This installation manual applies to microprocessor-based ignition systems ADIG.648352.010, ADIG.648352.012, ADIG.648352.013 (hereinafter referred to as microprocessor ignition system) intended for operation in the electrical equipment of cars with four-cylinder and carburetor internal combustion engines.

The microprocessor-based ignition system is used in the automotive industry to improve engine performance in terms of durability, efficiency and exhaust gas emissions.

The microprocessor ignition system can be installed instead of the classic ignition system on any car with a four-cylinder carburetor engine internal combustion.

The wiring diagram for a car with a microprocessor ignition system is given in Appendix A.

The composition of the microprocessor ignition system (see Appendix B):

- sensor-distributor 75.3706 or similar in design -1 pc;

- ignition controller 22.3854 (for cars with a model 402 engine) or 22.3854-01 (for cars with a model 421 engine) -1 pc;

- absolute pressure sensor 45.3829 -1 pc;

- harness -1 pc.

The ignition coil, the EPHH solenoid valve and the EPHH microswitch for the microprocessor ignition system are used standard ones installed on the car.

The list of documents that should be additionally guided when carrying out work:

- for ignition controllers 22.3854, 22.3854-01 ADIG.648352.006RE;

- on the distributor sensor 75.3706> or similar in design;

- .

1 General instructions.

The installation of a microprocessor ignition system on a car can be done at service stations or on your own. On a car with a microprocessor ignition system, it is not allowed:

- disconnect the high voltage wires and check the ignition circuits for a spark, as this can lead to burnout of the high-voltage insulation and failure of the microprocessor ignition system;

- carry out preventive work with the distributor sensor with the ignition on;

- disconnect wires from terminals battery with the engine running, as this could damage the microprocessor ignition system.

1.1 Operating restrictions.

It is prohibited:

- connect the microprocessor ignition system according to a circuit different from that given in Appendix A;

- to operate the microprocessor ignition system with an unreliable connection of the electrical wires of the vehicle with the terminals of its electrical equipment;

- operate the system in case of unreliable contact of the controller body with the vehicle body;

- operate the microprocessor ignition system with incompletely inserted high-voltage wires into the sockets of the sensor-distributor cover and the ignition coil;

- open and disassemble the controller.

2 Security measures.

2.1 To prevent injury or damage to the system during installation work, disconnect the wire from the battery terminal.

2.2 Do not touch high-voltage wires and devices when the ignition is on.

3 Preparation for installation.

3.1 Before starting work, make sure that the engine compartment and the car engine are sufficiently clean, if necessary, rinse and dry.

3.2 Dismantling the classic ignition system:

- disconnect the lugs of the high-voltage wires from the distributor cover;

- disconnect the wire from the unnamed terminal of the distributor sensor and the tube from the vacuum regulator;

- remove the distributor sensor from the engine;

- disconnect the wires from the ignition switch, having previously marked them;

- remove the ignition switch.

4 Installation of a microprocessor ignition system.

4.1 General requirements for the installation of a microprocessor ignition system:

- installation of the system must be done carefully;

- the connection of the controller with the mass of the vehicle must be reliable, that is, ensure good contact;

- it is strictly forbidden to short-circuit the output contacts, as well as to make any switching of the connecting wires that are not provided for by the wiring diagram;

- installation wires connecting the controller with the devices of the ignition system on the car and the devices with each other must have a cross section of at least 0.5 kvdr. mm and must be provided with lugs for connection to the corresponding terminals.

4.2 The wiring diagram of the controller on the car is shown in Appendix A.

4.3 Installation sequence of the microprocessor ignition system:

- while turning the engine crankshaft, determine by the displaced air the beginning of the compression stroke in the 1st cylinder;

- set the piston of the first cylinder to the position corresponding to the initial ignition timing (4-6) according to the instructions for the engine. crankshaft to TDC;

- insert the shank of the distributor sensor with the removed high-voltage cover into the hole in the engine housing so that the roller clutch cams enter the grooves of the engine drive bushing;

- having installed the slider and attaching the distributor cover in place, make sure that the direction of the slider corresponds to the high-voltage terminal of the first cylinder;

- tighten the screw of the octane-corrector indicator plate so that the pointer on the engine coincides with the middle division of the octane-corrector scale;

