) UAZ Patriot car on the platform Ssang yong Musso was purchased as a set of units. Then the documents were drawn up and all design changes are registered with US... Now the car is registered with the traffic police and can officially undergo a state technical inspection.

Engine replacement, frame replacement, body replacement

You know, there is an expression - "Everything, and no x .. I really!" It was the best fit at that moment to describe the condition of the car!

Theoretically, we have a unique car, and even existing in a single copy and, most importantly, again, theoretically, significantly superior to the standard Patriot in terms of ability to move on public roads!

But practically ... To put it mildly, something is not right .. Something was missing. First of all appearance left much to be desired: a narrow track, squeezed torsion bars and tires slightly cracked from standing for a long time made him very "tired". The main thing was not to touch the car when approaching the car. paintwork... If you still had to touch him, it became completely sad, because it was rough to the touch.

It was no better inside .. Despite the fact that the Patriot body is one of the first Patriot bodies (more precisely the eighth, the number ends with 000008). Accordingly, at the factory, the salon was blinded from what was. And there was everything from the excellent model 3162 and the curved Nizhny Novgorod panel (the same as the Iranian patriot, only black and curved, it leads them from the sun). Window lifters, of course, manual. Naturally, there was no radio tape recorder, and there were no speakers either. The trouble is simple!

Also, the safety belt buckle did not work.

No, in fairness, I must say that in general, the Oise-Musso was in a normal technical condition and independently, the first time passed the State Technical Inspection, remember such an event? In 2010, it has not yet been renamed.

THAT must be completed after receiving approval from NAMI.

That's why I say - "Everything, and not at .. I really." In general, everything is good, but not impressive and not happy. Not happy with the appearance, not happy with the interior, not happy with the level of comfort, lack of air conditioning and a number of technical issues.

Such as: under the hood of the devil, a circle of "skillful hands" and that, probably would have done better.

The gearbox beats slightly on the body - the wings are not correctly made and not correctly adjusted - the gears are not engaged clearly. Etc. I will not list everything, it is not interesting.

In general, after completing all the documents, a political decision was made to make light tuning.

We bring to your attention a small photo report on the work done with brief description main stages.

First of all, it was necessary to tidy up the appearance, option one - repainting!

The car was completely disassembled, the transmission tunnel was redone (seen in the photo). Now the curtain is correctly positioned, the cable does not rub against the checkpoint, the checkpoint no longer hammers against the body. The fastening of the panel for the patriot one has been improved. Soundproofing work has begun.

In this form, UAZ-Musso left for painting in December 2010.

And in March 2011. I returned safely from the painting.

See how it glitters! What a gloss !!!

This photo clearly shows the redesigned transmission tunnel and the "curved" clutch pedal, slightly curled to the left.

When I was driving, I thought, I think. It turned out not - the pedal bracket was slightly bent. I had to refine it.

All work, except for painting, was carried out in the Brava service, widely known in narrow circles, which is located in Peredelkino.

For which many thanks to Alexander Chernov!

THREE year endured this disgrace! Thank you, dear! May God grant you health! All the best!! Good bride !!!

In this photo, UAZ-Musso just drove into the shop.

Salon, doors - everything is empty! They threw out everything old. Everything will be new: interior, carpets, ceiling, door fittings, door trims, etc., everything will be new from the Patriot!

Under the hood only the engine radiator and the ABS modulator with brake pipes.

Noise isolation is ready! There is Swedish vibration damping material on the floor. Thickness 4mm black. 5mm with foil. The cost of one sheet is 500x500 550 rubles. Good material by the way, I recommend!

Acoustic preparation has been made in the doorway.

The ceiling is pasted over in two layers. First, a rubber-based vibration damper, then, with a second layer of Izolon 4mm.

Installed new windshield and regular patriot soundproofing of the motor shield.

The engine board has been modified for the DELPHI heater with air conditioning. The old-style stove tap is used as an element for connecting the engine compartment and interior hoses of the stove. A DELPHI valve is used to control the flow of antifreeze.

A DELPHI heater with air conditioning was installed (installed on the Patriots from 2008 to 2012), and the top of the new panel.

