through grooves in the shafts, the automatic transmission housing and the drum.

Preview - click-to-enlarge.

Preview - click-to-enlarge.

On the first, on the left, the photo is a section of a torque converter eight-speed automatic transmission of a Lexus car, and on the second - a section of a six-speed preselective Volkswagen automatic transmission

The overrunning clutch slides freely in one direction and wedges with the transmission of torque in the other. Traditionally, it consists of an inner and outer ring and a cage with rollers located between them. Serves to reduce shocks in the friction clutches when shifting gears, as well as to disable engine braking in some automatic transmission modes.

A set of spools was used as a control device for the automatic transmission, which controlled the oil flow to the pistons of the friction clutches and brake bands. The position of the spools is set, both manually, mechanically by the selector knob, and automatically. Automation can be electronic or hydraulic.

The hydraulic automatic system uses the oil pressure from the centrifugal regulator, which is connected to the output shaft of the automatic transmission, as well as the oil pressure from the gas pedal pressed by the driver. As a result, the automation receives information about the speed of the car and the position of the gas pedal, depending on which the spools are switched.

The electronics use solenoids to move the spools. The cables from the solenoids are located outside the automatic transmission and lead to the control unit, which is sometimes combined with the fuel injection and ignition control unit. Depending on the position of the selector lever, accelerator pedal and vehicle speed, the electronics decides on the movement of the solenoids.

Sometimes, the automatic transmission is provided for without electronic automation, but only with the third forward gear, or with all forward gears, but with the obligatory shift of the selector handle. They will advise you on gearbox breakdowns and repairs.

Now almost all cars are equipped with automatic gearboxes. But not everyone knows where these "boxes" came from, how they are arranged and what are their advantages and disadvantages. Read about this and much more in this material.

Classic torque converter automatic transmissions emerged as a result of the merger of several parallel developments. At the beginning of the 20th century, many companies began to work on the development of "automatic machines". The first prototype of a modern automatic transmission was put into production Ford company, creating a mechanical "box" with a planetary gear. This gearbox was two-speed and required two pedals to operate it. One pedal shifted the lower gear to the highest and vice versa, and the second switched on the movement reverse.

The second development is a semi-automatic gearbox. It has automated clutch control. In other words, the clutch shifted automatically, and the gears were controlled by the driver. The developers of these units were Talbot and Newton. Despite the considerable age of semiautomatic devices, they are still used. True, not on cars, but on scooters. In addition to the above companies, semi-automatic machines were developed by Reo and General motors.

Another prototype of the "automatic" is the Kotal checkpoint, endowed with an electromechanical planetary gear. Drivers operated such "boxes" using a lever mounted on the steering column. The Kotal consisted of three planetary gears. Two of them ensured forward movement, and the third served for reversing and as a neutral position.

