The Rapid liftback is gaining popularity and is about to come out on top in terms of sales among its relatives, overtaking the current leader - Octavia. To make the car attractive both externally and in terms of filling, and at a price, the developers made a win-win move - they borrowed many solutions from other cars of the Volkswagen concern: the platform from the Polo Sedan, some of the nodes from Fabia, the exterior from the Octavia.

We will check how this "hybrid" is doing with service. Recall that we assess maintainability in points that correspond to the total standard hours (according to the official grid) spent on certain operations.

REPLACING CANDLES AND OIL FILTER: THREE FROM CASKET

Rapid for Russian market available with three gasoline engines- these are aspirated 1.2 and 1.6 and turbo 1.4. They are well known from other models of the concern. All - with a timing chain drive, which does not require maintenance.

The younger engine - a three-cylinder 1.2 - is found mainly on the Fabias of the previous generation. Belt attachments designed for the entire life of the engine, but usually takes care of 100,000-150,000 km. Its automatic roller tensioner is located next to the generator and has a stopper to secure it in a loosened position. But using it for an easier belt replacement is extremely inconvenient, it is better to forget about it altogether. To loosen the tensioner, a "50" torx is used under the black plastic roller cover. The strap is easier to change from above, but remember to sketch or photograph how it stood. Surprisingly, you can easily put it wrong.

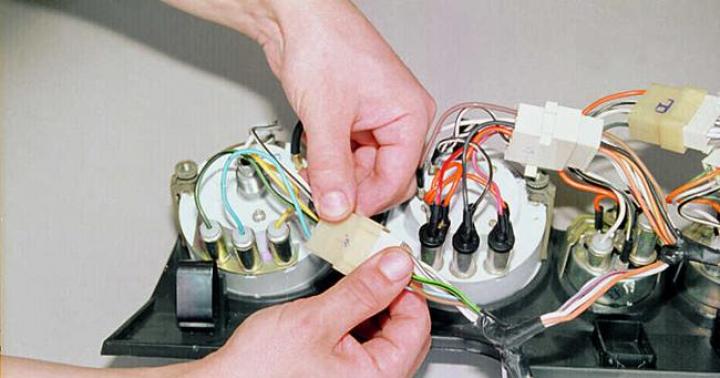

The individual ignition coils are hidden under a decorative plastic cover with four latches. As with most modern gasoline engines of the Volkswagen concern, they are sitting in vnatyag candle wells. To remove the coils, you need a special puller or its homemade counterpart, otherwise there is a great risk of damaging them. Another inconvenience: the connectors on them are upside down. For an inexperienced person, removing the connectors without seeing the type of retainer is problematic. And it is impossible to remove the coils with them from the wells. For candles you need a head "on 16". Replacement according to the regulations - every 60,000 km.

The air filter housing is located behind the battery, on the left. The top cover is secured with four self-tapping screws. Element replacement interval - 30,000 km.

Middle brother - the four-cylinder 1.6-liter engine is familiar from the Polo Sedan. It has a belt tensioner roller that is more conveniently located than the 1.2 motor. We loosen it with a key "17" counterclockwise and put any suitable stopper in a special hole when it goes beyond the tide on the block. To do this, like changing the belt itself, is easiest from the bottom.

The plug replacement algorithm is the same as on the motor 1.2. The only difference is in the fastening of the decorative coil cover: two latches in the front and two guides in the back.

The air filter housing is located behind the motor. The top cover is secured with five self-tapping screws. For more convenience, when replacing the filter, remove the ventilation hose from the valve cover. It is simply put on the fitting.

The 1.4 supercharged engine has the same attachment drive as the 1.6 engine. But replacing the candles turned out to be more difficult. The lid is fixed with four “30” torxes, access to the coil of the fourth cylinder is very limited. At a minimum, you need to dismantle the ventilation pipe running directly above it. Then it all depends on manual dexterity - the branch pipe from the turbine to the throttle assembly interferes with removing the connector from the coil. If the connector does not lend itself, it will have to be eliminated by unscrewing two “30” torxes on the turbine, and squeezing out a couple of large latches on the throttle. Remove all hoses and lines from the branch pipe, as well as the air flow sensor connector. When reassembling, it is important to lubricate the O-ring rubber on the turbine, otherwise it could break. The air filter housing is located on the left. The top cover is fastened with six "20" torxes.

