The front axle of the Spicer type, which is installed on the UAZ Patriot and the UAZ Hunter, is combined. It simultaneously performs the functions of driving and steered, and is a rigid hollow beam, inside which the main hypoid gear and differential are located.

Front axles Spicer with a track gauge of 1445 mm are installed on UAZ Hunter cars and models based on it, catalog number 31605-2300011 - the final drive gear ratio is 4.111, or 31608-2300011 s gear ratio 4.625.

Front axles Spicer with 1600 mm track gauge, catalog number 3163-2300011, 3163-2300011-10, 3163-2300011-10, gear ratio 4.111 or 4.625 are installed on UAZ Patriot, UAZ Pickup and UAZ Cargo cars.

The main gear and differential of the front and rear axles of the Spicer type on the UAZ Patriot and UAZ Hunter are similar in design. All maintenance and repair instructions also apply to the front axle. The front axle is additionally serviced and repaired steering knuckles.

Steering knuckle and hub Oise Hunter and Oise Patriot without anti-lock braking system ABS.

Steering knuckle and hub UAZ Patriot with anti-lock braking system braking ABS.

The steering knuckle of the front axle Spicer is equipped with constant velocity joints of the Birfield type CV joint and spherical pivot assemblies. To reduce the wear of the front axle parts and save fuel when operating the car on paved roads, together with the axle disengagement, the front wheel hubs should also be disconnected using the clutch. Install the front wheel deactivation clutch on the front axle or remove it from the axle in the disengaged position.

During maintenance of the front drive axle, the clearance in the bearings of the pivots, the toe-in of the wheels and the maximum angles of the wheels are checked and, if necessary, eliminated, the fastening of the steering knuckle is checked and tightened. When inspecting the steering knuckles, attention is drawn to the serviceability of the wheel stop-limiters, bolts and the reliability of their locking.

There is no need to add grease to the ball pins and ball joints with Birfield joints during operation. The lubricant is changed during repair. Only recommended lubricants are used. To lubricate the joints of equal angular velocities SHRUS of the Birfield type, lubricants SHRUS-4, SHRUS-4M or their imported analogs are used.

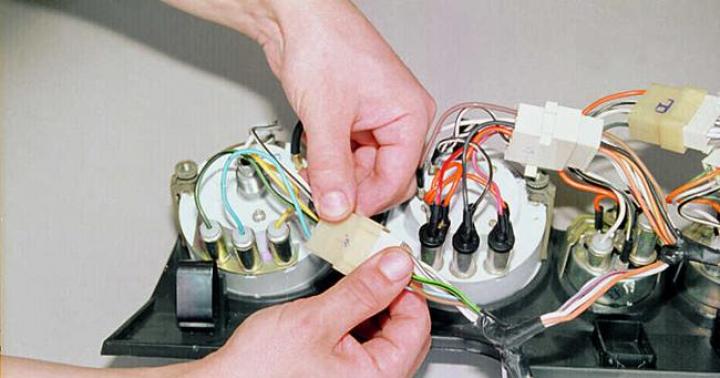

Adjusting the tightening of the ball pins of the steering knuckle of the front axle Spicer on the UAZ.

The steering knuckle ball pivot tightening is adjusted at the factory with a preload along the common pivot axis. During the operation of the vehicle, special attention should be paid to the tightening condition of the steering knuckle pins. With the wear of the rubbing spherical surfaces of the liners or pins, the preload disappears and a gap forms along the common axis of the pins. This gap is eliminated by tightening the clamping sleeve.

Operation of the front drive axle Spicer with clearances in the pivot assemblies leads to premature failure of the upper pivot liner. In operating conditions, it is most convenient to tighten the clamping sleeve of the lower kingpin:

- unscrew the nut and remove the lining with the gasket

- tighten the clamping sleeve with a special wrench until the gap is eliminated, first hitting the threaded end of the king pin with a copper hammer

- by turning the key 10-20 degrees, pull this bushing to create a preload along the common axis of the pins

- install a lining with a gasket and tighten the nut by applying a torque of 80-100 Nm.