And also the ceiling is already assembled:

The entire suspension was defective, the defective parts were replaced with new ones.

Rear suspension was in excellent condition. Only the shock absorbers were replaced.

In the front hall, several silent blocks had to be changed - they were slightly cracked from time to time and from downtime.

The shock absorbers were also replaced. Well, of course, we adjusted the torsion bars !!

Wheel spacers are installed.

Collected and adjusted all the doors. We installed glass and door seals. All new!

Under the hood: a new heater, a new trapezium of new wipers. The hoses of the stove are laid humanly. The wiring is pre-assembled so that you can start the engine

First start of the engine after the bulkhead:

The bumpers have also been replaced.

The front was all battered fiberglass. And the back, stupidly about ... whether in painting. The bumpers were painted last.

In this form, the Oise-Musso stayed for the winter and met 2012.

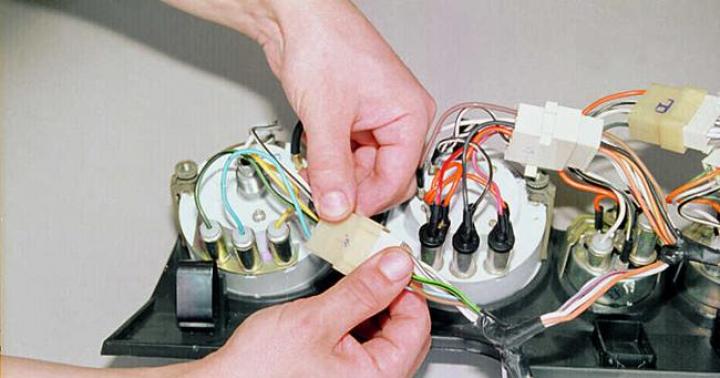

Docking of the UAZ and Musso wiring was done by a professional auto electrician.

Well, as he did, he altered it.

Everything seemed to have been done, and everything worked. But it looked terrible. It was impossible to disassemble this wiring without using wire cutters. Therefore, wherever needed, connectors were installed. The harnesses were laid a little differently.

And so, in the coming 2012, there was a time and some circumstances coincided, which made it possible to continue working.

The main and most important circumstance is that after 3 months the panels of the trunk and rear arches came !! HURRAH!!! It can be clearly seen in the photo! Without them, it was impossible to assemble the floor, put seats, etc.

The same professional electrician installs the rear speakers.

In this photo, he continues to put the rear speakers.

Pay attention, the work is going on in the street, Chernov drove us out, thank God, so far into the territory, and not outside the gate.

Almost everything is ready under the hood!

All wiring is in place, in corrugations. There is not enough washer reservoir, air conditioning hoses and a new battery.

The installation of electric fans and sound signals is visible.

The electric fans turn on when the air conditioner is turned on.

The engine is cooled by a mechanical fan through a viscous coupling.

We put the headlights and fenders.

Rear seats folded. The rear seat frame and folding mechanism are homemade.

The floor is fully assembled.

Leather seats, borrowed from Toyota, were pulled in interior color

In this form, UAZ-Musso met 2013

Combined door upholstery. At the top, there are leather inserts in the color of the seat upholstery.

Rear passengers are very comfortable - plenty of legroom. The floor is almost level. (for comparison - UAZ-Musso on the left, UAZ Patriot 2012 on the right)

To "refine" the floor tunnel and cover the loop of wires, it was necessary to make an original casing in the future.

The complete fine-tuning of the car took three years in the end.

Now this car looks like this:

Video Drift UAZ-Patriot on ice from Andrey Lunin.

To buy "Spare part Torsion bar front left on a car SsangYong Musso (FJ) 1995" on the auto parts portal Avto.pro, you need to follow these steps sequentially:

- choose a suitable offer for the purchase of a spare part, - a new page with an information card of the seller will open;

- contact the seller directly and check the correspondence between the code of the auto part and its manufacturer, for example: "Torsion bar front, left for Ssang-yong Musso 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006 model years", as well as the availability of spare parts in the warehouse.

