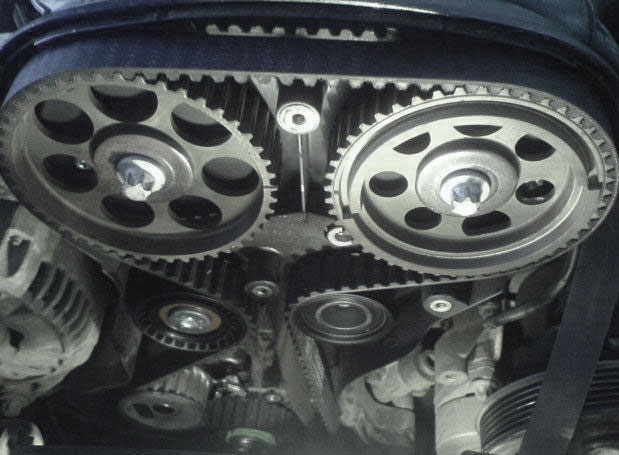

Timing belts are an important part of the car, which help to synchronize the operation of the two main shafts of the engine: the crankshaft and the camshaft. Meshing with the driving and driven pulleys on the shafts is carried out due to grooves (less often due to the action of frictional force) located on the inner side of the belt. Cord-cloth or cord-cord rubber with various modifications of the composition or surface layer to increase wear resistance and reduce noise from operation is used as a material of manufacture.

As with all areas of the auto parts and components market, there is a lot of competition among manufacturers in the timing belt category. Most of them are distinguished by very mediocre manufacturing technology, which negatively affects the quality of the final product. Through careful analysis of user reviews, leading experts' opinions and experiments carried out by reputable experts, we have selected for you six of the best manufacturers of timing belts. All applicants presented in the rating are worthy of your priority attention.

unique templates and modules for dleThe best timing belts in the middle price segment

3 Lemforder

One of the best auto parts manufacturers

Country: Germany

Average price: 1000 rubles.

Rating (2017): 4.7

One of the five companies of the German concern ZF, engaged in the production of a wide range of auto parts, including timing belts. The market coverage is wide: in addition to the quite understandable support of the German car industry, among the belts from Lemforder, you can find models for Korean (Hyundai, Kia), Japanese (Toyota, Honda), American (Ford, Chevrolet) , as well as Russian (VAZ) cars.

Regarding the company, only one fact is alarming: the once strong brand has recently (according to the assurances of professionals and experts of the car market) surrendered its positions and has become nothing more than a packer for other manufacturers. Fortunately, under the Lemforder logo, most often there are either Korean or German (from brothers in the concern BOGE and Sachs) spare parts, the quality of which meets high standards.

Advantages:

- timing belts available for various price categories;

- large assortment of goods;

- high quality products under the company logo.

Disadvantages:

- goods from other manufacturers appear more and more often under the company logo.

2 Bosch

The optimum ratio of price and quality

Country: Germany

Average price: 800 rubles.

Rating (2017): 4.9

An old German company founded in 1886 in a place called Gerlingen. We all know Bosch as one of the best manufacturers of household, construction and garden equipment, but only a few know that the company is equally successful in the production of auto parts and components, including timing belts.

Most consumers speak of their products complementary - the cost of belts is relatively low, and the quality with moderate use is excellent. Of course, they cannot withstand large overloads, but not all products from renowned manufacturers can boast of this.

Advantages:

- a large number of supported car models;

- low counterfeitability of goods;

- high quality products (with moderate use);

- low cost.

Disadvantages:

- when installing a new kit, a slight lapping of the belt to the profile of the pulleys is required.

1 Balakovo

The best domestic manufacturer of timing belts

Country Russia

Average price: 500 rubles.

Rating (2017): 4.9

The only representative of the cohort of the best manufacturers of timing belts from the Russian side. The secret of success is simple and unobtrusive: the Balakovo plant is exclusively engaged in the production of rubber technical products. Accordingly, if the efforts of not one department, but an entire shop and even a plant are thrown into the solution of one big task, then success should come immediately.

If we talk about the quality of belts, then it is practically in no way inferior to foreign counterparts. Belt wear with adequate use vehicle comes around the guaranteed mileage (sometimes the belt runs longer). The range covers a wide the lineup cars: this includes the entire B1 platform from the Renault-Nissan concern, available to domestic users, as well as VAZ cars (Grant, Priora, Kalina, etc.).

