The button for choosing between gas and petrol is an integral attribute of LPG, without which switching from one type of fuel to another, and with it saving on costs, will become impossible. This button (or switch) makes it possible to switch from one fuel to another without having to stop and open the hood of the car.

LPG control button

The control button, or switch for the LPG mode, is made in the form of a small side with a two-position switch, which has a common bus and two extreme ones. Gas indication - blue or green backlight, for gasoline the switch is yellow, orange or red.

Despite the indisputable advantages - the relative cheapness in terms of the cost of refueling the car, up to ten times cleaner exhaust and environmental care, much rarer service and repair of engines - HBO has and weak sides, and one such "bottleneck" is a button or switch that allows the car to switch from petrol "soldering" to gas and vice versa. You can mount the button either next to dashboard, either near the pedals or in another convenient location.

LPG button for carburetor

For carburetor engines, a simplified connection diagram is considered, corresponding to the 1st generation of HBO. It was from this that private car owners began to transfer their cars to driving from gas. There is absolutely no electronics here - the system works only on electromechanics.

The LPG button of the 1st generation has three positions: 1 - petrol, 2 - gas, the middle (zero) position is neutral. In the latter case, petrol and gas are blocked by the corresponding valves, while the switch illumination is turned off.

It is unacceptable to supply petrol or gas immediately in one of these modes. The driver can switch without going through the neutral mode. If you go from “gas” to “petrol” or vice versa, bypassing “neutral”, straight ahead, both types of fuel are fed into the engine at once. Gasoline cannot ignite due to the fact that the gas does not allow it to do so. The gas, in turn, will not burn, but will decompose into carbon and hydrogen, deposits (coking) will appear on the valves and pistons. The engine, even if it has started quite successfully, will stop immediately.

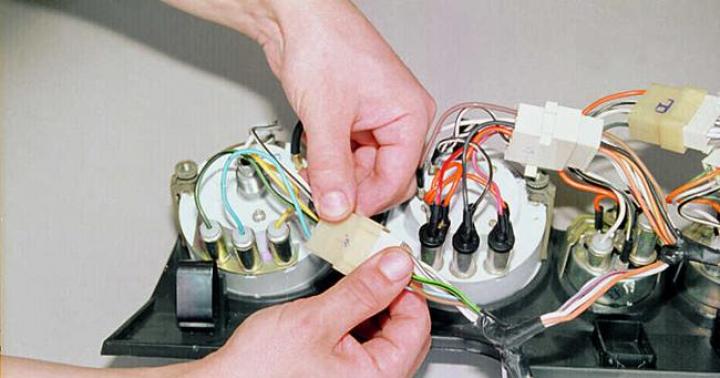

Scheme for the LPG button

As an example - all the same HBO 1st generation. Before connecting the "younger" generation, it is not out of place to find out how the "older" was connected. The button block has 4 wires here:

- Red serves as the "+" of the ignition coil.

- Black - "mass", common.

- Brown - passes through a noise filter that suppresses current surges; 10 turns are wound on the central core from the ignition coil.

- Yellow - serves as a "+" from the device that locks and locks the gasoline supply valve.

By accidentally confusing the polarity, you risk burning the device that is switched by the button. All wires and tracks are designed for their current and voltage.

2nd generation LPG button

The switch (turning on and off the HBO mode) has the following color coding of the wires - there are also several of them:

- Brown - goes to the spark ignition circuit, or is wound on a high voltage wire connecting to the first cylinder. In the latter case, it is necessary to wind at least 10 turns.

- Black - common bus, connects to the car body.

- Red - positive, connected to the spark ignition coil, wound through a fuse.

- Yellow - feeds the petrol pump.

- Blue - controls the gas injection reducer, starts up on the assembly replacing the injectors.

- White - controls the remaining gas sensor in the cylinder.

The latter is an optional feature - not all 2nd generation LPG systems use such sensors. Most of the installed LPG systems of the 2nd generation use the most common switches for gas and petrol modes - they are unlikely to need an indication of the remaining gas in the cylinder. But the switching - in comparison with the control in the 1st generation carburetor HBO - is slightly spaced differently, although there are also only three modes;

- 1 - gasoline, LPG is completely disabled, and cannot be turned on under any circumstances.

