Concrete rings are used in the arrangement of water supply systems for residential buildings and summer cottages, gas pipelines, inspection, waste and sewer systems, in the industrial and domestic spheres. Design features of products:

- additional;

- wall;

- prefabricated;

- with a quarter;

- with the bottom;

- with lids, etc.

Types of rings

Additional elements are used provided that the dimensions of the standard rings are not suitable. Supporting (auxiliary) structures facilitate the construction of objects that are not multiples of the height of standard well rings. The sizes of the rings correspond to standard products, but differ in lower height. Manufacturing of products is made to order.

Reinforced concrete through structures perfectly cope with their tasks when arranging a drainage, sewer, network water supply and gas supply well. Product diameter: 70 cm, 1m, 1.5m, 2m, 2.4m, 3m. Height: 30, 50, 60, 90, 120, 150, 180, 200 cm.

Wall devices provide the creation of a neck, they are used for all types of wells: sewer, water and gas. Dimensions: D 0.7 x H 0.3 to D 2 x H 0.9, weight from 135 to 1500 kg.

To prevent the possibility of displacement of the rings after installation, special grooves are installed on them, which do not allow the moment of displacement. To achieve maximum strength and durability, experts recommend giving preference to vibrated, steamed and reinforced products with a wall thickness of 10-11 mm that do not allow water to pass through. Installing the first element with a bottom will provide an increased level of sealing.

Reinforced rings

Reinforcement of the product is made by vibrocompression, similar to standard structures. After pressing, the products take on a dense and homogeneous appearance, allowing them to maintain their shape and moisture resistance. When arranging reinforced rings, they are fastened with a cement mixture, contributing to the maximum reduction of water penetration into the soil. For the development of reinforced concrete rings, factory conditions are required. Improved techniques help to obtain a perfectly even coating of structures and reliability in use. The cost of the rings is determined by their diameter.

How to determine the size?

The parameters of all elements of the well (rings, covers, bottoms, clamps and rivets) are determined by its type and purpose. The rings must have the same parameters (in length and cross-section), the lid and bottom must have the same parameters in the horizontal section. To avoid confusion in the parameters of the rings, a special marking is used. It allows you to find out the height and diameter of products.

Standard ring dimensions:

- cross section 700 - 2500 mm;

- length 700 - 1200 mm;

- walls 80 - 120 mm.

Additional elements with non-standard dimensions are developed by special order. The mass of the rings is determined by their dimensions. The smallest have a mass of 40–45 kg, and the largest - 1500 kg.

Attention! For the arrangement of drainage wells ideal option will become reinforced rings.

How are well rings marked?

To determine the parameters of the rings, the rule of GOST 8020-90 is used, where the letter values are indicated:

- KS - rings for walls;

- PO - slabs for overlapping;

- PD - panels for laying on roads;

- PP - floor panels;

- PN - panels for arranging the bottom.

Numerical values determine the cross-section and height of the rings (for example, KS 15.9 are rings for walls with a cross-section of 1500 mm and a length of 900 mm).

Design features

The main components of wells include rings and covers, determined by their functionality.

Well rings contribute to the formation of the barrel and neck of the structure, the bottom and cover ensure their reinforcement. The diameter of the rings varies from 80 to 200 cm with a step of 50 cm, the height varies from 70 to 90 cm, structures with a height of 120 cm have the greatest parameters.

For the arrangement of the water supply system, KS8-7 marking products are used, less often KS10-9 well devices are used. They cope well with their tasks when arranging shallow pits. KS 8-7 rings allow you to increase the depth of the wells. Maca KS 8-7 indicates a lower weight, which simplifies self-assembly.

For sewer systems, reinforced concrete rings KS10-9, KS15-9, KS20-9 are used. For revision and prefabricated engineering solutions, models KS15-9, KS10-9, KS8-7 are used. To carry out repair work (deepening) of the well, KS6-7 structures are used. Given the possibility of covering them with a hatch, the selected structures can serve as the neck of the well.

