Repair of the Gazelle checkpoint in DVK-service is the quality of components, experience of personnel, low prices.

In the DVK car service We will repair the checkpoint of your GAZelle in a short time, using original parts GAS. Our prices will pleasantly surprise you. Below you can see an example of our work.

This article shows the gazelle checkpoint repair in the DVK service. The work is not a step-by-step instruction for self-repair... Using an example, the stages of work will be shown, the reasons that prompted the visit to the car service are described.

1. Gazelle 2008 release, loud noise in the gearbox.

2. Bottom view, check point removed.

3. Gearbox dismantled

4. Remove the primary shaft bearing cover

5. Unscrew the bolts and remove the shift lever housing (stage cover)

6. Unscrew the mount and remove the speed sensor

7. Unscrew the bolts securing the gearbox housing

![]()

8. Remove the input shaft bearing retaining ring

9. We separate the gearbox housing

10. Remove the cover for fixing the gear selector rods

11. We release the forks of a choice of transfers

12. We take out the rods of a choice of transfers

13. In place of the rods, we install temporary plugs so that the clamps do not run away, in the future it will turn out in vain they tried!

14. The photo shows the secondary shaft bearing retaining ring. Unclench, take out.

15. Shafts assembly

16. Dismantling

17. Dismantling side view

18. And it's the same

20. The culprits start. The bearings of the input and output shafts are worn out

21. The clutch is internal first, second gear. Conclusions on the face

22. Washing the gearbox housing

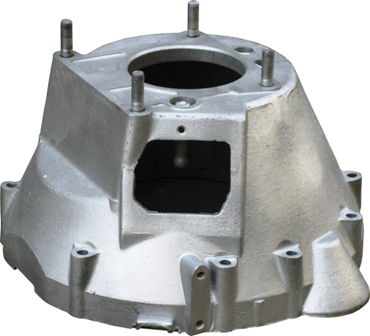

23. Replacing the rear of the gearbox housing (crack)

24. Assembling in reverse order. Primary shaft.

25. Retaining ring of a primary shaft

26. Ibid, only irrelevant)

27. Installing the input shaft needle bearing

28. Gearbox support

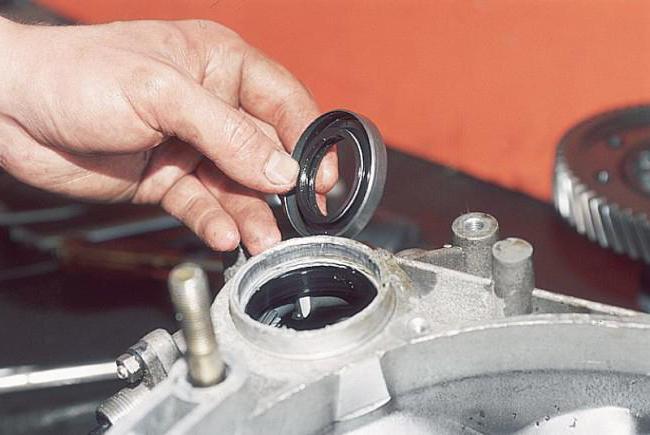

29. Installing oil seals in our case, two at once

30. Installation of shafts, previously rejected bearings and an internal clutch assembly were replaced.

31. Installation of forks of a choice of transfers on the same place

32. The speedometer drive is back

33. How it all began, we put in place the bearing cover of the input shaft

![]()

34. Assembly is complete, it remains to screw the cover of the stage

35. Parallel replacement of the clutch release bearing

36. A few remaining bolts and finish!

Video GAZelle checkpoint repair

It should be remembered that careful handling and prevention can significantly increase the service life of the Gazelle gearbox. To do this, you need to change the oil on time, not only in the engine, but also in the box (according to those standards, this is not done often), periodically check the oil level, and visually inspect for leaks. Also, if there are extraneous sounds, do not wait until the last, but come to the car service on time and fix the malfunction, as this can cause more serious repairs.