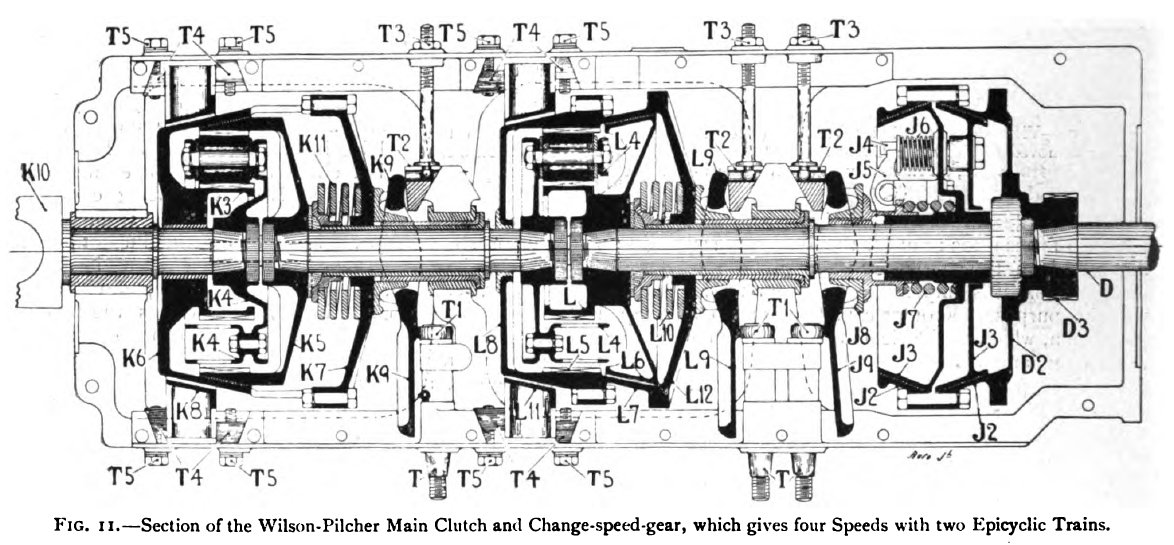

The next prototype of modern automatic transmissions was the "box" "Wilson". Its gear lever is the forerunner of modern gear selectors. But this type of checkpoint was also not fully automatic. The driver made the choice of gear manually using a lever - the ancestor of the selector, and to engage the gear, it was necessary to press the pedal with your foot. This development was used not only on cars, but also on military equipment. In particular on tanks.

The "box" produced by the Normanville company was arranged very similarly. Using it, the driver also switched gears using a lever, but there was no need to press the pedal - the gears were shifted automatically.

After all the above technologies, hydraulic elements were introduced into the checkpoint. In particular, fluid couplings, which were then replaced by torque converters. Fluid couplings made it possible to soften jolts when shifting gears.

At that time, the checkpoint acquired a new design - it was a fluid coupling in alliance with the usual two-stage "mechanics" and some automatic equipment. With the advent of fluid couplings, the driver could already stop and not turn on the neutral position of the selector. Initially, such gearboxes were installed on Chrysler cars.

The first full-fledged "automata" and their development

The world's first automatic transmission was created by the General Motors concern. This development was called the Hydra-Matic and appeared in 1940. Its design was an alloy of a fluid coupling and a four-speed planetary gear with automatic control.

Starting from 1940 and for a quarter of a century, "automatic machines" had different designs and modes of operation, but in the mid-1960s, the modern scheme of automatic transmission modes - P-R-N-D-L - was finally established. Also at this time push-button and toggle switches ceased to exist. All control was now carried out using the selector.

In the 1970s, "automatic machines" did not receive much development, but in the 1980s, in order to save fuel, all the developers decided to produce a four-speed automatic transmission, where the fourth gear had a small gear ratio(less than 1) - in one word - "overdrive".

In the 1990s, automatic transmissions finally come to their modern form due to computerization. Solenoids have also been introduced to control fluid flows. At the same time, automatic transmissions begin to receive various additional modes, and in addition, five-speed "boxes" appear. To the delight of the drivers, many "automatic machines" have ceased to require an oil change, since its service life has become equal to the service life of the "box" itself.

Nowadays, automatic transmissions are developing by increasing the steps. In 2002, a six-speed automatic transmission was created (BMW), in 2003 - a seven-speed (Mercedes-Benz), in 2007 - an eight-speed (Toyota) and a nine-speed "box" is to be released soon.

Modern device

Let's now take a look at what a modern automatic gearbox consists of.

The design of a modern automatic transmission includes a torque converter and an automatic planetary gearbox. These elements can also be subdivided.

The converter consists of three impellers - pump, turbine and stator. These elements require maximum manufacturing precision. Because of this, they cannot be changed separately and therefore, often, the torque converter is a one-piece non-separable mechanism that cannot be repaired and should serve the entire service life of the automatic transmission. At correct operation, of course.

The torque converter is mounted in approximately the same place as the clutch of the "mechanics" - between the engine and the automatic transmission crankcase. It is connected to the motor using a flywheel, and the connection to primary shaft"Boxes" are carried out by means of a turbine wheel. Sometimes, instead of a turbine wheel, cardan shaft, but this is more the exception than the rule. The main function of the torque converter is to convert the torque from the engine to the automatic transmission.

Now let's move on to the actual automatic transmission device. It includes a planetary gearbox, friction and freewheel clutches, as well as connecting shafts and drums.

Friction clutches are used for gear shifting. They are used to connect and disconnect the elements of the "box". These couplings carry out their work by compressing the disc pack with a piston. In turn, the overrunning clutch at the moment of compression of the disc pack slips into the free space and is connected to the desired gear.

The automatic control system consists of a package of spools that control the oil flow. The spools are adjusted by means of a selector switch by the driver, as well as in automatic mode.

The automatic transmission system is of two types - hydraulic and electronic. In the first case, reading the information about the position of the gas pedal and the gained speed, the "box" switches to the required gear. To obtain information, the automatic transmission uses oil pressure from the centrifugal regulator and from the gas pedal.