When creating a prefabricated well with a shallow shaft to accommodate the first ring and subsequent deepening by hand, it deepens under its own weight. The following component parts are laid on top of it until the specified depth of the well is reached. Areas for joining reinforced concrete rings are treated with a concrete mixture with further overlap with a cover - a reinforced concrete slab with a hole. Well covers are marked: PP6-2, PP8-2, PP20-2-1, PP15-2, PP10-2. Their cross-section ranges from 1160 to 2500 mm, and their weight ranges from 250 to 3000 kg.

Reinforced concrete glass - a ring with a bottom, presented in the form of a monolithic structure that provides the functions of the foundation. Products are marked with KCD.

Attention! When purchasing rings for a well, experts recommend giving preference to a concrete grade from M500.

Additional elements

For ease of use and ease of installation, use additional accessories... They can be supplied complete when ordering rings or sold separately.

Sizes of rings with a bottom (DK)

When arranging reinforced concrete structures, it is important to provide for the maximum level of tightness of the structure to be installed. This is facilitated by monolithic rings with a bottom. Externally, they are presented as solid products, preventing the possibility of the accumulated sewage leakage, due to the presence of the lower monolithic element.

Dimensions of rings with a lock

Monolithic structures are distinguished by the presence of a recess and protrusions at the top and bottom of the ring. This makes it easy to vertically align parts and prevent horizontal displacement. A high level of moisture resistance is achieved due to the tightness of the lock connection.

Quarter Rings Markings:

As an example, a variant of KS-15-9ch is considered, where

- KS - through ring;

- 15 - flow area;

- 9 - length;

- H - the presence of a castle (quarter).

Well covers (PC)

Based on the purpose of the well, a hole for the hatch is required, providing convenient access to engineering solutions... This is facilitated by cylindrical reinforced concrete structures, closed at the top with a cover with an opening for a hatch (made of cast iron or a sand-polymer mixture).

Positive characteristics of reinforced concrete rings with a cover include:

- monolithic connection of the ring with the cover;

- durability due to the strength of the materials (concrete mix and steel reinforcing elements for the frame);

- ease of installation.

Bottom plate

The bottom plate is structurally represented by a monolithic reinforced concrete plate used for waterproofing the well. When buying a bottom, you should take into account the load placed on it. In some cases, the use of heavy concrete and reinforcement with reinforcement is required. The marking of structures is represented by letters (PN - product type) and numbers (PN7, PN10, PN15 and PN20).

So, the product PN 15 is used for wells with an internal cross section of 150 cm, and PN 10 for wells with an internal diameter of 100 cm.

Floor panels (PP)

Concrete panels with a rounded opening for mounting the hatch (made of cast iron or sand-polymer mixture). It provides access to water and sewerage communication solutions. Floor slabs with hatches prevent contamination of wells and protect against accidental entry of people into it. The dimensions of the plates of different markings have different meanings, but the holes for mounting the hatch correspond to the standard parameters. This allows you to arrange the hatch in accordance with regulations.

Floor slab brands:

- PP10-2;

- PP15;

- PP20-1;

- PP with a hatch made of polymer-sand mixture (PP 10-2 with LPP).

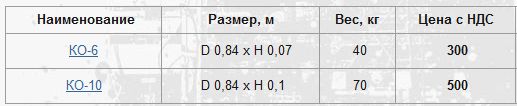

Dimensions of support rings (KO)

Installation of structures is carried out at the neck of the well, allowing you to bring the mark of the hatch with a cover to the design value. They are used when renovation work and reconstruction of highways, allowing to ensure the coincidence of the level of road surfaces and the height of the well. The absence of support rings is only allowed when the well is located far from the highway and places where pedestrians move.

Well houses

The cabins serve to provide decorative properties and prevent the formation of silt at the bottom, avoiding annual cleaning.

The house protects the water in the well from debris, allowing you to save money on the installation of filter systems. Sun protection prevents the growth of organisms and bacteria by preventing water heating. Freezing is excluded in winter. A closed well increases child safety.

The house has a shaft for a cable with bearings, which simplifies the process of extracting water from the well. The water tank is placed inside the structure, which allows you to get water at any convenient time. Galvanized houses are resistant to natural precipitation and have a long service life.

Attention! For the installation of houses, preliminary installation of an octagonal washer is required, which covers the upper ring.

Types of houses:

- steel;

- concrete;

- metal-plastic;

- from the lining;

- forged;

- from a log house (oak or pine);

- from the block house.