Thanks! DVK service

The gearbox of any car is a rather complex unit, which is not so easy to repair without proper preparation. The slightest disruption in the working process can lead to damage to the mechanism on the go, which is fraught with an emergency. Nevertheless, having minimal skills and having studied the operating instructions, disassembling the box ("Gazelle") with your own hands does not look like something supernatural.

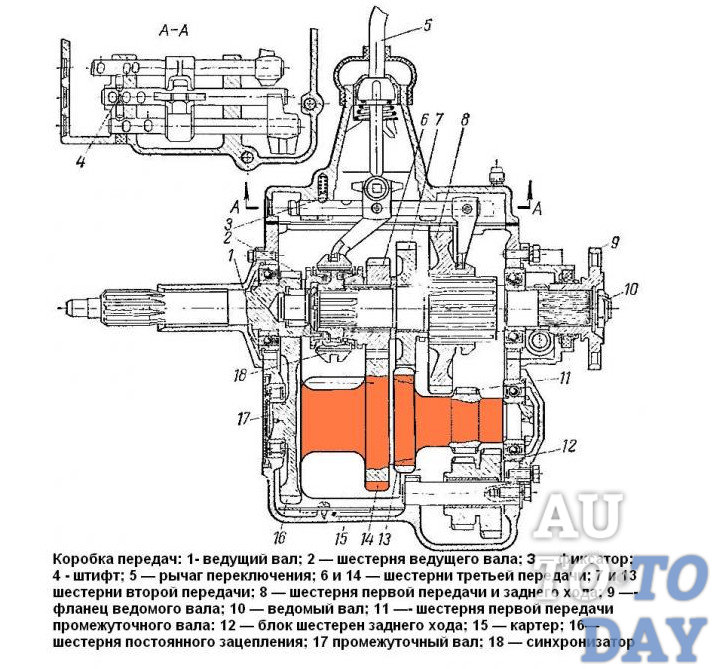

Gearbox device

The gear shift unit of the mechanical type under consideration has five stages. To carry out such an operation as disassembling the box ("Gazelle"), you need to know the device of the element. Its package includes:

- a pair of aluminum crankcases that are bolted together;

- primary and secondary shaft, aggregating with cardan and crankshaft;

- there is also an intermediate mechanism, equipped with the razor teeth of the first and reverse gear, as well as a block with gears and a speedometer drive;

- inertial synchronizers;

- sub-spring-type ball-type fastening elements;

- blocker of simultaneous activation of gears;

- lever damper.

It is advisable to carry out the operation with a partner. Disassembly / assembly of the gearbox ("Gazelle") will require knowledge of the vehicle's materiel, the ability to dismantle and correctly assemble the unit after repair. When performing work, it is necessary to observe patience, accuracy and safety.

Dismantling the checkpoint: step by step instructions

Disassembly of the Gazelle Next box is carried out in the following sequence:

- The car is placed on the inspection pit.

- The crankcase is completely free of oil.

- The cardan is removed.

- The location of the hinge and the box extension in relation to each other is marked, including the flanges rear axle(marks are made with a file).

- The latch of the intermediate support is dismantled (we use keys 12 and 13).

- The fasteners of the cardan with the drive gear flange are unscrewed (keys 14 and 17).

- The gearbox shank is removed by shifting it back and pulling it out.

- The resulting hole is temporarily blocked with a rag.

- Next, you need to get the lever and remove the cover inside the cab.

- At the next stage, we unclench the spacer sleeve, remove the rubber pad and the locking element.

- It remains to unscrew the cap, remove the lever, turn off the speedometer and the switch of the light element reverse.

Then the gearbox is removed, the pressure pipes and fixing brackets are disconnected, as well as the cross member of the assembly by swinging and pushing back the gearbox itself. It is advisable to protect the block head by placing a wooden bar.

Dismantling the gearbox ("Gazelle Business and Next")

This action also takes place in several stages. When performing work, remember that the checkpoint weighs more than thirty kilograms, which requires additional precautions.

