The main purpose of the timing (gas distribution mechanism) of any car is to synchronize the camshaft (s) and the crankshaft. The correct functioning of this mechanism greatly affects the efficiency of the motor. The timing can be made in the form of a chain or a belt, the first option is usually more reliable. On the UAZ Patriot with the ZMZ 409 engine, this mechanism has a chain in its composition.

And now, a little about why it may be necessary to replace the timing chain with a UAZ patriot with a 409 euro 4 engine. The thing is that with a high mileage of a car, the timing, made in the form of a chain, can stretch, which subsequently leads to a rupture or chain slip. The factory prescribes the replacement of the chain in the region of 80,000 km.

How is the timing of the "Patriot"

In fact, ZMZ 409 is the twin brother of the injection 406 engine, which was installed in the Volga and Gazelle. Structurally, they are very similar, respectively, and the 409 engine inherited the same problems (more on this below). ZMZ 409 has two camshafts made of cast iron. These camshafts rotate on bearings, which are obtained by connecting the cylinder head plane with removable aluminum covers.

These covers are processed together with the cylinder head, so putting them from another car will not work without changing the cylinder head.

The timing drive here consists of a pair of single-row plate-link chains. This option is less reliable than one double-row chain, besides, plate-link chains tend to break unexpectedly, without any prior "sound warning", by which it can be understood that it is about to break. If it is not possible to supply a more reliable double strand chain, then a roller link chain is a good option, which is also more reliable.

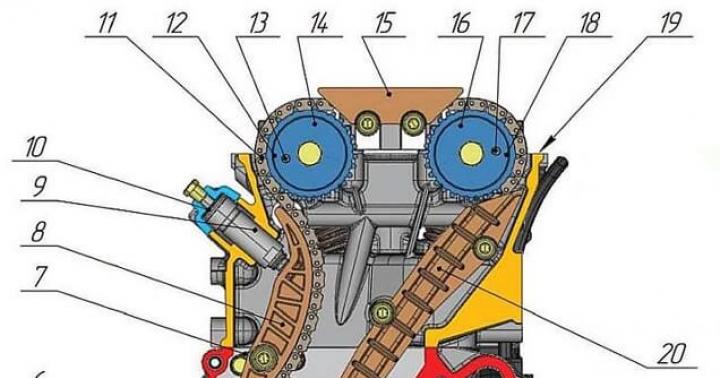

Timing Patriot with a ZMZ 409 engine includes the following elements:

- crankshaft gear;

- Plastic shoe for chain tension;

- Hydraulic tensioner;

- The so-called "upper" chain;

- Large driven gear promvala;

- Small drive gear promvala;

- Shoe bolt support;

- Another shoe for chain tension;

- Another hydraulic tensioner;

- Noise reduction washer;

- "Lower" chain;

- Special mark on the gear housing;

- Pin;

- Intake camshaft star;

- "Calmener" of a chain top;

- Exhaust camshaft star;

- Pin;

- Another mark on the gear housing;

- The upper plane of the cylinder head;

- Medium chain damper;

- Lower chain damper;

- M1, M2 - marks on the cylinder block body.

Signals for replacement

The main signal that the Patriot needs a timing replacement is extraneous metallic sounds coming from under the hood, such noise can be described as a kind of “rattling”. Due to inexperience, you can confuse a breakdown with knocking valves. Although hydraulic compensators are installed on the 409 motor, it is necessary to fill in high-quality oil so that the valve clearance is adjusted correctly. Problems with the timing of the Patriot, as a rule, are characterized by a loss of power at low speeds.

It turns out that if the mileage approaches 80,000 thousand km. and / or chain stretching goes beyond the operating range of the hydraulic tensioner - there is only one way out, namely, installing a new chain instead of the old one. Otherwise, you run the risk of staying in the middle of the road in the company of a stationary car at the most inopportune moment for this, somewhere far from home, as is usually the case according to the “law of meanness”.

