The UAZ car is common on Russian roads, it is distinguished by its reliability and the ability to move on paved areas and off-road. UAZ gearbox - mechanical type with 4 steps. The mechanism is distinguished by the presence of synchronizers, the function of which is to equalize the speed. This is one of the key elements of any transport. The functionality of other systems and the quality of driving a car depend on its work.

Device and principle of operation

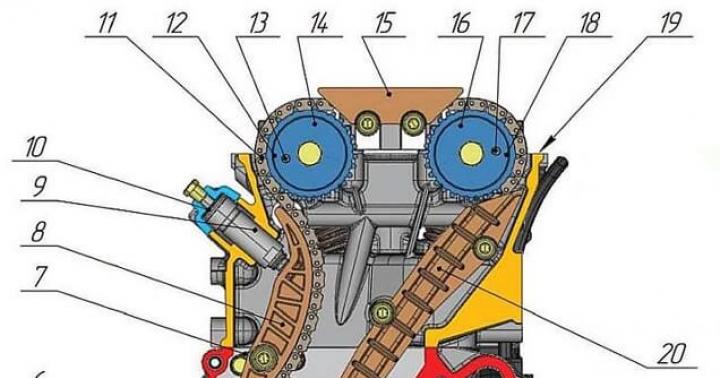

The gearbox diagram contains information about the main and additional elements of the system. The UAZ gearbox device includes the following units and parts:

- Fully synchronized setup providing speed equalization and smooth shifting.

- Primary shaft on 2 bearings.

- Helical intermediate gears of the shaft drive.

- An angular contact ball bearing, consisting of 2 rows and located on the back of the shaft, is necessary for the perception and timely reaction to the loads that occur during driving in the radial and axial planes.

- Transfer case, consisting of a main axle shaft and a gear with a volumetric working resource.

Such design features make it possible to move in reverse. The mechanical type of gearbox has the main advantage of a long period of operation. A car with a similar device copes well with difficulties while driving over rough terrain.

Faults and repairs

The first signs indicating a malfunction automotive system, should force the car owner to diagnose. In some cases, this can be done on your own. Simple breakdowns are repaired by hand. More complex malfunctions are best left to a service center.

Signs indicating the need to repair the UAZ checkpoint:

- deterioration of management;

- squeaks and extraneous noise when changing speeds;

- independent transmission activation.

In most cases, when unusual noise is observed, the cause lies in the wear or defect of the bearings and gears. Tight gear shifting indicates a malfunction of the synchronizers.

The main cause of problems is the natural wear of parts.

The need to check the transfer case is indicated by the deterioration of the adhesion of the wheels to the roadway, the increased noise level from the area of \u200b\u200bthe unit. Damage is facilitated by: negligent operation of transport, untimely Maintenance, the use of low-quality Supplies, fuel and transmission oil, lack of control regarding the volume of working fluids.

UAZ cars (loaf) have the most spacious body. The body of the machine is made of durable material. The vehicle is equipped with security systems, durable power unit, which is capable of developing a power of more than 100 Horse power, transmission system.

All-wheel drive cargo-passenger UAZ, which has cross-country ability, began to be mass-produced at the Ulyanovsk Automobile Plant in the mid-1960s.

UAZ transmission components

On cars of the UAZ - 452 family of a new sample, there is manual transmission(four-stage). Inertial-type synchronizers provide easy gear shifting. Five-speed box ADS transmissions is synchronized in all forward gears.

UAZ can be equipped with a 5-speed manual transmission Daimos (DYMOS). This gearbox is known for its reliability. The average resource of its work is 300,000 km. Filler plug located in the middle of the box, draining from below. They can be unscrewed with a hex wrench. When oil is drained, special containers should be prepared. New fluid must be filled up to the level of the oil filler hole on the box. The dipstick allows you to accurately determine to what mark the liquid is filled. An alternative to the probe can be a long nail. For preventive purposes, every 15,000 km it is necessary to measure the oil level.

The presence of mechanics on this option vehicle fully justified. It is important to use such a machine on rough terrain, off-road. In addition to this, there will be no problems with towing.

The gearbox has external shift levers. The lever in the cab moves freely both parallel and perpendicular to its axis.

The machine is equipped with a transfer case. In the design of the transfer case on the UAZ 452: drive axle shafts, gears. All listed components are in a cast-iron crankcase. The crankcase and cover are connected with nuts. The shift fork rods are securely fixed in the cover.

