Introduction

An electric drive is an electromechanical system designed to convert electrical energy into a mechanical one, which sets in motion the working bodies of various machines. However, at the present stage, the electric drive is often entrusted with the task of controlling the movement of working bodies according to a given law, at a given speed or along a given trajectory, therefore, it can be more accurately said that an electric drive is an electromechanical device designed to drive the working bodies of various machines and control this movement .

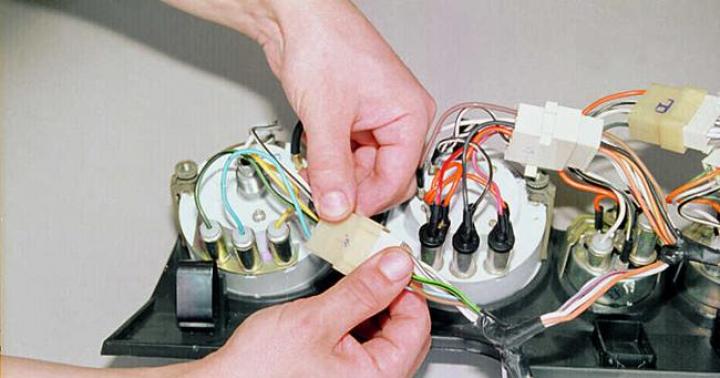

Typically, an electric drive consists of electric motor, which directly converts electrical energy into mechanical energy, mechanical part transmitting energy from the engine to the working body, including the working body and motor control devices regulating the flow of energy from the primary source to the engine. As a control device, both a simple switch or contactor and an adjustable voltage converter can be used. Together, the listed devices form energy channel drive. To ensure the specified parameters of the movement of the drive, it is designed information control channel, which includes information and control devices that provide information about the specified motion parameters and output coordinates and implement certain control algorithms. These include, in particular, various sensors (angle, speed, current, voltage, etc.), digital, pulse and analog regulators.

1. Initial data for the calculation

The kinematic diagram of the electric drive of the roller table in front of the shears for cutting the rolled metal into blanks is shown in Fig. 1.1. A flawless cut method is provided.

Electric drive of the roller table in front of the shears for cutting the rolled metal.

1 - electric motor,

2 - brake pulley,

3 - reducer,

4 - longitudinal shaft,

5 - conical pair,

7 - tackle,

8 - cut workpiece,

9 - axis of scissors

Roller table weight m NS= 5.5 kg · 10 3

Roller weight m R= 1.0 kg · 10 3

Measured length of cut blanks l= 5.7 m

Roller diameter D R= 0.4 m

Number of rollers n=15

Trunnion diameter d C = 0.15 m

Maximum sliding speed NS swing= 1.4 m / s

Minimum (creeping) travel speed NS m in= 0.42 m / s

Running time at creeping speed t min= 0.7 s

Permissible acceleration a= 2.1 m / s 2

Roller moment of inertia J R= 20 kg m 2

Rolling wheel moment of inertia J TO= 1.0 kg m 2

Longitudinal shaft moment of inertia J V= 5.0 kg m 2

Distance between rollers l R= 0.8 m

Cycle duration t C= 42.5 s

Bevel gear efficiency s FUR=0,92

2. Preselection engine

The moment on the longitudinal shaft of the roller table drive is determined by the sliding friction moment in the roll journals and the rolling friction moment of the rollers on the roll.

where m= 0.1 - coefficient of sliding friction in the trunnions;

f= 1.5 · 10 -3 - coefficient of rolling friction of rollers on the roll, m.

The value of the engine power is calculated

Using the reference book of S.N. Veshenevsky, we select four engines of higher power. Two motors direct current parallel excitation, two asynchronous motors with a wound rotor. We enter the engine data in table 2.1.

Table 2.1

|

R, kW |

n, rpm |

J, kg m 2 |

i 2 |

J i 2 |

||||

where i - ratio, is determined by the formula:

For further calculation, we use the engine with the smallest number J i 2 ... In this case, it is an asynchronous motor of the MTV 312-6 brand.

We write out his data from the directory.

3. Construction of a tachogram and load diagram

According to the operating cycle of the roller table electric drive, we build a tachogram (Fig. 3.1)

The technological process is carried out in the following sequence. The trolley (rolled metal from the ingot) is fed by a chain conveyor (schlepper) onto a roller conveyor. The drive starts and moves the trolley towards the scissors. The front end of the roll passes the axis of the scissors to the axis of unsupported stop. In this case, the drive is initially decelerated to the minimum speed v min, and after a predetermined time t min it stops. The workpiece is cut. The cut off workpiece is removed. The roller table is started again, the process continues until the entire length of the rolling stock is cut into measured blanks.

Rice. 3.1. Roller table electric drive tachogram

The time intervals in the tachogram sections are calculated according to the formulas of uniform and uniformly accelerated movement known from physics.

To construct a load characteristic, it is necessary to calculate the dynamic and static moments of specific production mechanisms according to the formulas:

We calculate the resulting moments at each site using the formula:

Based on the calculations obtained, we build the load characteristic (Fig. 3.2).

4. Checking the motor for heating and overload capacity

electric drive motor tachogram

To check the motor for heating, the method of equivalent values is used, which involves a simple calculation of the rms values of power, torque, and current.

For asynchronous electric motors with phase rotor M = C " mFI 2 cos q 2 (here c 2 is the shear angle between the magnetic flux vector F and the rotor current vector I 2 ). Power factor cosц 2 ? const, but varies depending on the load of the electric motor. At a load close to the nominal, F cos c 2 can be approximately taken constant and, therefore, M? TO" mI 2 ... Given the proportionality of the torque and current, the condition for checking the motor for heating can be taken:

So the engine passes the heating test

The motor is also checked for overload capacity, based on the load diagram.

where is the maximum load moment (determined by the load diagram), N? m;

Maximum engine torque, N? M.

According to reference data for the MTV 312-6 engine

147,04<448, значит, двигатель проходит проверку на перегрузочную способность.

5. Calculation of the static mechanical characteristics of the electric drive

The mechanical characteristic of blood pressure is expressed by the Kloss formula.

M kg> M cd,

where M kg, M cd - critical moments in the generator and motor modes, respectively.

If we neglect the stator reactance, we get a simplified Kloss formula:

where is the critical slip of blood pressure.

The rated slip of the blood pressure is determined by the formula:

Synchronous rotation frequency magnetic field HELL:

Rated speed is determined

The rated torque of the AM is determined by the formula (4.2)

The critical moment of blood pressure is determined by the formula (4.4)

To construct the mechanical characteristics, we calculate the moment according to the formula (5.2) and the angular velocity according to the formula:

We enter the obtained data into table 5.1 and build a mechanical characteristic (Figure 5.1).

Table 5.1

|

M, N? M |

||||||||||

|

, rad / s |

||||||||||

|

M, N? M |

||||||||||

|

, rad / s |

Mechanical characteristic asynchronous motor MTV 312-6 brands

6. Calculation of transients and dynamic characteristics

If in the process of starting the engine the moment of static resistance is constant, which in practice takes place in many cases, then the peaks of current and moment are usually chosen to be the same at all stages.