- 2 - the car starts up on gasoline, but after warming up the engine, it immediately switches to gas consumption.

- 0 - "plant" on gasoline, switching to gas only at certain speeds, above which it is impractical to continue working on liquid fuel.

You can customize the operation of the engine on gas as you see fit. There are times when LPG or gasoline is temporarily not needed - it is even possible to completely exclude them from work, but in the case of the "gas only" mode, it will be necessary to replace them with more heat-resistant ones, originally designed for gas. The fact is that gas firing is carried out 150-200 degrees higher than at the ignition temperature of gasoline.

3rd generation LPG button

The difference between the LPG button of the 3rd generation and the same device of the 2nd is as follows. They are not as significant as it might seem at first glance. Here, gas or gas mixture is pumped through the factory power system. In the 3rd generation, in contrast to the 2nd, gas is pumped directly into the intake manifold. In general, the scheme remains the same - the buttons for the 2nd and 3rd generations are connected in approximately the same way.

4th generation LPG switch button

For the LPG buttons of the 4th generation, the intermediate position is completely removed. This switch has only two positions: for gas and for petrol.

To switch from gasoline to gas, the driver can do this already while driving, without waiting for anything - there would be the right amount of gasoline in the gas tank and gas in the gas cylinder, only then the system will work accurately. To do this, you need to click on the button. At the same time, the gasoline light is on, the gas light will blink. As soon as the engine reaches the required temperature and the gas reducer sets the required pressure in the gas supply, the gas injectors will open automatically, and the gas injectors will close. This completes the switch from petrol to gas. At the same time, the petrol indicator on the button will go out, and the gas indicator from the blinking mode will switch to the constant glowing mode.

The electronic control unit in the 4th generation LPG systems is quite versatile compared to the previous systems of the "older" generations. However, different from each other gas supply systems in different models have a different mode of light warning about switching from petrol to gas and vice versa. You can freely switch between modes - as long as you have not started, or are already on the way, it does not matter. In the case when the engine is already (or still) warm, it is advisable to switch to gas at least a few seconds after a successful start.

When you switch from gas to petrol - while driving along the road with you, press the button to switch from gas to petrol. When the button is pressed, the petrol injectors turn on, and the gas injectors stop working. In this case, the gas indication will go out, and for gasoline, it will light up. You can also switch from gas back to gasoline while parking - there are no speed limits here. The indication of gas and petrol modes on different models with LPG of the 4th generation may turn out to be different: somewhere these are blinking LEDs, and somewhere - continuously glowing.

The car can switch from gasoline to gas, if the first is over - and there is still plenty of the second. Or vice versa. All modern cars try to fail under auto-switching. This allows you not to be caught unawares by the end of the fuel - one is over, burn out the other, but in the middle of the highway, hundreds of kilometers from the A (D) ZS in the wilderness, you are unlikely to get up.

The engine cannot operate exclusively on gas, when special candles are not installed for gas, the spark ignition circuit is not transferred from 14 to 16 kilovolts. If the ECU supports emergency start on gas, for example, when there is no gasoline or the gasoline supply does not work, this is possible, however, the car starts and runs exclusively on gas, like the newest KamAZ trucks, where the diesel fuel supply is excluded by the manufacturer itself. In this case, the ECU is "stitched" initially for the "gas only" mode, and this is, one might say, the imperative of the times. These rules are valid for all LPG systems. In winter, starting on gas may not work, which is why the “gas only” mode is forced, emergency. Before turning on the starter, the button for switching from petrol to gas must be kept pressed.

By the way, with a blown fuse in the LPG system, the transition to gas and starting from gas is not carried out. In this case, the gas valve is closed, and the petrol valve is open. This allows you to switch to gasoline - and continue your journey for today.

