In search of an alternative energy source, the understanding came that it is not necessary to extract gas in mines in order to then burn it in boilers and engines internal combustion, combustible gas can be extracted from industrial waste and wood. A gas generator or, as it is also called, a gas generator by burning local fuel - firewood, peat, charcoal, sawdust and other wood waste, as well as sometimes other organic residues, can emit / generate combustible gases such as CO, CH4, H2 and others. There are several options for using the resulting gas, but in any case, each device is based on the principle of a gas generator. About how the gas generator works, what elements it consists of, as well as what processes take place inside it, we will describe in this article. We will also consider options for the further use of the resulting gas and places where such units can be installed.

So, what are the options for using the gas obtained in the gas generator?

First, combustible gas is sent to the gas stove in the kitchen and used for cooking. The second - combustible gas is burned immediately in a pyrolysis heating boiler with a gas generator, respectively, is used to heat a house or greenhouses. By the way, such boilers can be called a gas-fired boiler, solid fuel pyrolysis boiler, gas-fired boiler. All of them can be used both for domestic needs and for heating huge industries and workshops or enterprises. Third, combustible gas can be sent to an internal combustion engine, which serves as a drive for a pumping station or an electricity generator. A wood-fired gas generator makes it possible to obtain electricity in those regions where it is not possible to lay power lines, lay a gas pipeline, and it is difficult to supply gas in cylinders. In addition to autonomy, gas generators have other advantages, which we will discuss below.

Advantages and disadvantages of gas generators

As an example, consider the advantages and disadvantages of gas-fired heating boilers. Pyrolysis boilers belong to the category of solid fuel, but differ significantly from conventional wood or coal stoves, where the usual process of fuel combustion takes place.

Advantages of gas generating boilers:

- The efficiency of gas-fired boilers is in the range of 80 - 95%, while the efficiency of a conventional solid fuel boiler rarely exceeds 60%.

- Regulated combustion process in a gas-generating boiler - one bookmark of firewood can burn from 8 to 12 hours, for comparison, in a conventional boiler, burning lasts 3 - 5 hours. In gas-generating boilers with top combustion, the combustion of firewood lasts up to 25 hours, and coal can burn for 5-8 days.

- The fuel burns out completely, so it is not often necessary to clean the ash pan and flue.

- Due to the fact that the combustion process can be regulated (power is adjustable in the range of 30 - 100%), the operation of the boiler can be automated, such as gas or liquid fuel.

- Emission of harmful substances into the atmosphere from the gas generator is minimal.

- Gas-fired boilers are more economical than conventional ones.

- Fuel for gas generators does not have to be dried up to 20% moisture, there are boiler models in which wood up to 50% moisture and even freshly cut wood can be used.

- Possibility of loading unchopped logs up to 1 m long and even more into the boiler.

- In addition to firewood and wood industry waste, rubber, plastic and other polymers can be recycled in pyrolysis boilers.

- The high safety of the boiler compared to a conventional solid fuel boiler is ensured by automation and the materials from which the unit is made, and in particular the combustion chamber.

If we talk about gas generators that are used for electricity generation, they have exactly the same advantages, such as environmental friendliness, economy, high efficiency, high octane number 110 - 140, versatility in terms of fuel used and greater efficiency in winter.

Disadvantages of gas-fired boilers:

- For a gas generator, the price is 1.5 - 2 times higher than for a conventional solid fuel boiler.

- For the most part, gas generators are volatile, since a fan is used to suck in air, but there are also models that can work without electricity.

- If you use a gas-generating boiler at a power below 50%, then unstable combustion is observed - as a result of precipitation of tar, which accumulates in the flue.

- The heating return temperature must not be lower than 60 °C, otherwise condensate will form in the flue.

- Usually gas generators are demanding on the moisture content of the fuel, but as mentioned above, there are models in which even freshly cut wood can be burned.

No other significant shortcomings of gas generators have been identified.

By the way, gas generators are not such a new invention. Even in the middle of the last century, when most of Germany's oil resources were used, firewood was used as fuel for cars. Even trucks were equipped with gas generators. Modern units have not gone too far in their design, but, nevertheless, have been thoroughly improved.

The principle of operation of the gas generator - gas generator

Combustible gas is produced from solid fuel in a gas generator or gas generator. The main secret is that air is supplied to the combustion chamber, the volume of which is not enough for complete combustion of the fuel, while maintaining a high temperature of the order of 1100 - 1400 ° C. The resulting gas is cooled and sent to the consumer or internal combustion engine, if, for example, it is planned to produce electricity. We will consider in more detail the principle of operation of the gas generator below, specifying which process occurs in which element of the unit.

The device of the gas generator on wood

Consider a domestic gas generator device. I would like to note right away that pyrolysis boilers with a gas generator differ from the proposed scheme, since gas combustion occurs inside the boiler in the second combustion chamber. We will consider only the gas generator itself, at the output of which a combustible gas is obtained.

Gas generator housing made of sheet steel and has welded seams. The most common body shape is cylindrical, but it may well be rectangular. A bottom and legs are welded to the lower part of the body, on which the gas generator will stand.

Bunker or filling chamber serves to load fuel into the gas generator. It also has a cylindrical shape and is made of mild steel. The bunker is installed inside the gas generator housing and secured with bolts. On the cover of the hatch leading to the bunker, an asbestos sealant or gasket was used on the edges. Since asbestos is prohibited for use in residential areas, there are models of gas generators whose lid seals are made of a different material.

The combustion chamber located at the bottom of the bunker and made of heat-resistant steel, sometimes the inner surface of the combustion chamber is finished with ceramics. Fuel is burned in the combustion chamber. Resin cracking occurs in its lower part, for which a neck made of heat-resistant chromium steel is installed there. Between the body and the neck there is a gasket - a sealing asbestos cord. In the middle of the combustion chamber are air lances. The tuyeres are calibrated holes that connect to an air distribution box connected to the atmosphere. lances and junction box are also made of heat-resistant steel. A non-return valve is installed at the outlet of the air distribution box, which prevents the combustible gas from escaping from the gas generator. In order to increase engine power or to be able to use firewood with high humidity (more than 50%), it is possible to install in front of the air distribution box fan, which will force air inside.

Grate serves to keep hot coals burning. It is located at the bottom of the gas generator. Through the holes in the grate, the ash from the burnt coals falls into the ash pan. So that the grate can be cleaned of slag, its middle part is made movable. A special lever is provided for turning cast-iron grates.

