DEVICE FEATURES

The heating, air conditioning and ventilation system is a single complex that provides maximum comfortable conditions inside the car, regardless of weather conditions and driving conditions. The system includes a heater (increases the air temperature in any mode of operation of the system), an air conditioner (reduces the temperature and humidity of the air), an air blower (fan) and air ducts with a filter (provide air exchange in the cabin, clean the air from dust), as well as a control unit ( controls all elements of the system to obtain the specified comfort parameters).

FEATURES OF THE HEATING SYSTEM

The vehicle is equipped with a liquid-type interior heater.

The heater radiator is connected to the engine cooling system by two hoses running in the engine compartment. The radiator is placed in a plastic casing of the climate unit, installed under the central part of the instrument panel.

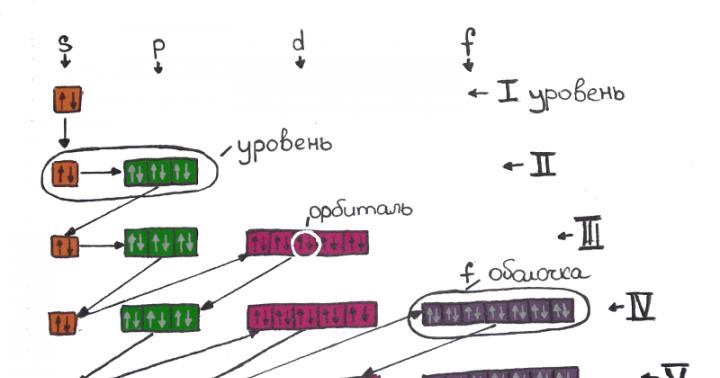

Main heater components (Fig. 12.1):

Heat exchanger (radiator) 6 of the heater, designed to heat the air entering the passenger compartment with the heat of the engine cooling liquid;

Fan (air blower) 11. Electric motor 12 of the fan excited by permanent magnets, providing

Rice. 12.1. Schematic diagram movement of air flows in the ventilation, heating and air conditioning system: 1 - windshield blower deflectors; 2 - air flow distribution flaps to the windshield deflectors and instrument panel deflectors; 3 - instrument panel deflectors; 4 - air ducts for heating the driver’s and passengers’ foot zones; 5 - damper for distributing air flow to the instrument panel deflectors and heating air ducts for the driver and passengers’ footwells; 6 - heater radiator; 7 - salon air filter; 8 - damper of the air recirculation system; 9 - air supply box; 10 - air intake in the car interior; 11 - fan impeller; 12 - fan electric motor;

13 - air conditioner evaporator; 14 - drainage hole for draining condensate; 15 - temperature regulator damper; 16 - housing of the heating and air conditioning system Rice. 12.2. Schematic diagram of the movement of refrigerant in the air conditioning system: 1 - combined pressure sensor; 2 - high pressure pipeline section; 3 - receiver-dryer; 4 - service valve of the high pressure line; 5 - condenser (air conditioner radiator); b - fan of the condenser and radiator of the cooling system; 7 - air conditioning compressor; 8 - pipeline section

|

|

low pressure

; 9 - service valve of the low pressure line; 10 - heater fan; 11 - evaporator;

12 - thermostatic valve

Rice. 12.3. Air conditioning compressor: 1 - pressure disk; 2 - drive pulley; 3 - front housing cover; 4 - electrical connector block for the electromagnet coil; 5 - low pressure pipeline fastening flange; 6 - valve block cover; 7 - flange for fastening the high pressure pipeline;

8 - fastening eye; 9 - pump housing; 10 - filler plug; 11 - pressure disk damper (2009+). adjustable supply of outside air to the heater and air conditioner dampers;

Damper 15 of the air temperature regulator coming from the heater into the passenger compartment. The amount of air passing through the heat exchanger of the heater, and the outside air passing bypassing the heat exchanger, depends on the change in its position;

Dampers 2 for distributing air coming from the heater through air ducts into the passenger compartment or for blowing the windshield.

|

|

Kia Ceed FEATURES OF THE AIR CONDITIONING SYSTEM Kia Cee "d vehicles are equipped with a compressor-type air conditioning system. The heater components and the air conditioner evaporator heat exchanger are arranged in one unit. The air conditioning system controls are located on a panel common with the heater controls.

The compressor (Fig. 12.3) circulates the refrigerant in the system. The compressor shaft is mounted in the aluminum front housing cover on bearings and sealed on the drive pulley side with an oil seal.

The compressor drive pulley is mounted on a double-row ball bearing and rotates constantly when the engine is running. When the air conditioner is turned on, torque is transmitted from the pulley to the compressor shaft through a friction clutch with an electromagnetic drive.