Manufacturing and installation

Rings of wells are represented by standard reinforced concrete products, developed in accordance with GOST 802090. The material for the production is a concrete solution used for the arrangement of in-depth structures in low-corrosive environments.

When choosing reinforced concrete rings, take into account the characteristics of the structure. For example, elements for wells located on highways require equipment with floor slabs and hatches. To achieve a given level of moisture resistance of products, monolithic structures with a bottom are used. The connection of individual reinforced concrete rings is provided by metal brackets. Support products allow you to bring the well to a given level.

The rings are mounted in one of the most convenient ways:

- construction option, using construction equipment for digging a pit;

- non-industrial way of uniform soil undermining along the entire perimeter of the structure.

When buying reinforced concrete rings, you should decide on the delivery method. Modern manufacturers offer delivery trucks and machinery with a loader crane for unloading and installing elements.

Video

Reinforced concrete rings are the most demanded product in the arrangement of wells, wells, inspection pits, septic tanks. Their use allows you to speed up the construction process without resorting to brick or monolithic concrete masonry.

All elements of reinforced concrete rings are made of concrete mix of grade 200. Running brackets must be treated with an anti-corrosion compound. By marking, you can determine the dimensions of the product, that is, the first number indicates the inner diameter of the reinforced concrete ring in decimeters, the second number is the height.

Concrete ring diameters table

| Name | outer diameter [mm] | inner diameter [mm] |

|---|---|---|

| KS-7 | 840 | 700 |

| KS-10 | 1160 | 1000 |

| KS-15 | 1680 | 1500 |

| KS-20 | 2200 | 2000 |

| KS-25 | 2700 | 2500 |

| KS-30 | 3200 | 3000 |

Depending on the purpose and operation, they produce different diameters of reinforced concrete rings, which classify products according to different types:

- KS 7.3 and KS 7.9 - are additional elements in the arrangement of the well. The inner diameter is 0.7 m. The wall thickness is 0.14 m.

The size of the diameter inside the ring coincides with the diameter of the hole in the well slab (cover). This type design is used to device the neck to the required level.

- KS 10.3, KS 10.6 and KS 10.9 - have an inner diameter of 1 m.

Most often, this standard size is used in private construction when it is required to build a sewer or water well. The wall thickness is 0.16 m. For ease of movement, running brackets are installed from the reinforcement of a periodic profile.

- KS 13.9 - the inner diameter of the reinforced concrete ring is 1.25 m, the walls are 0.16 m thick.

Rings with this size can be used in various areas of arranging wells (sewer, gas, water supply). Walking brackets are also provided inside the working chamber. It is rarely used due to its uniform size.

- KS 15.6 and KS 15.9 - the diameter inside the product is 1.5 m.The thickness of the walls is 0.18 m.

A very popular size of reinforced concrete products, which is used in the arrangement of water pipes, gas or cable communications. Also, rings with a diameter of one and a half meters are used as concrete rings for sewage. There are running brackets.

- KS 20.6, KS 20.9 and KS 20.12 - the inner diameter is 2 m.The walls are 0.2 m thick.

The sufficiently large size of the structure allows it to be used not only for its intended purpose. Some private clients buy a two-meter ring to create a small cellar. Even more interesting idea- reservoir in a suburban area (pool, pond).

Buy concrete rings of any diameter from the manufacturer

The ProBeton company produces and sells well elements of various types and sizes at attractive prices. All products have quality characteristics, that is, strength, frost resistance, water resistance. This is facilitated by the employees of the Quality Control Department and the laboratory.

Specialists of the sales department are ready to answer all your questions regarding the products. We will help you choose the desired type and diameter of concrete rings, their additional components, calculate the required quantity and weight. For your convenience, we will organize cargo transportation by our transport.

Reinforced concrete prefabricated wells are special elements of buried structures that are used for the construction different types communications: sewerage, water supply, gas supply networks and inspection wells. Depending on the field of operation, reinforced concrete rings of various diameters are used for the construction of prefabricated wells.

Reinforced concrete wells are a vertical hollow structure consisting of reinforced wall rings, a bottom and a cover on which a hatch is installed. As a rule, wells are almost or completely immersed in the ground and are located above or below the groundwater level in non-aggressive and slightly aggressive environments.