With electronic automation, everything is somewhat different. It uses solenoids to move the spools to the desired position. They also transmit information to the electronic control unit of the car and by receiving information about the speed and position of the gas pedal, a gear change occurs.

Pros and cons of "machine"

So, we found out where the automatic transmissions came from and what their design is. Now let's take a look at their merits and demerits. We will consider the pros and cons of "automatic" in relation to a manual transmission.

Let's start with the price. The price of an automatic "box" is much higher than a mechanical one. Consequently, a car equipped with an automatic transmission will also cost more. Also, repairs and maintenance will cost more, and "automatic machines" are repaired more often. After all, their service life is on average less. In addition, the automatic transmission places great demands on the operation and maintenance of itself.

The second equally important factor is management. Here, the "machine" has an unambiguous advantage. After all, thanks to it, you will not need to manually switch the clutch and select the desired gear. Automation will do everything for you. This option is great for beginners who are still poor at driving. And for experienced drivers, "automatic" will be more comfortable. Especially in the city. Indeed, when driving in a populated area, transmissions often need to be switched several times a minute, and this requires extra skills, time, nerves and everything else. This also includes the speed of transition from one gear to another. For an "automaton" this process is much faster. In addition, untimely gear changes can damage the engine and transmission, or simply shorten their service life. Automatically, this problem disappears by itself. On the other hand, an experienced driver, on the contrary, sometimes it is better to control the gears himself, rather than trust the electronics. Especially in difficult places.

If we talk specifically about technical aspects, then the "automata" are clearly losing. First, they increase fuel consumption. Not much, but still. Secondly, they carry more weight than mechanical gearboxes, which affects the various qualities of the car. And in case of some malfunctions, "mechanics" also wins. If your ignition is out of order or the battery has run out, then a car with "mechanics" can be started, so to speak, from a "pusher" and drive to a car service. In the case of the "automatic" you will need a tow truck. And from here comes another drawback of the automatic transmission. Cars with such "boxes" cannot be towed either on flexible or rigid couplings. While "mechanics" is great for both.

So, in terms of the number of pluses, the manual transmission definitely wins, but one plus of the convenience of operating the “automatic” can override all the advantages of the “mechanics”. Well, it's up to you, as always.

An option for which many are ready to take additional credit and the thing that interests us immediately after the engine is "automatic".

Today we will talk about a thing, which, like the engine, is a small world inside the auto world. How did it come about? Who invented it? Let's figure it out.

Today, “automatic” is understood as a hydromechanical planetary gearbox. Automatic gearboxes can also include boxes with automated shifting - "robots"; variators cannot be attributed at all (the latter are not gearboxes at all). Today the box is a system of a torque converter and a planetary gear system. And this imposes minor difficulties on the correctness of determining the primacy, since the torque converter was invented by the German engineer Hermann Fettinger at the beginning of the twentieth century, and the planetary gear system has been known since the time of Ptolemy. But the inventor Oscar Banker (at birth he was called Azatur Sarafyan) put everything together and made it work.

"So simple?" - you ask. - So just take and lay out all the facts? But what about the background? ”. Everything will be now!

Let's start with the main device that made the automatic transmission possible. This is a torque converter. It was invented exclusively for the needs of shipbuilding. At the end of the 19th century, high-speed steam turbines were increasingly used in the navy as a ship engine instead of the previous low-speed ones. steam engines... These machines were initially connected directly to the propellers of ships, and a little later this design began to cause the expected problems. It was not possible to increase the rotational speed of the propellers, and an additional mechanism was required to connect them to higher-speed steam turbines.

High-speed gear drives of high power did not know how to do it at that time. There was a proposal to use hydraulic vane machines so that the engine rotates the vane pump wheel and the work of the engine is converted into the energy of the liquid pumped by the pump. This fluid is then sent to a blade turbine, in which the energy of the fluid is converted into mechanical energy used to rotate the propeller.

The way out was the invention by G. Fettinger of a new hydraulic machine, uniting in one casing all impellers of a hydrodynamic transmission - a pump, a turbine, a guide vane (reactor). In such a machine (patent of 1902), energy losses in pipelines, spiral chambers, inlets and outlets are excluded, which almost doubled the efficiency. Already in 1912 the efficiency of the passenger steamer Tirpitz was 88.5%. Later on the ship "Wiesbaden" with a capacity of 15,000 - 20,000 liters. with. the hydrodynamic transformer had an efficiency of 91.3%.