The cost for the front, left torsion bar on the SsangYong Musso car and the price of analogs

At the moment you can choose the option purchase "torsion bar front, left" among the offers of 13 sellers at a cost: from UAH 1915.45 to UAH 3832.17. The site has offers for used and new auto parts from the cities: Kharkov, Krivoy Rog, Kiev. Please do not forget to check with the seller for the possibility of delivering the spare part to your city.Material for those who are just looking out for such a car.

So Musso and Korando. In essence, this is an absolutely identical car, one chassis, the same engines, transmission. Even the frame is almost identical, only the Korando is slightly shortened.

Both vehicles were also produced for the needs of the Korean army. They had a more ascetic appearance and somewhat specific equipment. Moreover, the first versions of civilian vehicles were unified and sometimes even had blackout lights.

But back to the civilian versions.

There were diesel engines according to MB - om601 and om602.

The injection pump is only in-line - everything is more than wonderful here, everything is Mersovian, for the engine and fuel, almost everything is put from the 124th body.

601th capacity does not go at all.

It is very, very different from om602, it would seem 20hp, but 2.3 does not go.

on the handle you can still swing it, but the handle is the same nonsense, the curtain is cable (most often) - as if you are stirring jellied meat with a spoon, it is unrealistic to guess which gear you stuck in, well, to break the backstage cable is just to spit.

It seems that somewhere in 2000, the cables were abandoned, but I have no reliable information on this.

If you take it only with 602m capacity and only on the machine (Australian BTR M74), or with 104m benz. and also on the machine (from 104m an unkillable, autonomous, in a vacuum Merso's box 722.3 was aggregated)

By the way, the gasoline ones were m102 and m104 - both are not bad. Unless the engine control unit sometimes died on the m104.

In the drain, the Koranda has an interesting geometry, but everything is spoiled by the traverse on which the box hangs - a real PLUG!

The car needs to be prepared right away, it's easy to lift, the Korando has 31 wheels without crap, in this version it's already interesting ... with the elevator, the booths fit into the three-door, 33, and 35 already need to trim the arches, the transmission pulls, except for the front axle!

In place in the arches, there is a difference between korando and musso. The musso has significantly smaller wheel arches. And there is simply nowhere to cut the rear arch from the interior. And in the front arch, the wheel must be driven forward by increasing the Caster.

Roughly, if you can put 35 "in Korando, but in Musso, alas, only 33".

But front axle - weakness... Dana30 in the literature is not intended to spin wheels more than 31 inches. The KSC is said to be stronger than the Tongil. But the KSC front differential was folded at 30th muda.

Frankly, without an elevator, this is a heavy frame puzoterka with a plow in the middle of the frame. In terms of cross-country ability in the base and without modifications, it will pass off-road even against the background of "parquet".

LSD is optional, but in practice I rarely met in the database.

Bridges - KSC or Tongil. But it turns out that the rear is almost an analogue of Dana44, and the front is very similar to Dana30, but the number of axle splines must be rechecked.

The base contains breathers with check valves, but it is better to raise them even higher - to remove the valves under the hood.

There are locks in rear axle put ARB RD116 / RD117, in front ARB RD100 / RD101

There is also Lock-Right.

With regards to the suspension lift.

My opinion is that the suspension cannot be strictly lifted.

Yes, you can turn the torsion bars in 5 minutes and the car will become higher. True, all this at the cost of the lever resting on the bump stop. This decision completely kills the rebound stroke and the car goes to the defense in any rut. Because the front has no downward movement and on any hanging in front instantly loses grip, the backside is buried alone and we sit.

It is absolutely impossible to kill the lights out!

Craftsmen are trying to put spacers under the top ball.

Updated: But, as it turned out, when the torsion bars are tightened, the front levers begin to work in the wrong, non-calculated plane and just go to a break, WHY! if you strengthen the levers, it already breaks the bracket off the frame.

Therefore, it is better not to do a suspension lift on these machines at all !!! even transferring the entire subframe together with the gearbox!

As a result, it turns out that the only way to lift such a car is to put big wheels... And that's all, period!

But even here you have to think and change the front differential to ARB RD100 / RD101, the standard one will not pull more than 31 ". Although 31" from the standard 29 "is already a good increase.