Loading hatches fitted with sealed lids. For example, the top loading hatch folds horizontally and is sealed with asbestos cord. There is a special shock absorber in the lid fastening - a spring, which raises the lid in case of excessive pressure inside the chamber. There are also two loading hatches on the side of the hull: one on top - for adding fuel to the recovery zone, the second on the bottom - for removing ash. Gas extraction is carried out in the recovery zone, therefore, most often in the upper part of the gas generator, but it is also possible to remove gas from the lower part of the unit. Gas is taken through a branch pipe to which gas pipeline pipes are welded. It is not necessary to immediately remove the gas outside the gas generator housing while it is hot, it can be used to heat and dry firewood or other fuel in the loading chamber. To do this, the outlet gas pipeline is carried out in an annular fashion around the chamber, between the gas generator housing and the bunker.

Cyclone filter And fine filter located behind the gas generator housing. They are made of pipes filled with filter elements.

Before entering the fine filter, the gas passes through cooler. And after the fine filter, the purified gas enters mixer where it mixes with air. And only then the gas-air mixture enters the internal combustion engine.

More clearly, the sequence of movement of combustible gas after it has left the gas generator is shown in the diagram below.

Firewood or other fuel burns in the combustion chamber, being oxidized by the air entering the combustion chamber through the tuyeres from the air distribution box. The resulting combustible gas enters the Cyclone filter, where it is cleaned. Then cooled in the filter coarse cleaning. Then the already cooled gas enters the fine filter, and then into the mixer. From the mixer, the resulting mixture enters the engine.

The process of converting fuel into gas

And yet: how is gas obtained from solid fuel? Inside the gas generator, a certain transformation process takes place, which is divided into several stages occurring in different zones:

Drying zone located at the top of the bunker. Here the temperature is about 150 - 200 °C. The fuel is dried with hot gas, which moves through the annular pipeline, as described above.

Dry Distillation Zone located in the middle of the bunker. Here, without air access and at a temperature of 300 - 500 ° C, the fuel is charred. Acids, resins and other elements of dry distillation are extracted from wood.

Burning zone located at the bottom of the combustion chamber in the area where the lances through which air enters are located. Here, when air is supplied and at a temperature of 1100 - 1300 ° C, charred fuel and dry distillation elements burn out, resulting in the formation of CO and CO2 gases.

recovery zone located above the combustion zone between the grate and the combustion zone. Here, CO2 gas rises, passes through hot coal, interacts with carbon (C) of coal, and CO gas is formed at the exit - carbon monoxide. Moisture from the fuel is also involved in this process, therefore, in addition to CO, CO2 and H2 are formed.

The combustion and reduction zones are called the active gasification zone. As a result, the producer gas consists of several components:

- combustible gases: SO(carbon monoxide), H2(hydrogen), CH4(methane) and СnНm(unsaturated hydrocarbons without resins).

- Ballast: CO2(carbon dioxide), O2(oxygen), N2(nitrogen), H2O(water).

The resulting gas is cooled to ambient temperature, then purified from formic and acetic acid, ash, suspended particles and mixed with air.

Types of gas generators

There are three types of gas generators: direct gas generation process, reverse and horizontal.

Semi-coke and anthracite can burn coal - non-bituminous fuel. Design difference of this type units in that air enters through the grate from below, and gas is taken from above. In gas generators of the direct process, moisture from the fuel does not enter the combustion zone, so it is specially supplied. Enriching generator gas with hydrogen from water increases the power of the generator.

Gas generators overturned or inverted process designed for burning tarry fuel - firewood, charcoal and waste. Their constructive difference is that air is supplied to the middle part - to the combustion zone, and the gas is taken below the combustion zone - in the ash pan. Typically, in units of this type, the selected hot gas is used to heat the fuel in the bunker.

Horizontal gas generators or cross process gasification systems are distinguished by the fact that air is supplied to them from the side - in the lower part of the body, and it is supplied at a high blowing speed through tuyeres. Gas sampling is carried out in front of the lance through the gas sampling grate. The active gasification zone in the horizontal process gasifier is very small and is concentrated between the end of the lance and the sampling grate. The start-up time of such a generator is much less, it also easily adapts to changing operating modes.

Place of installation of the gas generator

Gas generators and gas generating heating boilers can be installed both inside residential premises, for example, in basements and basement floors, and on the street.

The so-called pellet boilers are most often installed in the house, since their loading is not associated with a lot of garbage, and bags of pellets weigh a little and can be stored somewhere near the boiler.

Gas generators on wood, and especially on wood of great length, it makes sense to install on the street near the place where firewood is stored. So it will be possible to bring firewood on a wheelbarrow directly to the boiler or gas generator and not lower it into the basement of the house. A boiler standing on the street eliminates dirt and ash in the basement. This is especially true for wooden houses, where there are increased fire safety standards. The outer body of the boiler is made of stainless steel, which is not subject to corrosion. Also, the boilers are thermally insulated with bulk thermal insulation so that the ambient temperature has a minimal effect on the gasification process and the boiler start-up speed. The control system is housed in a steel casing under a cover so that precipitation does not fall on it. The chimney has double walls. If you are interested in how to connect a gas generator if it is on the street, then the answer is simple - the pipes are laid in the ground so that they are minimally cooled if it is a heating boiler. Heating pipes approach the boiler from below, and the boiler itself is installed so that it does not freeze during long breaks in use.

By the way, as already noted, the duration of the process of burning fuel in the boiler can be from 12 hours to up to 25 hours. Depending on the power of the boiler and the area of the heated room, it will have to be heated once every two days, and sometimes once a week. To keep the heat generated by the boiler for such a long period, a heat accumulator is used.

DIY wood gas generator

There is nothing super complicated in making a gas generator with your own hands. Many use such a unit for domestic needs or install it on a car. Before you start making a gas generator yourself, you need to familiarize yourself with the principle of its operation and choose the scheme of work that suits you.

You will need - a barrel, pipes or an old battery of radiators, fine and coarse gas filters, a fan. On the other hand, the set of elements can be very different, it all depends on the imagination of the performer.

Below is a video example of a self-made gas generator.

Scheme of the gas generator:

On the Internet you can find both photos and drawings for the installation of gas generators and pyrolysis boilers. There are even craftsmen who take a ready-made proven boiler as a basis and completely repeat it at home. It turns out much cheaper.

The difference between a pyrolysis boiler and a conventional gas generator is that it consists of two combustion chambers: fuel is burned in one and gas is formed, and gas is burned in the other and a heat exchanger is located. We have already considered the device and principle of operation of the gas generator, add only the second combustion chamber to it, which should be located at the top, and the heat exchanger on top. Sometimes the heat exchanger is placed on the side. Also, do not forget about different types of gas generators, so that the second combustion chamber can be located not only on top.