- loosen the nut securing the distributor sensor to the plate;

- holding the slider against its rotation with your finger (to eliminate gaps in the drive), turn the housing of the distributor sensor until it coincides with the electrode No. 1 of the cover according to the figure in Appendix D and tighten the nut for fastening the distributor sensor;

- for a more accurate installation of the distributor sensor on the engine, use a special device containing a connector, indicator and power wires, el. for a diagram of the device, see Appendix D;

- connect the device connector to the distributor sensor;

- connect the power supply wires of the device to the car battery, observing the polarity;

- turn the housing of the distributor sensor, having previously loosened the fastening nut, until the indicator stops glowing, while the position of the slider relative to the electrode No. 1 of the cover and the end of the curtain groove in the direction of rotation relative to the Hall sensor must correspond to the figure in Appendix D;

- fix the housing of the distributor sensor;

- disconnect the device from the storage battery and the distributor sensor;

- install the distributor cover and connect to the distributor terminals high voltage wires in the order of operation of the cylinders and the central high-voltage wire;

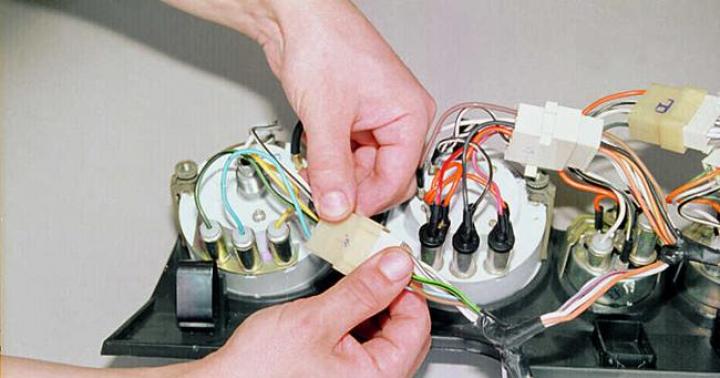

- replace the switch with the ignition controller with the harness connected and connect the X7 terminal from the harness to the car with the controller fastening nut;

- on UAZ vehicles, fix the absolute pressure sensor 45.3829 in the engine compartment on the body wall in the zone of the vacuum regulator tube length;

- connect the X2 harness connector to the absolute pressure sensor 45.3829 and to the sensor fitting a tube that was connected to the vacuum regulator of the distributor sensor from the carburetor;

- determine the optimal route of the harness with the HZ connector to the distributor sensor (the harness should not touch the engine) and connect the HZ connector to the distributor sensor;

- disconnect the wire going to the EPHH control unit from the EPHH solenoid valve, and connect connector X4 from the bundle in its place;

- disconnect from the EPHH microswitch on the engine carburetor the wire connecting it to the EPHH control unit and the EPHH solenoid valve and connect connector X8 from the bundle in its place;

- connect the wires from the terminal from the commutator and the X6 tip of the harness to the terminal block located next to the ignition controller to the terminal;

- connect the conductor from the switch terminal to the terminal block, the other end of the conductor near the distributor sensor remains free, because the conductor is not connected anywhere;

- connect the wires from the switch terminal and the X5 lug of the bundle to the terminal block.

5 Due diligence.

5.1 Correctness of setting the ignition timing.

The correct setting of the ignition timing is determined by the mileage.

Correction of the ignition timing is carried out by turning the housing of the distributor sensor relative to the engine housing.

The ignition moment is set at the border of the disappearance of detonation when the engine is running.

But it is best to check the correctness of the ignition timing and adjust it (if necessary) using a stroboscope. The operation is carried out according to the instructions for this device, while the set ignition timing must correspond to that specified in the vehicle operating instructions.

5.3 Typical malfunctions microprocessor ignition system, affecting the engine performance, and methods of their elimination.