To calculate the resistances, two of the following three values must be specified: M 1 (peak moment), M 2 (switching moment), (the number of starting steps). When choosing the values of M 1, M 2, z, one should be guided by the following considerations.

In the case of relay-contactor control, the number of starting steps is always significantly less than that of rheostats, because here the starting mode is regulated by the control equipment and does not depend on the operator. In addition, each starting stage requires a separate contactor and relay, which significantly increases the cost of the equipment. Therefore, the number of starting steps for contactor control for low-power motors - up to 10 kW - is made equal to 1 - 2; for engines of medium power - up to 50 kW - 20 - 3; for engines of higher power - 3 - 4 steps.

For an asynchronous motor of the MTV 312-6 brand, we take the number of steps z=3.

Analytical method

The switching point is found by the formula:

In this course project, you should take

Impedance of the rotor at the first stage:

Resistances of the following steps:

Section resistances:

Based on the data obtained, we build a characteristic (Fig. 6.1).

Graphical method

Resistance scale

The reduced rotor resistance is calculated by the formula

Starting characteristic of an asynchronous motor MTV 312-6

The magnitude T M called the mechanical time constant. It characterizes the speed of the transient process. The more T M, the slower the transient process is.

Within the rectilinear part of the AM characteristic for the mechanical time constant at the following expression is valid:

In this course project, it will be more convenient to use the expression for the mechanical time constant for straight-line characteristics:

The operating time on each starting characteristic can be determined

The equation for each stage of movement of the electric drive:

Using formulas (6.11) and (6.12), we calculate the dependences and for each step. The calculations are summarized in Table 6.2 and they are used to construct graphs of transient processes (Fig. 6.1 and Fig. 6.2.).

According to the constructed starting characteristic (Fig. 6.1), we determine the values, and enter them into table 6.1.

Table 6.1

|

1st stage |

2nd stage |

Stage 3 |

natural |

||

We calculate the dependencies and for each stage

For the rest of the steps, the calculation is carried out in the same way. We enter the obtained data into table 6.2.

Table 6.2

|

1st stage |

2nd stage |

Stage 3 |

||||||||

|

t from early, with |

||||||||||

|

natural |

||||||||||

|

t from early, with |

||||||||||

Transition timeline. M(t)

Transition timeline. (t)

7. Calculation of artificial mechanical characteristics

The mechanical characteristic of blood pressure is expressed by the simplified Kloss formula:

Introduction of additional resistance into the motor rotor circuit

To calculate the natural characteristic, we determine the nominal resistance of the rotor

Relative resistance of the rotor circuit with the included resistor

Defining the relationship

Slip on an artificial characteristic is determined by:

We build the mechanical characteristics M = f (s and) (Fig. 7.1) for the moments calculated on the natural characteristic, finding new values of s and.

Reducing the voltage applied to the motor stator

Electromagnetic torque asynchronous machine proportional to the square of the stator voltage:

where m 1 is the number of stator phases;

U 1ph - stator phase voltage, V;

R 2 - reduced active resistance of the entire rotor circuit, Ohm;

x 2 - reduced rotor reactance, Ohm;

R 1, x 1 - active and reactive stator resistance, Ohm.

Therefore, the following relationship will be true:

In this course project, it is required to build the mechanical characteristics of the AM (Fig. 7.2) at stator voltage and. To do this, it is necessary to recalculate the motor torques on each characteristic with constant slip values:

Changing the frequency of the stator current

In this course project, it is required to build the mechanical characteristics of the blood pressure for the frequency f 1 = 25 Hz and f 2 = 75 Hz. In order for the condition to be met:, we first determine the value of the speed of the ideal idle move for the new frequency value:

Determine the value of the critical slip for the new frequency value:

where is the frequency value in relative units (for f 1 = 25 Hz; and for f 1 = 75 Hz).

Because the critical torque remains constant, the rated torque also does not change, therefore, the overload capacity of the motor remains the same. You can calculate the rated slip of the motor by expressing it from the equation:

8. Development of a fundamental electrical circuit electric drive

The phase-wound rotor motor is started with inserted resistors in the rotor circuit. Resistors in the rotor circuit serve to limit currents not only during starting, but also during reverse, braking, and also when speed is reduced.

As the motor accelerates, resistors are pulled out to maintain the acceleration of the drive. When the start is over, the resistors are completely bypassed and the motor will return to its natural mechanical characteristic.

In fig. 8.1 shows a diagram of an asynchronous motor with a wound rotor, where, using relay-contactor equipment, the motor is started in two stages, and the voltage is simultaneously applied to the power circuits and control circuits using the QF switch.

The motor is controlled as a function of time. When voltage is applied to the control circuit, the time relays KT1, KT2, KT3 operate and open their contacts. Then the SBС1 "Start" button is pressed. This leads to the operation of the KM1 contactor and starting the engine with resistors introduced into the rotor circuit, since the KM3, KM4, KM5 contactors do not receive power. When the KM1 contactor is turned on, the KT1 relay loses its power and closes its contact in the KM3 contactor circuit after a time interval equal to the time delay of the KT1 relay. After the specified time has elapsed, the KM3 contactor turns on, bypassing the first starting stage of the resistors. At the same time, the KM3 contact in the KT2 relay circuit opens. Relay KT2 loses power and, with a time delay, closes its contact in the contactor circuit KM4, which operates after an interval equal to the time delay of relay KT2, and shunts the second stage of resistors in the rotor circuit. At the same time, the KM4 contact in the KT3 relay circuit opens. Relay KT3 loses power and, with a time delay, closes its contact in the circuit of the contactor KM5, which operates after an interval equal to the time delay of relay KT3, and shunts the second stage of resistors in the rotor circuit.

Dynamic braking is carried out by disconnecting the motor from the three-phase current network and connecting the stator winding to the DC network. The magnetic flux in the stator windings, interacting with the rotor current, creates a braking torque.

To stop the engine, the SBT "Stop" button is pressed. The KM1 contactor is de-energized, opening its contacts in the motor power circuit.

At the same time, the KM1 contact is closed in the KM6 contactor circuit, as a result of which the KM6 contactor is triggered and closes its power contacts in the DC circuit. The stator winding of the motor is disconnected from the three-phase network and connected to the DC network. The engine goes into dynamic braking mode. The circuit uses a time relay with a time delay when opening.

At a speed close to zero, the KT contact opens, as a result of which the KM6 contactor is de-energized and the motor is disconnected from the network.

Intensity of braking is regulated by means of resistor R. In the circuit, blocking is applied by means of break contacts KM1 and KM6 for the impossibility of connecting the motor stator simultaneously to the DC and three-phase current network.

Conclusion

In this course project we have carried out: pre-selection of the engine; carried out the construction of a tachogram and a load diagram; checked the motor for heating and overload capacity; calculated the static mechanical characteristics of the electric drive, transient processes and dynamic characteristics, artificial mechanical characteristics; and also made the development of the electrical circuit diagram of the electric drive.

When using an adjustable electric drive, energy savings are achieved through the following measures:

Reduction of losses in pipelines;

Reducing throttling losses in control devices;

Maintaining optimal hydraulic conditions in the networks;

Elimination of the influence of idling of the electric motor.