Replacement process

It must be understood that replacing timing chains on a 409 UAZ Patriot engine is a complex process, especially for engines with Euro 4 toxicity standards. So, for such a repair, you will first need a garage with a pit, or an overpass, since access to the engine compartment is a prerequisite from below. In addition, you will need a number of tools:

- hex key 6 mm;

- chisel and hammer;

- heads for a collar in sizes "12", "13" and "14";

- a set of wrenches in sizes from 10 to 17;

- device for setting the valve timing;

- add. accessories: container for draining coolant from the radiator, jack, gear puller.

Install the car so that you can crawl to the engine compartment from any side. Then, turn off the ignition, disconnect the “-” terminal from the battery. It’s not so easy to get close to the timing mechanism, first you have to unscrew everything that closes it. Drain the coolant into a container prepared for this, then unscrew the radiator and pipes.

(Optional) Loosen the oil pan bolts and then remove it after draining the engine oil first. This procedure will further facilitate the installation of the timing. If you do not want to drain the oil, then unscrew only the front oil sump bolts.

Next, remove the power steering pump belt. The same must be done with the alternator + water pump (pump) belts. Remove the supply hose to the pump, remove the cylinder head cover (after removing all ignition coils). After that, it is necessary to disconnect the front cover of the cylinder head by unscrewing 4 bolts, and then remove it together with the viscous fan clutch and the propeller itself.

Next, you need to disconnect the water pump, which is attached with three bolts. Remove the crankshaft position sensor (aka timing sensor) by unscrewing one bolt that holds it on. Remove the crankshaft pulley, this may require a three-arm puller.

Disassembly of the timing mechanism

Unscrew the bolts securing the cover of the hydraulic tensioner of the upper chain, remove it together with the gasket. It is important to do this carefully, because the hydraulic tensioner spring presses on the cover. After removing the spring, remove the hydraulic tensioner itself. Similarly, you need to do with the lower hydraulic tensioner. Loosen the 7 bolts securing the chain cover. Remove the cover carefully, as there is a risk of damage to the gaskets or the crankshaft oil seal.

Unscrew the shoe fastening bolt (number 7 on the diagram) of the chain tension and remove the shoe, do the same with the lower shoe. Now you need to disconnect the camshaft gears (14 and 16 in the diagram) from the camshafts themselves - open-end wrenches for 12 and 17, as well as a hammer, will help here. Or use a special puller.

Unscrew the dampers that prevent further dismantling. Each of the dampers rests on two bolts. To remove the intermediate shaft sprockets (5, 6 see the diagram), you need to bend the plate and unscrew the sprockets fastening bolts by inserting a screwdriver into the special grooves on the gear wheel, thus keeping the gears from turning. After dismantling the chain, wash it and gears in gasoline, inspect for damage.

Timing assembly

Assemble the entire mechanism in reverse order. The installation of timing marks on a 409 engine occurs after the assembly of the mechanism, when the chain is located on the gears. Before starting assembly, be sure to lubricate the chains and timing gears with engine oil. First of all, press the gear onto the crankshaft, do not forget about the bushing + o-ring, which should be there. Rotate the crankshaft until the gear and block mark (M1) match, the piston of the first cylinder must be at the top (TDC position).

Put the chain guide, put the chain on the crankshaft gear. Install the intermediate shaft driven sprocket so that the pin is aligned with the hole. Here you also need to match the labels (M2). Install the promshaft drive gear from above, tighten the mounting bolts and bend the edges of the locking plate in order to avoid arbitrary unscrewing. Next, you need to press the tensioner to tension the chain - until the timing marks (12 and 18) coincide with the upper plane of the cylinder head.

After the timing mechanism is assembled, it is necessary to install in its place all those parts that were dismantled initially. These are cooling hoses, fan, belts, valve cover, water pump. If the pallet on your Patriot was fastened through a gasket, change it, it is allowed to use a heat-resistant sealant instead of a gasket. At the end, pour antifreeze or antifreeze into the cooling system. If the engine oil was drained (the pan was removed), then do not forget to fill in fresh. Put the "-" terminal of the battery back in place and try to start the engine.

The gas distribution mechanism on the UAZ Patriot we are considering, taking into account that the 409 engine is on it, has one great purpose, and many of the experienced drivers know about it, to synchronize the camshafts and crankshafts. Plus, through this mechanism, cycles are set for closing and opening valves.