There is a slot, bearings. There is a helical gear for the speedometer drive. An intermediate shaft is fixed on the "loaf" bearings. This box has reliable gears with straight teeth.

Thus, the checkpoint on the UAZ 452 consists of many components and assemblies. This unit needs regular maintenance.

The need to diagnose the gearbox UAZ model 452

This vehicle must be diagnosed if control began to deteriorate, characteristic creaks began to be heard when gears were changed or gears began to change spontaneously. The UAZ transfer case should be checked if the grip of the wheels with the road has noticeably deteriorated, a rumble begins to appear, an increasing noise during its operation.

During the passage of maintenance, the masters must check the system for oil leaks, the level of lubrication. All worn parts in the transmission system must be replaced with new ones. Also, diagnostics involves lubricating the axis of the levers, adjusting the front links.

Scheduled diagnostics in a professional auto repair shop allows you to accurately determine the existing nature of the problem with the box, eliminate existing problems at an early stage.

Causes of breakdowns

As a rule, the need to replace the main components at the gearbox arises with their natural wear and tear.

Causes of gearbox breakdowns

The main reason for oil leakage from the gearbox is the presence of an increased level of fuel in the system. For a checkpoint on a UAZ, use quality oil. If the liquid does not have the proper quality, then characteristic noises from the side of the box may occur due to this. When the synchronizer or its parts are worn out, it is always difficult to change gears. Pay attention to the details of the switching mechanism. When the gear teeth are deformed, self-disengagement of gears is often noted.

Gearbox removal process

Repair of a checkpoint on a UAZ 452 is quite possible to do it yourself. This requires:

- a set of wrenches, including the wrenches needed to tighten the nuts;

- screwdrivers;

- hammer;

- chisel;

- pliers.

Dismantling algorithm.

The car must be on level ground. It is necessary to drain the oil from the two boxes by unscrewing the drain plugs. Next, the front seats, hatch halves, clutch release fork, transverse frame, gear levers from the boxes are removed.

The speedometer shaft, suspension mounts in the undercarriage, levers are subject to removal brake system. As a result, an exit to the clutch housing opens. A box is fixed on it with fastening nuts, which must be unscrewed, then the UAZ gearbox is carefully pulled out along with transfer gearbox before the splined shaft comes out of the flywheel. The driver will need an assistant to remove the box.

The assembly of the UAZ gearbox requires due attention. With self-assembly, the driver may have difficulty installing the input shaft in the clutch system. With this process, it is necessary to actively move the box so that the shaft gets into the splines.

As soon as the disassembly into individual component parts has taken place, the box must be washed in kerosene and dried. All component parts are checked for integrity. First of all, this concerns the crankcase, shafts. If the threads on the shafts are damaged, they must be replaced. It seems dangerous to operate the machine if the gears are chipped.

Thus, the timely repair of the UAZ "loaf" checkpoint helps to extend the life of the box.

About UAZ

If you are the owner of an UAZ and there are suspicions about the failure of the box, then you must definitely take up the repair. The unit breaks down when the driver has to keep the shift lever on the move when they start shifting on their own (to prevent this, drivers tie them up with ropes). Creaks are heard.

To get acquainted with the repair technology, read about the repair of the UAZ 452 gearbox yourself. First of all, you need to find the type of UAZ box that is on the car. Despite the difference between car models, they install uniform transfer boxes. Because it is that the repair is actually carried out identically. For this purpose, you will need a set of keys, some tools and aids (a list of them is given below).

The beginning of the repair of the UAZ 452 gearbox on its own: gearbox, transfer case

On most models of this type of car, both parts are one. The weight of such a node achieves 75-82 kg, therefore an assistant is needed. If on a car being repaired, of course, a safety cage, then there is an option for removing under repair Checkpoint UAZ 452 at home use a manual winch.

The car must be put on a level place, because then it will have to be moved 0.5 m forward or backward. First drain the oil. Both boxes have a common volume, but the water drain plugs are separate. While the oil is pouring out, you need to remove the front seats and unscrew them, and then remove the hatch halves to the floor of the car. Next comes the turn of removing the speedometer rods.

When the oil drains, wrap the drain plugs at their destination. Under the drum hand brake there is a cross member of the frame, it must be removed. Disconnect the front axle couplings and unscrew the front cardan. If you find a weakness in the nuts, then you need to remove this part.