The engine does not affect the layout of the engine compartment. All motors have the same uncomfortable filler neck for oil. It has internal sills, so the grease must be poured very slowly so that it does not overflow.

Oil filter on all units it is located in front, above the generator. When replacing the filter, use a rag to avoid oiling the parts underneath. The 1.2 engine has a cartridge-type filter with a replaceable inner element. We turn out its plastic case with a “36” head. Other units have one-piece filters. We use pullers or improvised tools for them.

Antifreeze drain plug is not provided. The fluid is designed for the life of the motors. In the event of a forced drain, you will have to remove the lower radiator pipe.

Three gearboxes are offered to Russian buyers to choose from: a five-speed mechanics, a six-speed automatic and a seven-speed DSG robot. Oil change is regulated only for the machine - every 60,000 km. In other units, it is filled for the entire service life. But no one is immune from repairs that involve draining the oil.

The manual transmission is friendly with motors 1.2 and 1.6. Engineers nevertheless took care of the ease of changing the oil: there are the usual filler and drain plugs. The filling hole is also a control hole. The normal oil level is at the edge.

The hydromechanical automatic device is only available for the 1.6 engine. It is installed on many models of the concern, and the most common on the Polo Sedan. The drain hole is both a control hole and a filler hole. A measuring tube for a hexagon "5" is screwed into it. The height of the tube corresponds to the normal oil level in the box warmed up to 35–40 degrees and the running engine. To drain the grease, unscrew the tube completely, then put it back in place and fill in the oil.

The service uses special containers and hoses for this, but you can do with a regular syringe for boxes. You just need to make a tip for the hose for the hole with the tube. For the sake of fairness, I note that such an inconvenient scheme is also used by other manufacturers.

The DSG box is only paired with a 1.4 turbo engine. It is much easier to change the oil in it than in a hydromechanical machine: there is an ordinary drain plug from the bottom, and oil (in a volume of 1.9 liters) is poured through the breather from above.

To replace any technical fluids, you must remove plastic protection a crankcase that does not have technological holes. It is secured with nine "25" torxes. Do not overtighten them, otherwise you will rip the threads in the embedded elements.

REPLACING BATTERIES, FILTERS AND BRAKE FLUID: EVERYTHING EXCEPT

Replacing the battery will not be difficult. The power fuse plate is secured to the positive terminal and the battery case with two large latches. We unfasten it from the battery and remove it together with the weakened terminal. The battery itself is secured in front with a metal plate with a “13” bolt.

Adjustment mechanism parking brake passed from Fabia. Access to it depends on the equipment of the machine. On machines without an armrest, it is sufficient to remove the rectangular niche behind the lever. And if you have an armrest, you will have to suffer - it has hard-to-reach mounts. Even after removing the armrest, you will have to partially dismantle and slightly raise the center console and manage to crawl up to the adjustment mechanism. You don't need to go there without an urgent need.

The cabin filter is located at the feet of the front passenger, on the left (as in the Fabia and Polo Sedan). The replacement interval is 15,000 km.

The remote fuel filter is located to the right of the tank. Replacement interval - every 60,000 km. When removing it, the servicemen do not relieve pressure in fuel system... This does not affect the amount of spilled gasoline. The filter has an arrow for the direction of installation, but even without this it is impossible to place it incorrectly. It is secured to the body with a plastic clamp.

Design brake system depends on the motor. Cars with a 1.4 engine have all disc brakes. The front caliper is fixed with two guides for a hexagon “7”, and the pads are devoid of anti-squeak springs in the guides of the bracket. The rear caliper is tightened with two “13” bolts, and to replace the pads, a “recessed” is needed - the caliper piston can only be pressed in by rotation.

Rapids with 1.6 engine have the same front brakes, and drum at the rear. No special tools are needed to replace the rear pads.