The turning moment of the ball joint or the steering knuckle housing, if the ball joints were not disconnected from the axle shaft casing, with the outer and inner sealing rings and the steering knuckle joint removed in either direction relative to the common axis of the pivots, should be within 10-25 Nm (1.0-2.5 kgcm ).

If the control parameter is not reached, then re-tighten the clamping sleeve by turning the wrench another 10-20 degrees and tighten the nut to the specified torque. If the steering knuckle has been disassembled, then during its assembly it is necessary to adjust the preload along the common axis of the pins and the correct relative position of the ball joint with the steering knuckle body to prevent the ball joint from displacing.

The tapered surface and thread of the clamping sleeve, the friction spherical surfaces of the pivot and the liner are lubricated with LITOL-24 grease before being installed in the assembly. Screw the clamping sleeves up to the stop of the pins into the liners on both sides, ensuring the equality of dimensions A and B from the ends of the steering knuckle housing to the sphere of the ball joint. Inequality of sizes A and B is allowed no more than 0.2 mm. To obtain sufficient accuracy, measurements of dimensions A and B should be carried out in plane B.

Increasing the torque by 20-30 Nm alternately, tighten the clamping sleeves to a final torque of 200-250 Nm. Fill the cavities above the clamping sleeves with LITOL-24 grease. Install the washers with spacers and tighten the outer nuts with a torque of 80-100 Nm. Check dimensions A and B. No clearance in the pivot unit is allowed.

The turning moment of the ball joint or the steering knuckle housing, if the ball joints were not disconnected from the axle shaft casing, in either direction relative to the common axis of the pins should be within 10-25 Nm (1.0-2.5 kgcm. If these parameters are not achieved, then the adjustment must be repeated by pulling or releasing the clamping sleeves from the bottom and from the top by the same amount.

Checking and adjusting the maximum angles of rotation of the wheels in the front Spicer axle on the UAZ.

Checking the maximum angles of rotation of the wheels is carried out at a special stand. The angle of rotation of the right wheel to the right, and the left wheel to the left should be within the range of З1-32 degrees. Adjustment is made with the swing limit bolt.

Toe-in is regulated by changing the length of the lateral rod. Before adjusting, make sure that there are no gaps in the joints of the steering rods and the bearings of the hubs. Having loosened the tightening of the lock nuts with the right and left threads, the required toe-in value is set by rotating the adjusting nipple.

Checking and adjusting wheel alignment must be done at a special stand for each wheel. Toe-in of the front wheels, for each wheel separately - 0 ° 1'32 "- 0 ° 4'36", total - 0 ° 3'04 "- 0 ° 9'12". In the absence of a stand, it is allowed to check and adjust the wheel alignment along the inner surfaces.

Toe-in at normal tire pressure should be such that dimension A, measured along the centerline of the sidewall of the tires at the front, is 0.5 to 1.5 millimeters less than dimension B at the rear. At the end of the adjustment, the lock nuts are tightened with a torque of 105 - 130 Nm.

Possible malfunctions front axle Spicer on UAZ.

Violation of the camber angle of the wheels, wobbling when driving and uneven tire wear.

- Large clearance in the bearings of the front wheel hubs

- Wear of pivots, liners of pivots

The car does not hold the road well.

- Deflection of the covers of the axle shafts of the front axle

Leakage of lubricant through the ball seal.

- Oil seal wear

Increased tire wear.

- Wrong toe, bent or incorrectly adjusted track rod.

SUVs UAZ Patriot, Hunter from the factory are equipped with two drive axles: front and rear. Thanks to the presence of two bridges on the UAZ Patriot SUV, its cross-country ability is unmatched. The front axle, in contrast to the rear, is steerable. This indicates that the front axle is engaged only when necessary. The bridge that is installed on the UAZ is called Spicer. It was developed back in the distant 90 years, and every year it was improved and supplemented. Today, there is such news that Spicer will soon replace the old designs of units that are installed on "loaves" and "goats".