If the UAZ 3303 gearbox is being repaired, you need to be more careful with the couplings. The car is moved 0.5 m (in any direction) and the rear cardan is removed through the hatch. Disconnect the muffler from the distribution box and loosen the clamp it has. Then alternately remove such details as:

- clutch pan;

- fasteners for the oiler from the input shaft (it is located on the right, on the bell);

- 4 bolts that hold the clutch fork cover;

- adjustment of the cylinder rod and fork.

The transfer case is wrapped with a rope and suspended. Remove the following details:

- pillow bolts;

- nuts holding the fastening of the box with the bell.

With these actions, the engine, when the UAZ 452 checkpoint is repaired at home, must be supported with a jack. When the box is released, it is lowered and removed from under the car. The levers must be removed in advance. On the bell, you need to change the studs with new ones.

If you need to repair the UAZ Patriot checkpoint, then you need to take into account that the location of the box and the bell is reversed there. This also applies to the location of the rods. But completely do-it-yourself development for the repair of the UAZ 452 checkpoint is suitable for use.

UAZ Loaf checkpoint repair (removal, repair, installation)

UAZ 469. Gearbox repair. Part 1

Features of disassembly semi-synchronized gearboxes. Partial defect. Support the project.

Unscrew the bolts and nuts, disconnect the gearbox and its transfer case. A gasket is installed between them, reinforced with sealant, so you will have to hit the bracket for attaching the assembly to the frame several times.

Checkpoint diagram UAZ Patriot

Disassembly and assembly on their own

At the beginning must be removed input shaft cover and unscrew the left nut that is on it (see Fig.). Now we need to remove its bearing. If it fails, it must be replaced. Its roller "brother" is installed inside the shaft, it also needs to be changed. Then the retaining ring is removed from the secondary roll. Unscrew the stopper of the double row bearing. The shaft must be knocked out and the part changed.

Next comes the third gear clutch assembly. Copper synchronizers are replaced along with crackers. Then it's the gear's turn reverse gear. Unscrew the intermediate shaft front bearing box. Do not hit it with a hammer or a core: it is made of silumin and may crack.

Be careful not to damage its rubber seal because it is difficult to get it out. On the removed shaft, the gears and all bearings are replaced. After that, the box is assembled in the reverse order. When installing the roller on input shaft, it is abundantly lubricated with "Litol". All nodes and parts are put in place one by one, so as not to be mistaken.

Transfer case, complete assembly of the gear unit and its installation

Loosen the nuts of the flanges and shafts, remove them. The hand brake must be checked for operability, if necessary, it must be replaced. Remove all covers and replace seals. Unscrew the speedometer rod drive and breather (its need to be replaced). Check bearings and change if necessary.

The assembly of the transfer case is done in the reverse order. These steps are repeated when working with other types of this brand of car (including when repairing the UAZ Hunter gearbox). Install the mounting bracket to the frame. They put transfer case on the handbrake drum and, holding the gear, lower it into place through the power take-off hatch.

Before this, a lock washer is placed from the intermediate shaft. They tighten the bolts and nuts, put on the cover with levers and check the operation of all gears. change release bearing, remove the levers, drag the entire knot under the car and hang it on a rope. Put the release bearing assembly on the box and strengthen the spring. Then the input shaft and clutch are inserted. This is done in the following way:

- move the box up and down;

- turn the engine by the flywheel;

- put the node in place;

- attach pillows.

The oiler of the splines of the input shaft and the fork are attached in place, the speedometer drive, universal joints, handbrake, and covers are put in their place. In place, it is necessary to return the cross member of the frame and fix the muffler bracket to the transfer case.

The hand brake is adjusted and adjusted, the oil is changed. If the UAZ Hunter gearbox is being repaired, you may need not only these actions, but also adjustment of the rods. Screw the hatch on the floor, put the seats. This completes the repair of the UAZ 452 checkpoint on its own.

Tools and materials

For work you will need:

- open-end wrenches from 10 to 22;

- puller for bearings;

- screwdrivers (phillips and flat);

- platypuses (with bent noses and straight ones);

- copper pin;

- a piece of pipe as a key handle;

- chisel and core;

- hammer and mounting blade;

- small jars for collecting nuts and screws;

- socket wrenches from 10 to 36;

- lithol;

- red sealant;

- a set of gaskets and retaining rings for the car.