Cars with a 1.2 engine have smaller front brake discs and, accordingly, all the elements are different. The front pads are with anti-squeak springs, and the caliper is secured with two “12” bolts. The rear drums are the same as for versions with a 1.6 engine.

Change brake fluid simple - the fittings are conveniently located. It needs to be updated every two years.

Access to the lamps in the right headlight is free, but on the left everything again depends on the motor. On machines with motors 1.2 and 1.4, the battery is shifted slightly forward, and this eats up some of the free space. Fortunately, the lamps and their sockets have a simple fixation. Remove the battery if you are running out of room to maneuver. Removing the headlight is not an option - this cannot be done without dismantling the bumper.

We change the halogen lamps in the front fog lights from the outside. First, we remove the edging, and then the headlights themselves. To access the light bulbs in rear light, it will have to be dismantled, which does not require special skills.

The production of the Skoda Rapid began in 2012. The car was equipped with a wide lineup both gasoline and diesel engines: 1.6MPI (105 and 110 HP), 1.2MPI, 1.2TSI (86, 105, 90, 110 HP), 1.4TSI (1.4 turbo), 1.4TDI, 1.6TDI. Accordingly, the spark plugs on the Rapid can be both ignition and glow. Both those and others differed depending on the volume and modification of the engine.

On the conveyor, as an original and later as an original, spark plugs were supplied by such companies: NGK (T40227C-G08, PZKER7A8EGS, PZFR6R), BOSCH (F7HER02, 0 241 140 519, Y6LER02) and Brisk (DOX15LE-1). And the Skoda Rapid glow plugs are produced by: BERU (GE115, PSG002) and BOSCH (D-Power 57). We will consider which ones on which engine they are worth in more detail.

Skoda Rapid spark plugs

The original code of spark plugs for Skoda Rapid gasoline engines differ from the type of engine and its volume, as well as restyling.

For 1.6MPI, 105 hp (CFNA) engines, there were candles with the original number 101 905 601 F. After 2015, modernized versions of 1.6, 110 hp (CWVA, CWVB) appeared, for which candles with the number 04C 905 were provided 616 before 2016 and 04C 905 616A after 2016.

For 1.2MPI motor - 101 905 601 F (Bosch) or 101 905 618 A (Brisk).

For 1.2TSI, 105 HP (CBZA, CBZB) - 03F 905 600 A and 1.2TSI, 90 and 110 HP (CJZC, CJZD) - 04E 905 601 B.

For 1.4TSI (CAXA) - 101 905 626 and (CZCA) - 04E 905 601 B.

The technical parameters are shown in the table below:

| Article and dimensions of spark plugs for gasoline engines Š koda Rapid | ||||||||

|---|---|---|---|---|---|---|---|---|

| Engine | vendor code | Thread length, mm | Thread size | Key size, mm | Clearance, mm | Heat number | Center electrode material | price, rub. |

| 1.6 MPI, 105HP (CFNA) | 101 905 601 F | 19 | М14x1.25 | 16 | 0.9 | 6 | nickel | 556 |

| 1.6 MPI, 110HP (CWVA, CWVB) | 04C 905 616 04C 905 616A | 19 | М12x1.25 | 16 | 1 | 6 | nickel | 626 |

| 1.2MPI | 101 905 601 F 101 905 618 A | 19 | М14x1.25 | 16 | 0.9 | 6 | nickel | 556 |

| 1.2TSI, 105hp (CBZA, CBZB) | 03F 905 600 A | 22 | М14x1.25 | 16 | 0.9 | 6 | nickel | 1099 |

| 1.2TSI, 90, 110hp (CJZC, CJZD) | 04E 905 601 B | 19 | М12x1.25 | 16 | 0.7 | 7 | platinum | 1033 |

| 1.4TSI (CAXA) | 101 905 626 | 22 | М14x1.25 | 16 | 0.9 | 6 | iridium | 1078 |

| 1.4TSI (CZCA) | 04E 905 601 B | 19 | М12x1.25 | 16 | 0.7 | 7 | platinum | 1033 |

For the 1.6 (CFNA) and 1.2MPI motor, you can also find an analogue with an iridium center electrode - Bosch 0 242 240 654 (479 rubles) or Denso - IK20TT (620 rubles).