5.3.1 Lack of flares in engine cylinders

5.3.2 Difficulty starting the engine and (or) engine operation intermittently.

| Cause of malfunction | Remedy |

|---|---|

| Partial carbon shunting of spark plugs | Remove carbon deposits from candles |

| Loose attachment of the distributor wire tips | Replace distributor wires |

| Violation of the gap between the electrodes of the candle as a result of electrical erosion | Adjust the gap between the spark plug electrodes and check the gap with a feeler gauge |

| Overlap (short circuit) between the side electrodes on the inner surface of the high-voltage distributor cover | Replace the high voltage distributor cap |

| Turn-to-turn circuit in the primary winding of the ignition coil | Replace ignition coil |

| Violation of insulation of high-voltage wires | Replace high voltage wires |

5.3.3 Decreased engine power (increased fuel consumption, poor throttle response).

6 Maintenance.

6.1 Maintenance of the ignition system elements (distributor sensor, coil and spark plugs) is carried out at each maintenance(THEN).

6.2 During maintenance, the reliability of the electrical contacts, the condition of the high-voltage insulation and the fastening of all ignition devices are checked. At each service, wipe the surface of the distributor sensor cap and the ignition coil with a clean, lint-free cloth and moistened with gasoline or other degreasing liquid.

6.3 During operation, it is necessary to keep the high-voltage parts of the ignition system clean and prevent moisture, dust and dirt from entering them, which can lead to partial shunting and current leakage, breakdown of high-voltage parts or surface overlap.

6.4 To avoid burnout of sockets in high-voltage parts, high-voltage wires should be sufficiently well secured and fit into the sockets of the sensor-distributor cap, ignition coil and spark plug tips.

6.5 After washing the car or overcoming a ford, there may be moisture on the high-voltage wires and ignition system devices, as well as inside the cover and on the ignition distributor rotor, which must be removed by wiping with clean chamois or other lint-free material.

The trip computer (MC) shown in Fig. 37, is installed in a variant version instead of watches in cars VAZ 2110, VAZ 2111, VAZ 2112. MK has 15 functions, divided into 3 groups (see Table 2). The group is selected using buttons 1, 2 and 3.

In each group, the functions are divided into basic and additional. The main functions are scrolled through the ring by buttons 1, 2 and 3. Additional functions are scrolled through the button 5. With the ignition off, the computer is always in the "Current time" mode. At removed battery the clock rate and all accumulated parameters are saved for at least 1 month.

ADJUSTING COMPUTER FUNCTIONS

Clock drift correction

Press button 4 in the "Current time" mode. On the sixth signal of the exact time, press button 1, while the seconds are reset and the hours are rounded.

Setting the current time (calendar)

- Press button 4 in the "Current time" ("calendar") mode.

- Use buttons 5, 6 to set the required hour (day) value.

- Press button 4.

- Use buttons 5, 6 to set the desired value of minutes (month).

- Press button 4 to finish setting the time (calendar).

Setting the alarm

- Use buttons 5, 6 to set the required hour value.

- Press button 4. By buttons 5, 6 set the required minutes value.

- Press button 4 to finish setting the alarm.

- In the "Time of day" mode, the alarm symbol will light up (the alarm clock is on).

* If the counter of any of the accumulated parameters ("Travel time", "Travel time with stops", "Total consumption", "Trip mileage") is overflowed, all accumulated and calculated ones ("Average fuel consumption", "Forecast mileage on the remaining fuel "," Average speed ") parameters, with the appearance of a two-tone sound signal.

* If the counter of any of the accumulated parameters ("Travel time", "Travel time with stops", "Total consumption", "Trip mileage") is overflowed, all accumulated and calculated ones ("Average fuel consumption", "Forecast mileage on the remaining fuel "," Average speed ") parameters, with the appearance of a two-tone sound signal.

Turn off the alarm

- Press button 4 in the "Alarm" mode.

- Press button 1 to turn off the alarm. “—.—” will appear in the digits, and in the “Current time” mode, the alarm symbol will not light up (the alarm is turned off).

Adjusting the brightness of the indicator backlight

When the side lights are on, the illumination level is adjusted with the dimmer on the instrument scale. When the side lights are off, the backlight level is adjusted by software:

- - press button 4 in the "Travel time with stops" mode. All single segments (pictograms) will be displayed on the indicator, which is a sign of the backlight level adjustment mode, and the number corresponding to the backlight level as a percentage of the maximum value will be displayed in digital digits;

- - use buttons 5, 6 to set the required level of backlight brightness; press button 4 to end the brightness adjustment mode.

Fuel level sensor calibration

- To carry out the correction, it is necessary to drain all the gasoline from the tank.