List of sources used

1. Veshenevsky S.N. Characteristics of motors in an electric drive. - M .: Energiya, 1977 .-- 472 p.

2. Chilikin M.G. "General course of the electric drive". - M .: Energy 1981

3. Crane electrical equipment: Handbook / Yu.V. Alekseev,

A.P. Theological. - M .: Energy, 1979

Similar documents

Description of the metal blank of the part, the choice of the machine. Calculation and construction of the load diagram of the main electric drive. Checking the electric motor of the main electric drive for heating. Construction of a load diagram and a tachogram of the feed drive.

term paper added 04/12/2015

Operating modes of crane mechanisms. Selection of the type of electric drive, motor and power converter. General information on the applications of various electric drives, calculation of the tachogram and load diagram. Checking the selected motor for heating and overload.

thesis, added 03/08/2015

Determination of the cycle time, start and stop of the electric motor. Construction of the load diagram of the mechanism. Checking the selected motor for heating, for load capacity. The choice of the frequency converter and its rationale. Mechanical characteristics.

term paper, added 12/25/2011

Choice of motor and gearbox. Cutting on lathes. Engine operation during face trimming. Calculation of static and dynamic forces in the mechanism and construction of a simplified load diagram. Calculation of the required power and the choice of the engine.

test, added 01/25/2012

Description of the design of the passenger elevator and the technological process of its work. Designing an electric drive: selection of a kind of current and a type of electric drive; calculation of engine power; determination of the moment to the motor shaft; check for heating and overload.

term paper, added 11/16/2010

Development of an open-loop system of an electric drive of the working mechanism (lifting the boom of a quarry crawler excavator). Engine selection and definition of catalog data. Calculation of resistances of rheostats and braking modes. Checking the engine for heating.

term paper added 08/13/2014

Selection of the type of electric drive and electric motor. Calculation of the load diagram of the electric motor. Checking the engine for heating. Schematic diagram of the power unit. Transition to the system of relative units. Transfer function of the current regulator.

term paper, added 10/27/2008

Mechanical deep drilling rigs. Engine selection, construction of a refined load diagram. Calculation of transient processes in an open system, dynamic indicators of an electric drive and the possibility of damping elastic vibrations.

thesis, added 06/30/2012

Preliminary calculation of the power of the electric motor, determination of the gear ratio of the gearbox. Building a tachogram and load diagrams, checking the engine for overload capacity and power. Calculation and construction of the mechanical characteristics of the drive.

term paper, added 09/24/2010

Preselection of power and type of electric motor. Calculation and construction of static natural mechanical characteristics of electric motors for various modes of its operation. Selection of the electric circuit of the electric drive and its elements, checking the engine.

The choice of the electric motor and elements of the control system of the automated drive, which provides the desired range of rotation speed control at a given load diagram. Drawing up a schematic diagram and calculating static characteristics.

Saratov State Technical University

Department of AEU

Coursework on Electric Drive

"Calculation of the electric drive"

Saratov - 2008

1. Choosing an electric motor

2. Calculation of the parameters of the transformer

3. Choice of valves

4. Calculation of the parameters of the anchor chain

5. Calculation of the parameters of the control system

5.1 For the upper limit of the range

5.2 For the lower end of the range

6. Calculation of cutoff parameters

7. Construction of static characteristics

Conclusion

Application

1. Select the electric motor and the elements of the automated drive control system, which, at a given load diagram, provides a range of rotation speed control D = 75 with a relative error = 15%. When starting the engine and overloading, the torque must be kept within the range from M1cr = 85 Nm to M2cr = 115 Nm. Rated angular speed n = 1950 rpm.

2. Make up schematic diagram drive.

1. Choosing an electric motor

Let's calculate the equivalent moment using the load diagram:

Let's calculate the engine power:

Based on the power of the engine and the rated angular speed, we select the PBST-63 electric motor with the nominal parameters:

Un = 220 V; Pн = 11 kW; In = 54 A; nн = 2200 rpm; wя = 117; Rя = 0.046 Ohm; Rd = 0.0186 Ohm; ww = 2200; Rv = 248 Ohm.

Let's calculate the actual torque and engine parameters:

2. Calculation of transformer parameters

Secondary voltage and transformer power:

kc = 1.11-coefficient of the scheme

kz = 1,1-safety factor, taking into account the possible voltage drop

kR = 1.05 is a safety factor that takes into account the voltage drop in the valves and the switching of the current in the valves.

ki = 1,1-safety factor, taking into account the deviation of the current shape in the valves from the rectangular km = 1.92-scheme factor

Based on the voltage of the secondary circuit and power, we select the transformer TT-25 with nominal parameters: Str = 25 kW; U2 = 416 ± 73 V; I2ph = 38 A;

uк = 10%; iхх = 15%. Let's calculate the resistance of the transformer:

3. Choice of valves

Taking into account the speed control range, we select a single-phase electric drive control system. Average valve current:. Valve rated current:. kz = 2,2-safety factor, m = 2-factor, depending on the rectification circuit. The highest reverse voltage applied to the valve:

Valve rated voltage:

We select valves T60-8.

4. Calculation of the parameters of the anchor chain

The highest permissible value of the variable component of the rectified current:

Required armature inductance:

The total inductance of the motor and the transformer is less than required, therefore, a smoothing choke with inductance must be included in the armature circuit:

Choke active resistance:

Active resistance of the armature circuit:

5. Combingt control system parameters

For the upper limit of the range

What corresponds to the adjustment angle According to the dependence, we determine the change in the EMF and the adjustment angle:

which in percentage terms:

Lower range limit:

Which corresponds to the adjustment angle

According to the dependence, we determine the change in the EMF and the angle of regulation:

In this case, the transmission coefficient of the converter is equal to:

The transmission coefficient of the SPFU is determined according to Fig. 2 Applications:

Overall system open-loop gain:

Largest open-state static error:

which in percentage terms:

Largest static error when closed:

Consequently, at the lower limit of the control range, the relative error is greater than the permissible one. To reduce the static error, we introduce an intermediate amplifier into the control system. Determine the required transmission ratio of the entire system in the open state:

Therefore, the transfer coefficient of the intermediate amplifier must be at least:

6. Calculation of cutoff parameters

As a Zener diode V1, we take a Zener diode D 818 (stabilization voltage Ust1 = 9 V Uy max = 11 V).

Current cutoff transfer ratio:

Stabilization voltage of the Zener diode V2:

The functional diagram of the electric drive is shown in Fig. 1 Appendices.

An integrated amplifier-limiter with zener diodes in the feedback circuit was used as an amplifier.

7. Plotting static characteristics

The limiting voltage is found from the static characteristics of the SPPC (Fig. 2 Appendix.):

Conclusion

During the calculation term paper the methodology for calculating the parameters of the main components of an electric drive, such as an electric motor, a transformer, a pulse-phase control system and a thyristor converter, was studied. The static characteristic of the electric drive was calculated and built, giving an idea of the speed of the drive with a change in the armature current electric motor, load diagram giving an idea of the load that the drive experiences during operation. Also, the schematic and functional diagrams were drawn up, giving an idea of the electrical elements included in the control system of the electric drive. Thus, a whole complex of calculations and constructions was implemented, which develops the student's knowledge and ability to calculate the electric drive, as a whole, as well as its main parts.