In 1904, the Startvent brothers from Boston showed their prototype automatic transmission. The box had two gears, and the essence of the mechanism was very similar to a slightly modified manual gearbox. The problem was that the industry at that time was not ready to make such boxes in series, so things did not go beyond the concept.

Ford took the next step with its Model T. The car was equipped with a planetary gearbox and had two gears forward and one reverse. The advantage of such a box was a significant simplification of control, and we remember that the car was created not for the engineers of the Fredericks, but for ordinary Billys who did not know the instructions. There were no synchronizers in the gearboxes then, and gear shifting was not as easy as it is now. On the T, the gearbox was pedal controlled, and all that was required was to shift in time.

Then there was a gearbox from General Motors and Reo in the mid-1930s. To some extent, that box can be considered the first "robot", since it was a mechanical box in which the clutch was automated. And a little later, a planetary gear system was added, which brought the design closer to modern automatic transmissions.

The planetary gear was very convenient for the designers automatic transmission... To control its gear ratio and the direction of rotation of the output shaft, carried out by braking individual parts of the planetary gear, relatively small and, moreover, constant forces could be used with the use of clutches and band brakes as actuating mechanisms. Controlling the latter with the help of servo drives in those years did not cause any particular difficulties, since it was already well worked out, for example, on tanks, where the clutches were used for turning. In addition, there was no need to equalize the speeds of individual elements, since all planetary gears are in constant mesh. In contrast to this, the automation of a "classical" manual transmission, with all the logic of such a decision, in those years encountered a number of significant difficulties, primarily associated with the lack of servo drives suitable for the principle of gear shifting used in it: for moving gears or engagement clutches and introducing them into engagement with each other, reliable and fast-acting actuators were required, providing sufficiently large forces and working strokes - much larger than those required to compress the clutch block or tighten the band brake. This problem received a satisfactory solution only closer to the mid-50s of the 20th century, and it was suitable for mass models only in recent decades, in particular, after the appearance of multi-cone synchronizers like those used in DSG-type gearboxes.

An interesting box was "Wilson", installed on the small car of the British firm BSA. Band brakes were used to brake the elements of the planetary mechanism. The choice of gear was carried out by the steering column lever, and the transfer was directly switched on by pressing the pedal. The Wilson box was a preselector, that is, the driver could preselect the desired gear, which was included only after pressing the gear shift pedal, which was usually located in the place of the clutch pedal - without the need to precisely coordinate the actions of the lever and pedal, which simplified driving and accelerated shifting, especially in comparison with the then unsynchronized manual transmissions. But the main merit of the Wilson box is that it was the first to receive a switch, almost like in modern boxes, and for Americans it remains the standard to this day. In addition, all the positions of the switch were already practically consistent with the generally accepted (legislatively positions P-R-N-D-L were adopted in the mid-1960s).

However, the world's first fully automatic transmission was created by another American company, General Motors. In the 1940 model year, it became available as an option on Oldsmobile cars, then Cadillac, later - Pontiac. It bore the commercial designation Hydra-Matic and was a combination of a fluid coupling and a four-speed planetary gearbox with automatic hydraulic control. The control system took into account factors such as vehicle speed and throttle position. The Hydra-Matic was used not only on vehicles from all GM divisions, but also on vehicles from brands such as Bentley, Hudson, Kaiser, Nash and Rolls-Royce, as well as some military vehicles. From 1950 to 1954, Lincoln vehicles were also equipped with the Hydra-Matic automatic transmission. Subsequently German manufacturer Mercedes-Benz has developed on its basis a four-speed automatic transmission, which is very similar in principle of operation, although it has significant design differences.

The real boom in the development of "automatic machines" was in the 1950s, and by the mid-1960s the boxes were almost identical to the modern ones. They even replaced whale blubber with synthetic lubricants, which seriously reduced the price of boxes and their further maintenance.

In the 1980s, the boxes received economical four-stage versions, but most importantly, microprocessor control, which made it possible to significantly reduce the number of moving elements (all control was carried out using solenoids, not mechanics).

Today you will no longer surprise us with a 7-speed automatic, but the other day 10-speed automatic machines from VW should be delivered. The boxes have become more reliable, an order of magnitude more convenient, and most importantly - faster and more economical than good "mechanics". It would seem that manual transmissions should have remained in the past and where they are really needed, but the desire to make money does not allow automakers to take such a step. Perhaps electric cars will spur them on?

- , May 27, 2015