- Press and hold button 4 for more than 2 s in the "Fuel level" mode. The indicator will show a blinking number "0".

- Press and hold button 3 for 1 s until a confirmation beep appears. After that, the indicator will show a blinking number "3".

- Pour 3 liters of gasoline into the gas tank using a measuring container, wait the time required for the fuel level sensor to calm down, press and hold button 3 for 1 s until a confirmation beep appears.

- Continue this procedure to a maximum value of 39 liters, after which the computer automatically exits the mode.

Overspeed alarm installation

- Press button 4 in the "Medium speed" mode.

- Use buttons 5, 6 to set the required speed threshold.

- Press button 4 to exit the overspeed alarm setting.

for products automotive electronics

produced by "ELARA" 1

(compiled on 3 sheets)

|

Validity - from January 11, 2003 until cancellation. | |||

|

Name, |

Unit price, RUB: 2 |

||

|

designation |

without VAT |

VAT included |

|

Ignition systems | |||

|

Engine control unit "ELARA M" | |||

|

46.3763 (cars GAZ-3110 "Volga") | |||

|

Scanner - diagnostic tester "ELARA" | |||

|

Additional resistor 2502.3729 * | |||

|

(cars GAZ-3111) | |||

|

Additional resistor 22.3729 | |||

|

(GAZ cars) | |||

|

Electric motor with pump 47.3780 | |||

|

(single-wire, 12V, 20mm) GAZ cars | |||

|

Electric motor with pump 471.3780 | |||

|

(two-wire, 12V, 18.8mm) UAZ cars |

403 , 66 |

||

|

Electric motor with pump 472.3780 | |||

|

(two-wire, 24V, 18.8mm) KAMAZ vehicles | |||

|

Electric motor with pump 473.3780 | |||

|

(single wire, 12V, 18.8mm) GAZ cars | |||

|

Headlight washer pump 46.3780 | |||

|

(cars GAZ-3102) | |||

|

Heating and ventilation unit control unit 3310.8109001 | |||

|

(cars GAZ-2750) | |||

|

Heating and ventilation unit control unit 3310. | |||

|

(cars GAZ-2750 Lux) | |||

Display and control systems | |||

|

Display unit BSK 10A 12.3860 | |||

|

(cars VAZ-2110) | |||

|

Display unit BSK 10M 12.3860 | |||

|

(cars VAZ-2110) | |||

|

Display unit BSK 16.3860 | |||

|

(cars VAZ-2114) | |||

Switching devices | |||

|

Glow plug control unit 25.3763 | |||

|

(cars VAZ-21045) | |||

|

Rear fog light relay 22.3777 | |||

|

(12V, VAZ cars) | |||

|

Rear fog light relay 22.3777-01 | |||

|

(24V, PAZ vehicles) | |||

|

Protection and switching unit 5002.3722 * | |||

|

(cars GAZ-3111) | |||

|

Programmable wiper breaker | |||

|

12.3777-01 (GAZ-3102 vehicles) | |||

|

Evaporator temperature sensor | |||

|

(VAZ cars) | |||

|

* Special offer!!! System automatic control heater cars GAZ-3111 |

Note.

1. When shipping products in individual packaging, the cost of the latter is added to the unit price.

2. Prices are excluding sales tax (5%) for individuals when paying in cash

3. Depending on the amount of the order volume, discounts are provided according to the following:

|

Order volume, |

Discount, |

|

Thousand. rub. | |

|

up to 200 | |

|

from 201 to 400 | |

|

from 401 | |

Research and production instrument-making enterprise "ELARA" Russia, Cheboksary, Moskovsky prospect, 40.

Marketing and Sales Director for Civilian Products:

E-mail: ***** @ *** ru

Director of the direction "Autoelectronics"

E-mail: ***** @ *** ru

Marketing service of SE direction "Autoelectronics":

E-mail: ***** @ *** ru

Internet shop http: // www.

Warranty service:

Service Center: (83

Regional representatives:

"Promplast", Nizhny Novgorod

E-mail: ***** @ ***

"Avtokomplekt", Cheboksary

tel., E-mail: ***** @ ***

Regional warehouses:

warehouse in Moscow: (095)

m. Novoslobodskaya, "Avionika"

Nizhny Novgorod

Modern cars are equipped with a large number of electronic devices: ignition system switches, engine control units, diagnostics, on-board computers, etc. with some of these devices installed on domestic cars VAZ and GAZ, we will introduce our readers. This information can be useful to both professionals, tech and amateurs engaged in the repair of such equipment. Today we will talk about the display unit of the on-board monitoring system.