In order to properly repair the UAZ 452 gearbox on their own, it is necessary to strictly adhere to the sequence of actions described above. Difficulties in the repair of other models of this brand may be caused by a different arrangement of the main parts of the machine, for example, rods. The oil change must be carried out according to technical requirements For of this type car.

Do-it-yourself UAZ 469 gearbox repair is a feasible task for a person who wants to save money. Other UAZ owners (for example, UAZ loaf) can take note of all of the above and make repairs gearboxes UAZ, given some difference in the details and the location of the rods.

Post Views: 3

If you are the owner of an UAZ and there are suspicions about the failure of the gearbox, then you must definitely take up the repair. The unit breaks down when the driver has to keep the shift lever on the move when they start shifting on their own (to prevent this, drivers tie them up with ropes). Sometimes squeaks are heard.

To get acquainted with the repair technology, read about do-it-yourself gearbox repair. First you need to determine the type of UAZ box that is on the car. Despite the difference between car models, the same transfer boxes are installed on them. Therefore, we can assume that the repair is carried out almost the same way. This will require a set of keys, some tools and aids (their list is given below).

The beginning of the repair of the UAZ 452 gearbox on its own: gearbox, transfer case

On most models of this type of car, both parts are one piece. The weight of such a knot reaches 75-82 kg, so you will need an assistant. If the car being repaired has a safety cage, then you can use a manual winch to remove the UAZ 452 gearbox for repair on your own.

The machine must be put on level ground, since subsequently it will have to be moved 0.5 m forward or backward. Drain the oil first. Both boxes have a common volume, but the fluid drain plugs are separate. While the oil is pouring out, you need to remove the front seats and unscrew them, and then remove the hatch halves to the floor of the car. Next comes the turn of removing the speedometer rods.

When the oil drains, wrap the drain plugs in place. Under the handbrake drum is the frame cross member, it must be removed. Disable the clutches front axle and unscrew the front driveshaft. If you find a weakness of the nuts on it, then you need to remove this part.

If the UAZ 3303 gearbox is being repaired, you need to be more careful with the couplings. The car is moved 0.5 m (in any direction) and the rear cardan is removed through the hatch. Disconnect the muffler from the distribution box and loosen the clamp on it. Then, in turn, remove such details as:

- clutch pan;

- fasteners for the oiler from the input shaft (it is located on the right, on the bell);

- 4 bolts that hold the clutch fork cover;

- adjustment of the cylinder rod and fork.

The transfer case is wrapped with a rope and suspended. Remove the following items:

- pillow bolts;

- nuts holding the fastening of the box with the bell.

With these actions, the engine, when the UAZ 452 checkpoint is being repaired on its own, must be supported with a jack. When the box is released, it is lowered and removed from under the car. The levers must first be removed. On the bell, you need to replace the studs with new ones.

If you need to repair the UAZ Patriot checkpoint, then you need to take into account that the location of the box and the bell is reversed there. This also applies to the location of the rods. But in general, the technology for repairing the UAZ 452 checkpoint on its own is suitable for use.

Unscrew the bolts and nuts, disconnect the gearbox and its transfer case. A gasket is installed between them, reinforced with sealant, so you will have to hit the bracket for attaching the assembly to the frame several times.

Checkpoint diagram UAZ Patriot

Do-it-yourself disassembly and assembly

First you need to remove the input shaft cover and unscrew the left nut that is on it (see Fig.). Now we need to remove its bearing. If it fails, it must be replaced. Its roller "brother" is installed inside the shaft, it also needs to be changed. Then the retaining ring is removed from the secondary roll. Unscrew the stopper of the double row bearing. The shaft must be knocked out and the part changed.

Next comes the third gear clutch assembly. Copper synchronizers are replaced along with crackers. Then comes the turn of the reverse gear. Unscrew the intermediate shaft front bearing box. Do not hit it with a hammer or a core: it is made of silumin and may crack.

Be careful not to damage its rubber seal because it is difficult to get it out. On the removed shaft, the gears and all bearings are replaced. After that, the box is assembled in the reverse order. When the roller is installed on the input shaft, it is abundantly lubricated with Litol. All nodes and parts are put in place one by one, so as not to be mistaken.