Application

Fig.1 Functional diagram of the electric drive.

|

To download work you need to join our group for free In contact with... Just click on the button below. By the way, in our group we help with writing educational papers for free. A few seconds after the subscription has been verified, a link will appear to continue downloading the work. |

|

| Free evaluation | |

| To raise originality of this work. Anti-plagiarism bypass. | |

|

REF-Master- a unique program for self-writing abstracts, coursework, control and diploma theses. With the help of the REF-Master, you can easily and quickly make an original abstract, control or coursework based on finished work- Calculation of the electric drive. |

|

| How to write correctly introduction?

Secrets of the ideal introduction of a term paper (as well as an essay and a diploma) from professional authors of the largest abstract agencies in Russia. Learn how to correctly formulate the relevance of the topic of work, determine goals and objectives, indicate the subject, object and research methods, as well as theoretical, regulatory and practical base Your work. |

|

|

Secrets of the ideal conclusion of the thesis and term paper from professional authors of the largest abstract agencies in Russia. Learn how to correctly formulate conclusions about the work done and make recommendations for improving the issue under study. |

|

| |

|

(term paper, diploma or report) without risks, directly from the author.

Similar works:

06/29/2010 / term paper

Calculation, justification for the choice of an electric motor: duration of activation, lifting force, power, angular velocity. Features and methods of calculating the rope-block system, drum, gearbox (weight, dimensions). Study of the layout of the electric hoist.

08/17/2009 / thesis

Determination of periodic, aperiodic components of symmetrical short-circuit current, short-circuit surge current, individual components of asymmetrical short-circuit. Calculation of voltage, construction of its vector diagram.

08/14/2010 / term paper

Calculation of the moments of resistance on the rudder stock, the procedure for calculating the electro-hydraulic drive, checking the electric motor for heating. Calculation and construction of the load characteristic of the electric motor of the steering device according to the generator - engine system.

01/28/2009 / test

Frequency regulation of an asynchronous motor. Mechanical characteristics of the engine. The simplest analysis of operating modes. The equivalent circuit of an induction motor. Control laws. The choice of a rational control law for a specific type of electric drive.

03/19/2010 / term paper

Technical characteristics of the technological unit, classification of cranes by design. Requirements for the electric drive and the control and signaling system, the choice of the magnitude of the supply voltages. Calculation of power and selection of the drive motor.

07/20/2008 / thesis

Machine-tool plant: power supply, load schedules, center of electrical loads, power supply scheme, capacity of capacitor units and transformers, selection of voltages, plant networks and currents, economic part and labor protection.

5.10.2008 / term paper

Industrial automation. Gaining skills in the calculation of an electronic automatic bridge. Description of the device and its principle of operation. Measurement, recording and regulation of temperature. Design of automatic control systems.

1. Analysis and description of the "electric drive - working machine" system

1.1 Quantification of the state vector or tachogram of the required motion process

1.2 Quantifying the moments and forces of resistance

1.3 Drawing up a design diagram of the mechanical part of the electric drive

1.4 Construction of the load diagram and the mechanical characteristics of the working machine

2. Analysis and description of the "electric drive - network" and "electric drive - operator" systems

3. Choice of fundamental decisions

3.1 Construction of the mechanical part of the electric drive

3.2 Selecting the type of drive (motor)

3.3 Choosing a method for adjusting coordinates

3.4 Evaluation and comparison of selected options

4. Calculation of the power drive

4.1 Calculation of parameters and selection of the motor

4.2 Calculation of parameters and selection of the power converter

5. Calculation of static mechanical and electromechanical characteristics of the motor and drive

6. Calculation of transient processes in an electric drive for a cycle of work

7. Checking the correctness of the power calculation and the final choice of the engine

1. Analysis and description of the "electric drive - working machine" system

1.1 Quantification of the state vector or tachogram of the required motion process

The speed of the electric drive during dressing and at idle speed, which is selected from the speed range from 1.45 m / s to 2.4 m / s.

According to the description of the technological process [1], you can build a tachogram of the required movement process. At the request of the process, the cycle of work occurs at a constant speed. Start-up and changeover to another speed are not included in the work cycle. The tachogram is shown in Figure 1.

Figure 1- Tachogram of the workflow

Let us determine the value of the minimum angular speed of the engine based on the tachogram and the conditions of the task:

![]() (1)

(1)

where i is the gear ratio of the gearbox;

v 1 - the minimum speed of movement of the sheet;

R is the radius of the working and supporting rollers.

Maximum angular speed of the engine:

![]() (2)

(2)

where v 2 is the maximum speed of movement of the sheet.

Consider two cases:

1) driving the maximum length of the sheet at the minimum speed;

2) running the minimum length of the sheet at maximum speed.

First case.

Rolling time:

![]() (3)

(3)

where L max is the maximum sheet length.

According to the condition of setting the PV of the mechanism - 75%. Let's define the cycle time:

![]() (4)

(4)

Idle time:

Second case.

![]()

![]() (6)

(6)

We will choose an engine with a design mode S1 since there are no pauses during the drive cycle.

1.2 Quantifying the moments and forces of resistance

Knowing the total total moment at maximum load, referred to the work rolls, it is possible to determine the static moment reduced to the shaft:

![]() (7)

(7)

where is the efficiency of the mechanism (considered unchanged).

The idling torque, given to the engine shaft, is set and is equal to:

![]()

The torque on the motor shaft during dressing is determined by the formula:

1.3 Drawing up a design diagram of the mechanical part of the electric drive

For a theoretical study, we replace the real mechanical part of the electric drive (Figure 2) with a dynamically equivalent reduced design scheme, consisting of concentrated inertial elements interconnected by elastic links, and having the same energy reserve as the real original drive system. The parameters of the equivalent reduced design scheme are the total reduced moments of inertia of the masses formed by the reduced masses, the bonds between which are assumed to be rigid, and the equivalent reduced stiffnesses of elastic mechanical bonds.

Figure 2 - Kinematic diagram of the mechanism

The electric drive consists of the following kinematic elements:

1 - electric motor;

2 - reducer;

3 - six cage;

4 - universal spindles;

5 - working stand.

The moment of inertia of the couplings between the engine and the gearbox is 16 kg * m 2, the moment of inertia of the couplings between the gearbox and the gear stand is 40.2 kg * m 2, of one spindle - 0.003 kg * m 2. The moment of inertia of the gearbox, reduced to the motor shaft, is equal to 30% of J dv.

The number of spindles -17, the number of working rollers -17, support - 15.

The mechanical part of the electric drive of the sheet-straightening mill is a three-mass system consisting of rotors (armatures) of motors with half-couplings on the shafts - J1, a gearbox with half-couplings on its input and output shafts - J2 and the working body of the machine, also with half-couplings on the input shaft - J3. The elastic links of this system are the stiffnesses of the C 12 and C 23 couplings.

Let's calculate the parameters of the resulting circuit.

First mass moment of inertia:

where J pm1 is the moment of inertia of the half-couplings on the motor shafts.

The moment of inertia of the gearbox with half couplings on its input and output shafts (taking into account that the moment of inertia of the gearbox, reduced to the motor shaft, is equal to 30% of J dv) is:

where J pm2 is the moment of inertia of the half-coupling on the output shaft of the gearbox.