By purpose, reinforced concrete wells are divided into several types:

- Plumbing. They are elements of the water supply network, heat and water supply and are intended for the installation of valves (so-called shut-off valves) in order to regulate the flow of various liquids, fire hydrants, measuring equipment, etc.;

- Sewer (drainage, treatment). Designed to create sewerage systems at bends, in places of pipe drops, etc. Serve to combat groundwater that destroys the foundation;

- Gas pipelines. Serve as elements of main gas pipelines.

By functionality, wells are divided into several types:

- Inspection - used to monitor the operation of the entire system;

- Drop-offs are necessary in places with strong pipe drops, when the network turns or the network level drops due to the peculiarities of the landscape. They are used when combining pipelines of different depths into one network;

- Swivel. These wells are used in places of pipe bends in order to avoid blockages. Also often used as sightseeing;

- Filtration (filtering) wells - necessary for wastewater treatment. Installed above the groundwater level;

- Accumulative. They are used for accumulating waste water and are usually installed at the lowest point of the site to ensure the optimal slope of the sewer pipeline.

The advantages of using reinforced concrete as a material for the production of wells:

- The strength of the products. Reinforced concrete allows the wells to withstand the load that occurs due to soil pressure, and its dense structure is not subject to erosion by groundwater;

- Concrete wells are applicable in most soils;

- The smooth surface of concrete wells does not allow debris to cling to the walls and form blockages. In addition, concrete can be perfectly cleaned, and no special equipment and qualified specialists are required for cleaning;

- Unlimited service life. Concrete products are famous for their durability even when used in aggressive environments and places where the level of humidity is high;

- Simplicity and ease of installation and repair. The elements of the collection well can be easily mounted on top of each other. Thanks to this, during the repair, it is not required to completely replace the structure - it is enough just to replace or repair the worn out element;

- Inertness of concrete - it has no effect on water quality.

Reinforced concrete wells assembled consist of several elements: wall rings, bottoms, covers and hatches. Road construction involves the use in some cases of wells equipped with floor slabs. The presence of certain elements in the structure depends on the purpose of the collection well. Technically, these elements are divided:

- Concrete rings. They are through thin-walled hollow cylindrical elements that serve directly for the formation and laying of the well;

- Well covers or, as they are also called, floor slabs. These plates provide not only to protect the water from contamination, but also prevent the danger of a person falling into the well. They have a special hole in their design for installing a hatch;

- Bottom plates (bottoms). Monolithic reinforced concrete slabs, which serve as the bottom and perform the function of waterproofing wells;

- Support rings. These are additional elements that are intended for structures of non-standard heights for road construction. They are identical in size to standard rings, but have a much lower height;

- Support plates. They have a rectangular shape with a round or rectangular outlet in the middle, which is subsequently closed by a round-shaped iron hatch or a rectangular grate for wastewater. The rectangularity of the base plate protects the well itself from destruction. Thanks to this form, the load is directed evenly over the entire perimeter of the slab, and the walls of the well receive a minimum load, which helps to maintain the long-term functionality of the structure itself;

- Rings with caps. They are located at the top of the structure and ensure the safe functioning of the wells. The hole in the cover, on which the cast-iron hatch is installed, is necessary to ensure free access to the inside of the well;

- Sewer wells are unified cylindrical concrete structures that are designed to create underground sewage systems, gas and water supply. Inside the sewer well there is a metal mesh with a thickness of 0.6 - 1 mm;

- Cast iron hatches. They close the wells and prevent large foreign objects from entering the system, as well as protect against accidents.

When choosing reinforced concrete wells, it is necessary to take into account the characteristics of the structure being erected. For example, concrete rings for wells located on highways are always equipped with floor slabs and hatches, and, if necessary, to ensure the watertightness of the structure, concrete rings with a bottom are used.

Prefabricated reinforced concrete wells are manufactured in accordance with the requirements of GOST 8020-90 and series 3.900.1-14. "Reinforced concrete products for round wells for water supply and sewerage", issue 1 "Instructions for use and working drawings" made of heavy concrete with a compressive strength class of B15. The well base plates are made of B20 heavy concrete. The frost resistance concrete grade for the working chambers of the wells is not less than F75, for the rest of the products - not less than F100. The waterproof mark must be at least W6.