NOTES

If the system is working properly, when the air conditioner is turned on, a click is heard - this is the clutch pressure plate, under the action of an electromagnet, engages with the drive pulley, and the compressor rotor begins to rotate.

Rice. 12.4. Air conditioner condenser: 1 - receiver; 2.4 - condenser tanks; 3 - honeycombs; 5 - flanges for fastening pipelines; 6, 7 - mounting brackets

But during operation of the air conditioner, the following compressor malfunctions may occur.

1. If, when the air conditioner is turned off, the clutch makes noise during rotation. extraneous sounds, it gets hot or there is a burning smell, then its bearing has probably begun to deteriorate. In this case, it is necessary to replace the bearing (see “Replacing the drive pulley bearing,” page 271). In some advanced cases, it may be necessary to replace the compressor clutch assembly or its components.

2. If you don’t hear a click after turning on the air conditioner, then the following problems are possible:

There is a refrigerant leak and the control system blocks the compressor from turning on;

The pressure sensor in the system has failed;

Malfunctions in the electrical circuits of the control system;

The coil winding of the clutch electromagnet burned out;

Engine control module for any reason (high engine coolant temperature, high revs engine) blocked the compressor from turning on.

3. If the clutch rotates easily and freely, but when you turn on the air conditioner you can clearly hear extraneous noise or even the engine stalls, then the compressor is most likely jammed. The internal pumping part of the compressor cannot be repaired. In this case, the compressor will have to be replaced.

4. And the last, most unpleasant option. A click is heard, the clutch easily rotates the compressor shaft, but the air in the cabin does not cool. In this case, the compressor runs idle, pumping nothing. This malfunction can only be determined by an experienced specialist with special monitoring and diagnostic equipment.

The cause of the malfunction can be most accurately determined after a complete diagnosis at a specialized service center for the repair of automobile air conditioners.

Condenser (air conditioner radiator)

(Fig. 12.4) of a multi-flow type is located in front of the radiator of the engine cooling system. It is attached using four brackets to the radiator frame. The condenser honeycombs are made of flat, thin-walled aluminum tubes with internal longitudinal baffles for rigidity and external fins to improve heat transfer. Aluminum tanks, with flanges for connecting pipelines. The height of the tanks is divided into sections, therefore, passing through the condenser, the flow of refrigerant changes direction several times.

In the condenser, the vapors of the refrigerant compressed by the compressor are condensed and the heat released is removed into the surrounding air.

When the air conditioner is turned on, the engine control unit turns on the power circuit for the electric fan of the engine cooling radiator, which improves heat exchange in the condenser and reduces the pressure in the air conditioning system.

USEFUL TIPS

At least once a year, preferably before the start of summer operation, wash the fins A of the condenser honeycomb from adhering dirt, dust and de-icing agents B. This will improve heat transfer, reduce pressure in the system and increase the service life of system elements. Do not use washing equipment with a stream of water to wash the condenser. high pressure

. This may cause damage to the B thin-walled fin plates. Even with regular cleaning, the need to replace the condenser arises much more often than we would like. The fact is that it is the first to absorb the flow of deicing agents, dirt and pebbles from the road. And the walls of the tubes are thin... In most cases, the condenser is damaged by corrosion in the third or fourth year of operation.

If the seal of the condenser is compromised as a result of corrosion, it will be more expensive to repair it. Even if an argon welder manages to patch the hole, a leak may soon appear in another place. By the way, the pressure in the system on hot days can reach 25-28 bar.

After each experiment with patching the condenser, you will need to pay for removal and installation, welding of the condenser and refilling the system with refrigerant. So it is better to immediately install a new condenser. Instead of an expensive original one, it is quite possible to buy a cheaper condenser from authorized manufacturers of spare parts.

The evaporator is located in the heating and air conditioning system unit in the cabin. The evaporator is made of aluminum tubes with external fins to improve heat transfer. Passing through the evaporator tubes, the boiling refrigerant actively absorbs heat from the air blowing on the outer finned surface of the tubes. The air is cooled and supplied by a fan to the vehicle interior.

When the air passing through the evaporator cools, the water vapor contained in it condenses.

engine shield, drains under the bottom of the car. If the ambient air humidity is high, a puddle of water may form under the car, which is an indirect sign that the air conditioning system is working properly.

WARNING_______________________

During vehicle operation, particles of road dust and dirt settle on the outer surface of the evaporator, damp from condensation.

This layer becomes an excellent environment for life and rapid reproduction of putrefactive bacteria and fungal cultures. Over time, an unpleasant odor appears in the car. It is felt especially strongly when the air conditioner is turned off and in humid weather. In order to minimize the risk of this problem, when purchasing a new car, it is necessary to carry out preventive treatment of the evaporator with special chemicals and regularly replace cabin filter and clean the drain pipe. If, despite the measures taken, the smell still appears, contact a specialized car air conditioning repair service to disinfect or flush the evaporator. If the contamination is very severe, the evaporator will have to be replaced.