The moment of inertia of the working member of the drive with half-couplings on the input shaft, reduced to the motor shaft, is calculated by the following expression:

![]() (11)

(11)

where J roll is the total moment of inertia of the working and support rollers;

J shp is the moment of inertia of the spindles;

J pm - moment of inertia of half-couplings;

i - gear ratio of the gearbox.

Let's define the moment of inertia of the roller:

where L is the length of the roller, m;

D - roller diameter, m;

Density of the material (= 7.66 * 10 3 kg / m 3).

Given the number of working and support rollers, we get:

Spindle moment of inertia:

Then the moment of inertia of the working body will be equal to:

Rigidity of the coupling between the gearbox and the gear cage, referred to the motor shaft:

![]() .(15)

.(15)

Considering that when the elastic elements are connected in parallel, the stiffnesses add up, we find the stiffness of the C 12 and C 23 couplings, which are the elastic links of the three-mass system:

where С м1 - stiffness coupling sleeve between motor and gearbox.

Calculation of transients in a three-mass system is complicated, therefore we transform the system into a two-mass one.

|

Let's calculate the parameters of the circuit. Equivalent stiffness of a two-mass design scheme:

The transition and justification for the transition to a single-mass settlement scheme will be given below.

1.4 Construction of the load diagram and the mechanical characteristics of the working machine

The load diagram of the mechanism is the dependence of the torque given to the motor shaft as a function of time per cycle.

The working cycle is the alternation of the drive during the movement of the sheet and idle work the machine before the start of the next cycle. We build a simplified load diagram of a working machine, which is built according to the static loads calculated for each section of the work cycle, that is, without taking into account dynamic loads. Dynamic loads are not included in the work cycle as the machine runs at a constant speed.

A simplified load diagram is as follows:

At the idle speed interval, the torque is equal to the idle torque;

In the dressing interval, the torque is equal to the sum of the moments of static on the axis of the work rolls, reduced to the motor shaft and idling.

The load diagram is shown in Figure 5.

Figure 5 - Load diagram of the mechanism

The mechanical characteristic of the working machine is the dependence of the reduced static moment on the speed of the motor shaft. According to the assignment, this dependence is close to parabolic.

The mechanical characteristics of the working machine are shown in Figure 6.

Figure 6 - Mechanical characteristics of the working machine

2. Analysis and description of the "electric drive-network" and "electric drive-operator" systems

The electric drive of the sheet-straightening mill is powered by a 3-phase network alternating current frequency 50 Hz, voltage 380V.

The standards provide for and allow for a voltage variation of ± 10% and a frequency of ± 2.5% (GOST 13109-87). This phenomenon is caused, among other things, by the presence of other powerful consumers of energy in the conditions of the workshop, plant. This significantly affects the operation of engines, imposes additional requirements on the organization of their work.

Using the QF1 circuit breaker, we connect the voltage to the frequency converter.

By pressing the START button, the drive is switched on, then the drive works in automatic mode, no operator is required for constant control of the drive operation.

3. Choice of fundamental decisions

3.1 Construction of the mechanical part of the electric drive

The kinematic diagram of the main electric drive of the sheet-straightening mill is shown in Figure 2. The main operation - straightening, is performed using rotating rolls located in the working stand. The upper work roll moves in a vertical plane, and the axis of the lower roll is always in a fixed position.

The transmission mechanisms in the rolling mill consist of a gearbox, a gear stand, working spindles and couplings.

The gearbox is designed to enable the use of a motor with a relatively high rated speed at low rolling speeds and thereby reduce the size and cost of the engine and the entire installation as a whole.

The spindles are used to transfer rotation to the rolls from the gear stand. The need for their application lies in the fact that with a change in the position of the upper roll, the distance between this roll and the gear stand, as well as the angle between the shaft of the gear stand and the spindle, also change.

Couplings are used to connect the gear cage and the motor to the gearbox.

3.2 Selecting the type of drive (motor)

The basis for choosing the type of motor is the technical specifications for the design of the drive of the sheet-straightening mill:

Long-term operation;

Infinitely variable speed control within a given range.

The following drives meet the above conditions:

1 Frequency converter - asynchronous motor;

2 Controlled rectifier - DC motor;

3 Cascade circuit;

4 Generator - engine.

3.3 Choosing a method for adjusting coordinates

When choosing a method for controlling coordinates (speed), it is necessary to take into account the energy aspect of choosing a control method. This means that the minimum size of the motor and its full use for heating takes place when the speed control method according to the indication permissible load corresponds to the dependence of the load on the speed.

Since the mechanical characteristic of the mechanism is a viscous load, it is advisable to use a speed control method with a constant power, i.e. regulation with P = const. In the case of using this method, the engine is provided with the best thermal conditions.

In the system, a frequency converter (AIN PWM) is an asynchronous motor, the required speed is obtained by changing the frequency and generating the voltage on the stator (volt-frequency control) or by adjusting the frequency and forming the vector of the main flux linkage of the machine (vector control).

In systems controlled rectifier - DC motor and generator - motor, the required speed is obtained by changing the armature supply voltage.

In a cascade scheme, speed control is carried out by introducing an additional EMF into the rotor circuit of the machine.

3.4 Evaluation and comparison of selected options

The generator - engine system is outdated, therefore, when comparing the selected options, it will not be taken into account.

Carrying out strict technical and economic calculations is not possible due to the lack of the required initial data, therefore, to assess and compare the selected options, we will use an approximate method - the “method of expert assessments”. Comparison of solution options is made with respect to n characteristics of the system that are important from the point of view of the design goal by comparing certain values of the corresponding quality indicators q i. Quality indicators serve to quantitatively characterize the degree of fulfillment of the requirements of the assignment for the design of the electric drive, as well as other requirements of the working machine.

The evaluation of electric drives will be carried out according to the following quality indicators:

1 - regulation range;

2 - efficiency of the electric drive;

3 - power factor;

4 - weight and size indicators;

5 - the cost of the electric drive;

6 - reliability of the electric drive;

7 - resource of work;

8 - operating costs;

9 - control accuracy;

Let us evaluate the fulfillment of the requirements for the i-th characteristic of the system according to the following criterion:

5 - the requirements for the i-th characteristic of the system are fulfilled very well;

qi = 4 - the requirements for the i-th characteristic of the system are fulfilled well;

3 - the requirements for the i-th characteristic of the system are satisfied satisfactorily;

2 - the requirements for the i-th characteristic of the system are fulfilled unsatisfactorily.

The FC - IM and UV - DPT systems with speed feedback provide a very large control range, therefore the requirements for the control range are fulfilled very well. In a cascade circuit, the range is limited by the power of the converter, i.e. when the range is increased, the inverter power becomes greater than the motor power, so the requirements for the control range are satisfied satisfactorily.

The efficiency of power drives is high enough that the drive efficiency requirements are met very well.

All drives meet the power factor requirements well.

The mass and dimensions of the drive are determined by the mass and dimensions of the motor and converter. Modern drives FCh - IM and UV - DPT have very good weight and size indicators, therefore the requirements for the weight and size indicators of the drive are met very well, and the cascade circuit has slightly worse weight and size indicators, therefore the requirements for the weight and size indicators of the drive are met well.