Details about the timing on the Patriot

As already mentioned, the chain mechanism is the main connecting element of the camshaft and crankshaft. With the active use of your car, the elements begin to wear out, which leads to all sorts of breakdowns. Many have encountered the fact that after some time the timing mechanism begins to stretch, as a result of which the chain tension weakens, and this may well lead to its slipping or even breaking. The manufacturer of the Patriots officially declares that the timing chain should be replaced every 80 thousand kilometers. In this article, we will tell you in the same way how to change the chain correctly and with your own hands, using, among other things, timing marks.

I would like to note that the domestic UAZ Patriot, or to be more precise, its 409 engine immediately has 2 timing chains, and not one as is customary on other cars, if it meets the Euro-3 standard, in the Euro- 4 costs only one chain. They are called the lower and upper timing chains. It follows that this mechanism as a whole on UAZ is a rather complex mechanism that requires a competent approach in carrying out various repairs, even in replacing chain elements.

Happy owners of the UAZ Patriot from time to time begin to wonder when it is necessary to replace the timing chain on a car so that a breakdown does not occur on the road at the wrong moment? After all, everyone knows that there are cases of a chain break while driving, which will certainly entail a large number of unpleasant consequences. The most objective factor that indicates that the chain should be replaced soon will be its condition, which can be assessed visually. You should also pay attention to an unpleasant metallic sound when the engine is running. Such a sound is heard necessarily from under the bonnet space, and should be a signal for the driver to check and, probably, the subsequent note of the timing chain.

If you see that the car has reached the mark of 80 thousand kilometers, and it is impossible to tighten the mechanism, the chain tensioners do not allow it, then it is 100 percent time to allocate time and money and use the timing marks to replace. How to change and do everything right, we will tell further.

ZMZ-409 Euro-4 standard is equipped with a single-row timing chain from the factory. This modification of the UAZ Patriot is more vulnerable, and the circuit breaks much earlier than the other version, and this happens often, completely unexpectedly for the driver. Experts recommend that when the chain breaks on the UAZ Patriot, when a replacement is required, install a two-row one, which will extend the working life and be more efficient in operation, and the next unexpected break will not occur, because you will hear unpleasant sounds in advance, signaling wear and tear and that it's time for a replacement.

Step-by-step process of replacing a timing chain on a UAZ Patriot

When you found out that the UAZ Patriot needs to replace the timing mechanism due to wear and tear, then you definitely need to find out how the timing chain is replaced on the car we are considering using the timing marks. Consider the algorithm for working on a car with a 409 engine and complies with the Euro-3 standard.

What tools do you need to prepare:

- Chisel.

- Hammer.

- 12, 13, 14 heads on the collar.

- 6mm hexagon.

In addition to the listed tool, you should stock up on accessories, in particular, this is a container into which you need to drain the coolant from the radiator, more on this later.

How to change the chain for UAZ Patriot step by step:

- The first thing that is required is to drain the coolant from the radiator into a previously prepared container.

- We dismantle the radiator.

- We dismantle the power steering pump drive belt and, accordingly, the fan pulley.

- Remove the water pump and alternator drive belt.

- Remove the supply hose.

- Remove the cylinder block cover.

- We remove the water pump from the power unit.

- Remove the crankshaft rotation sensor.

- We unscrew all bolted connections.

- Remove the upper chain tensioner cover.

- We remove the hydraulic tensioner.

- Remove the lower chain tensioner cover.

- We also remove the hydraulic tensioner in this case.

- Unscrewing 7 bolts and remove the cover. This should be done carefully, since the likelihood of damage to the crankshaft oil seal is easy.

- We unscrew one bolt from the lower and upper chain device, after which we remove them together with the sprockets.

- We dismantle the gears of the camshafts. For this purpose it is necessary to remove the mounting bolts.

- Gears are removed using a specialized puller.

- We remove elements. Use the photo below with lettering.

- Unscrew the 2 connection bolts #2.

- Bend back plate #6.

- We remove the gear, then the chain mechanism, which should be pulled up.