Advantages:

- assortment covering the range of Russian cars;

- high quality even by high European standards;

- good reviews from specialists based on the results of functional tests;

- low cost.

Disadvantages:

- there are no visible flaws.

The best premium timing belts

3 Dayco

Best price. Most underrated brand

Country: USA

Average price: 1 750 rubles.

Rating (2017): 4.9

An old American manufacturer of timing belts for engines internal combustion, which also specializes in the production of tensioners, dampers, water pumps and hoses (at an average level). For domestic users, Dayco is something distant and little-known, so skepticism about the purchase is an integral part of the company's trade policy.

Unlike competitors, the supply of spare parts to the primary (factories) and secondary markets are approximately equal to each other. Unfortunately, in Russia counterfeit belts are very common, therefore, on the vastness of the world wide web, you can find a lot of negative reviews. In connection with this state of affairs, American belts are significantly inferior in popularity to German spare parts from Contitech.

Advantages:

- the cost level is approaching the middle segment;

- patented technology of covering the belt profile with Teflon compound to increase wear resistance and reduce operating noise;

- there are belts for VAZ cars: "Priora", "Kalina", "Grant" and earlier models.

Disadvantages:

- there are many fakes in the domestic market - belts fail after a short run.

2 Contitech

Best quality

Country: Germany

Average price: 2,400 rubles.

Rating (2017): 5.0

Contitech is an offshoot of Continental that manufactures rubber suspension components, timing belts for internal combustion engines, and other automotive parts and components. Like the leader of the rating, the Gates company, Kontitek cooperates directly with automobile factories, however, find their products on secondary market much easier, although the cost will be quite high.

As for the reliability and overall quality, there are no complaints about the German company regarding these components - the belts run for a long time, sometimes even deliberately more than the declared value. There are no visible problems, however, when installing belts from this manufacturer, it often takes time for the final correct fit into the profile of the driving and driven pulleys.

Advantages:

- high quality products from a leading manufacturer of car tires;

- increased service life due to periodic improvement of component wear resistance.

Disadvantages:

- some belts require lapping along the groove profile.

1 Gates

The most famous manufacturer of timing belts

Country: Belgium

Average price: 3,000 rubles

Rating (2017): 5.0

Perhaps the most famous manufacturer of belts for internal combustion engines. The Belgian concern covers not only the automotive industry: Gates are involved in the computer, and in the agricultural, and even in the metallurgical industry.

As for the timing belts specifically, they are very difficult to find in the secondary market. The fact is that Gates, on the rights best manufacturer, conducts direct cooperation with leading automotive concerns, and supplies only a small part of its products to the spare parts market. Therefore, components can be ordered either directly from the factory or through the service center. The cost is high, however, it is fully consistent with the inherent quality.

Advantages:

- the most famous manufacturer of timing belts;

- the highest quality products;

- cooperation directly with car manufacturing plants.

Disadvantages:

- high price.

How to choose a reliable timing belt

Choosing a timing belt is similar to choosing auto parts in general, but with one small caveat. Be sure to pay attention to the following aspects before purchasing:

Price. The main and obvious indicator, "litmus test" for determining a fake. To identify the original belt, you should study the offers from several distributors - a sharp price difference in the direction of reduction in price directly indicates an attempt to sell a counterfeit product from hands.

Brand. The second important parameter, which, nevertheless, cannot guarantee 100% originality of the product. The skill of the current counterfeiters has gone far ahead, however, the acquisition of products of a well-known brand in most cases avoids problems with the further operation of the belt.

Differentiated numerical designation. A branded product is cut from a large blank, the marking of which contains a differentiated digital designation. If absolutely all the numbers are repeated on the finished belt, then with a high degree of probability this is not the original.

No mechanical damage. When the purchase question has already been practically resolved, it remains to be convinced of the external integrity of the product. Check the product for tears, cuts and wear of the inner part, as any defect can lead to an early failure of the belt.

The presence of the original hologram and the corresponding certificate. To protect products from falsification, many companies resort to quality certification and placing a special hologram on the box (less often on the product itself). Make sure you have this mark and be sure to ask for a certificate accompanying the product before making your final choice in favor of one or another option.

It is not uncommon for a VAZ 2110 car to whistle in the V-belt connection of the generator. For this reason, it is required to tighten or completely replace it. Today we will tell you in detail about the tightening procedure, as well as tell you how it changes.