The cost requirement in HC - DC drives and the cascade circuit is fulfilled very well, and in the FC - IM drive it is somewhat worse due to the fact that the cost of the PC - IM is slightly higher than the cost of the HC - DC and the cascade circuit.

An asynchronous squirrel-cage motor does not have a collector unit and brush contacts, therefore, the requirements for reliability and service life are met very well. In a cascade circuit, the engine does not have a collector unit, but has a brush contact, therefore, the requirements for reliability and service life are met well. The DC motor has a collector assembly, therefore, the reliability requirements are not met satisfactorily, and with proper maintenance of the collector, the service life requirements are satisfied satisfactorily.

The drive of the PCh - IM does not require operating costs, therefore the requirements for operating costs performed very well. In a cascade circuit, periodic checking of the brush contacts is necessary, so the operating cost requirements are met well. In the UV-DPT drive, a more frequent inspection of the collector unit is required, as well as periodic cleaning of the brushes, therefore, the requirements for operating costs are satisfied satisfactorily.

In the UV - DPT drive, the control accuracy requirements are met very well. In the drive of the PCh-IM, the requirements for the control accuracy are well fulfilled. In the cascade scheme, the requirements for the control accuracy are satisfied satisfactorily.

The choice of the option as the best one depends on how equal the characteristics of the system are, i.e. you need to evaluate their significance. For this, the weight coefficients λ i are introduced, which can be determined as follows:

5 - i-th characteristic the system is critical to the design goal;

4 - - “- very large, but not decisive;

li = 3 - - “- important;

2 - - “- it is desirable to take into account;

1 - - “- immaterial for the purpose of development.

The task of an electric drive is to perform useful work with a minimum of losses, therefore, the efficiency of an electric drive is of decisive importance.

The consumption of reactive power from the network is normalized (for exceeding the norm, the enterprise has to pay a fine), therefore the power factor is of decisive importance.

Since a sheet-straightening mill is a continuous-action unit and its unforced downtime leads to huge losses, therefore, reliability and service life are of decisive importance.

According to the assignment, the drive must provide a relatively small control range, therefore this quality indicator is not very large and decisive and can be described as important.

Cost matters a lot. However, as you know, cost is closely related to quality; therefore, such an indicator as cost is of great, but not decisive, importance.

Usually at metallurgical enterprises there are premises sufficient to accommodate the mill, therefore, the mass and size parameters of the mill are not very large and of decisive importance. However, with an increase in the mass of the mill, its cost also increases, therefore this indicator can be described as important.

The evaluation chart is shown in Figure 7.

Figure 7 - Evaluation diagram (quality indicators: 1 - regulation range; 2 - efficiency of the electric drive; 3 - power factor; 4 - weight and dimensions; 5 - cost of the electric drive; 6 - reliability of the electric drive; 7 - service life; 8 - operating costs; 9 - regulation accuracy)

The choice of the best solution is made by determining the weighted sum, ( the best way has a large amount) according to the formula:

where is the quality indicator;

Weight coefficient;

Weighted amount.

Let's define the weighted sums:

As a result, we get that the following drive has the maximum weighted sum: frequency converter - asynchronous motor.

Therefore, this drive is subject to further calculation.

4. Calculation of the power drive

4.1 Calculation of parameters and selection of the motor

The design operating mode of the engine is long-term with variable load, since there are no pauses during engine operation, and the load changes in jumps (Figure 5).

Since the necessary initial data for calculating the motor power by the methods of average losses, there are no equivalent current, therefore we will use a less accurate method - the method of equivalent torque, assuming that constant losses, motor resistances do not change during operation, and also that the torque developed by the motor, proportional to the current.

According to the load diagram and the mechanical characteristics of the working machine, the equivalent torque is equal to:

(21)

(21)

where ![]() - coefficient of deterioration of cooling of the machine when working at speed;

- coefficient of deterioration of cooling of the machine when working at speed;

Cooling deterioration coefficient during pauses, depending on engine ventilation (for closed self-ventilated motors = 0,45 -0,55)

Range of regulation when working at speed.

The additional load created by the dynamic moment will be taken into account by the safety factor.

Let's calculate the equivalent torque without taking into account the coefficient of deterioration of the cooling of the machine when operating at a speed different from the nominal one for two limiting operating modes of the drive:

1) drive the maximum length of the sheet at the minimum speed:

;

;

2) running the minimum length of the sheet at the maximum speed:

Let's take the moment the largest of the two given cases:

![]() .

.

According to the instructions of the project, it is required to ensure operation in the speed range, therefore, the engine speed:

![]() rpm; (22)

rpm; (22)

![]() rpm; (23)

rpm; (23)

The minimum engine speed is n dv = 500 rpm, it is less than required. Therefore, we will regulate the drive in the 1st zone.

Using a variable frequency drive, we will be able to provide the required speed.

Let's estimate the required engine power:

The criteria for choosing an engine are as follows:

When choosing, it is necessary to choose an engine with in order to more fully use the engine in terms of power.

However, the industry produces engines (standard series 4A) with a power of more than 197.3 kW (200 kW) only for revolutions above 1000 rpm (104.6 rad / s) and above, and with an increase in power, the rated speed of the motors increases.

Also, with an increase in the rated speed of the motor, the rated torque decreases, according to the formula

whence it follows that in order for the engine not to overheat during operation, it is necessary to overestimate the engine power.

Thus, it is necessary to select an engine with a capacity ![]() and

and ![]() rpm However, there is no standard motor (4A series) with such parameters.

rpm However, there is no standard motor (4A series) with such parameters.

Due to the impossibility of performing a high-power drive with one motor, we will build an electric drive consisting of two machines. The interconnected electric drive in high-power installations allows to reduce the load of each drive and thereby facilitate transmission to the working body, reduce the total moment of inertia of the motor rotors.

Thus, we select engines (series 4A) with identical parameters from the reference book (therefore, further calculations will be performed for one engine):

4A355M12U3 (IP44),

R n = 110kW - rated power,

n = 500 rpm - synchronous rotation frequency,

s n = 0.02 - nominal slip,

Nominal efficiency,

![]() - the moment of inertia of the rotor,

- the moment of inertia of the rotor,

The multiplicity of the critical moment,

Multiplicity of starting torque,

Oe .; o.e.; o.e.; o.e.; o.e. - parameters of the equivalent circuit in p.u.

The rated speed of the motor is:

Motor rated torque:

![]() (28)

(28)

In order for the motor not to overheat, it is necessary that the torque permissible for heating the motor (equal to the rated torque of the motor) be greater than or equal to the torque equivalent:

(29)

(29)

Thus, the selected motor is heated.

We check the correct choice of the motor in terms of overload capacity and starting conditions.

The drive starts up at idle speed, then:

![]() (30)

(30)

Overload capacity:

(31)

(31)

where U = 0.9U n - we take into account a possible decrease in the supply voltage by 10%.

4.2 Calculation of parameters and selection of the power converter

It is required to select a frequency converter with the following characteristics:

Converter type - AIN PWM;

Control law - P = const;

Power supply: ~ 3 380V 50Hz;

Converter power - P = 75 kW.