When assembling the chimney, try to assemble it in the reverse order of the movement of smoke, so any muck will settle on its walls less. The chimney itself is best made easily disassembled so that it can be easily and quickly cleaned. The space around the heating boiler must be free, as it heats up during operation. After installing the boiler, you will have to study its “habits” and choose the optimal operating mode for yourself, in which all resins burn out.

I would like to note that the gas generator can be considered not only as a burner of useful wood, but also as a waste disposal unit. It can burn the remains of linoleum, bags, bags, rubber, plastic bottles and other household waste.

People invented electricity, learned how to use solar and wind energy, extract various minerals, such as oil and gas. However, most of them still continue to burn wood in furnaces. Sawdust and other waste from the woodworking industry can be used if you make a gas-generating car on wood with your own hands. Many masters today successfully operate such devices.

- methane;

- unsaturated hydrocarbons;

- carbon monoxide;

- hydrogen.

- oxygen;

- water;

- carbon dioxide;

- nitrogen.

Show all

The principle of the car

A feature of the gas generator for a wood-burning car is the unit in which the gas mixture is extracted. Then it enters the internal combustion engine, where it is burned. As a result of these processes, the machine moves. When using such a device, it must be taken into account that it takes up a lot of space and needs to be used additional equipment

- filters, pipes and radiator.

A feature of the gas generator for a wood-burning car is the unit in which the gas mixture is extracted. Then it enters the internal combustion engine, where it is burned. As a result of these processes, the machine moves. When using such a device, it must be taken into account that it takes up a lot of space and needs to be used additional equipment

- filters, pipes and radiator.

A gas generator is a device that turns wood into gas. Everyone knows that gas is an alternative energy source for cars. This is confirmed by a large number of gas stations. However, getting fuel on your own is not only possible, but quite real. The onboard structure is capable of producing as many resources as the vehicle needs. However, there is one caveat: hot fuel is less efficient, especially if impurities are present in it. Therefore, the first step is to cool it, and then clean it.

After leaving the unit, the gas moves through the pipes to the filter, and then to the radiator. During movement, it is cleaned of dust and acids. In addition, its temperature decreases. In the process of passing through the labyrinths, impurities settle on the walls in the form of liquid or solid particles. Through a special tee, the gas is combined with oxygen and sent to the engine. Then the mixture reaches not only the required condition, but also ends up in the engine. After that, the gas enters the combustion chamber and sets the car in motion.

The suspension, interior, engine and clutch of the car remain in place. The only problem is where to place the gas generator and how to lay the pipeline so that the machine looks like a steam locomotive. All these questions should be studied in detail before starting work.

The essence of the gas generator

It is quite possible to make a car on wood with your own hands. The manufacture of a gas generator is a feasible task, however, as well as its installation. To begin with, it is important to understand the features of the unit and the essence of the process. The design itself is presented in the form of a cylinder narrowed at the bottom. Figuratively, you can call it a bunker, a store for firewood in which is a cylindrical part. In the narrow half, combustion occurs.

It is quite possible to make a car on wood with your own hands. The manufacture of a gas generator is a feasible task, however, as well as its installation. To begin with, it is important to understand the features of the unit and the essence of the process. The design itself is presented in the form of a cylinder narrowed at the bottom. Figuratively, you can call it a bunker, a store for firewood in which is a cylindrical part. In the narrow half, combustion occurs.

The workpieces themselves fall under the influence of their own weight. This ensures an uninterrupted supply of fuel to the combustion source. Ash settles in a special container, which periodically requires cleaning. Firewood is loaded into the hatch from above.

Small workpieces are tightly placed from the grate to the lid. The latter is hermetically sealed to minimize leakage. The device is kindled, after a while the car can hit the road.

The design should not be confused with an open fire. The oxygen required for combustion is supplied in portions through a special tube. On the opposite side there is a hole for the gas outlet. With portioned air supply, active combustion is not carried out. Wooden blanks undergo pyrolysis - they smolder on low heat, actively releasing a combustible mixture.

Wood burning car - made in Donetsk

The main purpose of the gas generator is to produce a combustible gas called carbon monoxide. It is this substance that will burn in the internal combustion engine. This procedure can be positioned as complete and partial combustion, during which carbon monoxide is formed. In addition, carbon dioxide is released. When burned in contact with moisture, firewood forms a mixture that consists of:

In addition, during the combustion process, several non-combustible components are released. These include:

Types of structures

There are three types of gas generators for a car. If oxygen is supplied from the bottom, and gas is taken from above, this is a direct-flow product. With such an arrangement of nozzles, the gas mixture is released during combustion at the bottom of the cone. In the process of movement of gases through coal and chocks of wood, air and heat are released. After the blanks are passed through a hot gas mixture, they are dried and prepared for pyrolysis.

There are three types of gas generators for a car. If oxygen is supplied from the bottom, and gas is taken from above, this is a direct-flow product. With such an arrangement of nozzles, the gas mixture is released during combustion at the bottom of the cone. In the process of movement of gases through coal and chocks of wood, air and heat are released. After the blanks are passed through a hot gas mixture, they are dried and prepared for pyrolysis.

If the supply of oxygen to support combustion is carried out at the beginning of the narrow part of the bunker, and the gas mixture is taken from below, then this type of device is called reverse or overturned. The wood is ignited inside, above the grate zone. Pipes for gas removal are located below the grate. A similar principle of operation is similar to a smoking pipe.

There is also an alternative option - the combustion chamber at the reverse gas generator is limited by a special inclined partition. Opposite the oxygen supply pipe, on the back side of the partition, there is a niche from which combustible gas is taken. Oxygen supply and gas exhaust pipes are located on the same level. The pipe supply line crosses the bunker across, so this design is called horizontal.

3) Do-it-yourself wood-burning gas generator #3

Direct-flow and horizontal gas generators have shown themselves well when using peat, charcoal or coke. The overturned type of equipment is widely used for riding dry wood chocks.

Device Features

A characteristic feature of all gas generators is the movement of carbon dioxide (carbon dioxide) through decaying coal. In this case, the gas mixture gives off excess air and is converted into carbon monoxide. It is desirable that a cyclone filter be placed between the heat exchanger and the combustion chamber. This is necessary to ensure that the gas mixture is purified from all kinds of mechanical impurities. Such a device can trap about 90% of flying dust.

A characteristic feature of all gas generators is the movement of carbon dioxide (carbon dioxide) through decaying coal. In this case, the gas mixture gives off excess air and is converted into carbon monoxide. It is desirable that a cyclone filter be placed between the heat exchanger and the combustion chamber. This is necessary to ensure that the gas mixture is purified from all kinds of mechanical impurities. Such a device can trap about 90% of flying dust.