Why there is a whistle

There are several reasons for the characteristic whistle-like sound.

- Weak tension. The element slips, and this occurs most actively in dark time days. The increased intensity of whistling at night is explained by the fact that the generator additionally works for lighting.

- The component is gradually destroyed. The belt can dry out, due to which its structure is disturbed, it literally crumbles into pieces. The first signs are cracks, and then whole pieces break off. When driving, the pulley touches, slipping begins. Only replacement is required here.

- Although moisture rarely hits the belt and evaporates almost immediately, the connection can still whistle. In this situation, tension is required.

- The generator itself wedges.

Dimensions (edit)

It is quite possible that for your 16 valve VAZ 2110 you selected the wrong size of the alternator belt. This is often the cause of whistling. The correct size of the alternator belt for the 8-valve VAZ 2110 should be determined in advance, even before going to the auto parts store.

Sizes are different, and they are individual for each VAZ model.

Speaking specifically about the "top ten", then here adhere to the following rules for choosing the size of the belt:

- In the absence of an air conditioner and a hydraulic booster, it will fit 742 millimeters;

- If the car provides for the presence of a hydraulic booster, then the size will be 1115 millimeters;

- If an air conditioner is also present, then optimal size- 1125 mm.

Some craftsmen regularly use to replace their own belts from other AvtoVAZ models - Priora and Kalina when repairing their "ten".

Performing tension

If there is no wear on the V-belt drive, but there is a whistling sound, first of all, check the tension level. We will not use complex terminology, but simply advise you to press with some effort on the belt in the middle.

If the tension is correct, then the belt will bend by no more than 8 millimeters. If the deflection is greater, then the element will have to be pulled, and if it practically does not bend, the tension will have to be loosened.

The whistle is not the problem. Because of weak tension the battery is not charged efficiently, and the drive itself begins to wear out faster. Excessive tension can damage the alternator bearings and stretch the belt.

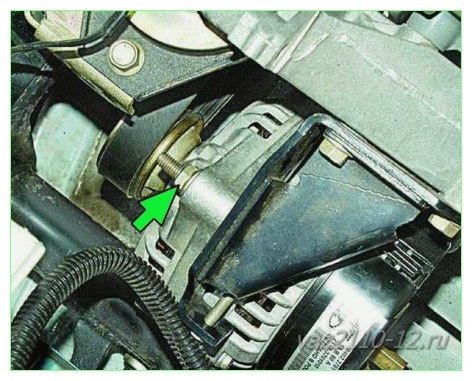

The correct tension of the VAZ 2110 alternator belt is performed as follows:

- Loosen the generator mounting from the bottom and top. A nut is used for this;

- Turn the adjusting bolt and adjust the belt;

- If you want to make the tension more, the bolt turns to the right. Thus, you move the generator away from the cylinder block;

- To loosen the tension, move in the opposite direction - to the left;

- Using a wrench, grab the mounting bolt and turn the crankshaft a couple of turns, then check the tension;

- If all is well, the tension is correct, the nut can be tightened back.

We have already figured out how to tighten the alternator belt. But such measures are not always relevant. If the element is cracked, overstretched and no longer stretched, then there is no choice but to replace it with a new one.

In fact, the replacement cannot be called a complex procedure. Follow the instructions and you will succeed.

- Slightly loosen the nut of the bolt from the lower mounting of the car generator, as well as the tension nut.

- Loosen the very tension of your belt additionally. How to do this - you already know from the previous section, where we talked about tensioning the alternator belt.

- Move the generator to the side power unit to remove the belt from the pulleys crankshaft and a generator.

- The next step is to install the new item. To do this, you need a quality belt purchased from a trusted store. What exactly this part will be, and what size is not difficult to determine. But quality comes first.

- First, the belt is put on the crankshaft pulley.

- Now it goes to the alternator pulley.

- The last step is to repeat the tension adjustment procedure. You already know perfectly well how this procedure is carried out, so problems should not arise.

As practice shows, many experienced drivers of the VAZ 2110, who have been driving this particular model for many years now, carry an additional alternator belt with them in the trunk.

This is due to the fact that its breakage can occur at the most inopportune moment. This node cannot be called the most weak point"Tens", however, problems may arise with it. And it is better for you to be prepared for such a situation.

Otherwise, you will have to call a tow truck, go to the nearest station Maintenance paying big money for the services of craftsmen. Although, if you had a spare alternator belt and a standard set of tools, if it broke, you would have spent literally a couple of tens of minutes and calmly continued driving with a new belt. Therefore, the choice is always yours!