We select the Omron 3G3FV A4750 CUE converter. Highly dynamic with great control depth. Starting torque up to 150% from 3 Hz. It features a vector control mode, the ability to work with full torque in the region of zero frequencies and improved dynamic characteristics: has the function of automatically detecting the parameters of the electric motor. 7 digital inputs (6 of them are programmable), 3 analog inputs (1 programmable) (0-10V or 4-20mA). 2 analog outputs for monitoring frequency or current. 2 programmable relay outputs (up to 1A). 2 opto-isolated outputs Built-in RS232 / RS485 / 422 + PID + Energy saving + neuro-Fuzzy + crane characteristics.

Table 1 - Characteristics of the converter

| Parameter |

Meaning |

| Power, kWt) |

|

| Input voltage (V) |

|

| Input Frequency (Hz) |

|

| Allowable voltage fluctuation |

from -15% to + 10% |

| Frequency range (Hz) |

|

| Output frequency resolution (Hz) |

|

| Engine management |

volt-frequency / vector with feedback |

| Carrier frequency (kHz) |

|

| Communication capabilities |

Modbus; Compo Bus / D (Device Net); Profibus DP Sysmac Bus; Interbus |

| Analog output (0-10V) |

|

| Number of fixed speeds |

|

| Analog speed reference |

|

| Acceleration / deceleration time |

from 0.01 to 6000 sec. |

| Degree of protection |

The frequency converter provides complete protection of the converter and the motor against overcurrent, overheating, earth leakage, and phase failure.

5. Calculation of static mechanical and electromechanical characteristics of the motor and drive

The mechanical characteristic is calculated by the formula:

(32)

(32)

where is the phase voltage across the stator;

Active resistance of the stator phase, Ohm;

Active resistance of the rotor phase, reduced to the stator circuit, Ohm;

Inductive resistance of the stator phase, Ohm;

Inductive resistance of the rotor phase, reduced to the stator circuit, Ohm;

s - slip;

Ideal idle speed (magnetic field).

The resistances of the stator phases and the reduced resistances of the rotor phases are calculated according to the reference data.

Basic resistance value:

![]() (33)

(33)

where as the basic values of voltage and current we take the nominal values of the phase voltage and stator current:

![]()

Let us construct a natural mechanical characteristic according to the formula (41) using the mathematical package Mathcad, taking into account that, substituting, postponing the moment M along the x-axis, and the motor speed along the y-axis.

The natural mechanical characteristics of the engine are shown in Figure 8.

Figure 8 - Natural mechanical characteristic of the engine

Let's calculate the electromechanical characteristics of the engine.

As the base current value, we take the nominal value of the rotor current reduced to the stator circuit.

The dependence of the reduced rotor current on slip is determined by the formula:

(36)

(36)

The dependence of the stator current on slip is determined by the formula:

(37)

(37)

where is the relative rotor current;

The maximum value of the relative rotor current;

Relative magnetizing current;

Rated stator current.

Maximum value of relative rotor current:

(38)

(38)

where is the critical slip;

![]() .(39)

.(39)

Relative magnetizing current:

(40)

(40)

Rotor current:

(41)

(41)

We construct the natural electromechanical characteristic of the rotor current and the electromechanical characteristic of the stator current, using the mathematical package Mathcad, substituting, plotting the current I along the x-axis, and the motor speed along the y-axis.

Natural EMR of the engine are shown in Figure 9.

Figure 9 - Natural electromechanical characteristics of the engine

Since a PI regulator is used for speed regulation (it will be shown below), which gives zero static error, therefore, the mechanical characteristic of the drive will be absolutely rigid.

Figure 10 - Mechanical characteristics of the drive

6. Calculation of transient processes in an electric drive for a cycle of work

To obtain simpler transfer functions of regulators, it is necessary to go from a two-mass design scheme to a single-mass design scheme.

Justification for the transition to a single-mass settlement scheme:

Only motor variable feedbacks are used;

Natural vibration frequency:

Transition condition:.

As shown below, the T of the drive is 0.0258, then ![]() ... Then the transition condition is fulfilled () and, therefore, one can go to a single-mass design scheme.

... Then the transition condition is fulfilled () and, therefore, one can go to a single-mass design scheme.

The total moment of inertia of a single-mass design scheme will be equal to:

A single-mass design scheme is shown in Figure 11.

Figure 11 - Single-mass design scheme

When regulating, the dependence of the torque permissible for heating the motor on the speed should repeat the dependence of the static torque on the speed.

To control the drive, we will use a two-loop automatic control system with volt / frequency control with sequential link correction, with an internal torque control loop and an external speed control loop.

With volt / frequency control, two control channels are organized: a supply frequency control channel and a voltage control channel. The speed is stabilized by adjusting the voltage as a function of frequency and as a function of load.

Consider a frequency control channel.

By expanding the equations of the dynamic mechanical characteristics in a series and linearizing the obtained equations in the vicinity of the point M = 0, s = 0, we obtain a linearized model of an induction motor, which is valid for.

Due to the fact that it is difficult to measure the motor torque in an asynchronous electric drive, disturbance control is used instead of torque control by deviation. Because the disturbing effect for the torque control loop is speed, then we will introduce a positive feedback on the speed, with the transmission coefficient.

We will regulate the engine speed by the deviation by introducing a negative speed feedback.

The block diagram of the frequency control channel is shown in Figure 12.

Figure 12 - Block diagram of the frequency control channel

Consider a torque control loop.

For static mode:

Zero error will be provided if:

![]() .(44)

.(44)

Maximum motor torque:

With volt / frequency control with:

![]() (46)(47)

(46)(47)

Electromagnetic time constant:

![]() (48)

(48)

Mechanical stiffness:

![]() (49)

(49)

The frequency transfer coefficient of the converter is determined by the ratio of the maximum signal at the output of the converter to the maximum signal at the output of the torque regulator:

![]() .(50)

.(50)

The maximum value of the limiting torque is equal to the critical moment of the natural characteristics of the engine:

From equation (45) we find K pm:

The torque regulator is represented as a P - regulator.

The limiting value of the feedback gain, providing torque control with zero error:

![]() (53)

(53)

To calculate the velocity contour, we represent the torque contour in the form of a link:

By designating ![]() , we obtain the transfer function of the optimized torque control loop:

, we obtain the transfer function of the optimized torque control loop:

![]() (55)

(55)

The block diagram of the speed control loop is shown in Figure 13.

Figure 13 - Block diagram of the speed control loop

The negative speed feedback sensor gain is calculated as the ratio maximum speed for the corresponding task voltage:

![]() (56)

(56)

The small uncompensated time constant of the speed control loop is the electromagnetic motor constant, i.e. accept ![]() .

.

The large compensated time constant of the speed control loop is the mechanical constant of the motor.

To obtain a zero error in statics and forcing transient processes in dynamics, the speed controller must be a PI controller.

Let's tune the speed controller to the symmetrical optimum.

Desired transfer function of the speed loop set to symmetrical optimum:

![]() .(57)

.(57)

Transfer function of the controlled object:

![]() (58)

(58)

Dividing the desired speed loop transfer function by the control object transfer function, we obtain the speed controller transfer function:

![]() ;

;

![]() .

.

In order to remove overshoot, according to the command, it is necessary to put a filter with a time constant and the following transfer function at the input of the speed loop:

![]() (61)

(61)

Calculation of transients is performed in the Matlab package.