Transfer case, complete assembly of the gear unit and its installation

Loosen the nuts of the flanges and shafts, remove them. The hand brake must be checked for operability, if necessary, it must be replaced. Remove all covers and replace seals. Unscrew the speedometer rod drive and the breather (it must be replaced). Check bearings and change if necessary.

The assembly of the transfer case is done in the reverse order. These steps are repeated when working with other types of this car brand (including when). Install the mounting bracket to the frame. They put the transfer case on the parking brake drum and, holding it by the gear, lower it into place through the power take-off hatch.

Before this, a lock washer is placed from the intermediate shaft. They tighten the bolts and nuts, put on the cover with levers and check the operation of all gears. They change the release bearing, remove the levers, drag the entire assembly under the car and hang it on a rope. Put the release bearing assembly on the box and strengthen the spring. Then the input shaft and clutch are inserted. This is done in the following way:

- move the box up and down;

- turn the engine by the flywheel;

- put the node in place;

- attach pillows.

The oiler of the splines of the input shaft and the fork are attached in place, the speedometer drive, universal joints, handbrake, and covers are put in their place. In place, it is necessary to return the cross member of the frame and fix the muffler bracket to the transfer case.

The hand brake is adjusted and adjusted, the oil is changed. If the UAZ Hunter gearbox is being repaired, you may need not only these actions, but also adjustment of the rods. Screw the hatch on the floor, put the seats. This completes the repair of the UAZ 452 checkpoint on its own.

Thanks to Alexander Dorokhov for sending me many pictures of his box. Based on these pictures, I wrote this article.

This picture shows the cover with the shift forks. Visually, I did not notice any wear on the forks! But it is necessary to move the forks with your hands. If they begin to hang out on the rods - So you need to unscrew the wire that fixes them and tighten the bolts tighter! So visually they look great.

Now looking inside the box. You can only breathe. Here, you don’t even need a feeler gauge to see how much wear the gear of the second gear and the end of the output shaft in the area of the coupling teeth have. Ideally it should be 0.2mm. On the worker, of course, a little more. But here you can clearly see that the gap is at least 3.5 mm. Such a gear is only for ejection. Because her coupling teeth will grab only halfway. Compare for yourself the length of the teeth and the width of the backlash.

When the input shaft is removed, inspect it. The synchronizer is no longer good for anything, since its guide teeth are clogged to dullness. The clutch teeth have already done a good job. From the bottom of the teeth, uniform strips of working out are clearly visible. But from above, on the other hand, the rust on the far half of the tooth is clearly visible. This suggests that the gear clutch, when the gas was released, became sideways or was squeezed out. So that the input shaft is ejected along with the synchronizer.

We take out the synchronizer sleeve with the hub. Visually. The fourth gear teeth on the clutch look great. Unfortunately, their lateral wear from the teeth of the input shaft is not visible?

I wonder if the retaining ring came out on its own? If so, then the locking groove on the output shaft has broken into a cone and the ring has been squeezed out of it under load. So you have to go to the turner and he will carefully straighten this red-hot groove with a very strong cutter. A spacer or washer is visible behind the ring, as you like. It will be necessary to immediately put a new bearing on the shaft at the turner, put the retaining ring back in the groove and the turner will immediately turn a new distance washer for you. The washer should be so thick that it sits between the bearing and the retaining ring with a slight tightness or no more than 0.1 mm in the red. Although it is possible that the store sells new retaining rings and spacers of different thicknesses. In any case, for land Rover that's how it's done. But I hope the retaining ring has been removed.

Here, too, I observe a kind of wear on the walls. If yes! That means you need to put a new lock washer thicker. But, if the synchronizer hub also hangs on the splines of the shaft. It is best to change the shaft too! Although the splines look neat and there are no signs of wear. Most likely the shaft is in good condition.

Addition to what was written:

The retaining ring itself can play along the shaft in the groove. The main thing is that when they were planted on the shaft, the third gear and the synchronizer clutch, the gap between the retaining ring and the synchronizer clutch was minimal. That is, the larger the gap, the more the gear and clutch dangle on the axis. Therefore, we strive to ensure that all gears and clutches have the minimum possible backlash. Ideally, from 0.1 to 0.2 mm. Although I collected boxes in which this backlash was 0.5 mm. But the less the better. If the gap between the lock washer and the synchronizer hub is more than a millimeter? You need to put a thicker lock washer. Or it’s more difficult to do if the backlashes are not removed, because the third gear gear is new, and the end of the shaft to which it is pressed is already very worn out. It is necessary to grind a little this end on the shaft to which the gear is pressed. And put a bronze washer 3 ... 4 mm thick there. of such thickness that she would choose the entire walk of the 3rd gear gear on the shaft and press the synchronizer clutch to the retaining ring.