- The lower element is removed in the same way.

Such a procedure as replacing the timing chain in the considered popular UAZ Patriot is time-consuming and requires adherence to the exact sequence in the actions performed, and, of course, concentration. After you have removed the gears and chains, they should certainly be washed in gasoline and visually inspected for various damage. Tensioners, gears or chains that have clearly visible damage must be replaced.

We assemble the timing mechanism on the Patriot

The assembly of the removed mechanism is always carried out in the reverse order. Do not forget that the installation of the crankshaft gear on the UAZ Patriot requires a process such as pressing. The shaft must be installed so that the timing marks match, that is, the mark on the cylinder block must necessarily coincide with the mark on the crankshaft gear. These very marks are indicated by the numbers 1 and 2 in the photo below.

- Then we install the chain guide and put the chain on the gear. Before this, do not forget to lubricate the chain with engine oil.

- We put the element on the driven gear by installing it on the so-called intermediate shaft. The process will be completed when marks 4 and 5 match.

- We screw the bolts of the promshaft gear, do not forget to fix them with a special locking plate.

- Until the marks on the gears match, press the tensioner.

- Lubricate the parts with engine oil and install everything in the reverse order.

Summing up

In the end, I would like to note that you can change the timing chain directly to UAZ Patriot in your own garage, the main thing is to allocate free time, get everything you need, and strictly follow the sequence of actions when replacing. Of course, if you turn to specialists, the work will be done many times faster, and the 409 engine will run like clockwork.

The main purpose of the gas distribution mechanism on the UAZ Patriot SUV is to synchronize the crankshaft with the camshaft, but, in addition, also to be able to set cycles for opening and closing valves. The functionality of the gas distribution mechanism directly affects the efficiency of the car's engine, so it is very important that the mechanism is in good working order. The main element connecting the crankshaft and camshaft is a chain mechanism. But over time, the operation of the car tends to wear out the working elements, as a result of which various breakdowns occur. In particular, the timing chain mechanism stretches over time and weakens the tension of the chain, which can lead to its rupture or slippage. So, the UAZ Patriot manufacturer has established that the elements of the timing mechanism must be replaced every 80,000 km. Today we will pay attention to the process of replacing the timing chain on the UAZ Patriot Euro-3 SUV with our own hands.

Initially, it should be noted that the UAZ Patriot SUV, or rather, its ZMZ-409 engine in the timing mechanism, has not one chain mechanism, but two. They are referred to as the upper and lower timing chains. Therefore, the design of the timing on the UAZ Patriot Euro-3 SUV is a complex mechanism that requires a qualified approach to repair work, in particular, to replace chain elements.

Often, SUV owners wonder when it is necessary to replace the timing chain so that there are no troubles on the road? Sometimes there are situations when an open timing chain occurs on a UAZ Patriot car, which entails a lot of negative consequences. The main and objective factor indicating that it is necessary to replace the element soon is its condition. If during engine operation a metallic sound is heard from the engine compartment, then it is time to check the condition of the timing chain tension.

If the chain tensioners do not allow the mechanism to be tightened, and the car’s mileage reaches the mark of 80 thousand, then it is recommended to spend time and money and replace the chain. How to do it yourself on the UAZ Patriot Euro-3 SUV, let's take a closer look.

The ZMZ-409 Euro-4 engine from the factory has single-row timing chains. On this modification of the UAZ Patriot, the timing chain break occurs earlier than in Euro-3 and unexpectedly! But if you really need to replace the product, it is recommended to install only a two-row one. The two-row chain has a significant service life, which increases its efficiency, and long before the break, the engine begins to emit extraneous sounds, warning of wear.

Replacement process

If the replacement period has come or you find out that the chain on the SUV is worn out, then a process such as replacement will be required. Before proceeding with repair measures on the UAZ Patriot Euro-3 SUV, you need to make sure that you have the following tool:

- hex key 6 mm;

- heads on the knob "12", "13", "14";

- hammer and chisel.

In addition, you will also need accessories, such as a container for draining coolant from the radiator, etc., but more on that later.