And then the investigation is already underway - large wheels simply do not climb into the arches, in order to increase the space in the arches, you need a body lift! + it is possible to cut arches, and for very big wheels- and then and then at once.

The main thing here is to understand that the body lift itself ground clearance does not change a single mm! All that a body lift gives is an increase in free space in the arches for large wheels! This is not a goal with only a means to an end, to increase ground clearance and flotation!

Elevator up to 2 "is done at all with little blood... You just have to remove and adjust the fan casing, increase the inlet pipe from air filter... Adjust the "sorcerer" (distributor braking efforts) and readjust the checkpoint rods.

A 2 "(5cm) lift is almost perfect for rolling 31", no more!

I personally stopped there.

If you want more, then it is also not difficult, but you need to lengthen the steering universal joint, extend the hose from the filler neck to the tank, change brake pipes, but in principle, this is not difficult either. And the main thing! for an elevator more than 2 ", it is necessary to strengthen the support pads of the body, they can be pulled out!

The suspension is relatively strong, for 50tyk I only managed to tear slightly the silent bands of the upper arm and unscrew one nut of the front stub.

At 100tkm, the bushings of the front upper levers, the rods of the front stabilizers, and the parking brake cables were finally replaced.

The silent blocks of the lower levers of the rear axle went to 150tkm for replacement, but most likely from the fact that they pulled the blade in winter and cleaned the snow (heavy load on the axle and levers).

Also, by 150tkm, I finally broke the splined front universal joint, it was completely replaced.

In addition to the suspension above, the vacuum seals were changed 2 times over 150tkm + Once - the needle bearings of the axle shafts. Replaced fan viscous coupling. One crosspiece of the rear universal joint. The main radiator has rotted and dripped from our reagents - it has been repaired. The pipe of the kondeya is rotten - it is rolled over. The pipes of the internal combustion engine oil supply to the oil cooler are rotten. More precisely, they did not even rot, they "sweated" along the rolling near the oil filter. Were re-rolled. Both the front and rear crankshaft oil seals have been changed.

By 200tkm it was already more unpleasant. Earlier by 100 thousand, in winter, my leaking sports horses jammed, and broke off the upper mount of the shock absorber rod both on the right and on the left. After that, the suspension was welded and poured, even more powerful shock absorbers and very powerful springs were installed (the thickness of the standard rod is 14mm, I have 16.5mm). On this suspension, the car began to hold the road very well and I somehow completely relaxed ... from overloading and "low flying" on gravel roads / graders in the rally stage mode, first I broke the lower shock absorber pin on the right, and then completely tore the whole the upper support platform of the spring and shock absorber (although this was already a consequence of the previously poorly welded separation along the shock absorber). This is how it looked .. So powerful shock absorbers are not only good, but also bad;) For the rally mode of operation, it was necessary to do a pair and distribute the load on two points.

This seems to be all for today ...

And more about the suspension - regular ammo, a rare nonsense, you need to put in front of the terrano, the back from the 80s Kruzak, from the 90s, or from the trooper. how the original rear springs, also junk, put from w123 (sedan, back). Although here, too, you should not be too zealous (see above).

The body is more than, there are no questions, the frame is even better, but it's worth spilling. Rust is found along the edges of the doors and on the rear door. On the frame, rust can be found mainly only in the back - in the rear wheel arches, under rear bumper and around the spare wheel.

On landing, try it, the landing is high, I don't like it. Another very short seat, with long legs is uncomfortable!

In servicing, you must always remember that each oil change must be additionally done:

1. Inject spline bridges (2pcs).

2. Syringe crosspieces of cardan shafts (4pcs).

3. Check the backlash of the front wheel bearings.

4. Check the gap in the vacuum hubs.

5. Check the oil levels in the gearboxes (2pcs), the distributor and the box. Check for water emulsion.

6. Check the patency of the breathers and the operation of the non-return valves.

Now the weak points:

1. The electric motor for turning on the transfer case - it is necessary to seriously isolate, the motor itself is tenacious, but the wiring sometimes rotts,

2. Standard front hubs on vacuum, need to be serviced, or immediately changed to manual

3. Until the 2000s, there were PBR brakes - junk (in the sense that the fixing bracket flies off and the caliper falls on the disk, it's very fun to go like this in the wilderness), then let's go mando - it's better, you should immediately transfer the PBR to Mando

4. On machines with a part-time transmission, the front universal joint sags on the splined shaft from inactivity and vibration, there are weak anthers ... if it is not already killed badly, it should be injected more often, even if it is almost never used.