Reinforcement of working chambers of reinforced concrete wells is carried out by volumetric reinforcement cages, made on special machines, according to the type of cages used to reinforce round reinforced concrete pipes. Road construction also permits the fabrication of frames by bending conventional mesh reinforcement. Reinforcement of the bottom of the wells is carried out with nets cut from the volumetric frames at the holes, with the exception of water and gas wells, the bottom of which is reinforced with special reinforcing nets. For the reinforcement of structures, reinforcing steel of the following types and classes is used: thermomechanically hardened bar steel of At-IIIС and At-IVС classes in accordance with GOST 10884; rod hot-rolled grades A-I, A-II and A-III in accordance with GOST 5781; reinforcing wire of class Вр-I in accordance with GOST 6727.

Prefabricated reinforced concrete wells and elements are marked with an alphanumeric designation, where:

- КЛ - working chamber of the sewer well;

- ВС - the working chamber of the sinkhole;

- KFK - working chamber of the household sewage well;

- KDK, DK - working chamber of the well of intra-quarter networks;

- KLK - working chamber of the storm sewer well;

- KLV, VD - working chamber of the stormwater drainage well;

- KVG - working chamber of the well of water and gas supply networks;

- KS - wall ring of the working chamber or the neck of the well;

- KO - support ring;

- PO - base plate;

- PD - road slab;

- PN - bottom plate (bottom);

- PP - floor slab;

- PC - wall ring with covers;

The numbers after the letters indicate the diameter in decimeters of the working chamber, neck or hatch of a reinforced concrete well with which the element is mated. The numbers after the dot in the mark of the wall rings - the height of the ring in decimeters. Lowercase letters after numbers in the brand of wall rings indicate the design of rings with additional design features: a - with two holes for the passage of pipelines, b - with four. The numbers after the hyphen in the brand of floor slabs - the type of load-bearing capacity of the slab.

In the improvement of the site for permanent residence inexperienced the owners face a number of problems during construction.

In order not to waste time and money on the work of unskilled builders, you need to independently study material properties purchased by you.

Study arrangement a private house is better with knowledge of the matter.

One of the main stages of successful private construction is planning and construction well.

Varieties of wells

5 to 50 metersspringsTypes of wells for receiving drinking water

- Well mine type

- Tubular well

Most popular type of wells. Often built in rural areas where the depth ground waters in the area 5-15 meters.

Convenient material for correct and durable use will be wood, brick and reinforced concrete.

The pit for a mine well, you cannot dig next to household buildings, the required distance for correct construction is 25 meters

In this case, the place for the well should be on a hill, melted surface water with dirt should never penetrate into the well water. To do this, do protection the upper ring of clay or humus.

This type of construction is possible only drilling method... It is applicable for areas with stony relief and deep bedding of underground drinking water.

For proper installation and use, they install underground filter elements... For everyday light use, it is better to equip this type of well. simple pump.

What are the rings for the construction of wells

For professional fastening of the internal base of any well, only reinforced concrete rings.

Quality building materials are made from concrete brands М200 - М500... When casting rings, steel rods are used for reinforcement.

This is optional, but to improve performance by strength design is nothing better.

- Well rings

They are widely used in construction all types of wells, mines and drainage structures.

- Bottom rings

Manufactured to ensure normal monolithic bottom in many well-type constructions.

This type of rings provides reliability constructions. The connection of rings with a mechanical lock is carried out due to folds at the joints.

They are applicable for tightness the complete base of the well. Horizontal displacement is nearly impossible with this type of reinforced concrete structure.

- Rings with "mechanical" cap

This item is used on outer crown well type constructions. Represents itself folded ring with a concrete cover, in the cavity of which there is a hole for convenient use.

Additionally.

Additional elements are used to form a correct and integral well-type structure. In particular:

- Concrete covers for wells.

- Concrete well bottoms.

Both elements comfortable when repairing or restoring wells.

Sizes of concrete rings for wells and their cost

Before purchasing reinforced concrete material and auxiliary devices, it is necessary to calculate the required dimensions according to the construction site plan.