Today we will pay attention to the Spicer front axle of the UAZ Patriot SUV. What is it, the features, the pros and the way of adjusting the product.

Spicer bridge carter consists of cast material, into which the axle shafts are pressed. The axle housing is closed with a crankcase cover. The transverse plane of the device has no connector, which increases the reliability and stiffens the structure. Also, the differential and the main gear of the Spicer axle are located in the same crankcase, which ensures high accuracy of engagement and operation of the device. All these features lead to an increase in the performance of products.

Now, in order to service the device, it is enough to remove the crankcase cover and carry out the necessary repair or replacement of products. Periodic monitoring of the oil level in the system, timely replacement of seals and bearings, as well as elimination of backlash in the gears and differential - all this is the main criterion for servicing the unit.

The Spicer bridge is equipped with new types of joints (CV joints), which feature is durability. These hinges require periodic lubrication of the structure, for which the SHRUS-4 material is used. It is unacceptable to use Litol-24 for the lubrication of hinges.

No less important point is also the value of the gear ratio of the Spicer bridge. Devices with two values of the gear ratios of the front axles on the UAZ Patriot are produced: 4.11 and 4.62. Bridges with a value of 4.11 are installed on the UAZ Patriot SUV with gasoline engine, and 4.62 for diesel units.

Construction and layout

The photo below shows a diagram of the Spicer front axle device with digital designations. Consider the main mechanisms that make up the Spicer front axle.

- 3 - driven gear, which has a greater number of oblique teeth than the leading one;

- 9 - roller bearing, which requires replacement when worn;

- 13 - flange;

- 16 - bridge housing;

- 21 - driving gear and shaft;

- 23 - nut, with the help of which the differential bearings are adjusted.

In the diagram, it can be seen that the Spicer bridge has many small parts, without which the operation of the front unit is impossible. We will not consider all of them, but at the time of repairing the device, be sure to control the location of each part. Otherwise, the product will need to be re-disassembled and repaired.

Advantages

The UAZ Patriot SUV is equipped with a wide-type front device. The advantages of this design are the following points:

- Increased track gauge, which has a positive effect on stability vehicle both on the road and off-road. The track has been increased to 160 cm.

- This had a positive effect on the possibility of increasing the steering angle of the front wheels up to 32 degrees. In this case, the SUV received better maneuverability on and off the road.

- The strength class of the steering knuckles has been increased, due to which the frequency of lubrication and repair work is reduced.

- Thanks to the new suspension, the UAZ Patriot received better handling and stability.

Reinforced gear cover

Thus, these advantages indicate that the SUV has high off-road stability, as well as cross-country ability, which is important for such a unit.

Adjustment

Adjustment is the process by which the device must be adjusted to function correctly to prevent further defects from occurring. Adjustment of the front Spicer axle is carried out mainly after repair work. In rare situations, axle adjustment is carried out in the event of wear on bearings or collars. Consider how the bearings of the Spicer front axle are adjusted on the UAZ Patriot SUV.

So, the adjustment is carried out in the following order:

If adjustment of the Spicer bridge is required without replacing bearings, then the process includes the following steps:

- The axle shafts are unscrewed, and the crankcase cover is removed. Before that, do not forget to drain the oil from the bridge.

- In the differential of the bearings, a clearance should be set equal to the value of 0.15 mm. This is done using the same adjusting nuts.

- The side clearance should be 0.2 mm. To do this, the gear turns and the measurement is carried out at 6 points.

- To increase the gap, unscrew the nut, and to reduce it, screw it in.

- The bearing is compressed in the direction of the axle, with the help of which the preload is adjusted.

- The Spicer front axle can then be reassembled and filled with oil. This completes the bridge adjustment.

As you can see, the Spicer front axle differs in its parameters from its predecessors, therefore, the placement of such products on an SUV entailed an improvement not only in cross-country ability, but also in the durability of the units.