On the side surface of the evaporator there is a flange for attaching a thermostatic valve.

|

|

The block type thermostatic valve is located in the evaporator housing.

The valve is attached to the pipelines and the evaporator using flange connections. Having passed through the throttling hole in the valve body, the liquid refrigerant sharply reduces its pressure and begins to boil. A control element is installed in the valve body, which changes the flow area of the throttling hole depending on the pressure and temperature of the refrigerant. The control element is set at the factory and cannot be adjusted during operation.

The receiver-dryer is installed on the condenser on the left side and forms a non-separable unit with it. Inside the housing there is a filter element (cartridge) filled with desiccant granules (silica gel). The liquefied refrigerant passing through the receiver is cleaned of possible impurities, dirt and moisture.

At the bottom of the housing there is a hole for replacing the filter element.

In case of repair or replacement of elements of the air conditioning system, if it was in an open state (any components were removed, pipelines were destroyed, etc.), the receiver-dryer cartridge must be replaced. Otherwise, after charging the system, the refrigerant will not be dried and acids may form inside the system, which will destroy the air conditioner parts from the inside.

Pipelines connect all elements of the air conditioning system into a single sealed circuit. The pipelines and their mounting flanges are made of aluminum alloys.

Rice. 12.5. Design of the flexible insert hose: 1 - outer protective sheath; 2 - fabric cord of the load-bearing frame; 3 - plastic sealing layer; 4 - internal oil-resistant layer

Protect metal sections of pipelines from dents and kinks. Any narrowing of the pipeline flow area leads to a decrease in system performance.

Service valves for connecting diagnostic and filling equipment are located on the pipelines.

NOTE

|

|

The valves are closed with threaded caps to protect them from dirt. The caps are marked with the letters “H” and “L” for the high and low pressure lines, respectively.

The valves are equipped with spools that are similar in design to the wheel tire spools, but differ from them in size.

A special key is used to turn the spools in and out.

WARNING

The pressure sensor is installed in the engine compartment on the right side in the high pressure line section of the pipeline.

Based on sensor signals, the electronic engine control unit turns off the air conditioning compressor in the event of depressurization of the system or an emergency increase in pressure in it in order to protect the compressor from overloads.

|

|

The control unit panel for the heating, air conditioning and interior ventilation system is installed on the instrument panel console.

The controls for the heater, air conditioning and ventilation are described in detail in the subsection “Heating (air conditioning) and ventilation,” p. 26.

Depending on the version of the control unit panel, the system/interior air temperature sensor is located...

In the instrument panel to the right of the steering column...

Or directly in the front panel of the control unit. To eliminate incorrect temperature readings due to the influence of heated panel elements, the sensor is equipped with a forced airflow system. The system ensures uniform air flow from the front of the vehicle through the sensor housing. To ensure proper air movement, keep the inlet of the sensor housing free from any solid particles or liquids. This is especially true in cases of dry cleaning of the interior. When cleaning the interior with a vacuum cleaner, it is strictly forbidden to bring the suction tip of the vacuum cleaner pipe to the sensor inlet. If air flow through the sensor housing is obstructed, the normal functioning of the automatic climate control system is disrupted.

|

|

The outside temperature sensor, although located at the front of the vehicle behind the radiator trim in a solar-protected and ventilated area, is susceptible to factors such as warm air from the engine and radiation from heated asphalt. Therefore, its readings can sometimes be somewhat high, especially after a long period of standing in traffic jams.

|

|

The outside temperature readings can be considered correct when driving for at least 10 minutes at a speed of at least 40 km/h.

To increase the efficiency of the climate control system and more comfortable distribution of air flows in the cabin, a solar illumination sensor A is installed on the instrument panel near the glass of the wind window on the right side. Depending on the degree of heating of the cabin by the sun's rays, according to sensor signals, air flows are directed to the area of the driver's face or legs and front passenger.

Refrigerant. The system is charged with HFC-134a (R 134a) refrigerant. The total filling volume is (500±25) g Refrigerant added

NOTES

special oil FD 46XG (PAG) for compressor lubrication. It is strictly prohibited to use other types of refrigerants and oils in the system. During operation

car air conditioner

From time to time situations arise when the air conditioning system requires servicing or repair. For this purpose, modern diagnostic and repair equipment is used. The most common situation is the depressurization of the system and the release of refrigerant from it.

To detect leaks, highly sensitive halogen leak detectors with sound indication are used.

In some difficult cases, the so-called “ultraviolet” method of diagnosing the tightness of the car air conditioning system is used.

The method consists of introducing a special dye into the system in microdoses.

|

|

In places of microleaks, the dye, together with the refrigerant, gradually reaches the outer surface of the system elements.