The radiator plays an essential role. Cooling, the gas becomes more concentrated and decreases in volume. This contributes to the supply of more fuel to the internal combustion engine. Engine power during operation directly depends on the temperature indicators of the gaseous mixture. This is because the gas is resistant to detonation, so it must be cooled to increase compression.

A fine filter element made of two canisters is considered compact. Mineral wool and slag in granules are placed inside the tanks. They will clean the gas well. At the bottom of the filter and heat exchanger, it is imperative to install taps. This is necessary to drain the condensate. After cleaning and cooling of the gas mixture, dew falls. Every 200 km of driving, about 3 liters of liquid is collected in the tank.

Welds and joints must be sealed, because in the event of a leak with the constant addition of firewood, the speed and performance of the car engine will remain at a minimum level. The assembled unit must be well fixed so that it does not collapse from vibration during movement.

do-it-yourself gas generator for cars

A wood-burning gas engine for a car can be of various shapes and sizes. There are no specific requirements for these indicators. However, it must be borne in mind that the device must necessarily be created from metal with a thickness of at least 3 mm. Where exactly to install the structure, each motorist decides for himself.

A wood-burning gas engine for a car can be of various shapes and sizes. There are no specific requirements for these indicators. However, it must be borne in mind that the device must necessarily be created from metal with a thickness of at least 3 mm. Where exactly to install the structure, each motorist decides for himself.

When choosing a location, it is important to consider not only the dimensions of the entire unit, heat exchanger and filters, but also the length of the nozzles. It is important that the batch of fuel is loaded through the cover from above. While the engine is running, refueling is carried out with a slight emission of gas. If the internal combustion engine is turned off, and the mass continues to burn in the device, loading a new batch is accompanied by the appearance of a plentiful cloud.

You can place such a device only outside the car and always behind. This is because the structure must be freely accessible. The longer the planned distances without refueling, the more sizes products. The constituent elements of the apparatus must be made in accordance with the dimensions of the hopper.

Gas generator on truck can be placed between the cab and the board on the driver's side. Pipes, heat exchanger and filter element may be placed behind the cab. The fine filter should be located on the opposite side of the cabin (behind the passenger door). For convenient removal of condensate, pipes and drain valves are led below the fine filter element.

On passenger car the device is recommended to be installed on an open part. To do this, you can modify the trunk, weld a trailer, etc. It all depends on the taste preferences and fantasies of the owner. It is not recommended to install the equipment in the trunk under the lid, since during its operation smoke and coal dust will enter the car interior.

Gas generator - unit which produces combustible gas. After running the latter through cleaning filters and a cooling radiator, a clean and cold gas mixture is obtained. Carbon monoxide can replace the classic fuel option, providing the engine with smooth operation. Gasoline internal combustion engines operate with a gas generating device without significant performance losses.

DIY manufacturing

The production of any device begins with the production of a drawing. After studying the detailed information, a person has an idea of \u200b\u200bthe external design of the unit. Then it remains to bring your idea to life.

To make the device look aesthetically pleasing, you should choose the right details . For its manufacture you will need:

First you need to make 5-6 holes at the top of the pipe. It will become the top of the structure. An oxygen supply tube should be welded to one of the holes obtained. Gas will come out through the rest. In the lower part it is necessary to weld a perforated stainless steel bottom. Get the grate part, which will accommodate the coals. Dust will come out through the holes.

From the inside of the resulting glass, a metal cone is welded to supply coal. Then a metal sheet should be welded with a hole the size of which matches the inner diameter of the pipe. The structure must be placed perpendicular to the top of the tube. The sheet will become the bottom of the bin. The functions of the latter will be performed by a can.

The resulting workpiece is placed in a barrel and welded in such a way that there is room for ash below, and the neck of the can is placed above the barrel. Then one of the can holes must be aligned with the combustion chamber and connected with an oxygen supply tube. Further, a metal sheet is welded in the upper part, which covers the difference in the size of the neck of the can and the barrel. The structure is ready.

The resulting workpiece is placed in a barrel and welded in such a way that there is room for ash below, and the neck of the can is placed above the barrel. Then one of the can holes must be aligned with the combustion chamber and connected with an oxygen supply tube. Further, a metal sheet is welded in the upper part, which covers the difference in the size of the neck of the can and the barrel. The structure is ready.

Making a car on wood with your own hands is not as easy as it might seem at first glance. The procedure requires a lot of effort and time. However, for a skilled craftsman who is ready to experiment and is not afraid of difficulties, this is a very real task. It is very important to study in detail the device and the principle of operation of the product, as well as to correctly draw up its drawing.

Alas, no one has yet been able to identify a pike that speaks in a human voice and fulfills all the whims, but the equivalent of a self-propelled wood-burning stove exists and has long been known. Of course, this is not at all about cars moving on So, how to make a car on wood with your own hands?

Is it real?

The statement that a car runs on wood is by no means an April Fool's joke. Your personal transport may well be powered not by banal gasoline, but by such delicious foods as construction waste, which has a woody base.

The idea of such an alternative type of fuel is by no means new, such cars existed during the Second World War, and in some countries where liquid fuel is similar to jewelry, they can be found in large numbers to this day, for example, in the secret of such a magical car is simple - this is a wood-fired gas generator, a kind of magical combination of quite ordinary and earthly material and a high-tech device.

Gas generator, wood-fired car

How does this mysterious mechanism work? Is it possible to make a car on wood with your own hands? Combustible natural gases, such as ethylene or propylene known to us, are quite realistic to produce on our own, and for this you do not need to dig the ground and acquire your own well. It is enough to get a gas generator: just buy it or go the more complicated way, making it with your own skillful hands.

How does a gas generator work in a car?

In the gas generator, by pyrolysis, known to everyone from the school bench, cellulose, or, more simply, all kinds (the same firewood), turns into the same gas, the fuel we are looking for. To obtain the desired product, the simple destruction of firewood is not enough. The reaction must take place at a temperature in excess of 1000 degrees Celsius, with a limited supply of oxygen. Of course, the resulting magical mixture must also be rid of any absolutely unnecessary impurities and cooled, because the cooled gas gives more much-needed auto energy. On sale you can find boilers operating using a gas generator, but, alas, this design is not suitable for personal vehicles. So you will need to turn your workhorse into a fire-breathing dragon yourself.

Peculiarities

The gas generator is a key element thanks to which the car goes on firewood. It is quite possible to build a gas generator with your own hands. Yes, it takes up a lot of space, but so many opportunities immediately appear. The forest is being cut down - the car is moving. You can create a car on wood with your own hands, and your four-wheeled friend will absorb everything that burns if cellulose is included in the composition. Cones, husks, scraps of parquet, in warm countries - coconut husks, even raw firewood. The oven is happy with anything. That's just wet wood will smoke mercilessly.