The cost of the Spicer front axle is quite impressive, so it is very important not to bring it to the point of malfunctioning and to fix them in time. Indeed, even if the front axle is not the main device, then its failure will simply lead to the fact that the UAZ Patriot will not be able to move off-road. Why, then, do you need an all-wheel drive jeep? Therefore, summing up, it should be noted that diagnostics and preventive measures are required not only for the motor and chassis, but also for the direct drive of both the front and rear wheels. Because front-wheel drive wheels are used in rare cases, it is important to know that you can check the serviceability of the bridge by periodically switching it on and moving off-road. This way, you can be sure that the jeep will never let you down.

You can check your MBM and reduce it if needed!

For cars UAZ Patriot and UAZ Hunter, as well as all models based on them, front and rear single-stage drive axles of the Spicer type with a one-piece crankcase are installed, named after the American engineer Clarence Spicer, author of more than thirty patents and owner of the Spicer Manufacturing Company, now - Dana Corporation ...

The front and rear axles of the Spicer type began to be installed on the UAZ-3160 and UAZ-3162 Simbir cars, instead of the bridges of the old design, and from them they were inherited by UAZ Patriot, UAZ Pickup, UAZ Cargo and UAZ Hunter.

Front and rear axles of the Spicer type on the UAZ Patriot, device.

The front axle is combined, it simultaneously performs the functions of driving and steered, is a rigid hollow beam, inside which the main hypoid gear and differential are located. From the main gear, the torque is transmitted to the front hubs through the axle shafts.

The axle shaft is a single piece with constant velocity joints (CV joints) of the Rceppa-Bearfield type, named after its inventor Alfred Rceppa and the American company Bearfield, which produced it under a patent. It is more compact than the Bendix-Weiss hinge on Timken bridges and can handle larger angles and transmit more torque.

At present, the front axles of the old design of the Timken type, which are still installed on cars, are equipped with such hinges. For this reason, they have acquired the name - hybrid bridges.

The rear axle is a rigid hollow beam, at the ends of which the hubs of the driving wheels are mounted on bearings, and the main hypoid gear and differential are located inside. From the main gear, the torque is transmitted through the axle shafts to the hub. The front and rear axles have main gears and differentials of the same design.

Features of the design of the front and rear axles of the Spicer type.

Spicer axles are largely unified with the old Timken-type single-stage axles, they have the same differential bearings, rear axle half-shafts and almost all parts of the hub assemblies.

The thickness of the driven gear substrate in the new axles was increased by 8 millimeters, which reduced noise and increased the reliability of the final drive. The new differential can be used on old single-stage axles with a split crankcase, provided that an expansion ring is installed on the spike of the cup.

The currently produced front and rear Spicer axles have a final drive ratio of 4.111 or 4.625. The first ones are installed mainly on UAZ vehicles with gasoline engines, and the second - for cars with diesel engines, and all vehicles from the 2015 model year onwards.

On UAZ Hunter cars and all models based on it, so-called narrow axles with a track gauge of 1445 mm are installed, the catalog number of the front axle is 31605-2300011 - the gear ratio of the main gear is 4.111, or 31608-2300011 with a gear ratio of 4.625. Catalog number rear axle 31605-2400010-30 - gear ratio 4.111 or 31514-2400010-10 - from 4.625.

Wide bridges with 1600 mm track gauge, front axle catalog number 3163-2300011, 3163-2300011-10, 3163-2300011-10, gear ratio 4.111 or 4.625 are installed on UAZ Patriot, UAZ Pickup and UAZ Cargo cars. Rear axle part number 3162-2400010-10, 3163-2400010, gear ratio 4.111 or 4.625.

Checking and maintenance of the front and rear axles of the Spicer type on the UAZ.

Front and rear axle maintenance is about maintaining the required level transmission oil in their crankcase, it should be at the lower edge of the filler hole, and its timely replacement.

And also in checking seals, timely detection and elimination of axial clearances in the gears of the main drive, periodic cleaning of the safety valve, tightening all fasteners and cleaning the magnetic plug from metal particles when replacing the transmission oil.