Buy button HBO

The LPG button is one of the cheapest accessories in the LPG system. In fact, these are one or two switches placed in a small box, supplemented with hinged radio components and wires. It costs no more than 300 rubles. Not a single button is complete without light indication - this allows you to see the switch even at night in the salon of a car parked even on the street where there are no lanterns. Although the product is very simple and reliable, they even try to fake it, selling flimsy and untested devices to car owners. It is not worth saving on such a simple product.

Do not try to put a 1st generation button on a 3rd or 4th generation system. If you see a different number of button wires on the switches different generations, then this is exactly the case: it seems that they have assembled, nothing superfluous, and the system with LPG works abnormally or does not switch the type and type of fuel at all.

You can order a product both on the Internet and find it (if you know well what this button looks like and do not confuse it with other similar switches) at the nearest auto shop or at the car market. The main thing is that it works - and it is extremely comfortable to use it.

Modern HBO of the 4th generation is currently the most optimal and reliable option for various mobile gas systems. In it, the supply of the gas mixture to the injectors of each cylinder of the engine internal combustion carried out and managed separately.

Gas cylinder 65 liters inside the trunk. There may be round cylinders. Fuel filler neck inside the boot, leaving plenty of room inside

Features of operation of LPG of the 4th generation

The equipment allows for combined power supply of the engine with petrol and gas. Switching from one power mode to another can be done manually from the cab, as well as automatically. The small control panel contains an LED gas level indicator and a fuel switch. The usual location of the control panel is under the steering column on the left near the headlamp directional adjuster.

The gas indicator contains four green and one red LEDs arranged in one row. When one green LED comes on, there is 10 liters of gas. Usually this reserve is enough for 100-120 km of run. When the red LED lights up, it signals the presence of an emergency fuel remaining, which can be enough for 50-80 km of run. It warns of the need to refuel gas at a gas station.

A separate red LED, located in the upper corner of the remote control and working in a blinking mode, signals that the engine is still running on petrol, but the system is preparing to switch to gas fuel. This happens every time the engine is started until it reaches a normal temperature and warms up well.

Engine Power Mode Switch Button and Gas Amount Indicators

Since the engine has both a gasoline and a gas power supply system, this duplication doubles the reliability of its operation. In addition, the duration of the run at one filling with petrol and gas fuel is significantly increased. This is beneficial on long trips to sparsely populated areas, where the network of gas stations is rare and of poor quality. It also adds the ability to increase protection against theft of the car, an easily removable and installable switch, the removal of which blocks the supply of petrol and gas to the injectors.

HBO of the 4th generation is especially beneficial for car owners whose engines are equipped with an expensive fuel injection system with cleaning exhaust gases... It not only provides significant savings in expensive high-octane fuel AI-98, but also saves resources.

This equipment is designed for vehicles that meet environmental requirements of Euro-3 and more. It has a pulsed gas-air mixture injection system, which operates under the control of a separate control unit coupled to a microprocessor. processes the commands of the microprocessor and generates control signals that open the electromagnetic gas injection nozzles and blocking the gasoline mixture supply injectors.

The concentration of the supplied fuel mixture is monitored by a system of sensors that determine:

- gas pressure;

- reducer temperature;

- gas temperature.

If the pressure of the supplied gas falls below the threshold value, the electronic unit automatically turns off the gas injectors and opens the petrol injectors, switching the engine to petrol power.

Composition and scheme of operation of the 4th generation HBO

HBO includes three components:

- LPG filling cylinder;

- Multivalve;

- Gas preparation, distribution and injection unit.

The multivalve is installed on the neck of the gas cylinder. It is designed to ensure the filling of the cylinder and the economical and safe consumption of gas in the process of supplying a running engine. It includes:

- 3 valves - inlet (filling), outlet (consumption) and emergency (high-speed);

- cylinder filling indicator;

- fuel intake pipe.

The high-speed valve ensures that the flow channel is closed in the event of a rapid gas leak in the event of a break or damage to the connecting tube from the cylinder to the engine.