Replacement analogs are shown below:

Glow plugs Skoda Rapid

Skoda Rapid was equipped with two diesel engines with a total volume of 1.6 liters (1.6 TDI l4 and 1.6 TDI Green Tec l4) and two with a volume of 1.4 liters. Original candles supplied for motors (CAYC, CAYB, CLNA, CXMA) correspond to the article - 03L 963 319 (BOSCH), 03L 963 319A (NGK) and 059 963 319 J (Beru). All plugs for these engines - diesels are interchangeable. Also for the 1.4 diesel there are candles with a pressure sensor - 03L 905 061 G.

The original article numbers and their sizes of the glow plugs are presented in the table:

List of popular analogues on diesel engine is given below:

When to change the spark plugs for the Škoda Rapid?

According to the regulations, spark plugs must be changed every 60 thousand km or after 4 years of vehicle operation. But in practice, ordinary candles with a nickel center electrode rarely travel more than 30 thousand km, an average of 15 thousand km. Iridium and platinum candles as a rule, they take care of the prescribed time.

As for, there are no specific deadlines for replacing the glow plugs in the routine maintenance. A distinctive feature of the glow plug, in contrast to spark plugs for gasoline engines, is that they do not have a specific time frame for replacement. They are changed as they fail, on average about 2-3 years. The resource of the simplest candles with a metal spiral is 50-80 thousand km, ceramic ones will last much longer - up to 160 thousand km, and some candle models made in Japan- up to 240 thousand km.

If one candle is out of order, then this will practically not affect the operation of the engine, it will probably even start normally with two inoperative candles, but only in the warm season. And despite the fact that the failure of one candle will not affect the others , nevertheless, if during the check it was found that only one candle was out of order, change better all kit so that the resource of all candles is developed evenly.

The Rapid liftback is gaining popularity and is about to come out on top in terms of sales among its relatives, overtaking the current leader - Octavia. To make the car attractive both externally and in terms of filling, and at a price, the developers made a win-win move - they borrowed many solutions from other cars of the Volkswagen concern: the platform from the Polo Sedan, some of the nodes from Fabia, the exterior from the Octavia.

We will check how this "hybrid" is doing with service. Recall that we assess maintainability in points that correspond to the total standard hours (according to the official grid) spent on certain operations.

REPLACING CANDLES AND OIL FILTER: THREE FROM CASKET

Rapid is available for the Russian market with three gasoline engines - aspirated 1.2 and 1.6 and turbo 1.4. They are well known from other models of the concern. All - with a timing chain drive, which does not require maintenance.

The younger engine - a three-cylinder 1.2 - is found mainly on the Fabias of the previous generation. The attachment belt is designed for the entire life of the engine, but typically covers 100,000–150,000 km. Its automatic roller tensioner is located next to the generator and has a stopper to secure it in a loosened position. But using it for an easier belt replacement is extremely inconvenient, it is better to forget about it altogether. To loosen the tensioner, a "50" torx is used under the black plastic roller cover. The strap is easier to change from above, but remember to sketch or photograph how it stood. Surprisingly, you can easily put it wrong.

The individual ignition coils are hidden under a decorative plastic cover with four latches. As with most modern Volkswagen gasoline engines, they sit in vnatyag candle wells. To remove the coils, you need a special puller or its homemade counterpart, otherwise there is a great risk of damaging them. Another inconvenience: the connectors on them are upside down. For an inexperienced person, removing the connectors without seeing the type of retainer is problematic. And it is impossible to remove the coils with them from the wells. For candles you need a head "on 16". Replacement according to the regulations - every 60,000 km.

The air filter housing is located behind the battery, on the left. The top cover is secured with four self-tapping screws. Element replacement interval - 30,000 km.

Middle brother - the four-cylinder 1.6-liter engine is familiar from the Polo Sedan. It has a belt tensioner roller that is more conveniently located than the 1.2 motor. We loosen it with a key "17" counterclockwise and put any suitable stopper in a special hole when it goes beyond the tide on the block. To do this, like changing the belt itself, is easiest from the bottom.