In counting an important milestone will be the frequency of use and consumed volume

wellAt the initial stage, a prepared well pit is laid bottom or a ready-made ring with a bottom. Then the usual rings or folded. The last step will be the installation of a concrete cover with a hatch.

Understanding this sequence in work, you should take into account the order material procurement... It is problematic to select the required diameter without an experienced advisor.

For error-free installation of the entire well structure, rings and components during production mark... The actual height and diameter of the product is applied to each of the reinforced concrete products.

For professional work on the construction of well-type facilities, GOST 8020-90... It has the title: "Concrete and reinforced concrete structures for wells of sewage, water supply and gas supply networks."

The most popular are reinforced concrete rings with markings KS 20, KS 15 and KS 10... And the most common height for these rings is 90 centimeters.

The table shows the manufactured ones. There are special data for each marking.

For example, if the ring is KS 20-9, then its diameter will be equal to two meters, and its height - 90 centimeters.

Marking

| Marking | Dimensions. |

Concrete grade |

|||||

| Length | Width | Height | |||||

| KS7-3 700mm 800mm 290mm 0.05 130mm A200 KS7-6 700mm 840mm 590mm 0.10 250mm A200 KS7-9 700mm 840mm 890mm 0.15 380mm A200 KS10-3 1000mm 1160mm 290mm 0.08 200mm A200 KS10-6 1000mm 1160mm 590mm 0.160 400mm A200 KS10-9 1000mm 1160mm 890mm 0.24 600mm A200 KS15-3 1500mm 1680mm 290mm 0.13 290mm A200 KS15-6 1500mm 1680mm 590mm 0.27 660mm A 200 KS15-9 1500mm 1680mm 890mm 0.40 1000mm A200 KS20-6 2000mm 2200mm 590mm 0.39 980mm A200 KS20-9 2000mm 2200mm 890mm 0.59 1480mm A200 |

from600 | ||||||

| Prices are average, with delivery in Moscow and VAT. | |||||||

From the table we see that there are markings for reinforced concrete rings custom sizes ... Such products are applicable in cases where it is necessary to repair or complete the rings.

For example, the prepared area for the installation of the entire structure does not allow the use of rings of a standard size in depth or width.

An important value is the actual thickness product stacks... For each well structure, the thickness is determined depending on the weather conditions throughout the year.

If the depth freezing significant soil, then for the durability of the entire well column, rings with good thick walls.

It is better to play it safe with this volume, otherwise the ring with temperature difference will crack. The thickness of reinforced concrete rings affects their cost according to the table below.

The production technology of reinforced concrete rings for well-type structures is simple. For release quality rings, it is enough to comply with the conditions specified in GOST.

Drilling deep wells and wells for obtaining clean drinking water cannot be produced at a depth of more than 60 meters... The fact is that underground waters beyond this limit are either oversaturated with salts, or are useless for the body (they are distillates).

Installation of rings under no circumstances can you trust handymen. You risk not only getting an unsuccessful design, but also completely ruining concrete products.

Wells with a frame made of reinforced concrete in almost all climatic conditions on the territory of Russia, it is necessary to protect against freezing and spring waste water.

This moment cannot be ignored when building a new well. The fact is that frozen well with drinking water it is very difficult and sometimes too dangerous to get back to normal.

Since ancient times, in the countryside crowns wells at the level of freezing were insulated clay or humus... These materials are time-tested.

Concrete rings for sewage systems, the sizes and prices of which depend on the type of construction, today do not lose their popularity - even though there are also completely ready-made plastic containers on sale. This happens because concrete is traditionally characterized by durability, ease of repair and an affordable price.

Such concrete sewer rings are produced using a special technology from high quality raw materials. The cement slurry will be based on M400 or M500 cement - the best choice for durable exterior building structures. Fine-grained crushed stone, water and sand are also used. The manufacturing process involves the use of a reinforcement mesh wrapped in a circle, which is then poured with concrete.

Thanks to the use of reinforcement, reinforced concrete rings for sewage are designed for enormous loads. They withstand different climatic conditions and are characterized by aesthetic appearance... Such constructions are quite justifiably used when:

- construction of drinking wells;

- installation of sewer wells and septic tanks;

- the device of cesspools;

- construction of various underground communications.