The display unit of the on-board monitoring system (BI BSK-10, hereinafter referred to as the unit) is designed to display the state of vehicle components using ten light and one sound signaling devices. The list of monitored parameters and the color of the corresponding light signals is given in the table.

The operating unit can be in one of five modes:

1. "Off" - the key is not in the ignition lock.

2. "Waiting" - the key in the ignition switch in the "off" position. If the driver's door is open, the unit registers the "forgotten key in the ignition switch" event and beeps for 6 seconds.

3. "Pre-departure control of signaling devices" - when the key is turned to the "ignition" position. The duration of the mode is 4 s. One beep sounds and all warning lights turn on for 4 seconds. The malfunctions "insufficient oil level", "insufficient level of coolant", "insufficient level of washer fluid" are monitored, and their value is remembered, however, the light signals do not turn on until the end of the mode.

4. "Pre-departure control of parameters" - after the end of the "pre-departure control of annunciators" mode and a pause of 1 s. The duration of the regime is 6 s. Triggered light indicators first blink for 6 s with a frequency of 1 Hz, then light up continuously until the malfunction is eliminated or the key is turned to the "off" position. The sound signaling device turns on simultaneously with the light signals for 3 s.

Registered faults "Insufficient oil level", "Insufficient coolant level", "Insufficient level of washer fluid", "Malfunction of brake lamps and side lights"and" brake pad wear "are stored until the key is turned to the" off "position.

5. "Parameter control with the engine running" starts after the end of the "pre-departure parameter control" mode. The monitoring of malfunctions "insufficient oil level", "insufficient level of coolant", "insufficient level of washer fluid", malfunction monitoring "open doors", "unfastened seat belts", "malfunction of brake light and side lights", "wear of brake pad "continues.

The device consists of two main parts (Fig. 1): a microprocessor and an indicator mounted on the A1 control board and on the A2 indication board, respectively. Both boards are installed in a plastic case.

(click to enlarge)

The block appearance is shown in Fig. 2. A 15-pin connector is used to connect power and sensors.

The output signals of the sensors come from the contacts of the XP1 connector to the inputs P0.0-P0.5, P2.0-P2.5 of the microcontroller DD3 through matching circuits A1B1-A1B12 and Schmitt triggers DD1, DD2. Outputs P1.0-P1.7, P3.1, P3.2 of the microcontroller are designed to control transistor switches A2B1-A2B10, which, in turn, switch LEDs HL1-HL10. To generate a sound signal that simulates the ringing of a bell, a dynamic head HA1 is used, which is connected through an isolating capacitor C9 to the output of an amplifier on transistors VT7, VT8, controlled by the outputs РЗ.б, Р3.7 of the microcontroller DD3.

When the key is inserted into the car's ignition switch, the supply voltage is supplied from pin 11 of the XP1 connector through the VD9 diode, which protects the unit from polarity reversal, to a voltage stabilizer made on VT1-VT6 transistors. The VD11R8R9VT6 circuit turns off the power to the unit if the voltage is on-board network exceeds 24 V. The stabilizer provides a minimum voltage drop (no more than 0.6 V at full load) and allows a pulse input voltage of up to 150 V.

The DD3 microcontroller contains a built-in clock generator that works with an external ceramic resonator CSA-8.0MTZ by MSHATana 8MHz.

A fixed-duration reset signal for the DD3 microcontroller after the supply voltage is applied or if it drops below 4.2 V is generated by a node ("supervisor") consisting of a threshold element on a VT10 transistor, a VD12 zener diode and a one-shot on DD4.3, DD4.4 elements ... In standby mode (ignition off, front doors closed) the DD3 microcontroller is in a "sleep" state, while the current consumed by the unit does not exceed 7.5 mA. If the key in the lock is turned to the "ignition" position or any front door is opened, the node on the DD4.1 element and the VT9 transistor generates an interrupt (log. 0) at the PZ.Z pin of the DD3 microcontroller, bringing it out of the "sleeping" state.