The plug replacement algorithm is the same as on the motor 1.2. The only difference is in the fastening of the decorative coil cover: two latches in the front and two guides in the back.

The air filter housing is located behind the motor. The top cover is secured with five self-tapping screws. For more convenience, when replacing the filter, remove the ventilation hose from the valve cover. It is simply put on the fitting.

The 1.4 supercharged engine has the same attachment drive as the 1.6 engine. But replacing the candles turned out to be more difficult. The lid is fixed with four “30” torxes, access to the coil of the fourth cylinder is very limited. At a minimum, you need to dismantle the ventilation pipe running directly above it. Then it all depends on manual dexterity - the branch pipe from the turbine to the throttle assembly interferes with removing the connector from the coil. If the connector does not lend itself, it will have to be eliminated by unscrewing two “30” torxes on the turbine, and squeezing out a couple of large latches on the throttle. Remove all hoses and lines from the branch pipe, as well as the air flow sensor connector. When reassembling, it is important to lubricate the O-ring rubber on the turbine, otherwise it could break. The air filter housing is located on the left. The top cover is fastened with six "20" torxes.

The engine does not affect the layout of the engine compartment. All motors have the same inconvenient oil filler neck. It has internal sills, so the grease must be poured very slowly so that it does not overflow.

The oil filter for all units is located at the front, above the generator. When replacing the filter, use a rag to avoid oiling the parts underneath. The 1.2 engine has a cartridge-type filter with a replaceable inner element. We turn out its plastic case with a “36” head. Other units have one-piece filters. We use pullers or improvised tools for them.

Antifreeze drain plug is not provided. The fluid is designed for the life of the motors. In the event of a forced drain, you will have to remove the lower radiator pipe.

Three gearboxes are offered to Russian buyers to choose from: a five-speed mechanics, a six-speed automatic and a seven-speed DSG robot. Oil change is regulated only for the machine - every 60,000 km. In other units, it is filled for the entire service life. But no one is immune from repairs that involve draining the oil.

The manual transmission is friendly with motors 1.2 and 1.6. Engineers nevertheless took care of the ease of changing the oil: there are the usual filler and drain plugs. The filling hole is also a control hole. The normal oil level is at the edge.

The hydromechanical automatic device is only available for the 1.6 engine. It is installed on many models of the concern, and the most common on the Polo Sedan. The drain hole is both a control hole and a filler hole. A measuring tube for a hexagon "5" is screwed into it. The height of the tube corresponds to the normal oil level in the box warmed up to 35–40 degrees and the running engine. To drain the grease, unscrew the tube completely, then put it back in place and fill in the oil.

The service uses special containers and hoses for this, but you can do with a regular syringe for boxes. You just need to make a tip for the hose for the hole with the tube. For the sake of fairness, I note that such an inconvenient scheme is also used by other manufacturers.

The DSG box is only paired with a 1.4 turbo engine. It is much easier to change the oil in it than in a hydromechanical machine: there is an ordinary drain plug from the bottom, and oil (in a volume of 1.9 liters) is poured through the breather from above.

To replace any technical fluids, it is necessary to remove the plastic crankcase protection that does not have technological holes. It is secured with nine "25" torxes. Do not overtighten them, otherwise you will rip the threads in the embedded elements.

REPLACING BATTERIES, FILTERS AND BRAKE FLUID: EVERYTHING EXCEPT

Replacing the battery will not be difficult. The power fuse plate is secured to the positive terminal and the battery case with two large latches. We unfasten it from the battery and remove it together with the weakened terminal. The battery itself is secured in front with a metal plate with a “13” bolt.

The parking brake adjustment mechanism has been transferred from Fabia. Access to it depends on the equipment of the machine. On machines without an armrest, it is sufficient to remove the rectangular niche behind the lever. And if you have an armrest, you will have to suffer - it has hard-to-reach mounts. Even after removing the armrest, you will have to partially dismantle and slightly raise the center console and manage to crawl up to the adjustment mechanism. You don't need to go there without an urgent need.