On engines that are equipped with a timing belt drive, this is a mandatory routine. Constant monitoring of the condition of the drive belt and its timely replacement are necessary due to the fact that a broken belt often leads to serious and expensive motor repairs.

In the event that a break occurs, the gas distribution mechanism stops, they do not have time to close. As a result, those moving by inertia hit the open valves, defects appear on the pistons themselves, etc.

In view of the above, it becomes clear that the choice of timing belts must be approached with the utmost responsibility and caution, since not only stability will directly depend on the quality, strength and overall reliability of the product. ICE operation, but also its serviceability.

In this article, we will look at how to choose a timing belt, when choosing a timing belt which company is better to buy, as well as what features and nuances should be paid attention to when buying.

Why, when and which belts are better to put: timing and belt drive features

Let's start right away with when to change the timing belt. The timing belt replacement interval is, on average, 60 thousand km. It is important to understand, however, that many additional factors affect the life of a product.

In some manuals for some vehicles, you can find instructions when the belt is proposed to be replaced after 70-80 thousand km, while for other cars the replacement is clearly prescribed already for 50-60 thousand. belt based on average. Hence, it turns out that such an indicator can be considered a mark of 50 or a maximum of 60 thousand km.

Let's go further. Before answering the question of which company to choose a timing belt and which best brand timing belt, let's focus on the problems associated with this element and its operation. It should be remembered that not only driving depends on the timing belt, but also precise synchronization with the work cycles.

In other words, the intake and exhaust valves must open and close at well-defined times, which will correspond to the strokes of intake, compression, piston stroke and subsequent exhaust from the cylinder. In this case, any belt displacement, insufficient belt tension, slippage and other deviations from the norm can lead to serious malfunctions in the operation of the power unit.

Experts identify a number of reasons why problems may arise:

- Excessive or weak timing belt tension. In the first case, the problems are associated with improper installation, and the belt itself is quickly stretched. In such conditions, rollers, bearings of the drive of the gas distribution mechanism and other elements (for example,) are also subject to increased wear.

If the timing belt is not tensioned enough, then the resource of the product is reduced, and it may also slip on the pulleys. Displacement even by one "tooth" leads to engine malfunctions or ICE breakdowns. To prevent possible consequences, it is recommended to carry out a tension control closer to the middle of the total belt life. In cases where the timing belt is loose, it must be tightened or replaced.

- The belt was replaced with a new one, but the timing rollers were not changed. This situation common and associated with the desire of owners to save money. Remember, the timing belt should be changed according to the mileage. If it is time to replace the belt, then the replacement is carried out together with the rollers, and regardless of the general condition of these elements.

As practice shows, the rollers may not make noise and rotate normally when checked, while after a short interval they may still jam. As a result, the belt breaks with all the ensuing consequences.

An exception can only be considered a forced belt replacement under the influence of certain factors. These include: the ingress of oil and technical fluids on the belt, delamination and cracking, mechanical damage, etc. In simple words, if the rollers with the belt have changed not so long ago, but then the belt is quickly damaged, then you can limit yourself to replacing only the belt.

In this case, it should be taken into account separately that the declared service life of a new belt will no longer correspond to the total resource of the rollers. For example, if the total service life of a new set of belt and rollers is 50 thousand km, but the belt is out of order after 20 thousand km, then after installing a new belt, it is optimal to subtract 20 thousand km that the rollers have already passed.

It turns out that the next replacement of the installed belt along with the rollers is better done after 30, and not after 50 thousand km. In this case, the main task is the need to avoid jamming of the rollers, which leads to the breakage of the drive belt.

- The car is constantly operated at high temperatures. As you know, the timing belt is a rubber product. In regions with constant high temperatures, such products tend to dry out quickly, lose elasticity, and crack.

The belt manufacturers themselves separately indicate the need to reduce the replacement intervals (by at least 20-30%) for vehicles that are in similar conditions. We also add that any defects in the timing belt protective cover mean that dirt gets on the belt in the engine compartment, possibly getting into engine oil and other technical fluids (depending on the general condition and breakdowns of the internal combustion engine). In this case, the planned resource of the product is significantly reduced.

The best timing belt manufacturers

So, having figured out the features and nuances of operating / replacing belts, you can go to the intricacies of their selection. Products of both domestic and foreign manufacturers are presented on the market today.