The gas preparation and distribution system consists of:

- a single-stage reducer when using propane or a two-stage reducer for methane. The reducer provides the transfer of fuel from a liquid to a gaseous state. The two-stage reducer also reduces the gas pressure;

- nozzle ramp with nozzles;

- filter for gas cleaning.

It is planned to start the engine using gasoline. Starting from gas is an abnormal mode and is allowed in case of a malfunction of the gasoline system. However, it places a heavy load on the gearbox diaphragm and significantly shortens its service life. With a stable warming up of the engine up to 20-300C, it automatically switches to gas supply. When the gas pressure drops to a threshold value, the engine automatically switches back to gasoline. In this case, a special sound signal is generated to warn the driver about the lack of gas.

HBO of the 4th generation prevents the appearance of various pops in the fuel intake channel, which are characteristic of poorly synchronized mechanical feed systems. Therefore, it can be safely mounted on engines with plastic manifolds and systems with an adjustable geometry of the gas mixture supply. After installing the equipment, it is imperative to correct the ignition timing, since the combustion time and the octane number of the gas are large. It requires more early ignition, i.e. greater lead angle.

Video: What is HBO? Generations of HBO

The industry produces special spark plugs for gas systems, although ordinary gasoline plugs work well with LPG. The ignition angle is adjusted using an electronic variator. The car owner can use the chip tuning capabilities to change the average engine characteristics set by the manufacturer, as well as set a different temperature automatic switching diet.

To increase the reliability of the engine, extend the life of the injectors and the gearbox and protect them from debris that gets into the cylinder when refueling from old containers at gas stations, the foremen advise using additional filters.

Benefits of fourth generation HBO

HBO of the 4th generation, in comparison with its older predecessors, has a number of undoubted advantages. These include:

- Maximum efficiency of the engine due to the accuracy of the formation of the required gas mixture for each of its operating modes.

- Soft work power unit, the complete absence of "claps" characteristic of early types of HBO.

- A high degree of environmental friendliness of the engine, which meets the requirements of Euro-3/4, due to the complete and high-quality combustion of fuel. In this case, the real reduction in motor power is not more than 2%.

- The versatility of the equipment, which allows it to be installed on almost all brands of modern cars due to software and hardware compatibility with the EOBD self-diagnosis system.

- Unified connectors of blocks, excluding errors of equipment installation due to inattention of personnel and reducing its labor intensity.

- High reliability of the equipment and affordable price, obtained through the use of modern production technologies.

The main problematic issues related to the operation of gas equipment

During the period of operation of a car with LPG of the 4th generation, there may be a deterioration in its dynamic characteristics... The reasons for this phenomenon may be:

- malfunction of the gearbox or its incorrect setting, including the dispenser;

- clogged filter;

- low temperature of the gas-air mixture (typical for winter period operation);

- excessive enrichment of the mixture due to the lowered temperature of the reducer.

Something else useful for you:

If the car takes a long time to start, this may be due to:

Video: HBO 4th generation on the Suzuki Grand Vitara new

- malfunction of the diaphragm of the reducer or its incorrect setting;

- defect of the supply solenoid valve (mechanical jamming of the armature or the presence of a short circuit of the turns);

- failure of the electronic unit, expressed in the absence of a permitting signal for gas supply or in the generation of an incorrect signal that does not correspond to the required amount of fuel;

- malfunction of the starter, which "saps" the battery voltage at start-up, as a result of which the solenoid valves do not work;

- wear of the piston and cylindrical surfaces of the engine, leading to a decrease in pressure in the cylindrical heads;

- If a vacuum reducer is used, an additional reason for poor start-up may be that insufficient vacuum is created in the inlet manifold due to the need for suction. In such cases, a separate electromagnetic pump can help out, providing a forced supply of fuel.

Maintenance of HBO of the fourth generation

1. It is required to perform weekly:

- external inspection of the tightness of the system, no gas leakage. Leaks can be detected by the characteristic odor of an odorous odorant and using a soapy solution. Leakage can occur through cracked tubing, worn seals, or loose, tightened hose clamps;

- removal of accumulated condensate in the gearbox through a special bottom plug. Untimely drainage of condensate can lead to its coking and clogging of the drain hole, which subsequently, when condensate accumulates, leads to a malfunction of the reducer-evaporator.