During inspection of the system, the dye begins to glow (fluoresce) under the influence of ultraviolet rays from a special lamp...

After repairing the car air conditioner, it is necessary to evacuate and charge the system with the appropriate refrigerant (R 134a).

The volume of refilling the car air conditioner is individual for each car model.

To carry out high-quality refilling of a car air conditioner you need:

Precision gauge blocks with special connecting tips;

Two-stage vacuum pump to completely remove air and water vapor from the system;

High-precision (division value no more than 5 g) scales for dosing refrigerant.

Due to the specific features of repairing the air conditioning system, this section describes only work on the removal and installation of individual elements and the system control unit. Work related to filling the system with refrigerant should be carried out in specialized service centers. The air conditioning system is charged with high pressure refrigerant. Contact of liquid refrigerant with a person’s skin causes severe frostbite, so if possible, carry out all work related to the maintenance, repair or dismantling of air conditioning system elements in specialized

service centers equipped with professional technological equipment. When carrying out work on your own, take precautions.)

PTC heater (

gasoline engines

A positive temperature coefficient (PTC) heater is installed at the rear of the heater core. A PTC heater is an electric heater that uses the PTC element as an additional heating device to compensate for the lack of a cabin heating source in vehicles with a high-efficiency gasoline engine. The air temperature in the cabin is increased by passing air through an electric heater. The name of the heater itself indicates a proportional change in resistance depending on temperature.

OPERATING PRINCIPLE

The heater ECU outputs the heater ON signal from the PTC and controls the PTC relay 1. The heater controller controls the state of relay 2 (PTC) and relay 3 (PTC) at intervals of 15 seconds. However, relay 3 PTC can be controlled when the battery voltage is above 12.4 V.

| Working conditions Heater control with PTC is possible under the following conditions: | Environment Heater control with PTC is possible under the following conditions: | Temperature Coolant |

| PTK Trigger | Below -20 °C | (+4°) |

| Below 75°C (167°F) | ON | (+4°) |

| 5°C (41°F) | - | Below 65°C (149°F) |

| - | 7 °C (44.6 °F) or higher | Below 65°C (149°F) |

OFF

Checking control logic (manual systems only)

Check the control logic of the heater with PTC:

Functional check

This test is performed with the PTC heater running.

Resistance measurement

| 3. Measure the resistance between terminal 1 and the PTC switching terminal (+) of the heater with PTC and the ground wire. |

You can talk a lot about cars, but the Inkom-Avto company knows only eight letters that can neutralize the minor shortcomings of any domestic or foreign car and cross out the advantages. Crash test! It is he who is the measure of all things when it comes to the life of the driver and passengers. We are pleased to inform you that Korean foreign cars Sid, for the purchase of which those who truly know a lot about cars come to our oldest car dealership in Moscow good cars, withstand crash tests “excellent”! And now about other advantages of Ceed.

Fuel prices are unlikely to drop in price in the coming years, and even wealthy people today are accustomed to saving money. We are a Ceed car dealer new in Moscow! – we hasten to declare with all confidence that this “brilliant Korean” is famous for the combination of seemingly incompatible positions: engine power and emphasized efficiency. Judge for yourself! The 1.6 engine boasts 122 horsepower, but at the same time consumes only 6.9 liters. Aren't such criteria an indication that driving a car purchased from Inkom-Auto a little more will be more profitable than riding the subway?

Let's take a look at car dealerships where Ceeds are sold, and prices vary like the weather in September - this is where you can not just look at the picture, but see with your own eyes such advantages as excellent design and interior comfort! This car can comfortably accommodate an entire Russian family! What about those loved by many? additional functions? Traditionally, the “brainchild” of the South Korean automaker Kia Ceed new, available to you both with a one-time purchase and also pleases with a set of basic functions that were originally included in this car!

By the way, about loans. Are you ready to become the owner of this car right now? Do you have enough funds? We are glad if you answered positively. But if more pressing expenses await you on the eve of the New Year, we hasten to ask the question: can you buy a car? Kia Ceed on credit, dooming yourself to almost double overpayment at the bank? The answer is known in advance. And this is not speculation! In some banks, lending conditions remain extremely unfavorable to this day. But not those with whom the Inkom-Avto company has been cooperating for 12 years! We are glad to tell you a professional secret!

In our oldest car dealership in Moscow, we can give you an elegant Kia Sid for free, but we sell the car in such a way that the price can rightfully be considered symbolic. I'm not kidding! We - official dealer company producing Ceed cars, which can offer you today the purchase of a car on the terms of obtaining an affordable and favorable loan, but that's not all! Owners of used cars are coming to us today. After all, we put into practice the “Trade In” sales technology, which allows you to accept an old car as a new one. Surprise your loved ones! Go on business to old car, and come back for a new one! Miracles happen!