The block indicates the open state of each door of the car. To keep an individual signal from each door switch and turn on the interior lighting when opening any door, VD5-VD8 diodes are used. Diodes VD1-VD4 prevent the supply voltage to the unit through the car interior lighting lamp.

The block mainly uses elements for surface mounting. Capacitor C9 - aluminum oxide SKR101M1EE11VM from JAMICON (replacement with a similar one is acceptable), capacitor C3 - tantalum size D for surface mounting, all other capacitors and resistors of standard sizes 0603, 0805 and 1206. Transistors MJE15031 and KT6851A can be replaced with transistors VS847 and VS857 - on KT3130A-9-KT3130Zh-9 and KT3129A-9-KT3129D-9, respectively.

On cars of the "Tenth Family", a clock or a computer is always installed next to the display unit. Now these computers are called "on-board computers" (BC). The computer display with the ignition off shows the time, but this is not its only function! We will list all the capabilities of the on-board computer on the VAZ-2112, and the instructions supplied by the VAZ will help us with this. Tables were copied from the instructions, which are important when setting up.

What bookmaker are we talking about? The answer is shown in the video.

The appearance of the front panel is shown in the photo below. You need to memorize the main keys: 1, 2, 3 and 5. All functions are divided into three groups. By pressing button 1, you can scroll through the functions of the first group. The same applies to other keys.

Regular BC for the hatchback "Lada-112"

The question is, why do we need button 5? Being in any of the three groups, this button activates additional functions. By the way, their number is equal to two.

Each group has different additional functions.

Swipe example

When the ignition is off, we see a clock on the display. Let's try to turn on the ignition and press key 1. The button itself can be pressed any number of times - the functions are switched cyclically. Their number is three.

Function group "Time"

If you need additional functions, press button 5. We have seen how to use the standard on-board computer for VAZ-2112, but the instruction is suitable for any "Tens".

BC operation in different modes

It is said above how to use the BC in the "Time" mode. The "Time" group is the first, but there are two more - "Fuel", "Way". We give tables for them.

Function group "Fuel"

Above is the table for buttons 2 and 5.

Function group "Path"

The functions activated by buttons 3, 5 are shown here.

Programming instructions

We will change different settings. We will also try to turn on the alarm, change the brightness of the backlight, etc. Thus, computer programming on the VAZ-2112 is also related to operation.

Configuring the fuel level sensor

The tank is initially empty. Turn on the "Fuel level" function (2-5) and press button 4 for more than two seconds. Then we follow the steps:

- Press button 3 for one second until the sound signal appears;

- We fill the tank with three liters of fuel. Wait 10-20 seconds and repeat step 1;

- Repeat steps 1 and 2 until 39 liters are filled.

We activate the overspeed alarm

By pressing button 3 we turn on the "Average speed" function. Press the key 4. Next, use the buttons 5 and 6 to set the required numbers. Finally, press the button 4.

To disable the option, use a high threshold value: 190 or 200 km / h.

Change the brightness of the backlight

We use function 1-3 "Time with stops". Press button 4. Use keys 5 and 6 to adjust. Press button 4.

Alarm

Go to the "Alarm" option (an additional function in the "Clock" list). Press button 4. Next, set the hour value (keys 5 and 6), press button 4, set the value of minutes (keys 5 and 6). By pressing button 4, the alarm is activated.

An alarm clock in a car is a necessary thing

It remains to figure out how to turn off the alarm. Follow all the steps until you set the hour, and then press the button 1. The alarm should turn off!

How to customize your calendar and clock

We have reached the most difficult chapter. Let's go straight to the action:

For quick adjustments, follow step 1 and step 2. If you then press button 1, the hours will be rounded up from 13:57 to 14:00. Or otherwise: it was 14:05, but it will become 14:00.

Our editorial 2112 with BC Gamma GF 212. We are completely satisfied with it

The most popular non-standard ammunition vehicle on the VAZ-2110 is the Gamma GF 212 model.

Its cost about 2500 rubles ... Installation is simple, you just need to connect to the K-line in the diagnostic connector and bring the power wires.

There are such useful functions as blowing out candles and more. We on our own can only recommend it among the large variety of models on the market.