So, replacing the chain on the ZMZ-409 engine of the UAZ Patriot Euro-3 SUV involves the following steps:

- Initially, it is necessary to drain the coolant into a specially prepared container, after which the radiator can be dismantled.

- The power steering pump drive belt, as well as the fan pulley, are being dismantled.

- The alternator and water pump drive belt is dismantled.

- The inlet hose is removed, and the cylinder block cover is also dismantled.

- It is necessary to dismantle the water pump from the ZMZ-409 engine of the UAZ Patriot Euro-3 SUV, and then remove the crankshaft rotation frequency sensor.

- Bolted connections are unscrewed, and the top chain tensioner cover is dismantled. After removing the cover, the hydraulic tensioner should be dismantled. After that, the hydraulic tensioner of the lower chain of the ZMZ-409 engine of the UAZ Patriot Euro-3 SUV is removed in a similar way.

- Next, unscrew the 7 bolts, then remove the cover. But at the same time, you should be careful, as you can damage the crankshaft oil seal.

- To remove the tensioners, unscrew one bolt from the upper and lower chain device, after which you can remove the products together with the sprockets.

- The next step involves dismantling the gears from the camshafts by unscrewing the mounting bolts. To remove the gears, you will need to use a special puller.

- The next step is to remove the elements. To do this, we will use the following photo with letter designations, which shows the timing mechanism of the UAZ Patriot Euro-3 SUV.

To begin with, two bolted connections at number 2 are unscrewed. After  To do this, it is necessary to bend the plate 6, thereby freeing access for unscrewing the bolt 5. Now you can remove the gear, and behind it the chain mechanism itself, pulling it up. The lower element is extracted in the same way.

To do this, it is necessary to bend the plate 6, thereby freeing access for unscrewing the bolt 5. Now you can remove the gear, and behind it the chain mechanism itself, pulling it up. The lower element is extracted in the same way.

Replacing timing elements is a laborious process and requires care and adherence to the correct sequence of actions. After removing the chain and gears, they must be washed in gasoline, and then visually inspected for damage. If the chain, gears or tensioners are visibly damaged, they must be replaced.

Let's briefly consider what the assembly process of this mechanism is.

Assembly of the timing mechanism

The assembly process of the mechanism is carried out in the reverse order of removal. In this case, the installation of the crankshaft gear implies an operation to press it. In this case, the shaft should be installed in such a way that the mark on the crankshaft gear coincides with the mark on the cylinder block. In the photo below, these marks are numbered 1 and 2, respectively.

After that, the chain damper is installed and the chain is put on the crankshaft gear. Before installing the chain, thoroughly lubricate it with engine oil.

Next, the element is put on the driven gear, installing the latter on the intermediate shaft until the locating pin enters the hole. It should also be borne in mind that mark 4 should be equal to mark 5. The bolted connections are screwed with the promshaft gear, fixing them with a locking plate. By pressing the tensioner, you need to tighten the element until the marks on the gears match. At the final stage, it is necessary to lubricate the elements with engine oil and install all the removed parts in the reverse order of removal.

Summing up, it should be noted that it is possible to replace timing elements on a UAZ Patriot SUV at home only if you have free time, the ability and skills to repair a car. At the service station, the work will be done much faster, and the engine will run like clockwork.

You can check your CBM and reduce it if needed!

You will need: a “6” hex key, “12”, “13”, “14” heads, a small chisel, a hammer.

1. Drain the liquid from the cooling system (see "Replacing the coolant").

2. Remove the radiator of the cooling system (see "Removing and installing the radiator").

3. Remove the power steering pump drive belt and fan pulley (see "Replacing the power steering pump drive belt and cooling fan drive viscous coupling").

4. Remove the alternator and water pump drive belt (see "Replacing the alternator and water pump drive belt").

9. Remove the crankshaft speed sensor (timing sensor) (see "Sensors of the engine management system").

10. Remove the crankshaft pulley (see "Replacing the crankshaft seals").

11. Remove the oil sump (see "Replacing the oil sump seal").

14. Turn out seven bolts and remove a cover of a chain. Remove the cover carefully so as not to damage the front crankshaft oil seal installed in it, the cover gaskets and the cylinder head gasket.