2. It is required to perform monthly:

cleaning or replacing the filter. To do this, disconnect the inlet tube from the filter and dismantle the filter. Clean or replace the filter element. There is a small magnet inside it, which should be replaced after cleaning the filter.

3. Disassemble and clean the gearbox once every two years. In doing so, care must be taken not to crush or tear the membrane. After cleaning and assembling the gearbox, it is imperative that a leak check is performed.

Gas can be used both on gasoline and on diesel engines... Gasoline engines will not surprise anyone, but diesel is a rather interesting design. It has a very high compression ratio, normal Gas engine would detonate in this case. But for gas, everything is fine, because it has a high octane number, which means it easily ignites without detonation at a high compression ratio.

Another feature of such an engine is that the diesel engine has no sparks, and the gas must somehow ignite. We solved this problem by injecting a small amount of solarium. As a result, such an engine turns out to be dual-fuel - it runs on gas, but the ignition occurs due to the injection of diesel fuel.

Equipment classification

Gas types

Gas equipment differs in the type of gas used - it can be compressed methane gas, which is in a cylinder under high pressure, and it could be liquefied propane / butane gas, which is in a liquid state in a cylinder. Gas becomes liquid when it reaches a certain pressure and is constantly in this state.

Equipment development

It is also customary to distinguish gas equipment by generations - from 1st to 6th. That's right, because gasoline supply systems have been constantly evolving all this time, from a simple carburetor to direct injection into the cylinder. Accordingly, gas for such engines must be injected in the same way so that the engine does not lose its characteristics.

When connected gas equipment it is important both to connect the gas itself and to the gas supply control system.

Gas supply. HBO connection diagram.

This diagram shows the following components of LPG:

- Gas bottle

- Multivalve

- Filling device

- Gas reducer

- Filter

- Gas injectors on the ramp

- Gas control unit

- Gas / petrol switch

We install gas equipment.

Gas injectors are installed on the engine. The fittings are cut and screwed into the intake manifold, and gas pipes from the nozzles go to the fittings, through which a metered portion of gas flows. The ramp with gas injectors is usually mounted not far, 15-20 centimeters from the fittings, the injectors are located on the ramp. The train must be supplied with gas from the reducer, cleaned through a filter.

Gas from the reducer flows to the gas injectors, after the reducer the gas passes through the filter and is cleaned of impurities.

The reducer must be warmed up, because when a gas changes from a liquid to a gaseous state, it cools down, and the reducer will be covered with frost. Therefore, it is connected to the engine cooling system and the transition to gas is carried out only when the engine warms up to 30 degrees. This was before the 4th generation of LPG. In 5th generation LPG systems, gas enters in a liquid state, and the transition to a gaseous state occurs after the injection of the nozzle, therefore, heating of the reducer is not required and the engine can be started on gas.

LPG electronics wiring diagram

Now that the gas is connected, you need to connect the control electronics.

The main control unit here, of course, controls this entire system.

It receives an input signal from sensors and a signal about opening / closing of injectors.

The input signal comes from the following sensors:

- Engine speed sensor (crankshaft sensor)

- Oxygen sensor (λ probe)

- Signal from petrol injectors

- Reducer temperature sensor (helps you know when to switch to gas)

- Gas / petrol switch

- Fuel level sensor.

The gas itself turns on when the gearbox warms up to a certain temperature, it cannot be forcibly turned on, if HBO of 4 generations and above is used, you can only switch it to forced operation on gasoline, or to auto mode, then the computer itself will choose which fuel to work on. When the gas runs out, the system automatically switches to gasoline.

Rising fuel prices are forcing most ordinary motorists and seasoned car enthusiasts to think about looking for an alternative to save on fuel in order to save money. One of the most profitable, economically viable and simple options saving money on fuel is the installation of a gas cylinder installation.