The entire list is wide enough, so let's focus on the most popular solutions. If we talk about what best belts The timing belt, the firms Gates, Contitech, Dayco and Bosch are the most respected and popular in this segment.

- The undisputed leader, which is always heard, is the manufacturer Gates. This company from Belgium specializes in the manufacture of drive belts for internal combustion engines and various specialized equipment. We add that the manufacturer supplies its products directly to the conveyors of many of the largest auto giants.

- The German firm Contitech is also on the list of the largest manufacturers, whose products are put on new cars during assembly. In parallel, the company manufactures drive mechanisms, air suspension elements, and other automotive parts.

- Dayco is an Italian firm. The company specializes in the manufacture of drive belts, rollers, bearings and other elements of drive mechanisms. The Bosch company from Germany, widely known among motorists, also offers high-quality timing belts in the range of a huge number of auto parts.

Which timing belt is better to buy

If speak about the right choice a new belt to replace, then there are several options.

- The most expensive, but at the same time the safest, purchase of a product in an official service, and the subsequent installation is usually done in the same place. Let's see why this is so.

As a rule, the "officials" products in the catalogs can be indicated under the brand of the automaker, and not the manufacturer of the belts itself. This also applies to many other spare parts, and such parts themselves are called original.

In other words, for example, the original branded timing belt for Opel / Chevrolet cars is offered under the GM brand with its catalog number... At the same time, these products are not manufactured by General Motors itself; the well-known company Gates supplies belts for GM.

At the same time, the cost of the original GM belt at the officials turns out to be, on average, 40-50% or more, and in retail it is 20-30% higher compared to the exact same belt, but already under the Gates brand. It turns out that such a belt is cheaper and in no way inferior in quality to an unoriginal analogue.

In view of the above, it becomes clear why, after removing the old belt for the first replacement, it turns out that the car has products with the Gates or Contitech markings directly from the factory, although the original spare part is designated in the catalogs as GM, AUDI, Volkswagen, etc.

For the sake of fairness, we add that there are different opinions on this matter, since many drivers argue about the difference in the quality of the original and not original spare parts... The main argument is that manufacturers allegedly supply the best products to conveyors, and products with reduced quality are sold at a lower price under their own brand.

- One way or another, but this information allows you to choose a second and more affordable way to select a belt. If the car was originally equipped with Gates or Contitech products, or you know exactly which manufacturers supply their belts to the manufacturer of your car, then there is no need to buy an original belt.

It will be quite enough to replace it with exactly the same high-quality analogue of one or another company supplying spare parts to the plant. As practice shows, such products serve no worse than the original.

- You can also not adhere to the rules at all, immediately opting for the appropriate option. In this case, in all cases, you need to be especially careful of counterfeits. And this is an essential and indisputable disadvantage of both the second and third methods.

Genuine quality belts from Contitech, Gates, Bosch or Dayco are reliable products that perform equally well with their tasks and confidently fulfill their declared resource (provided correct installation and compliance with other requirements for the maintenance and operation of the vehicle).

A few words about fake timing belts

Given the popularity of well-known brands, there are a large number of counterfeit products on the market. At the same time, the visual quality of the belt itself and packaging can be at a high level (print clarity, serial numbers, holographic stickers, etc.).

Moreover, even the sellers themselves (especially small entrepreneurs in car markets or novice dealers with no experience) can be firmly convinced that they are selling original goods and praising it in every possible way.

For example, consider the situation with Gates. We are talking about reinforced belts that have an increased resource (as the manufacturer himself assures, up to three times more than other manufacturers). The advertising brochures specifically indicated that instead of neoprene (chloroprene or CR), which is the basis for the production of many rubber products, the company uses nitrile (HSN, HNBR).

Taking into account the fact that there are rather high temperatures in the engine compartment, the nitrile belts remain elastic, do not crack as a result of a constant temperature drop (heating and cooling of the internal combustion engine in winter). Also, nitrile timing belts are not highly sensitive to the effects of engine oil and other technical fluids on them.

Thanks to these features, the manufacturer is able to give an extended warranty, which covers the entire declared service life of the belt (subject to correct installation and tension). However, fakes that are visually similar to the original can be made from cheaper neoprene, with all the ensuing consequences.

The buyer himself thinks that he has acquired a branded analogue, after which complaints begin about the quality of a particular brand in case of problems. As for the "officials" and original spare parts in their network, as a rule, counterfeits are much less common there.