Existing types of concrete rings

Concrete rings for sewage are divided according to the type of construction into two large categories:

Note: For the construction of a sewer well and a septic tank, not only well rings, but also rings with a cover and rings with a bottom can be used.

Advantages and disadvantages of concrete rings

Sizes and prices of concrete sewer rings may vary, but the advantages and disadvantages of such structures will still remain common. In particular, the advantages include:

- durability due to high-quality concrete mortar and a reliable frame made of reinforcement - they will last about 20 years or more;

- high degree of resistance to compressive loads;

- complete moisture resistance of the walls with proper waterproofing;

- installation without tangible time costs;

- the rings form a smooth surface, easy to clean and maintain;

- low cost, complemented by high quality;

- stability of the structure to shear stresses of the soil and the action of groundwater;

- frost resistance.

Important: To create sewer wells, reinforced concrete rings with low surface permeability are used, since they have to work in an aggressive environment.

As for the disadvantages of reinforced concrete rings, among them the main one can be called a large weight. Because of this, transportation is also difficult, and it is advisable to install it using special equipment.

Dimensions of concrete rings and their markings

Reinforced concrete rings are marked in accordance with GOST, and letters and numbers are provided in the marking. First, the type of construction is indicated - for example, KS - a wall ring or KSD - a wall ring with a bottom. Then two groups of numbers are indicated - first the diameter of the ring, decimeters, and then the size in height. The degree of permeability of concrete can also be marked:

- O - especially low;

- P - reduced;

- H - normal.

The standard sizes of sewer rings are 90 cm high, but there are also options with a height of 30 and 60 cm. They are called additional ones.

The most common diameters are within 1-2 meters, but 70-cm rings can also be used for a summer cottage. The thickness of the walls also differs - in the range of 7 ... 14 cm.

Many non-professional developers believe that a septic tank will perform better if it is made from large diameter concrete rings. It is also believed that a septic tank with a larger volume should be cleaned less often. But both of these statements are wrong. The diameter of the concrete rings for the sewer pit should be selected depending on the volume of wastewater produced by users in one day.

If you very rarely clean a large sewer well, then the sediment will begin to accumulate at the bottom and thicken. This process is called bridging. And if the substance at the bottom becomes superhard, it can only be removed by breaking it with a jackhammer. It is also impossible to leave such a "bottom" - because of it, the processes of natural filtration inside the septic tank will stop.

How to make a septic tank from concrete rings - installation features

A single-chamber or multi-chamber septic tank can be built from concrete rings. The sewer cesspool is considered the most simple device... It is a separate well made of concrete rings, located not far from the place where the waste water is discharged. Liquid waste is discharged thanks to the installed sewer pipe.

The disadvantages of a single-chamber septic tank are that it fills up rather quickly, the processes of fermentation of sewage in it do not occur quickly enough, and the sediment does not have time to fall out. The waste that merges here remains dirty, and therefore the single-chamber storage septic tank will have to be cleaned quite often, each time turning to the services of a sewer truck.

And multi-level septic tanks require more significant costs when creating, but they guarantee 100% high-quality wastewater treatment. As a result, practically pure industrial water is formed, which can be used for watering the garden and vegetable garden. In this case, sewage flows through three wells in succession, where the processes of fermentation and bacterial decomposition take place.

As for the installation of concrete rings under the sewage system, it happens as follows:

Also, during the installation process, it is necessary to provide for the laying of a sewer pipe - either for supplying wastewater to a septic tank, or for transporting liquid between levels.

Important: Sewer pipes are either mounted below the freezing level of the soil, or additionally insulated and insulated.

How much do concrete rings cost

Concrete ring prices vary depending on the type of construction and dimensions. The cost of the most popular sizes of smooth standard options for concrete rings for sewage is: KS-10-9 - 1550 rubles, KS-15-9 - 2750 rubles for a diameter of 10 and 15 decimeters, respectively.

And if we are talking about well rings with a lock, then their price can reach 1650 rubles for the KS-10-9ch model, and 3300 rubles for the KS-15-9ch model.

As for rings with a bottom, a model with a diameter of 10 decimeters KSD-10-9 costs 2,700 rubles, and a model with a diameter of 15 decimeters KSD-15-9 costs 4,650 rubles.