Disassembly:

- The bearing cover is removed, the sealing lip is changed.

- The rear axle bushing fasteners are removed.

- The retaining ring is removed as well as the breather.

- Using a hammer and a soft metal mandrel, the crankcases are disconnected.

- By turning the input shaft, reverse gear is switched on.

- The lever bodies, the plate with the gasket, the fastening of the front travel forks are dismantled.

- The springs and balls of the retainers are removed.

- In a certain order, the rods are removed (first 1, 2, 5 reverse, then the rest).

Using a key, unscrew the reverse axle mount, remove the retaining ring, remove the shafts, which are then disassembled if necessary, not forgetting to mark their relative position first. Disassembly of the box ("Business Gazelle") is completed, you can start repairing and assembling.

Assembly of the node

This manipulation is performed in the reverse order. After repair or replacement necessary elements, the shafts are installed at the same time. To do this, it is advisable to connect them with twine. Before starting assembly, carefully inspect the crankcase for cracks, rust, or other deformations.

Previously, all the parts should be soaked in kerosene, sand any cracks and notches, replace all defective elements, lubricate them special oil... The crankcase fasteners must be treated with sealant, and the existing gaskets must be replaced. Experts recommend replacing bearings every 80-100 thousand kilometers.

Disassembly of the box ("Gazelle") and its installation require attention and accuracy. The unit is mounted on a car by installing the assembled gearbox in the reverse sequence to removal. First, it is necessary to lubricate the slots, when installing the cardan - to trace the coincidence of the applied marks. After installation, you need to pour the required amount of oil into the crankcase and check the operation of the repaired unit.

Tools

Disassembling the box ("Gazelle"), the photo is presented above, requires certain tools and devices. Among them:

- a set of keys (for 10/12/13/14/17/19);

- several screwdrivers;

- brass barb and bump stop;

- wooden blocks;

- pliers (pliers);

- mount;

- hammer, pullers;

- emery, file;

- soft metal lining;

- rags, mandrel, reservoir for draining mining, GOI paste, gear oil of the SHRUS type.

In addition, you first need to worry about the presence of a viewing hole or overpass.

Disassembly of the box ("Gazelle"): when you may need

A number of factors can serve as a reason for urgent repair of the gear shift unit, namely:

- Inability to engage gear or significant difficulty in performing this action.

- Extraneous sounds and crackling when changing gears.

- Uncontrolled shifting of gears (very dangerous, especially in heavy traffic or at high speeds).

- Any extraneous or unusual sounds in the area of the node in question.

- The signal for urgent repair of the Gazelle gearbox is also smoke and an unpleasant smell.

Preventive inspection and diagnostics of the gearbox are recommended to be carried out no later than after three hundred thousand kilometers.

The main causes of gearbox breakdown

Disassembly of the box ("Gazelle" / 406 engine), as with others power units, may be required immediately. The following factors are most often the cause of the malfunction:

- deformation and destruction of worn parts or loosening of fasteners (causes a humming noise during system operation);

- destruction of bearings (a characteristic crunch is heard in the checkpoint);

- wear of the synchronizer rings (crackling appears when switching speeds);

- the presence of burrs, wear of gears, sticking in the drive causes difficulties with shifting;

- the speeds themselves can turn on or off when the gear teeth are skewed, the fasteners or the driven shaft are loosened;

- due to oil loss due to holes in the crankcase or loosening of the bolts, interruptions occur not only in the gearbox, but also in the aggregating units.

Conclusion

The Gazelle car in various modifications has become very popular vehicle in the domestic market. This hard-working small-tonnage machine is used in construction, utilities, transportation and other industries. Not surprisingly, owners prefer to carry out many repair operations on their own, while saving time and money.

It can be noted that the disassembly and assembly of the gearbox for modifications "Gazelle Next" or "Business" with your own hands is quite realistic. The main thing is to remember technical nuances, safety precautions and stages of work. In order to prevent the destruction of this important unit, do not forget to change the oil in a timely manner, diagnose the element, and also respond to the appearance of various failures in the operation of the unit or when extraneous noise appears. If you are not confident in your abilities, it is better to entrust the checkpoint repair to specialists.