4a. In order not to kill the front universal joint, you must use the front-wheel drive as often as possible! Only one thing! at the same time, never turn it on on dry asphalt. We drove onto a gravel road - they turned it on, let it work so that it doesn't sag. All this does not apply to machines with TOD!

5. Loss of vacuum, cracked tubes, etc. The machine does not stall by itself, the front does not connect. sometimes the problem is in the tee.

6. The handbrake is poorly protected, there are no plugs, the anthers are torn - it throws dirt into the drum. Needs regular processing and adjustment.

7. The guides of the rear calipers immediately close up, they must be processed or made of stainless steel.

8. The breather valves rot and the oil starts to press out of the bridges.

And also these cars "roll off" very much, like "ahh, merso diesel - yes it is a millionaire", well, and cut into the trash ... in this state and are sold

What to look for when examining:

1. Look very carefully at the body and frame, in this car you can go through everything, but the frame and body already, alas, do not look back door so as not to rotten

2. When driving, turn off all sounds, and carefully listen to the rear axle so that it does not buzz, accelerate to 100k, often starts buzzing only by> 100. Who does not know how the rear axle hums - find a tired gazelle minibus with a route implying a speed of> 60 km / h and into it, as an ordinary passenger. The howl of the rear axle is better than in her, nowhere to feel.

3. Watch vibrations, at 70-80 no vibrations should be close

4. Check how it works before, turn on full (4H), wait 20 seconds after the lamp comes on, turn the steering wheel all the way to either side, try to move, if the drive works, it will feel like the car is against a wall and something is holding it tightly, at the same time, if you turn on the gas, then the car will try to go jerkily, desperately turning the rear axle, the better the road surface, the more difficult it will be to move ... if there is no difference with the usual mode, the front end does not work, or the car is on ice or wet grass

5. Check the vacuum, turn on (4H) and after the lamp lights up, immediately turn off the key, if it stalls - ok, but if it doesn't stall right away, but continues to work as if choking, there is no vacuum, it runs away somewhere in the front end connection system. And in general, in principle, if the car stalls badly even in simple mode, there is a problem with vacuum somewhere. Similarly, check the performance of the vacuum pump - turn off the ignition and press the brake at the same time.

6. If the front end works, turn on and accelerate in a straight line up to 70-80, vibrations and hum should not be strong, but go strictly straight and do not turn the steering wheel, because it is generally impossible to drive on asphalt like that

7. It will stop, turn on neutral, squeeze the clutch + brake and turn on 4L (on the machine N + brake), it should turn on with a light click but without impacts! (but only in this order).

When properly switched on, the 4L lamp should be on, and 4H should go out when turned on, if 4L blinks at the same time as the 4H is lit, this means 4L was never turned on! - either we turn it on incorrectly (see above) or something is wrong with the electric motor of the handout.

Try to drive, it must go very slowly, for that it is a lowering row!

7a. Stop, completely lock the machine in place, again neutral + clutch + brake and turn off 4L - it should turn off without knocks! You can try turning it on / off back and forth a couple of times. For example, cheeks, but no blows. The truth with a gun is more difficult. With a machine gun, it can be easy to kick when you turn it off! This is due to the fact that in neutral the box still does not completely dissolve the drive shaft, and it still has a slight tendency to rotate, so this sometimes causes a slight kick on the machines when 4L goes back to 4H.

7b. If on the machine when you turn off 4L the blow is noticeably strong - there is a problem in the automatic transmission.