The cabin filter is located at the feet of the front passenger, on the left (as in the Fabia and Polo Sedan). The replacement interval is 15,000 km.

The remote fuel filter is located to the right of the tank. Replacement interval - every 60,000 km. When removing it, servicemen do not release pressure in the fuel system. This does not affect the amount of spilled gasoline. The filter has an arrow for the direction of installation, but even without this it is impossible to place it incorrectly. It is secured to the body with a plastic clamp.

The design of the braking system depends on the motor. Cars with a 1.4 engine have all disc brakes. The front caliper is fixed with two guides for a hexagon “7”, and the pads are devoid of anti-squeak springs in the guides of the bracket. The rear caliper is tightened with two “13” bolts, and to replace the pads, a “recessed” is needed - the caliper piston can only be pressed in by rotation.

Rapids with 1.6 engine have the same front brakes, and drum at the rear. No special tools are needed to replace the rear pads.

Cars with a 1.2 engine have smaller front brake discs and, accordingly, all the elements are different. The front pads are with anti-squeak springs, and the caliper is secured with two “12” bolts. The rear drums are the same as for versions with a 1.6 engine.

Usually everyone starts to write about MOT with MOT 0. But it’s not my destiny, because the car was taken from my father with a range of 51 300 km. Prior to that, it was serviced by a dealer's rukozhopov ... For 60,000 maintenance, the dealer broke 18,500 rubles ... I called for the sake of interest to a dealer in Ivanovo, they charged 19,600 rubles there. In short, well, nafig them. I went to the service center Sokol:

Where is my friend working now, who is a great specialist in VAG, for he previously worked at OD Ruslan (dealer of PV). It was he who previously served my Priora and moves on the 12shke, about which I wrote here. In general, I like that for those parts my cars are made by 1 person, and electronically by 1 person. I don’t start up any rukozhopov) Spare parts were bought as follows:

all this cost 2930r Candles at 360r / piece, Oil filter 310r, plug 70r, air filter 170r, fuel 940r.

These are the candles, as shown by the "autopsy" - exactly the same were from the factory. 360r piece ... I bought 4 candles for PRIOR for 200-250r))

The process has begun.

the secret was revealed why the dealer did not remove the protection when changing the oil. The bolt on the right is scrolling. As a result, it was decided to change the mortgage piece where the bolt is screwed in (I forgot what it’s called), we will change it later. I am very sorry that being at the dealer I didn’t make a scandal and didn’t make them change it. And so - "quality" on the face. A year and a half, and the bolts cannot be unscrewed. What did Suvfan say about Kalina? Obviously, the steel is the same here.

We started with butter. I refused Liquid Molly and switched to Lukoil. Genesis 5-40, picked up at Deacon.

This is how the liquidation-molly merged, after running about 7000 km on it. At first there was this color of the oil, then it flowed darker.

Moved on to fuel filter... The old one was sprayed with VDshka to easily remove

For me, as a former Priorovod, this arrangement of air and throttle is unusual.

On this side, the throttle is clean, on the other side it is not. I did not clean it, because you need to google how it's done.

This is what the old air looked like.

There are also ignition coils, though of a different shape and a different price. And here is the pulp, candles. All add-ons to change candles according to the regulations are dedicated. Pay attention to the gap, especially when compared to a new candle. On this site, I often saw messages that there was no need to change the candles before the schedule, someone even reproached me for being too extravagant when I changed the candles every 20,000 km on the prior (against the 30,000 schedule).

Next, it was necessary to reset the maintenance interval, I did it according to the instructions from the drive: "The actions are as follows: we press the button on dashboard(I remind you that since the 2016 model year there is only one button on the tidy and the algorithm for resetting the intervals is somewhat different), while holding the button, turn on the ignition. Let go of the button. The offer to reset the maintenance interval will be displayed, pressed the button - confirmed ".

Despite the replacement of oil and candles, no difference was noticed in the operation of the car) The total cost was: consumables: 2930r + oil 1600r, work 1260r = 5790r, which is three times cheaper than the dealer's.