In the model, we will use a single-mass conservative design drive scheme.

The drive model is shown in Figure 14.

Figure 14 - Drive model

The graphs of transient processes - the torque of the electromagnetic motor and the speed of the first mass, reduced to the motor shaft - are presented in Figures 15, 16.

Figure 15 - Graph of the transient process of the speed of the first mass

Figure 16 - Graph of the transient process of the electromagnetic moment

As a result of the simulation, it was obtained that the overshoot of the speed is:

![]()

7. Checking the correctness of the power calculation and the final choice of the engine

We will check the correctness of the power calculation using the method of average losses.

The total nominal motor losses are:

Variable rated motor losses are:

Then the constant losses will be equal:

Average losses for a cycle of work are equal:

(65)

(65)

where are losses in i-th moment time,

Cooling deterioration rate when operating at speed

T c = 6.9 s - cycle time.

Losses at the i-th moment of time can be determined from the following expression:

![]() ,(66)

,(66)

where ![]() ,

,

Engine load degree.

.(66’)

.(66’)

Substituting (66 ') in (65) we get:

(67)

(67)

Using expressions (67), we find the average losses per operating cycle.

To find the average losses by formula (67), we use the drive model.

First, we square the torque of the electromagnetic motor. Then we divide the resulting value by the square of the nominal torque and add. Then we integrate the resulting value and multiply by, we get the value of the average losses per cycle.

The model for finding the average losses per cycle is shown in Figure 17.

Figure 17 - Model for finding the average losses per cycle of work

As a result of modeling, it was obtained that the average losses per operating cycle are equal to:

![]() .

.

Then the engine load factor is:

![]() (68)

(68)

Thus, the engine is loaded at 80% (70%<80%<100%), следовательно, оставляем выбранный двигатель.

The estimated power required to drive the pump CNS 180-1900 is determined by the formula:

where Q is the pump flow, m 3 / s;

H is the head developed by the pump, m;

p is the density of the pumped liquid, kg / m 3,

(Cenomanian water has a density of 1012 kg / m 3);

s us - pump efficiency, rel. units

SPS operate continuously at a stable load.

Consequently, the pump motors operate in

continuous mode (S1). Then, the calculated power

pump unit (taking into account a safety factor equal to 1.2),

will be:

where K 3 - safety factor, rel. units;

h - transmission efficiency, rel. units

For the drive of centrifugal pumps CNS 180-1900, we choose synchronous motors, since they most fully satisfy the operating technology of the CNS and, in addition, have a number of advantages:

the ability to adjust the value and change the sign of reactive power;

the efficiency is 1.5 - 3% higher than that of an induction motor of the same size;

the presence of a relatively large air gap (2 - 4 times larger than that of an asynchronous motor) significantly increases the reliability of operation and allows, from a mechanical point of view, to work with large overloads;

strictly constant speed, independent of the load on the shaft, 2 - 5% higher than the speed of the corresponding asynchronous motor; the mains voltage affects the maximum torque of a synchronous motor less than the maximum torque of an induction motor. A decrease in the maximum torque, due to a decrease in the voltage at its terminals, can be compensated for by forcing its excitation current;

synchronous motors increase the stability of the power system in normal operating modes, maintain the voltage level;

can be manufactured for almost any power;

Taking into account all of the above, we choose synchronous motors of the STD 1600-2RUKHL4 type (manufactured by the Lysvensky plant).

Technical data of electric motors are given in table. 1.2.

Table 1.2

Technical data of the STD 1600-2RUKHL4 type engine

|

Parameter |

unit of measurement |

Meaning |

|

Active power |

||

|

Full power |

||

|

Voltage |

||

|

Rotation frequency |

||

|

Critical speed |

||

|

Rotor flywheel moment |

||

|

Maximum torque (multiple to the rated torque) |

||

|

Phase stator current |

||

|

Power factor |

0.9 (leading) |

|

|

Excitation voltage |

||

|

Excitation current |

||

|

Permissible flywheel moment of the mechanism, reduced to the motor shaft, at one start from a cold state |

||

|

Allowable direct start time with one cold start |

||

|

Permissible flywheel moment of the mechanism, reduced to the motor shaft, with two starts from a cold state |

||

|

Allowable Direct On-Line Starting Time for Two Cold Starts |

||

|

Permissible flywheel moment of the mechanism, reduced to the motor shaft, at one start from a hot state |

||

|

Allowable Direct On-Line Start Time with One Hot Start |

||

Synchronous motors of STD 1600-2 type are selected in a closed design with a closed ventilation cycle and one working end of the shaft, which is connected by means of a coupling to the pump CNS 180-1900. The stator winding of such motors has insulation "MONOLITH - 2" of heat resistance class F. These motors allow direct starting from full mains voltage, if the swing moments of the driven mechanisms do not exceed the values indicated in table. 1.2.

The operation of STD 1600-2 motors at a voltage above 110% of the nominal is not allowed, and when the cosots is lowered, it is allowed

provided that the rotor current does not exceed the nominal value.

In case of loss of excitation, these motors can operate in asynchronous mode with a short-circuited rotor winding. The permissible load in asynchronous mode is determined by the heating of the stator winding and should not exceed the value at which the stator current is 10% higher than the rated one. In this mode, work is allowed for 30 minutes. During this time, measures must be taken to restore the normal operation of the excitation system.

Motors STD 1600-2 allow self-starting with rotor field extinguishing and resynchronization. The duration of self-starting should not exceed the permissible time for starting the engine from a hot state (see Table 1.2), and the frequency should not exceed once a day.

Motors STD 1600-2 allow operation with an asymmetrical supply voltage. The admissible value of the negative sequence current is 10% of the nominal value. In this case, the current in the most loaded phase should not exceed the nominal value.

Thyristor excitation device (TVU) is designed to supply and control direct current of the excitation winding of a synchronous motor. TVU allows for manual and automatic regulation of the excitation current of the STD 1600-2 motor in all normal operating modes.

The TVU set includes a thyristor converter with control and regulation units, a power transformer of the TSP type. TVU are powered from an alternating current network of 380 V, 50 Hz. The supply voltage of the protection circuits is 220 V DC.

TVU provides:

transition from automatic control to manual control within (0.3 - 1.4) 1 nominal with the possibility of adjusting the specified control limits;

automatic start of a synchronous motor with excitation as a function of stator current or time;

forcing on the excitation voltage up to 1.75 U B H0M at the rated voltage of the power supply with an adjustable forcing duration of 20-50 s. Forcing excitation is triggered when the mains voltage drops by more than 15 - 20% of the nominal, and the return voltage is (0.82 - 0.95) U H0M;

limiting the firing angle of power thyristors by

minimum and maximum, limiting the excitation current to

rated value with time delay, as well as limitation

forcing current values up to 1.41 V nominal without time delay;

forced damping of the motor field by transferring the converter to the inverter mode. The field is extinguished during normal and emergency shutdowns of the engine, as well as during the operation of the automatic transfer switch (ATS), provided that the power supply of the TVU is maintained;

automatic excitation regulator (ARV) provides regulation of the excitation current STD 1600-2 to maintain the mains voltage with an accuracy of 1.1 U H0M.