What is the bottom line

If you take into account all the nuances described above, then you will not be able to unequivocally and reasonably answer which timing belts are the best and most reliable. As for the drivers themselves, in terms of the number of sales in the CIS countries, Gates and Contitech are in the lead, followed by Dayco and Bosch.

The main rule is that the best option will be the installation of either the original belt, which is installed on the car from the factory, or a high-quality analogue. In the latter case, it is necessary to separately verify that the product is a branded product.

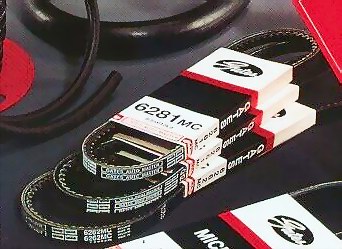

Alternator belts are devices that transmit the rotation of the internal combustion engine to its auxiliary units. Some devices are capable of driving several mechanisms at once. This part can affect the pump, hydraulic pump, various compressors and even a generator. In order for all of the above mechanisms to work smoothly and smoothly, it is necessary to replace the part in a timely manner, and, if necessary, adjust its tension. In today's article we will look at what alternator belts are. And also we will find out what their features are.

Today, alternator belts are divided into several types:

- wide;

- drive belts of normal section;

- fan.

Each of these parts is selected depending on the specific make and model of the car. For example, a Ford -

Transit "cannot be put on" Fiat-Ducato ", that is, each model has its own device. To the side this mechanism not so much worn out, many manufacturers include nylon and cotton in their composition. These two components are included in the outer coating of the part. Cogwheels transmit force using transverse teeth and a drive mechanism, which allows them to maintain a given shaft position. During operation, such systems do not require regular lubrication, moreover, they almost never vibrate or stretch.

With the development of technology, multi-ribbed alternator belts began to be used on cars. Such products are capable of operating a variety of mechanisms, including a hydraulic booster and These parts consist of several belts connected to each other. Such products are intended, as a rule, for powerful generators. The multi-strand device, due to its special design, has an increased service life and is more reliable than gear counterparts.

In addition, generators are widely used. They serve to accurately match the speeds of rotation of all mechanisms and devices. Motorists attach particular importance to double-sided wedge products. Such a Renault alternator belt has the best drive characteristics. There are also poly-V-ribbed products. Their composition is special in its own way. They have flat teeth on the upper base.

How long does it take to replace this part?

As a rule, the service life of the belt ranges from 50 to 60 thousand kilometers, depending on the type of machine. However, one should not assume that in this period of time this device will uninterruptedly provide reliable operation and rotation of all necessary devices. After several thousand kilometers, the car belt may loosen, therefore, from time to time, this mechanism should be adjusted and its current condition should be checked monthly.

Maintaining the appropriate voltage in the vehicle's on-board network during operation power plant lies on one of the elements of the electrical equipment of the auto - generator. The generator is the same electric motor direct current which works the other way around. If the engine rotates the rotor due to the supply of electricity to it, then the generator generates electricity from the rotational motion of the rotor. For the generator to generate energy that will supply on-board network auto, you need its rotor to rotate.

The design solution for ensuring the rotation of the rotor of the generator, as a result of which it generates electricity, was the drive from the crankshaft, since it rotates constantly from moment to stop.

The generator is driven by a belt drive. On crankshaft pulleys are installed on the rotor of the generator, in the grooves of which the belt is placed.

Two types of belts are used to drive the generator.

- The first type of drive belt is a conventional V-belt. Often this type of belt is used on cars that were produced earlier. These belts are used on cars where the drive was made only to the generator. The disadvantage of such a belt is the high probability of slippage.

Alternator V-belt

One of the variants of the V-belt, which replaced the usual one, is a toothed belt. The toothed belt also has a wedge-shaped profile, but it has teeth on the inside. These teeth provide improved power transmission and less slippage. However, it is also used on cars in which the drive from the pulley is performed only on the generator.

Cogged Alternator Belt

The high flexibility of this belt allows it to be used to drive a generator, as well as other attachments to the engine - a hydraulic booster, a liquid pump, etc.

All types of belts are made according to the same principle - the main material of the belt is special rubber, inside which 2-4 layers of reinforcing strong thread are placed.

Major problems with the alternator belt

Insofar as drive belt Since the generator is flexible, the main problems with it are breakage, severe wear, stratification and subsidence.