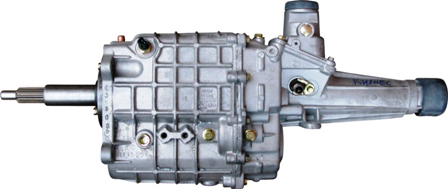

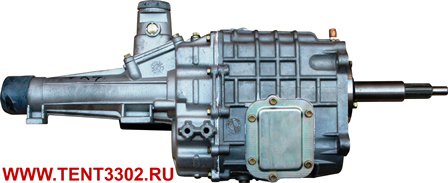

Cummins ISF 2.8 check point, gearbox for Gazelle-3302

STANDARD ... MOSTAT production.

Price RUB 31,000

Cummins ISF 2.8 check point, reinforced gearbox for Gazelle-3302

Cummins gearbox, gearbox for Gazelle-3302 with Cummins ISF2.8 engine new REINFORCED... MOSTAT production.

Price 34,000 rub. 1 year warranty

Gearbox Gazelle NEXT NEXT a21r22 of a new model, reinforced dv. Cummins ISF 2.8

Price 54000 rub. new (made by OJSC GAZ) 1 year warranty

Gearbox for Gazelle-3302 dv. Chrysler gearbox (Chrysler)

Price 31000

STAYER 560 gearbox, gearbox for Gazelle-3302

AK 330242-1700010

Price 31000

Transmission for Gazelle-3302 BUSINESS dv. UMP-4216

Price 22000 rub. new. (MOSTat) 1 year warranty

Gearbox for Gazelle-3302 dv. ZMZ-405-406

Price 25000 rub. new. (MOSTat) 1 year warranty

Gearbox gearbox for all-wheel drive Gazelle-33027 4x4 and Sable-2217 4x4

AK 33027-17000-10-02

Price 35000 rub. new (MOSTat) 1 year warranty

Gearbox housing for Gazelle-3302

AK 3302-1701014

Price RUB 3000

Gearbox shank for Gazelle-3302

AK 31029-1701010

Price RUB 3000

Shank (extension) of the check point for Cummins ISF 2.8 AK 3302-1701015

Price 5000 rubles.

Clutch housing ZMZ 406 405 (bell).

AK 4062.1601015-11

Price 4000 rubles.

AK 409.1601015

Price 8000 rubles.

Input shaft with bearing and synchronizer

for gearbox on Gazelle-3302

AK 3302-1701025

Gearbox input shaft, gearbox input shaft bearing, synchronizer.

Price RUB 3000

Gearbox bearings Gazelle-3302 repair kit

The composition of the gearbox repair kit:

Gearbox bearing kit

Gearbox oil seal kit

Gearbox gasket kit

Price 2000 rubles.

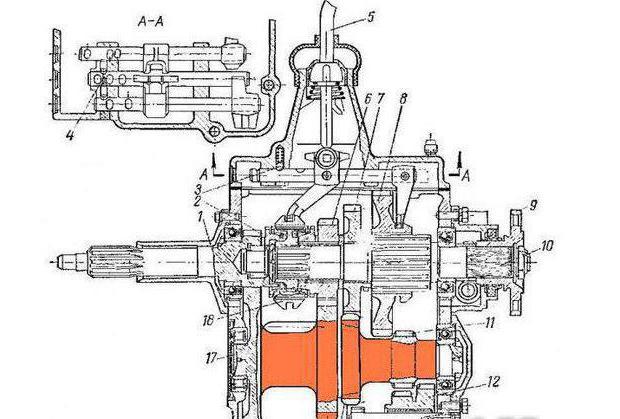

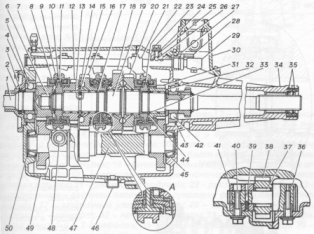

Cross-section of the transmission on the Gazelle-3302.