Today you will learn: how to install HBO on a car with your own hands, what parts, spare parts are needed, reviews of car owners after installing HBO.

Today, such a service is offered at almost every station. Maintenance, however, the presence of certain knowledge, minimal experience and direct hands will help save money and install HBO with your own hands, without resorting to the help of specialists. Today, one of the most stable installations is the 4th generation HBO. Most experts advise installing this particular setting.

Do-it-yourself HBO installation step by step

Do-it-yourself HBO installation is carried out in several stages. In this article, we will look at what exactly needs to be done when installing a gas cylinder system on a car and will help you develop a strategy for the fastest possible installation and debugging of the system.

List of equipment for installing LPG do-it-yourself

1 ... HBO kit. The choice of the kit directly depends on the car brand. The main set consists of wires, computer, harnesses, hoses, valves, nozzles, gas temperature sensors, pressure and reducer. In some cases, the equipment may differ.2 ... Gas cylinder. When installing gas equipment, most motorists try to achieve compactness. For this it is worth using cylinders in the form of a torus. One of the most demanded in the modern market is the Atiker cylinder with a size of 630 by 255 mm, which holds 54 liters of blue fuel.

3 ... Multivalve. The complete set of modern multivalves includes the device itself, an external system for filling cylinders and tubes.

4 ... Gas level sensor. A device that connects to the computer of the LPG installation. The main task of the sensor is to display the remaining fuel in the cylinders.

5 ... The programmer is universal. Used for debugging and configuring a computer.

6 ... Computer and disk with instructions for setting up. On the disc you will find firmware, instructions and diagrams.

7 ... Nozzles, harnesses.

8 ... Set of tools.

This is the minimum list of equipment that will be enough to install HBO with your own hands. Depending on the vehicle, the cost of the equipment may vary. In most cases, the amount depends on the brand, type, manufacturer, configuration and model of the cylinder. Installing HBO of the 4th generation will cost approximately 20 thousand rubles.

In some cases standard configuration HBO is not enough and the motorist has to buy:

✓ 2 copper hoses (6 and 8 mm in diameter, 1.5 and 8 m long;

✓ pressure sensor;

✓ connector for connecting the sensor to the HBO computer.

Gas equipment installation process

When installing a cylinder, it is extremely important to carry out calculations, according to which the hole with the multivalve should be located in the side of the car, namely, in the side of the fuel filling cap. Installation of the multivalve is carried out directly to the LPG cylinders using bolts, after which the level sensor should be installed. It is installed directly on the multivalve, depending on the particular set of the kit.

Next, a solenoid valve should be installed, which will open when an impulse is supplied from the "brain" of the installation. After that, it is necessary to carry out the installation fuel line and a device for filling gas into cylinders. In most cases, the 4th generation LPG equipment includes two lines: the main one and the filling line. To ensure them, you should use copper tubes fastened with barrels and copper bolts. It is advisable to fix the VCU in close proximity to the filler neck.

Having installed the lines, it is worth checking for their tightness using a compressor. A pressure of 5-6 atmospheres must be passed through the system, checking the presence of etching from the installed pipes.

A gearbox should be installed under the hood, the unit of which, in most cases, is located near the car's radiator. The outlet of the gearbox must be at the top and point towards the front. The gearbox itself should be placed slightly below the level at which the coolant is installed for easier access to the cooling system.

After assembling the nozzles and cutting them into the manifold, you should start assembling the line low pressure and then connect the injectors and the reducer using the hoses from the standard LPG kit. Pressure testing should be carried out only with a filled tank.

The installation of control systems and the wiring of the central distributor can be done before and after crimping. Next, you should check the operation of the engine in various modes and adjust the operation of the LPG system.

Installation of LPG equipment, especially of 4 generations, is a complex and time-consuming process. It must be carried out in accordance with all the norms and requirements presented in the instructions, as well as follow the recommendations from the disk "brains". Installation of such an installation by a beginner may take several weeks, but an experienced master will be able to switch the car to "gas" in a matter of days.

Do-it-yourself HBO installation video