So if you do not take into account the scorched desert, fuel can be obtained anywhere and not be tied to gas stations. A real dream for those who anticipate an apocalyptic future with a destroyed fuel supply infrastructure. And the cost of food for such a self-propelled gun will be about four times cheaper compared to ordinary gasoline. Do-it-yourself wood-fired cars are also an ecologist's dream, the amount of harmful emissions into the atmosphere is many times less here. All changes are made exclusively independently using the most ordinary tools and materials, no high technology.

Cons of using a wood-burning gas generator in cars

Of course, such a system also has its downsides. Firstly, the very design of a home-made gas generator is quite bulky, which means it increases the weight of the car. It must be placed somewhere, which will reduce the usable area, and at the same time reduce the carrying capacity. Gas stations themselves are not needed, but you will have to stop to throw firewood quite often, and even with its omnivorous nature, you still need to monitor the quality of what is sent to the furnace. Preferably nothing raw and without rot. Such a unit also does not awaken to life in seconds, it will take about 10 minutes. The speed is also quite consistent with the famous self-driving stove, as the motor power also decreases. The combustion process itself must be carefully monitored, a drop in temperature leads to the fact that the useful gas mixture necessary for the operation of the engine turns into completely unnecessary tar. Based on all of the above, in the old days, wood-burning cars were used mainly in those places where the latter (firewood) was in abundance. On all kinds of logging. Or where there was no other fuel as such, in the impassable wilderness.

Gas generator device

What is a wood burning gas generator for a car? The secret of the unit is quite simple. During the combustion of wood fuel, a gas is formed, which, freed from excess impurities, passes through the cooling stage, is mixed with air and injected into the

So you need the gas generator itself, different kinds filters, a mandatory cooling system, all kinds of pipelines and an electric fan - to speed up and improve the combustion itself. The system looks like this: the necessary fuel is loaded into a high cylindrical tank (a square is also possible), under which the combustion chamber itself is installed. The resulting gas passes through a purification system. Further, the fuel temperature drops to ideal, and then air enrichment - and the desired mixture ends up in the engine. Modern developments of craftsmen differ little from the attached old scheme, and therefore, if you do not equip a truck with a gas generator, but put it on a passenger car dear to your heart, you will either need to build a frightening structure in the trunk, or somehow attach the unit on an additional trailer to the car.

How to make a gas generator with your own hands?

Is it possible to make a gas generator with your own hands? Yes, but you will need a set of tools and the materials themselves. They will use: to create a corps, fuel tank(which will contain firewood), heat-resistant steel for a container where the combustion process will take place, various heat-resistant gaskets, ideally not asbestos, since it is considered dangerous to the body. All sorts of pipes that will connect all the nodes of the gas generator, filters to remove impurities (western colleagues are experimenting with the same wood mixtures), a special one that allows burnt elements to pass through, and such trifles as doors, covers and valves. Having got everything necessary elements and armed with a suitable drawing, you can proceed directly to the creation of such an apparatus as a home-made wood-burning gas generator with your own hands. The accuracy and individuality of gas generator design calculations in accordance with your car is desirable, but sometimes not required. Some, especially observant and handy "home-made" manage to copy the necessary unit, using standard drawings.

DIY wood gas generator

There are a few things to consider in order to get your car moving without endangering the life of the driver. The main thing is that the diameter of the pipes through which the mixture will enter the engine must be carefully selected, taking into account the power of the latter.

All components and parts of the gas generator must be airtight. It is necessary to carefully build all the nodes, avoiding pipes with too small a diameter or sharp bends in order to minimize the resistance when the gas mixture enters the motor. The main skills that optimizer inventors will need is experience with metal. Cutting various structures, welding, working with pipes - all this will be quite difficult for a beginner.

The firewood is burning, the car is moving?

There are certain tricks for moving on modernized car. We must not forget not only to throw firewood, but also to clean the ashes from a special container, and the combustion products will fill it quickly enough. In case of untimely cleaning, the process of operation of the gas generator on wood is distorted. It is also necessary to add fuel gradually, without waiting for its complete destruction. Ideally - when the tank is about half empty. Before turning off the engine, you must first wait a certain period until the unit has cooled down to the desired temperature.

During the combustion process, not only useful and cheap gas is released, but various toxic substances, and therefore special attention should be paid to the ventilation system. The gas generator must not be tested indoors. All nodes and solderings must be checked for leaks. A burning stove in your trunk can itself be a source of some mental anxiety. When properly assembled, the gas generator is completely safe, but accidents should be avoided whenever possible while driving, since in this case the risk of a fire in the car increases significantly.

Auto 30s and 40s

Wood-burning cars reached their heyday in the 30s and 40s. Since the changes that needed to be made to the vehicle were not dramatic, they were often carried out independently. To achieve the required engine power, sometimes they even created a turbocharging system. Some cars needed a more efficient generator, since the necessary combustion temperature in the furnace was maintained by a fan.

Wood-burning cars were popular in places where regular gasoline was not easy to get. So, during the Second World War, the designers of the VW and Mercedes concerns carried out their tests in this area. In our country, a wood-fired car (a gas generator in a car) has not lost its relevance in the post-war period. They mastered hard-to-reach areas where the ubiquitous gasoline had not yet had time to penetrate, and worked at logging and timber processing enterprises.

Cars in our time

Over time, interest in such units dried up, and wood-fired cars with a gas generator in the car settled as rusting skeletons somewhere on the periphery. Nowadays, research and testing in this area is carried out only by real enthusiasts.

And this is despite the fact that environmental organizations consider such installations extremely interesting, since waste can be used as fuel, and the level of pollution of mother nature is many times lower than when using an ordinary car with a gasoline engine. Modern creations, unlike their predecessors, can develop a decent speed of about 80 km per hour, and they need to refuel after hundreds of kilometers have been overcome. Fuel consumption here is measured by wooden bells, and those will require 50 kg per 100 km. This reduces the cost of transportation compared to the use of traditional fuels by 3-4 times.

Conclusion

So, we figured out how to make a wood-fired gas generator with our own hands. The design device is not so difficult, so almost anyone can handle it.

This article is for skilled enthusiasts who spare no time and effort to achieve results. Why such a preamble? Because here we will talk about how to make a gas generator with your own hands. This is a rather complex unit that produces fuel from firewood and coal that can replace traditional fuels - gasoline in a car and natural gas in a house. We will introduce you to the device of the gas generator and the difficulties associated with its manufacture, installation and operation.