15. Turn out a bolt of the top tension device and remove the tension device lever with an asterisk.

16. Similarly, remove the lower tensioner arm with an asterisk.

|

|

|

|

19. Turn out bolts 2 and take up a damper 1 chains. Bend the ends of the locking plate 6 and unscrew the bolt 5, for which keep the intermediate shaft from turning by inserting a screwdriver into the hole of the gear 3. Remove the gear 4 by inserting a screwdriver between it and the gear 3 and resting the screwdriver as a lever against the gear 3. Remove the gear 4 from the top chain and remove the chain by pulling it up. Remove gear 3 from the intermediate shaft and remove it from the lower chain. Remove the lower chain from the crankshaft gear. |

20. If necessary, remove gear 2 from the crankshaft, first remove bushing 1 and the rubber o-ring between bushing and gear. Then compress gear 2 with a puller. |

21. After removal, wash the chains and gears in gasoline, wipe and dry them.

22. Examine the chains. If cracks, chips, or significant signs of wear are found on the chain bushings, replace the chains.

23. Replace gears that have chipped or chipped teeth.

24. Replace damaged chain guides.

25. The tensioner sprockets must rotate freely on the axles. If the sprocket teeth are chipped or chipped, replace the tensioners.

26. If the gear was removed from the crankshaft, press it onto the crankshaft, install the sealing ring and bushing.

|

|

|

|

27. Turn the crankshaft so that mark 1 on the crankshaft gear matches mark 2 on the cylinder block. In this case, the piston of the 1st cylinder will take the TDC position. Install the chain damper 4 without tightening the bolts 3 fastening the damper. Put chain 5 on the crankshaft gear, after lubricating it with engine oil. |

28. Put the chain on the driven gear 1 and install the gear on the countershaft 2 so that the gear locating pin enters the countershaft hole. In this case, mark 4 on the gear must coincide with mark 5 on the cylinder block, and the chain branch passing through the damper 3 must be tensioned. |

29. Install the countershaft drive gear so that its locating pin fits into the hole in the driven gear.

30. Screw in two bolts of fastening of gear wheels of an intermediate shaft, having placed a lock plate under them. Tighten the bolts to 22–25 N m (2.2–2.5 kgf m) and secure them by bending the edges of the lock plate on the edges of the bolt heads.

31. Pressing the tensioner lever, tension the chain and check the alignment of the marks on the gears and the cylinder block.

32. Tighten the chain guide bolts.

33. Lubricate the upper chain with engine oil and then put it on the intermediate shaft drive gear, passing it through the hole in the cylinder head.

34. Put a chain on a gear wheel 2 and, having slightly turned an exhaust camshaft clockwise, establish a gear wheel 2 on it with the chain put on it. Pin 8 of the camshaft must enter the gear hole. Screw in a bolt 1. Turn a camshaft a key for a square on a camshaft. Then, turning the camshaft slightly counterclockwise, tension the chain. The intermediate and crankshafts must not rotate. Mark A must align with the top surface of the cylinder head. Turn out a bolt 6 and remove a gear wheel 4 from an inlet camshaft. Put a chain on gear 4 and install gear 4 with chain on the camshaft by slightly turning the camshaft clockwise. The pin 5 of the camshaft must enter the gear hole. By slightly turning the camshaft counterclockwise, tension the chain. Mark A on gear 4 must match the top surface of the cylinder head. The rest of the shafts must not rotate. Screw in the bolt 6. Tighten the bolts 1 and 6 to 46–74 N m (4.6–7.4 kgf m), holding the camshafts from turning with a key for the squares. Install damper 3 by pushing it into the hole in the block head. Install damper 7.

35. Install the chain cover and water pump. Apply a thin layer of Hermesil sealant or similar to the surfaces of the covers adjacent to the cylinder block and block head. When installing the chain cover, be careful not to damage the crankshaft oil seal.