To lubricate the Birfield type hinges, a special SHRUS-4 grease is used, which must not be put into the entire inner cavity of the steering knuckle, as before, but only into the hinge itself. The use of greases of a different type, including the traditional Litol-24, is unacceptable. During operation, adding grease to the joint is not required. The inner cavity of the steering knuckle is filled with Litol-24 grease.

Adjustment of axial clearances in the front and rear axle Oise.

Axial clearance in the bearings of the main drive pinion is not allowed, since if it is present, the gear teeth quickly wear out and the bridge may jam. The axial clearance is checked by swinging the drive gear by the propeller shaft mounting flange.

To eliminate the axial play of the pinion gear, tighten the flange nut. The nut has a punching in the groove of the threaded part of the drive gear and when tightening, more effort will be required on the wrench. The nut is tightened carefully until the axial clearance of the pinion gear is eliminated, avoiding its constriction, after which it will re-center. If the tightened nut cannot be tightened, then it should first be released by 0.5-1.0 turns, and then tightened until the axial clearance is eliminated and tightened.

Axial play in the bearings of the differential of the final drive is also not allowed. It is checked by swinging the driven gear with the crankcase cover removed. The axial clearance of the driven gear of the main drive is eliminated by tightening the differential bearing nut, after removing the lock plate.

Cars off-road are well known to the domestic consumer. The manufacturer equips them from the factory with a pair of driving axles at once: rear and front. The main difference between the two is that the design of the front is controllable and can be turned on if necessary. Despite the fact that the front axle of the UAZ Patriot was developed back in the 90s, it is actively used to this day due to its technical characteristics.

Before starting to disassemble the device and the reasons for repairing the front axle, it is necessary to dwell on its advantages in operation. Let's dwell on the following points:

Video review of the UAZ Patriot front axle design:

Description of the components and design diagram

The device of the front axle on the Patriot should begin with a description of the main elements and components. Among them:

- drive shaft and drive gear;

- driven gear with a large number of teeth;

- bridge housing;

- roller bearing;

- flange;

- nut for adjusting the differential bearings.

As for the difference in the structure of the structures of each of the driving bridges, there are no particular fundamental differences here either. At the front axle of the Spicer Patriot, power and torque are transmitted through a differential and final drive. The beam is hollow, and a pair of axle shafts are placed in it, which account for rotation from the driven gear.

The main types of malfunctions and their causes

Let's look at the possible malfunctions that lie in wait for the driver during the operation of the UAZ Patriot, related to the design of the bridge. As a rule, they are associated with excessive wear or operation in difficult conditions, or natural aging of metal components and can be expressed in the following symptoms:

Repair of key types of damage to the front axle of UAZ

Many types of Patriot front axle repairs can be done independently in a garage. This will help the following simple instruction, which concerns the most frequent types of repair work. Consider the adjustment of bearing clearance, which must be performed correctly in order for this unit to function for a long time. First, we select the diameter and thickness of the ring, which must exactly match the bearing of the drive shaft from the main gear.

During the rotation of the shaft, the moment is measured, the value of which should not exceed 1-2 Nm. In the same way, the adjusting ring for the driven gear is selected. When installing the differentials, the clearances should be set using adjusting nuts - this is clearly demonstrated by the scheme for repairing the front axle of an SUV. After carrying out the above manipulations, it remains to check the absence of backlash and check the contact areas of the gear teeth.

Another common case is the replacement of the drive pinion oil seal in the final drive. First, the flange is removed from the machine by unscrewing the mounting bolts, after which access to the gland itself is freed. The damaged element is removed from the seat and replaced with a new one by pressing it into its original place.

It is more difficult to dismantle the final drive - for this you must first hang out the front of the vehicle. By opening the drain neck, we remove the entire volume of grease from the system. First, the left and right axle shafts are removed, and then the tie rod end. After disconnecting cardan transmission the main cover is also removed in sequence. Along the way, with the drive gear, the differential bearing caps are also removed from their places. Next, the drive gear with the shaft and bearings is dismantled.