Scheme of the gas generator and the principle of operation

Carbon is the basis of the entire biomass of our planet, including wood and various coals, into which compressed plants have turned over millions of years. In internal combustion engines (ICE) we burn hydrocarbons extracted from the bowels of the earth: methane, propane and gasoline. They rise in price every year, forcing home craftsmen to look for new ways with the help of old inventions. One of them is cars with wood-burning gas generators, which appeared at the beginning of the last century.

In the first half of the 20th century, cars and trucks were equipped with wood-burning units.

The essence of the idea is to obtain a gaseous combustible mixture from wood by pyrolysis, consisting of several carbon-based compounds:

- carbon monoxide (CO);

- hydrogen in free form (H 2);

- the well-known methane (CH 4);

- other hydrocarbon compounds (general formula - CnHm).

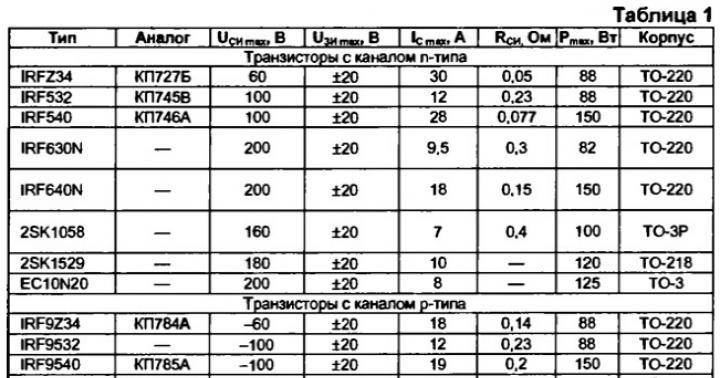

Note. The main combustible component of the mixture is carbon monoxide CO, the share of other substances from the above list is small. Other gases, called ballast gases, are also present in it - nitrogen, carbon dioxide (CO 2) and water vapor. Data on the percentage of substances in the final product and its calorific value are presented in the table:

To isolate gaseous fuel, a wood-fired pyrolysis gas generator (otherwise, a gas generator) is used, whose device is shown in the diagram. This is a closed container with grates filled with solid fuel through the upper bunker, instead of a chimney - a branch pipe for the outlet of the gas mixture. The principle of operation of the gasgen is as follows:

To isolate gaseous fuel, a wood-fired pyrolysis gas generator (otherwise, a gas generator) is used, whose device is shown in the diagram. This is a closed container with grates filled with solid fuel through the upper bunker, instead of a chimney - a branch pipe for the outlet of the gas mixture. The principle of operation of the gasgen is as follows:

- Ignition and burning of an array of firewood occurs from below, above the grate. Air is blown into the chamber through the tuyeres in a limited amount (35% of the volume required for complete combustion).

- A large amount of heat is released in the combustion zone, and as a result of the reaction of oxygen with carbon, carbon dioxide CO 2 is formed. The content of carbon monoxide and other flammable substances is low here.

- In the recovery (gasification) zone, under the influence of high temperature, carbon dioxide is saturated with carbon from wood and turns into a combustible compound - CO. Here, the decomposition of water vapor and the formation of free hydrogen occur.

- Hot gases, passing through the upper layers of the fuel, dry the wood and make it turn into semi-coke (dry distillation), which releases more carbon.

- The gas mixture leaves the gas generator housing and is sent for further purification to be fed into the internal combustion engine or boiler.

Functional diagram of a direct process gasifier

Functional diagram of a direct process gasifier For reference. The reduction of carbon dioxide (conversion to CO) proceeds with the absorption of heat released during the combustion process. By the way, there are no clear boundaries between the zones and they are shown conditionally in the drawing.

The principle of horizontal gasification - a mixture of combustible gases exits through the side nozzle of the generator

The principle of horizontal gasification - a mixture of combustible gases exits through the side nozzle of the generator For the sake of clarity, we have described the generation of fuel by a direct gasification process, when the fuel array moves against the air flow. There are other methods - the reverse process (air is blown from top to bottom) and the horizontal method shown above in the gas generator diagram. If you want to understand the theoretical points in detail, we suggest watching the following video:

Installation design

To successfully operate a car on wood or burn the resulting fuel in a boiler, one gas generator is not enough. The fact is that in addition to ballast gases, home-made fuel contains volatile impurities and tar, in other words, smoke and soot. Neither car motor, nor the burner device of the boiler is designed for such fuel and will quickly fail. Therefore, a filtering system was invented, which is part of the gas generator set and includes 3 additional units:

- coarse filter - cyclone;

- radiator - cooler;

- fine filter.

The sequence of placement of these elements is shown in the flow diagram:

The cyclone for the gas generator is a vertical cylinder with two nozzles and a cone at the end, as shown in the drawing. The contaminated gas mixture, getting inside it, moves in a circle at high speed, due to which large and medium ash particles are thrown onto the walls by centrifugal force and are removed through the hole in the cone.

Scheme of the cyclone, which cleans the power gas from impurities

Scheme of the cyclone, which cleans the power gas from impurities The higher the temperature of a gas, the lower its density. This means that the fuel at the outlet of the gas generator cannot be used in an internal combustion engine without pre-cooling, otherwise it simply will not ignite in the cylinders. Therefore, in industrial gas generating installations, immediately after the cyclone, an air or water heat exchanger is installed, followed by a compressor that pumps the cooled gas mixture into the distribution tank.

At the end of the technological chain there is a fine filter that removes small particles of soot and ash from the resulting fuel. An example of such a unit is the so-called scrubber, in which gases are cleaned by blowing through water. Now that we have figured out the technology for producing fuel, you can make your own inexpensive installation that can run an internal combustion engine on wood.

Homemade gas generator made by foreign colleagues

Homemade gas generator made by foreign colleagues Making a gas generator for a car

Before you make a workable gas generator for a car, we suggest that you familiarize yourself with some recommendations:

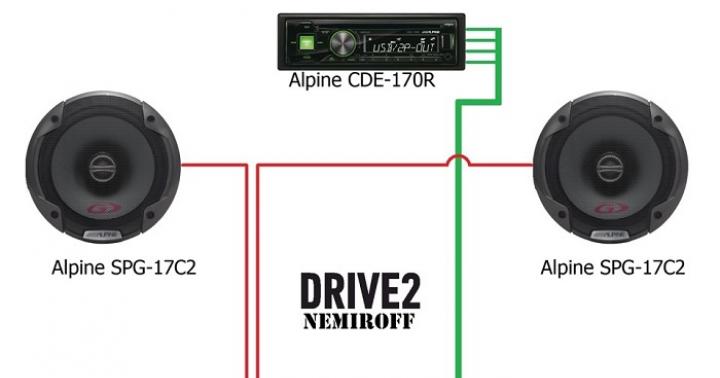

- Organizing the supply of power gas in a modern car with an injector is not an easy task. You will have to change the controller settings (firmware), otherwise the wood-fueled motor will not work. You need a car with an old fuel supply system - a carburetor.