Gearbox (check point) front crankcase and tail (rear crankcase) for Gazelle-3302

(longitudinal section): A - double-cone synchronizer box for Gazelle-3302; 1 - primary shaft of the gearbox for Gazelle-3302; 2-input shaft bearing cover; 3 - cuff; 4 - ball bearing of the input shaft; 5- checkpoint retaining ring for Gazelle-3302; 6 - roller bearing of the secondary shaft; 7 - breather; 8 - blocking ring; 9 - engagement clutch; 10 - synchronizer cracker; 11-hub of the 3rd, 4th gear clutch; 12 - a gear wheel of the 3rd transfer; 13 - pinion needle bearing; 14-semicircular retaining ring; 15 - half ring; 16 - a gear wheel of the second transfer; 17 - retaining ring Gearbox for Gazelle-3302; 18 - a gear wheel of the 1st transfer; 19 - secondary shaft; 20 - reverse gear; 21-fork for 5th gear and reverse; 22 - hub of the clutch for engaging the 5th reverse gear; 23 - retainer plate fastening bolt; 24 - plate; 25 - spring of clamps; 26- ball of retainers; 27- spring of the locking sleeve; 28-locking sleeve; 29-head of the rod for engaging the 5th gear and reverse gear of the gearbox for Gazelle-3302; 30 - body of the shift lever; 31- gear wheel of 5th gear; 32 - persistent washer; 33 - spacer sleeve; 34 - rear gearbox housing (shank); 35 - cuffs; 36 - the axis of the intermediate reverse gear; 37 - needle bearing of the reverse intermediate gear; 38 - intermediate reverse gear; 39-pin; 40- bolt of fastening of an axis of an intermediate gear wheel of a reverse gear of a check point on a Gazelle-3302; 41 - axle bushing of the reverse intermediate gear; 42 - ball bearing of the secondary shaft; 43-ring retaining the bearing of the secondary shaft; 44 - retaining ring; 45 - bearing; 46 - oil drain plug; 47 - intermediate shaft; 48 - oil filling plug; 49 - front gearbox housing for Gazelle-3302; 50 - adjusting ring.

A five-speed gearbox is installed on Gazelle-3302 vehicles. Weight (without refueling) - 32 kg. The gearbox housing for the Gazelle-3302 is made of aluminum alloy and consists of two parts - the front and rear (shank) 34 crankcases. Gearbox housing for Gazelle-3302 gearbox to ensure the necessary alignment of the shaft supports and the holes for the shift mechanism rods, it is centered on the mounting bushings pressed in the middle crankcase and connected to each other by ten bolts.

The primary shaft of the gearbox on the Gazelle-3302, as well as the gears of the 1st, 2nd, 3rd, 5th gears and reverse gears, installed on the secondary shaft 19, are in constant mesh with the gears of the intermediate shaft 47, have oblique teeth and rotate on needle bearings with plastic cages. The intermediate gear of the reverse gear of the box rotates on bulk rollers with a diameter of 3 mm on an axle, the supports of which are located in both gearbox housings for Gazelle-3302.

All transmissions Gearbox for Gazelle-3302

equipped with inertial synchronizers, the gear rims of which are connected to the gears by means of small splines. Synchronizers for 3rd, 4th, 5th gears and reverse gears have toothed rims made in one piece with the cones. The alignment of the revolutions of the included gear to the revolutions of the secondary shaft, necessary for shockless gear shifting, is achieved using the braking torque arising due to the frictional forces on the outer surface of the cone of the gear rim of the gear and the inner conical surface of the blocking ring 8 of the synchronizer connected through the hubs 11 and 22 with the secondary shaft 19 Synchronizer 1st - 2nd gears - double-cone, has an increased braking torque due to the additional friction surface formed by the outer conical surface of the inner ring 8 connected to the hub and the inner conical surface of the middle ring 9, connected by protrusions (protrusions enter the holes on the toothed crown 10) with included gear.