Belt breakage is rare, since significant effort is needed to break the reinforcing threads. It can only occur when one of the elements driven by the belt is jammed. For example, due to the destruction of the generator bearing, the rotor may jam, followed by a rupture of the belt.

Strong wear occurs over time, because the belt surfaces rub against the surface of the pulleys during the transfer of force. As a result, the profile of the belt decreases, it slips more and more, its transmission force drops and the generator ceases to deliver the required energy.

Broken car alternator belt

Belt delamination is often caused by damaged pulleys. Violation of the pulley geometry leads to the fact that on one side the belt wears out intensively, the reinforced thread extends beyond the edges of the rubber material, as a result, the belt is gradually divided into component parts. Delamination can also occur due to poor-quality manufacturing material.

Car Alternator Belt Bundle

Belt sagging also occurs over time due to wear. As the belt is worn out, its diameter increases, the belt tension weakens and slippage appears. Also, subsidence can be caused by poor-quality manufacturing material. Hit fuels and lubricants on the surface of the belt often leads to a change in the physical parameters of the rubber, because of which the belt can also sag.

The main sign of problems with the alternator drive belt is the appearance of third-party noises, in particular, squeaks and high-pitched squeals. Squealing is usually caused by belt slippage in relation to the pulley, which is often caused by excessive belt wear or sagging.

In a car where a tension roller is used to tighten the belt, the appearance of a squeal may indicate, in addition to belt wear, also a strong wear of the roller bearing.

A short squeal of the belt in winter indicates poor quality material. Such a belt at subzero temperatures significantly loses its elasticity, which leads to intense wear until the belt warms up. Such a belt will not last long.

Checking the condition of the alternator belt

The average belt resource is 50-60 thousand km. But the duration of its operation largely depends on the operating conditions and the quality of the belt itself.

Determination of the condition and level of wear of the belt depends on design features car. But this definition boils down to a visual inspection of the belt.

First, the belt tension is checked. The belt in normal condition should not sag when pressed at a certain distance specified in the technical documentation for the car.

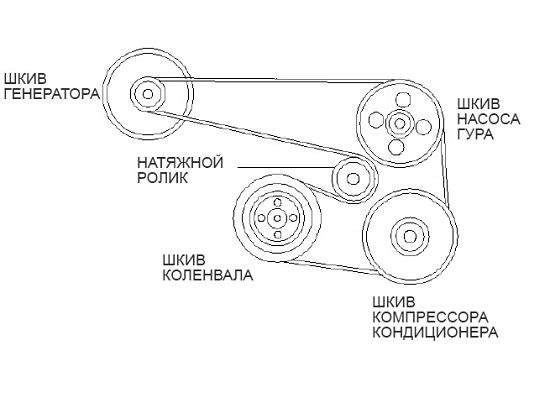

Alternator belt layout

Squealing can be eliminated by further tightening the belt tension. However, if there is nowhere to pull the belt, then it is strong.

If it is found that the belt is badly worn,. Before performing this operation, you need to purchase a new belt. Moreover, you need to select a belt according to the car model, as well as the type of belt. The V-belt will not be able to replace the multi-belt and vice versa.

Replacement for VAZ-2108

Consider how the replacement for different cars... To begin with, let's take a VAZ-2108 car, which uses a simple or toothed V-belt.

In this car, the belt drives only the generator and it is easy to replace it. You only need a 17 key, as well as a pry bar.

Video: Replacing the alternator belt VAZ 2108

First, you need to remove the used belt, for which the fastening nut at the bottom and the nut holding the generator on the tensioner are loosened. After loosening, the generator is fed to the engine, the heavily loosened belt is removed from the pulleys. A new one is installed in its place, the generator is pulled from the engine by the mount, thereby tensioning the belt. While holding the tension with the pry bar, the nut on the tensioner tightens. After that, the generator mounting nut is also tightened. After replacement, a check is performed. If no extraneous sounds are heard from the side of the belt when the engine is running, the replacement was successful. If a squeal appears, the belt is re-tensioned.

Replacing the alternator belt for Toyota Camry

Next, consider how the replacement is made by Toyota car Camry. This car uses a poly V-belt. However, it is also used to drive a compressor and a liquid pump. A special tensioner is used to tighten this belt.

If you make a replacement according to all the rules, then you will need to remove the right wheel, lining and engine protection to access the tensioner.