8. The handbrake should hold dead, but grasp high on a 6-7m click

9. Look at the frame bolts on the lift, the bolts should be straight, strictly perpendicular to the frame, if it is clear that the booth has moved away from the frame and the bolts are all tilted - there was an accident

10.Om601 / om602 shouldn't have any smoke at all, only if you press very sharply at 4 thousand revolutions while standing still - a little bit of gray-black can spit, but really a little bit completely

11. The engine must run very smoothly and quietly, no knocking! no sonorous clatter! these vortex chambers work approximately like modern HDI and even quieter

An attempt to make SY Musso drive like a car. And free up some space in the front wheel arch.

We must start with that your humble servant has been driving for a long time in different cars, more on front-wheel drive, but a little on the classic rear. And after a front-wheel drive car, any tall, heavy, frame SUV on solid bridges can be just scary.

So it practically happened. Although the front suspension is independent on two A-levers, the car rides and is controlled in a very specific way.

The first thing that upset me a little was no directional stability. Knowing that German engineers had a hand and thought to the creation of Musso, I absolutely could not understand this. For the W124 sold to the Koreans (aka, reborn as SY Chairman) rides just like a tram on the rails, even if there is a chipped dirt road under the wheels.

I always loved to turn the wheel alignment angles, and obviously this was exactly the case when it was necessary to urgently do something.

What is camber, castor, convergence and why they are needed, those who wish can easily find it themselves, and we will continue in detail in our Ssangeng.

Let's start with the specification:

As you can see, the Caster (longitudinal slope) is only 2 "3, which is extremely small. The same W124 has an angle of 9 degrees according to the specification, which explains its stability when driving.

But what pleases - the car has the ability to adjust all 3 angles of the front axle. Which gives ample opportunities for customization.

Adjustments can be completely different to the taste and color of each person. You can try whichever suits your driving style better. Personally, I needed to achieve high-quality directional stability and obedience of the car at speed.

There may be several recipes here. One of the options is to set the convergence a little to a plus (even on the brink of tolerance, and do not be afraid of rubber does not eat! More than 100tkm passed, everything is fine). And the longitudinal angle of inclination to cut as far as possible, far beyond the tolerances, to cut while the wheel arch allows and physically can be pulled out with embedded washers.

The main goal is to get as close as possible to the W124 as the standard of comfort for a rear-wheel drive car.

So now we look, but how to make the adjustment itself:

This quote from the service manual suggests that before adjusting something, it is highly recommended to set the pressure in the wheels. And check the vehicle's ground clearance.

Literally "Measure 'A' from the center of the lower arm rear mounting bolt end to the ground. Measure 'B' from the center of the steering knuckle shaft to the ground. If the difference between 'A' and 'B' is not within specification, adjust vehicle height using torsion bar height control bolt. "

translates as

"Measure the distance from the middle of the rear lower arm bolt to the ground. Measure the distance from the center of the hub."

The difference in these distances should be in the range of 31-36mm.

From myself I will add the following to the manual - the difference should be the same on both the right and left.

Further.

It is clear that if distances do not dance, then you need to turn the torsion bar.

There is one serious pitfall here. In order to correctly set the ground clearance, it is imperative to completely dissolve the stabilizer both from the front and rear. That is, completely unscrew one rod of the stabilizer both front and rear. Otherwise, the stabilizer will pull one side from the other and winding up the torsion bars in such a situation will lead to the fact that on the road it will very quickly break these stub rods, and the car will still stand crooked.

So the car is ready to install the desired wheel alignment angles. How adjustments are made directly:

Convergence:

Everything is simple, everything is like everyone else - we twist steering rod, Counter nut. The only remark is to twist at the very end, when the caster and camber are already exposed.

Camber and Caster:

Both are controlled by the offset of the upper arm of the front suspension. Or rather, placing the plates under the arm mount. As a result, we displace the upper ball in space, that is, directly and change the same installation angles. Camber is controlled by the long plate number 1 in the pictures above. The caster is regulated by plates number 2. Suitable plates from the Muscovite 412.

To increase the Caster, you need to shift the upper ball forward, that is, put a thicker plate under front bolt and remove the plate from under the rear bolt.

Empirically, I found that you can cut the caster up to about 6g, but I got too much camber. These two adjustments are interrelated. Therefore, experimentally, I stopped at 4g.

Here's something like this for me now:

Well, something like this.

Good luck and good luck on the road!