Video advice for repairing the front axle assembly of the UAZ Patriot:

Monitoring and scheduled maintenance

Experienced SUV owners pay particular attention to regularly checking the condition of the oil seals. If it is necessary to carry out replacement work, new oil seals must be lubricated with Litol-24. The design of the front axle allows such renovation work as needed.

The construction of the Spicer bridge, which is installed on, is structurally simple enough. Thanks to this, both maintenance and repairs can be performed independently, with the main tools in the arsenal. Long-term operation is always based on regular scheduled maintenance.

Particular attention should be paid to monitoring the lubricant level in the axle gearbox and replacing it. If you have the slightest suspicion about the appearance of extraneous noise or other symptoms, you should adhere to the repair sequences described here.

Video review of the front axle of the UAZ Patriot SUV:

For UAZ Patriot and UAZ Hunter cars, as well as all models based on them, front and rear single-stage drive axles of the Spicer type with a one-piece crankcase, named after the American engineer Clarence Spicer, are installed

Exterior view of the front axle "Spicer"

Spicer-type bridges began to be installed on UAZ-3160 and UAZ-3162 Simbir vehicles, instead of Timken bridges. But on these cars, as well as on the first models of UAZ Hunter, "narrow" bridges with a width of 1445 mm were installed.

UAZ Patriot began to install "wide" bridges with a track gauge of 1600 mm.

Design features

The crankcase of the axle consists of a one-piece cast crankcase of the main gear, casings (stockings) of the axle shafts pressed into it and a stamped crankcase cover.

The absence of a split in the transverse plane of the axle gives the structure high rigidity, the unloaded connection of the cover and the crankcase reduces the likelihood of leakage along the joint, and the placement of the main gear and differential in a single crankcase ensures high precision of engagement and more favorable conditions for the operation of bearings.

Thanks to all these design features, the actual life of the bridges has increased significantly. Also, now to access the main couple and the differential does not need to be removed and "halved" - just remove the cover.

To reduce warpage of the driven gear during its heat treatment and, as a result, reduce noise, increase the reliability and durability of the final drive, the thickness of the "backing" of the driven gear was increased by 8 mm. However, this measure led to a change in the left differential cup. But, the new differential can be used on the previous single-stage axles with a split crankcase, provided that an expansion ring is installed on the spike of the cup.

Spicer bridges are unified with old single-stage bridges in a number of other details. These are differential bearings, rear axle axle shafts and almost all parts of the hub assemblies. The front bearing with a double seal (469-2307086-03) and a new double-lip collar of the drive pinion flange are unified with similar parts of U-shaped ("military") axles manufactured by JSC UAZ.

As for the front driving and steering axles, here, in addition to the above points, it should be noted new joints of equal angular velocities ( CV joint) like " Beerfield", Which are much more durable than the hinges of the old design (" Weiss"). At present, all Spicer and Timken bridges are equipped with such hinges. It will not be superfluous to recall that to lubricate the Birfield hinges, a special SHRUS-4 grease is used, which should not be put into the entire inner cavity of the steering knuckle, as before, but only into the hinge itself. The use of greases of a different type, including the traditional "Litol-24", is unacceptable. During operation, adding grease to the joint is not required. The inner cavity of the steering knuckle is still filled with Litol-24 grease.

Main gear:

1 - bolt; 2, 33 - spring washers; 3 - driven gear; 4, 24 - semi-axes; 5 - an adjusting ring; 6, 22 - bearings; 7 - spacer sleeve; 8 - outer cage of the outer roller bearing; 9 - roller bearing; 10 - thrust ring; 11 - oil seal; 12 - reflector; 13- flange; 14 - washer; 15 - nut; 16 - bridge housing; 17 - an adjusting ring of the driving gear; 18 - outer cage of the inner roller bearing; 19 - inner roller bearing; 20 - oil deflector ring; 21 - shaft with a driving gear; 23 - differential bearing adjusting nut; 25, 39 - right and left parts of the differential housing; 26 - bolt; 27, 40 - support washers of the semi-axle gears; 28, 43 - semi-axle gears; 29, 45 - axles of differential satellites; 30, 41, 44, 46 - differential satellites; 31, 38 - differential bearing caps; 32 - retainer for differential bearing adjusting nut; 34, 36, 37 - bolts; 35 - cover of the main gear housing; 42 - gasket for the cover of the final drive housing

The "Spicer" bridges produced by the plant have a gear ratio of 4.111 (37: 9) or 4.625 (37: 8). Axles with a gear ratio of 4.111 are installed mainly on cars with gasoline engines, and with a gear ratio of 4.625 - on cars with diesel engines.