- The greater the power and displacement of the engine, the higher the performance of the gas generator should be. Accordingly, it will grow in size.

- To fit the unit in the trunk passenger car, you will need to cut out part of the bottom. If you do not want to touch the body, then immediately plan to put a wood-burning generator with filters and a cooler on the trailer.

- For the manufacture of the gasification chamber, where the temperature exceeds 1000 ° C, use low-carbon thick steel (4-5 mm).

- To reduce the tar content in the gas mixture, make a chamber with a neck, as shown in the drawing.

An important point. It is not necessary to increase the diameter of the gasification chamber (in the drawing it is 340 mm) in order to achieve greater productivity. The increase will turn out to be scanty, and the quality of wood processing will deteriorate. But it is not necessary to maintain a height of 183 cm, unless you put the unit on a trailer or on a truck frame. The fuel hopper and ash pan can be shortened.

To assemble the inside of an automobile gas generator (bunker), an old propane cylinder, a receiver from a Kamaz truck, or a thick-walled pipe will do. Given that the diameter of the steel vessel is 300 mm, the remaining dimensions must be proportionally reduced. The exception is the gasification chamber, its minimum diameter is 140 mm. Metal 1.5 mm thick will go to the casing and cover of the generator. The latter is sealed with a graphite-asbestos cord.

Variants of combustible mixture coolers from a car radiator and a heating battery

Variants of combustible mixture coolers from a car radiator and a heating battery Associated units - filters and coolers - are done as follows:

- Weld the cyclone from a used fire extinguisher or a piece of pipe with a diameter of 10 cm, as shown in the drawing. Attach the inlet to the side, the outlet to the top.

- The power gas cooler is best made from steel pipes in the form of a coil. There are other options: the use of old convectors, radiators and radiators.

- Make a fine filter from any cylindrical container (for example, a barrel) filled with basalt fiber.

You will receive more detailed information on assembling the gas generator on your own by watching the video:

To ignite and run the gasgen, you will need a snail-shaped fan installed in the engine compartment (a household vacuum cleaner will do for testing). The requirement for it is simple: the parts in contact with the gas mixture must be metal. fuel line, leading to the carburetor, is laid under the bottom of the car and is made of a steel pipe.

For reference. If charcoal is used instead of firewood, then there will be much less impurities at the output of the gas generator, which is good for the engine. Such fuel is burned out of wood using a simple technology - in a closed barrel or pit.

The bunker for charcoal is placed in the trunk of the "Zhiguli"

The bunker for charcoal is placed in the trunk of the "Zhiguli" Connecting and starting the internal combustion engine

Since the calorific value of the fuel generated from wood is much lower than that of gasoline, the air / fuel ratio must be changed for the engine to work properly. To do this, you will have to make a mixer and put it on the intake tract. The simplest type of mixer is an air damper controlled by draft from the passenger compartment.

Starting a cold engine on wood is another task. Therefore, you should not completely abandon gasoline, but only supply it during launch, and then switch to fuel produced by a gas generator. To implement switching to different types of fuel, make a mixer according to the scheme proposed in the book by I. S. Mezin “Transport gas generators”:

Now about the launch features and ICE operation on wood and coal:

- the size of firewood loaded into the bunker should not exceed 6 cm;

- raw wood cannot be used, since all the heat released will go to the evaporation of water and the pyrolysis process will be extremely sluggish;

- ignition is carried out through a special hole with a check valve with the fan turned on no later than 20 minutes before the trip;

- engine power is reduced by about 50% compared to driving on gasoline;

- it follows from the previous paragraph that the life of the engine on home-made fuel also decreases.

It is noteworthy that after short-term parking, the car starts up calmly from gas generator, without switching to gasoline. After a long period of inactivity, it will take 5-10 minutes to re-ignite the installation. How the car engine starts from a home-made wood-burning gas generator, see the following video:

Conclusion

Do-it-yourself wood gas generators can not only be put on cars, but also used for household needs. Pro heating boilers we have already spoken. Also, many homeowners use domestic electric generators powered by diesel or gasoline engines. If they are converted to firewood, then the energy received from the power plant will become much cheaper.

It is possible to obtain electricity both with the help of new technologies, which include wind farms, and by using methods that have been known for several decades. Energy generating devices include a gas generator. The device can be the main source of electricity and a backup, designed to support the operation of household equipment during temporary power outages. Gas generators are used to generate electricity and for space heating. High efficiency equipment is an acceptable alternative for heating private houses in the absence of natural gas.

Principle of operation and features

One of the main questions that arises for a person who does not encounter a wood-burning gas generator is what kind of principle the equipment has and what it is for. The use of such a device for obtaining gas allows us to solve several problems:

- create a backup power supply system for a private house;

- obtain comfortable microclimatic conditions during the heating season and at the same time obtain gas for other purposes (for example, cooking);

- ensure the operation of the internal combustion engine of the car.

By heating solid fuel to 1100 °C and limiting the access of oxygen to its combustion zone, it is possible to make the equipment pyrolytic. The basic principle of operation of the gasifier is to convert the cellulose contained in wood into olefins (propylene and ethylene) by means of a pyrolysis process. The resulting gases are cleaned by a filter system from soot, ash and other impurities, and then cooled. After cooling, the products end up in the secondary combustion chamber, where they continue to burn, heating the walls of the boiler. To improve the combustion process, air is supplied to the same furnace. The technical details are detailed in the video below.

The efficiency of pyrolysis boilers is higher compared to conventional wood-burning stoves and boilers, and the time and money spent on creating a home-made gas generator will pay off in the long run. Moreover, a wood-burning gas generator can be made not only for heating, but also for water heating equipment. To do this, the walls of the boiler, heated during the combustion of firewood, are connected to a heat exchanger.

Pros and cons of using wood gas generators

Among the advantages of using gas generators, it is worth noting:

- Efficient use of woodworking waste - sawdust, trimmings and wood chips. Usually such materials are classified as garbage and thrown away - the generator receives heat and gas from them.

- High efficiency of the gas generator, depending on the methods of counting calories, reaching 80-95%. For budget wood-burning boilers, the coefficient rarely exceeds 70%.

- Possibility of use in places remote from large settlements and having neither gas supply nor electricity supply.