Double cone synchronizer 1st - 2nd gear Gearbox for Gazelle-3302

: 1 - clutch; 2 - hub; 3 - secondary shaft; 4 - a gear wheel of the 2nd transfer; 5 - synchronizer cracker; 6 - synchronizer spring; 7 - gear wheel of the 1st gear of the check point for Gazelle-3302; 8 - inner ring; 9 - middle ring; 10 - a gear wreath; 11 - outer ring. The gears are switched on by connecting the internal teeth of the clutches 9 with the external gear rims of the synchronizers. The sides of the teeth of the couplings and rims of the synchronizers are chamfered inward and, when the position is on, form a lock that prevents the gears from switching off themselves. The protrusions on the teeth of the rims of the synchronizers of the third, fourth, fifth gears and the reverse gear limit the movement of the clutches when the gears are engaged. The movement of the clutch of the first and second gears is limited by the ends of the gears. Axial forces from the helical teeth of the pinion gears of the secondary shaft are taken up by the retaining rings 17 and 44, thrust washer 32, a collar of the secondary shaft and located in a groove on the secondary shaft by two thrust half rings 15, which are enclosed by a ring 14. The ball bearings of the primary and secondary shafts are fixed on the shafts by means of spring and retaining rings, and in the crankcases by means of external retaining rings. Intermediate shaft Gearbox for Gazelle-3302 rotates on tapered bearings installed in the blind seats of the front and rear crankcases. Bearing preload is created by selection and installation during assembly of one of the adjusting rings 50 in the seat of the front crankcase. The gears of the 3rd and 5th gears, the intermediate shaft drive gear are fitted with an interference fit on the shaft, on which the teeth of the 2nd gear gear and long teeth are cut, which simultaneously serve as rims of the 1st gear and reverse gear of the intermediate shaft. The head of the axle 36 of the reverse idler gear is installed in the bed of the rear case of the gearbox and is bolted. The opposite end of the axle enters the bushing 41, is fixed in it with a pin, and the bushing is also attached to the bed of the front crankcase with a bolt. Switching mechanism Gearbox for Gazelle-3302

contains rods on which gear shift forks and heads 29 are attached, in the grooves of which the lower end of the shift lever is located. Gearbox forks on Gazelle-3302 have removable crackers that fit into the grooves of the engagement couplings. The rods are fixed in the on and off position by means of balls 11 and springs 12. A locking device, consisting of two locking plungers and a locking pin, protects the box from simultaneously engaging two gears. In addition, a locking sleeve 16 with a spring 15 is located between the head of the reverse gear rod and the wall of the rear housing, which makes it impossible to accidentally move the shift lever from the 5th gear engaged position to the reverse gear position. Gear shift lever Gearbox for Gazelle-3302 It is equipped with a damper device that eliminates its bounce at resonance at high engine speeds, and is located in the housing 18, which is attached to the rear crankcase from above. With the help of springs and fuses, the lower head of the shift lever in neutral position is always located in the head of the 3rd and 4th gear selector rod. Oil drain plug 46 has a magnet that traps fine metal particles in the oil - wear products gearboxes (check point), crankcase and shank for Gazelle-3302.

Do not think that repairing a Gazelle checkpoint with your own hands is easy. The gearbox is a complex mechanism that transfers torque from the engine shaft to the drive wheels. Your safety depends on it and the slightest deviations in the operation of the checkpoint signal the need for diagnostics. You should not be afraid of difficulties - after all, the service station may not be nearby, but step-by-step instruction will help to successfully cope with the case even for a novice car enthusiast.

Features of Gazelle gearbox repair

The Gazelle checkpoint is reliable and durable. But constant loads sometimes lead to its breakdown. Repair of the Gazelle gearbox will require from the driver:

- knowledge of the materiel of the car;

- the ability to remove the checkpoint, disassemble, and then assemble and put in place;

- strict adherence to safety regulations;

- attention, accuracy and patience.