The clutch and teeth facing the third or fourth gear looks good. The edges of the teeth are intact. I don't see any wear. But if the gears change, then the clutch automatically changes as an assembly with the hub. Although I would put this part in the collection with the hub, just in case, in reserve. And if the money is really not enough, then I would put it. If everything is adjusted correctly, nothing will hang out and the transmission has not been knocked out before. I don't see crime. The main thing is that the hub on the shaft sits tightly.

The same goes for the hub.

The replacement synchronizer has blunted edges of the teeth. In this case, they will not slip to the side when the clutch teeth go through them, respectively, the gear lever will engage the gear with some difficulty.

The gears of the third gear are clogged to the point of bluntness, and even traces of chips are visible. It will be difficult to turn on the third gear, and even then every other time. She's not a resident! Only a replacement. former owner obviously did not bother to wait until the synchronizers equalize the speeds of rotation of the shafts. Moreover, Nigrol contributes to this.

And this is what it looks like from behind. The distance washer that stands behind has worked out a lot. It is necessary to buy a new washer, preferably adjusted in size. In extreme cases, carve a new one from bronze. I have a bronze one on Lada. The main thing is that the 3rd gear gear fidgets on the shaft no more than 0.2 mm. And the copper bushing has already begun to crumble. This means that the gear just dangled on the shaft. But she has a tolerance of 0.06mm.

Addition.

Now the hardest part. Yes, you can measure the inner diameter of the gear with a caliper or a digital dial gauge. Then measure the neck of the shaft, subtract one from the other and get the result. But unfortunately this measuring tool costs more than a new shaft and much more! Therefore, I can offer only two options.

1) The bushing on the new gear still has a ready-made size and you can hardly change anything here.

2) Now a way to check the runout of the shafts in the bushings. On fingers. And in the truest sense of the word. The human hand begins to feel the beating of parts in the region of 0.1 mm. Well, if you feel the beating already with a clear knock. So the runout is already in the region of 0.2 mm. and more.

But the most important thing here is not the beating of the gear on the shaft, but how great the walk of the gear along the shaft is.

The gear should walk as little as possible from the 3rd 4th gear clutch and to the stop end on the shaft. Ideally, 0.08 ... 0.2 mm.

And the second gear gear is out of competition. She worked out to such an extent that the development burned out the sharp edges of the coupling teeth. And this is about a millimeter. So the gear shied away on the secondary shaft by at least 3.5mm (second photo) with a tolerance of 0.2mm. This is what the museum needs!

The teeth on the gear of the first gear are also clogged, so that the second gear will turn on will be very problematic.

The intermediate shaft gear had no beaten teeth and no beaten splines. As a rule, it always is. If that realties did not damage the teeth of the intermediate shaft, then on the shaft, as a rule, only the bearings change. The exception is heavily damaged reverse gear teeth.

The teeth on the reverse gear are jammed. Quite a common defect. It also needs to be replaced, since wear goes to the cone, then the gear may begin to knock out after some time. Take a closer look at the larger gear - you can see it better from below.

The axis on which the reverse gear rotates looks good. I honestly don't remember it ever being changed.

But the bearing needs to be changed, since it already has wear. Roller bearings have the main symptom: if the roller has fallen out of the separator, then the bearing has worn itself out.

Judging by the photos. Crackers were removed from the synchronizer clutch. Nothing surprising. With such a large backlash of the gears (along the shafts), the clutch crackers of the 3rd and 4th gears began to climb out of the synchronizer clutch when the gears were turned on. After that, they began to bristle outward under the influence of the spring and as a result it was impossible to turn off the gears. Namely, so that this does not happen, I try to select all the backlashes on the shafts of the box and the switching forks during the repair.

Verdict. In the box, you need to change gear 1,2,3, gears. Also replace the input shaft, all bearings, gear reversing. Not strictly necessary, but you need a clutch with a hub and both synchronizers. If the new gears hang on the old shaft by more than 0.15 mm. (The hand perfectly feels a knock above 0.1 mm.) So the secondary shaft should also be replaced.