- The environmental friendliness of the installation compared to oil-fired boilers, which not only emit more harmful substances into the air, but also require the creation of special fuel storage tanks.

The widespread use of wood-burning gas generators is hampered by several disadvantages, the main of which can be called large dimensions devices. The video below shows a gas generator being used to heat a 1200 m² locksmith shop.

In addition, during operation, the equipment requires constant cleaning - the centrifuge, furnace and cooling elements are regularly cleaned. The disadvantages include the need for periodic replacement of "consumables" (filters for the gas obtained using the installation) and the use of only wood with a moisture content of up to 20%.

Firewood for kindling requires storage space, and gas begins to form only 20-30 minutes after the start of combustion. When using a gas generator for a private house, you should not pay attention to the last two shortcomings, but for a car these disadvantages are critical. It is almost impossible to regulate the temperature in the furnace, and the walls of the chamber are very hot, so the equipment lasts less compared to wood-burning stoves and boilers used for heating.

Making a wood-burning gas generator for a private house

An important nuance that should be taken into account when creating a wood-burning gas generator with your own hands is the equipment diagram. It indicates not only the elements, but also the direction of movement of air and gas flows. On the Internet, you can find different options for gas generators, and one of the most popular among domestic homeowners is a device that is assembled on the basis of a 200-liter metal barrel.

In the upper part of the cylindrical body, a wood bunker is arranged, the volume of which is assumed to be approximately 60–70 liters. As a filter element of the generator, a zigzag pipe is usually used. You can take for this and the body of the fire extinguisher. The filter is equipped with a tap that allows you to collect and bring out the condensate that appears during the combustion of raw wood.

The principle of operation of a wood-burning gas generator, the device and drawing of which are used to create homemade device, is as follows:

- firewood laid in the bunker gets into the firebox and burns;

- in the process of combustion, gas is formed, which enters through the coarse cleaning system into the skirt in the upper part;

- when passing through the cooling filter, the gas cools down and is discharged through a special pipe (for example, to the internal combustion engine or to an additional combustion zone).

During the combustion of wet firewood, the gas enters the “skirt” and, upon contact with cold air, leaves a small amount of water. The liquid passes through a separator made of a pipe with a ribbed plate inserted inside and drains out. To increase the efficiency of the boiler, the purified gaseous fuel obtained by burning wood is used for additional heating, getting into the second combustion zone. In this case, only carbon dioxide (CO₂) escapes.

The video below shows a variant of a gas generator for heating made of sheet metal.

By creating a gasgen with your own hands, you can provide for a boiler in the design. The water is heated by the return fuel gas, which is additionally cooled during this process. On average, such equipment provides heating of 5–10 liters of water per minute by 20–30 degrees.

Features of installation and use

The place for the equipment is selected taking into account the lack of smell in the produced gas and its danger to the human body. Therefore, install homemade gas generators on wood, preferably in separate rooms. The room must meet the same requirements as the boiler room - have good forced ventilation and a volume of at least 15 cubic meters.

To output the gas, a special gas pipe is used, fixed with clamps to the generator nozzle. Under the installation, a base made of fireproof materials must be provided. It is also worth noting that the work on assembling the gas generator should be carried out by a professional - if there is no experience in carrying out such work, it is better to refuse to make a home-made device for producing gas or increasing the efficiency of burning wood.

Automotive gas generator

The difference of the gas generator for vehicle is its compactness and increased reliability - although even such characteristics do not allow driving a car at high speed. However, acceleration to 80-90 km / h is quite possible. The material for the manufacture of an automobile gas generator is most often metal containers. Serial production involves the use of stainless steel, which reduces the weight of the generator and improves aesthetic parameters. Handicraft production of such devices leads to efficient, but not too neat-looking and heavy wood-burning stoves, the gas from which is transferred to the gas engine of the car.

Niva car powered by a gas generator

A good option for creating a gas fuel generator for a small car can be an old propane tank. For the internal part of the circuit, the devices provide for the use of a receiver from a truck with a volume of 20 or 40 liters. Thin metal is chosen for the grate, and ordinary pipes for heating are used for pipes.

The lid with fasteners is made from the top of the cylinder or sheet steel. It is sealed with an asbestos cord treated with graphite impregnation. A coarse filter is made from an old fire extinguisher or a piece of pipe corresponding in length. At the bottom of the filter element, a cone-shaped nozzle is installed through which the ash will be shipped. From above, the pipe or fire extinguisher is covered with a lid with a pipe built into it.

The presence of coolers, which are often used as bimetallic heating radiators, is required for two reasons:

- too hot gas has a low density and cannot ensure the efficient operation of the internal combustion engine;

- when hot gas comes into contact with hot engine parts, a flash may occur.

Another important element design - a mixer that allows you to adjust the proportions of the gas-air mixture. If the fuel concentration is not changed, the gas with a calorific value of 4.5 MJ/m 3 will enter the engine, which is 7.5 times less than that of conventional propane. By changing the proportion using a special damper, the gas-air mixture is brought into line with ordinary gas.

Check out a series of videos on creating a gas generator for a Moskvich car.

Vehicle installation

Before installing a wood-burning gas generator, you need to choose a suitable place. On trucks, the installation is located between the cab and the body, on buses - on the side (from the driver's side). For passenger car two options are allowed - installation in the trunk or on a separate trailer.

gas generator in luggage compartment looks neater and does not interfere with the design of the vehicle. But using such a device is inconvenient, and there is practically no space left for transporting goods. Separate installation of the device on a trailer not only saves space in the trunk, but also simplifies the repair of equipment. In addition, the trailed gas generator can be disconnected, if necessary, by switching the machine to gasoline or bottled gas. The disadvantage of the trailer option is the increase in the total length of the vehicle, which creates parking problems, and the additional cost of purchasing a trailer.

conclusions

By creating a home gas generator for heating a house or operating an internal combustion engine, you can get a device that allows you to partially replace natural gas and generate electricity, reducing wood consumption by increasing efficiency and increasing the burning time of one portion of solid fuel. The burning time of one bookmark of wood in the furnace of a gas generator, when using the resulting gas as an additional energy carrier, reaches 8–20 hours. The operation of the equipment is quite simple, except for periodic cleaning, and only filter elements require replacement.

Despite these advantages, it is impractical to install a home-made wood gas generator on a car. The savings will not be as significant as a decrease in the level of comfort of using the vehicle and unpredictable consequences for the internal combustion engine. The only compelling argument in favor of such a decision can only be problems with the purchase of gasoline.

An acceptable option is to assemble a gas generator for a private house with your own hands. In this case, the device will become a source of gas for a heating boiler, gas stove and a small home power station.