Important! You should not do gearbox repairs alone - you need a partner.

How the gearbox is arranged on the Gazelle

Transmission - mechanical, five-speed. Comprises:

- two aluminum crankcases (connected with 10 bolts);

- primary and secondary shafts (connected to the crankshaft and cardan shaft);

- an intermediate shaft with cut teeth of the 1st gear and reverse gear, a pressed gear block and a gear wheel of the speedometer drive;

- inertial synchronizers;

- spring balls for gear fixing;

- blocking the inclusion of gears at the same time;

- a damper lever device;

Interesting! The oil drain plug in the crankcase with a magnet retains metal fragments.

The Gazelle gearbox device allows you to react in time to the first symptoms in order to prevent more serious consequences.

Interesting! The oil drain plug in the crankcase with a magnet retains metal fragments.

The Gazelle gearbox device allows you to react in time to the first symptoms in order to prevent more serious consequences.

When a gearbox repair is needed

The signal for urgent repair of the Gazelle gearbox is:

- Inability to change gear or if it is difficult to do so.

- When you try to turn on the gear while driving, a loud crack is heard.

- Self-inclusion of the transfer (threatens the danger of an accident).

- Any extraneous noise, crunching, tapping at the checkpoint.

- Scheduled diagnostics of the Gazelle checkpoint should be carried out every 300,000 km.

The main malfunctions of the gearbox on GAZ 3307 cars

Long-term operation of Gazelle cars made it possible to make a list of the main faults of the Gazelle gearbox and their possible reasons:

- Cause of humming noise during operation- destruction of worn parts or loosening of fastening bolts;

- Crunch at the checkpoint- destruction of bearings;

- Crackle when switching- the synchronizer rings are worn out;

- Difficulty shifting speeds- jamming in the gearbox drive, wear of gears, burrs, etc. (you need to disassemble and look);

- Self-switching off speeds- misalignment of gear teeth, wear of rods and forks, loosening of gearbox and driven shaft fasteners;

- Oil loss- a crack in the crankcases, loosening of fasteners, wear of the gasket, oil seal, etc.

How to repair a Gazelle checkpoint

A breakdown is found, the reasons are clarified - it remains to start repairing. To do this, it is necessary to remove and disassemble the checkpoint.

Essential tool for removing and disassembling the box

For repairs, you will need a viewing hole or overpass, as well as tools:

- a set of keys (for 10, 12, 13, 14, 17, 19);

- screwdriwer set;

- beard;

- wooden blocks;

- pliers (pliers);

- mount;

- pullers;

- hammer;

- file, sandpaper;

- brass lining or copper hammer;

- mandrel for old oil seals.

- container for draining oil;

- rags;

- SHRUS-4, gear oil, GOI paste.

Step by step instructions on how to remove the box

When repairing a Gazelle checkpoint with your own hands, first of all, you need to drive the car onto an overpass or inspection pit. After that, proceed to remove the box:

Step 1- free the crankcase from oil;

Step 2- remove the gimbal:

- use a file to mark the position cardan joint and gearbox extension, as well as cardan flanges and rear axle;

- using keys 12 and 13, remove the fasteners of the intermediate support;

- using keys 14 and 17, remove the cardan fasteners to the flange of the main gear drive gear;

- remove the shank from the gearbox (pull it back and pull it out);

- Plug the hole with a rag.

- from inside the cab, remove the cover and the upper part of the lever;

- unclench the spacer sleeve, remove the rubber pad and locking sleeve;

- remove the floor seal and the protective cover, unscrew the cover and remove the lever.

Step 5- remove the checkpoint:

- unscrew the fasteners of the intake pipes and the bracket to the gearbox (keys 12 and 14);

- disconnect the gearbox from the clutch housing (4 nuts);

- protect the block head with a wooden block;

- remove the cross member of the gearbox mounting and shaking, giving back the box itself.