36. Install the hydraulic tensioners of the upper and lower chains, see "Assembly ("Charging") and installation of the hydraulic chain tensioners" . Install the crankshaft pulley. Screw in the bolt of the crankshaft pulley, then, turning on the fifth gear and braking the car with the parking brake, tighten the bolt to a torque of 104–128 N m (10.4–12.8 kgf m), holding the crankshaft from turning. When tightening the ratchet, the pulley is pressed onto the crankshaft.

37. Turn the crankshaft two turns by the ratchet and set the piston of the 1st cylinder to the TDC position (see operation 3). Check if the labels match.

38. Install the front cover of the cylinder head, first apply a layer of Hermesil sealant to the surface of the cover adjacent to the block head. Tighten the cover fastening bolts to 12–18 Nm (1.2–1.8 kgfm).

39. Install the cylinder head cover. Tighten the cover fastening bolts to a torque of 6.0–12 N m (0.6–1.2 kgf m). Connect the crankcase ventilation hose and tube to the fittings on the valve cover, and the wires to the ignition coils. Put on tips of high-voltage wires on spark plugs.

40. Install the previously removed attachments.

Many experienced motorists argue that the replacement of the timing belt with a UAZ Patriot diesel Iveco should be carried out every hundred thousand kilometers. This figure is approximate and largely depends on how the vehicle was operated.

Some models have a timing chain. It is alleged that its resource is greater than that of the belt, but this is not always the case. As practice shows, in some cases the need for replacement occurs after fifty thousand kilometers. In any case, the time to replace the chain must be determined by its condition and regularly checked visually for damage and loose tension. Also, is there any damage to the tension rollers.

[ Hide ]

Replacement cases

The timing belt on the UAZ Patriot on an Iveco diesel must be changed if the mileage specified in the instructions is reached. If oil stains, worn teeth or delaminations are found.

Step by step instructions for replacing the belt

The change process is simple, but it will require the removal of additional nodes and some rollers, so be careful.

Tools

- a set of keys;

- new tension rollers (they may need to be changed);

- screwdriver.

Stages

- First you need to remove the generator and air conditioning compressor.

- Having unscrewed the fasteners, you need to release the generator, and then take it away so as not to interfere.

- Now you need to unscrew and remove the fan impeller. We also remove the diffuser.

- We remove the fan drive by unscrewing the locknut under the manifold.

- Now you need to remove the bypass roller and tensioner.

- Next, remove the tensioner.

- We remove the pulley from the crankshaft, after unscrewing the four bolts.

- Remove the cover of the gas distribution mechanism.

- Rotate the crankshaft clockwise. It is necessary that the mark on the crankshaft becomes at 9.00, and on the distributive, at 12.00.

- Next, you need to fix the shafts.

- To fix the crankshaft, you need to unscrew the plug, and insert a screwdriver into the hole.

- Many motorists fix the camshaft with a drill of a suitable diameter inserted into the pulley hole.

- Now you need to unscrew the tensioner bolt and remove it.

- Next, you can remove the belt.

- We proceed to the final stage of installing a new timing belt.

- When installing a new one, we make sure that its marks coincide with the marks on the crankshaft at 9.00, and also with the mark on the camshaft pulley at 12.00.

- Install the tensioner.

- When pulling the belt, you need to make sure that the point coincides with the cutout or goes under tension.

- We put the removed parts in place, while do not forget to lubricate the rollers.

This video shows how the timing belt is removed on the UAZ Patriot in a matter of minutes.

Step-by-step instructions for replacing the chain

Replacing a chain is not the easiest job in a car service, but after reading our material and watching the video, you can certainly handle it.

Tools

Stages

Metal products from China have never been particularly reliable, this also applies to tension rollers.

Work on replacing a belt or chain on a UAZ is not difficult in itself, but it requires certain skills and attention. Therefore, it will be useful if a more experienced partner will insure you for the first time. Also, if you are unsure of your own abilities and are afraid that you can confuse something, film the disassembly process on camera. Then it will be easier to collect. Place the removed parts in pre-prepared boxes and jars. It often happens that some bolt, roller or washer gets lost, so be careful and attentive.

In the future, when operating the car, try to follow all the routine measures specified in the instructions that come with the car. Timely pass diagnostics at the service station and your car will work properly and smoothly for many years.