Front wheel hub

Hub front wheel UAZ with disc brakes, but without ABS

Front axle steering knuckle

Steering knuckle and hub.

1 - leading flange with a plug; 2, 10, 25 - gaskets; 3 - a hub with a brake disc; 4 - hub bearings; 5 - wheel bolt; 6 - brake disc shield; 7 - heat-insulating shield of the ABS sensor; 8 - pin; 9 - steering knuckle body; 11 - clamping sleeve; 12 - king pin; 13 - pivot liner; 14-bracket for fastening the ABS harness; 15 - spring; 16 - outer sealing ring; 17 - inner sealing ring; 18 - hinge; 19 - ball bearing; 20, 28 - thrust washers; 21 - pivot support; 22- outer cage of the oil seal; 23 - pad; 24 - nut; 26 - impulse disk; 27 - cuff; 29 - retaining rings; 30 - lock washer; 31 - nuts; 32 - lock washer

UAZ steering knuckle assembly diagram:

1 - brake disc shield; 2 - amplifier of the heat-insulating shield of the ABS sensor; 3 - heat-insulating shield of the ABS sensor; 4, 18 - bolts; 5 - impulse disk; 6 - hub; 7, 12 - bearing; 8 - lock washer; 9 - nut; 10 - lock washer; 11 - lock nut; 13 - thrust washer; 14 - cuff; 15 - pivot of the steering knuckle; 16 - gasket; 17 - steering knuckle joint; 19 - ball bearing; 20 - axle shaft casing

Adjustment of axial clearances in the front and rear axle Spicer

Axial clearance in the bearings of the main drive pinion is not allowed, since if it is present, the gear teeth quickly wear out and the bridge may jam. The axial clearance is checked by swinging the drive gear by the propeller shaft mounting flange.

Front axle "Spicer". Camber, convergence

The front axle is a steering axle. To facilitate driving, the front steering wheels have camber ( not adjustable) in the vertical plane and convergence in the horizontal plane.

Toe-in of wheels. A< Б на 1,5-3 мм.

To return the wheels to the middle position, the pivots of the steering knuckles are inclined in the longitudinal and transverse planes.

Positive camber is the deviation of the upper part of the wheel from the vertical plane outward.

The camber angle at the Spicer axles is a = 1 ° - 30 ". Wheel camber affects tire wear. When camber is up to 2 °, the wear will not be very large. camber gradually decreases to zero, and then the wheel deflection moves towards negative camber, which worsens wheel steering.

As a result of the inclination of the wheels during camber, forces arise that tend to return them in different directions when driving. Lateral wheel slip appears, which contributes to tire wear and makes it difficult to drive. To eliminate the harmful effects of camber, the wheels are installed with toe-in. At the same time, the distance between the rims of the wheels at the level of the front axle at the front is several millimeters less than at the rear.

The longitudinal tilt of the king pin (KASTOR) is designed to stabilize the steered wheels in the middle position, but its effect is noticeable only at high speeds with significant centrifugal forces. The stabilizing moment and the angular velocity of the wheel when returning to the neutral position serve as measuring the stabilization of the wheels when the car exits a turn.

Maintenance

Maintenance of the Spicer bridge is reduced to maintaining the oil level in the crankcase and periodically changing it, monitoring the condition of all seals and axle mountings and timely elimination of the resulting axial clearances in the gear and differential bearings.

The details of the maintenance and repair of Spicer bridges are described in the Manual for the maintenance and repair of the UAZPatriot vehicle IR-05808600.050-2005. Third edition. 2007