Important! The weight The checkpoint is 32 kg - be careful and try not to miss it!

Disassembly and assembly of the Gazelle gearbox

Troubleshooting requires overhauling the Gazelle gearbox. Disassembly of the checkpoint must be done in stages:

- Remove the bearing cover, change the oil seal (key 12, screwdriver, mandrel).

- Remove the reversing axle bushing fasteners (spanner 13).

- Remove the input shaft bearing circlip (thin screwdriver).

- Remove breather.

- Disconnect the crankcases (12 wrench, hammer and brass mandrel).

- Engage reverse gear (by turning the input shaft).

- Remove the gear fork mount (spanner 10).

- Remove the lever bodies and the plate with the gasket (key 12).

- Remove the springs and balls (3 each) of the retainers (magnetic screwdriver).

- Remove the rods in order - 1, 2, 5, reverse, 3 and 4 gears and the locking pin.

- Using a wrench 13, unscrew the fastening of the reverse gear axle and remove the circlip of the rear bearing of the output shaft.

- Remove the shafts (using a copper hammer) and disassemble them. When disassembling, carefully lay out the parts in order, mark their relative position.

Assembling the Gazelle gearbox after repair is carried out in the reverse order. The shafts should be installed at the same time (tie with twine). Before assembly, you should carefully inspect the crankcase (for cracks, notches, bumps). Wash all parts (in kerosene, diesel fuel), inspect (bearings, shafts, gaskets, gear teeth, etc.). Any traces of corrosion, grind the faces. Replace all broken or suspicious parts with new ones, lubricate transmission oil, SHRUS-4 (cuffs, splines, etc.). Treat the crankcase fasteners with sealant. Do-it-yourself Gazelle gearbox bearings should be replaced every 100,000 km.

Installing the gearbox The gearbox is installed in the reverse order. The slots must be lubricated with SHRUS-4. Next, a cardan is placed (you need to make sure that the marks match). After installing the gearbox, pour in 1.2 liters. oil into the crankcase (up to the filler hole). As you have seen, the work on the checkpoint repair is large and preparation for it must be serious.

Subscribe to our feeds in

If you have leaking oil seals from the Gazelle checkpoint, do not ring the bells. In this article, we will tell you step by step how to repair the Gazelle checkpoint with your own hands.

Repairing a Gazelle checkpoint is an easy procedure and it is much cheaper to do it yourself than to repair it at a service station. To do this, you will need to acquire some parts and tools, read our DIY gearbox repair instructions and learn how to disassemble the gearbox.

How to disassemble the checkpoint

In order to cope with this process you will need a set of keys and a screwdriver. Dismantling and repairing the Gazelle gearbox with your own hands consists in completely draining the oil, unscrewing the bolts, carefully removing the cover without damaging the gasket.

You will also need to remove the elastic clutch and the gearshift mechanism itself. Then remove the back cover and unscrew all the gears, pull out the bearing and the clutch fork. Next, you need to knock the clutch housing and block the intermediate shaft. You will need to unscrew a bunch of balls and springs. And using an impact screwdriver, unscrew all the remaining screws and completely disassemble the box. This process, as you can see, requires experience and knowledge. But to replace the oil seals, fortunately you need to go a little less way.

Tools

- Socket wrench for 30;

- screwdriver;

- mount;

- container for draining;

- key for 17;

- hammer;

- mandrel for old oil seals.

You will also need to purchase a drive oil seal, but first make sure which one you need, left or right. How do they differ from each other:

- different direction of the arrows on the inside;

- different numbers at the ends of catalog numbers;

- different color of the product.

Instructions

Done, do-it-yourself Gazelle gearbox repair done.

We wish you a smooth and trouble-free ride! Remember that many problems can be solved on their own without resorting to service centers and expensive procedures. Everything can be learned even the first time.

Video "Removing the box"

Watch the video on our website on how to properly remove a gearbox in a garage.

We tried to bring to you in more detail information on how to properly replace the oil seal, in return for this we expect warm words from you in our comments.