Replacing the alternator belt for the Renault Logan sedan is an important point, because of the key function that is assigned to the belt. In this article, we'll talk about how to change such a thing in a car as a generator belt.

Why change the Renault Logan belt

French carmaker that produces Renault Logan set the rate for the replacement of this unit (also of brushes) at 60 thousand km due to their breakdowns precisely through each such run, this is also typical for 16-valve motors 1.4 and 1.6, respectively. But a real car enthusiast must have his own rules for the frequency that increase the service life, plus you need to understand how to change the tension rollers in your car when the alternator belt is replaced.

After 15 thousand km on 16-valve engines, the belt tension force should be monitored, as well as the efficiency of the entire mechanism as a whole. And in some cases, by this time, replacement of the alternator belt is required.

If the rubber part of the belt itself is without visible defects, and the pulley is in normal condition, you should not install a new component. Otherwise, you will have to mount new part or make repairs if possible.

You should take into account the very complete set Renault Logan. A car can have a split system and a power steering system (GUR) at the same time, one can be installed, or the model does not provide for the presence of these elements at all. A similar layout is installed on sedans with an engine of 1.6 liters and 1.4 liters (similar "packaging" and 16 valves).

What problems can there be

- Signs of a malfunction are an uncharacteristic whistle from the engine compartment (this is the belt whistling). This suggests that most likely the pulley and the belt have a strong deflection, therefore, using the tool, the belt tension is increased, which eliminates the whistling sounds. But if a sound occurs in the event of a defect in the regulator or other problems, the installation of a new mechanism is required.

- The most drastic option to eliminate whistling is to install a new belt and pulley.

- Whistling occurs on parts with a broken regulator. If a whistle occurs and a malfunction of the regulator is established, this unit is removed from the trouser seat and installed.

- Also, the cause of malfunctions is a malfunction of the bearing elements. They break for a variety of reasons.

The owner of a French car Renault Logan with a volume of 1.6 liters with power steering, when installing a new component, should build on the advice of Renault when buying a new part.

Renault prefers Bosch alternators and belts. It is these components and assemblies that are mounted on the bases of the sedan.

Now you can find many alternatives, but for normal operation it is the Bosch components that should be installed.

Replacing the belt with power steering and air conditioning for Renault

How to replace the alternator belt with air conditioning correctly? A similar arrangement of Renault Logan with power steering and a split system can be found on Renault with a 1.6 engine, and less often with a 1.4 liter engine. More often, these trim points are characteristic of 16-valve propulsion systems. Do not forget that when the alternator belt changes, the tension rollers must also change.

What is the number of storeys for such events? All actions are performed on a cooled engine.

- In the engine compartment, using a 13 key, the screw that secures the bearing rollers is loosened.

- Then the bracket with the housing part of the Renault Logan regulator generator is screwed on.

- After that, the drive part and rings are removed from the functional for working with a split system and power steering. In this step, the rollers are replaced, because these parts are replaced along with the belt.

- Using a wrench, disassemble the roller assembly itself and the tension roller (for this, wrench No. 13 is used as before).

- When a new component has been installed and the roller elements (belt, drive and rings) have been replaced, the entire assembly is installed in a reverse iteration. When installing, it is necessary to fix the new roller holder for better fastening of the entire structure, it is required to tighten it.

- After that, the assembly of the structure (rings and drive) is carried out in the reverse version. The whole procedure is clearly described in the video.

A distinctive feature of the belt in this design is the presence of 5 grooves, while the pulleys for the drive of auxiliary devices have six. Thus, the alternator belt with air conditioning is replaced.

Replacing the belt on a Logan with power steering, but without air conditioning

To replace a power unit with a 1.6-liter power steering without a split system, a special tool is not needed. It is required when a new generator is installed. On 16 valve systems, such an arrangement is very rare. The repair process is carried out in several steps:

- In the engine space on a Renault Logan of 1.6 liters, it is necessary to squeeze the alternator belt strongly and check its tension, and also determine the degree of suitability of the bearings in the future. Tension if necessary. If over-tensioned, you will have to loosen the screw fasteners.

- The adjusting screw is released a little, rather than tightened, to replace the bearing and roller to relieve excess stress.

- Then all the spare parts are replaced, specifically: all new components are installed and the assembly is carried out according to the reverse scheme, the parts are tightened, as can be seen from the review, and the correct operation of the regulator is diagnosed.

- In order for the work of the repair plan to be carried out with high reliability, the Renault auto concern proposes to use a tester and a circuit for measuring network parameters. This will make it possible to more clearly determine the feasibility of installing a new belt, as well as assess the efficiency of the unit.

Model without power steering and climate system, how to replace the belt

Structurally, the mechanism is lineup Renault Logan in the absence of power steering is simpler. Therefore, repair actions, as well as direct operation to the owner, will not bring as much hassle as other configuration options. But on 16-valve engines 1.4 or 1.6, this version is practically absent.

But there is also a negative of a similar Renault Logan model - during repair actions, there is a high probability of deformation of the generator, when the generator belt is directly tensioned.

The generator is placed in a different place than usual. Consequently, it is more accessible - dismantling / mounting procedures do not actually take long.

- The very dismantling of a broken unit on Renault Logan and its further repair (or its components, for example, a ring or a pulley) is performed from the crankshaft.

- In this option, you should measure the exact tension of the new belt drive in order to exclude possible defects in the generator, tighten if necessary. For this, a special tester or other equipment is used to check the current health of other units - bearings and a regulator. But usually the force of tension is set visually to the motorist, because the use of such a device for measurements has its own specifics, so everything should be pulled correctly.

How to maintain generator brushes

When performing maintenance of the brushes, prevention is also carried out on the generator in the following stages:

- The generator contact brushes are dismantled.

- After that, the chassis levers are removed (this will give space when working with brushes).

- After that, the fasteners of the upper frame are removed.

- After that, the protection is dismantled from the motor crankcase. It is secured with bolts. When removing protection, you should be careful.

- When the shields are removed and disassembled, you should clean them, remove the dirt and reinstall the part.

Let's summarize

Therefore, replacing the alternator belt and brush elements on a French-made Renault Logan sedan is just an event for the driver, even without solid experience. renovation works... Now you know how to change the tension rollers in the model when the alternator belt is replaced with or without air conditioning. All the more, any motorist can perform prophylaxis. To solve problems, you just need to try your hand and everything will work out.

In accordance with the regulations Maintenance checking the condition of the drive belt auxiliary units we spend every 15 thousand km.

The belt must be replaced if cracks, tears or peeling of rubber from the fabric base are found on it. Forcibly, regardless of the condition, we replace the belt every 60 thousand kilometers.

Depending on the vehicle configuration, there are three options for the accessory drive schemes.

Option 1

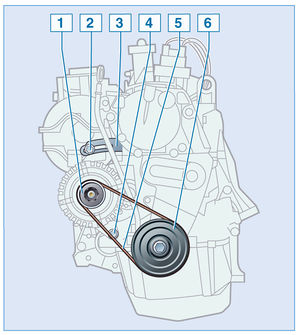

Drive circuit of auxiliary units of a Renault Logan car with power steering and air conditioning:

2 - tension roller;

3 - pulley of the power steering pump;

4 - generator pulley;

5 - air conditioner compressor pulley;

6 - support roller;

7 - belt

The belt tension of a power-assisted and air-conditioned vehicle is automatically adjusted by the tensioner. To replace the belt, remove the right mudguard in the engine compartment.

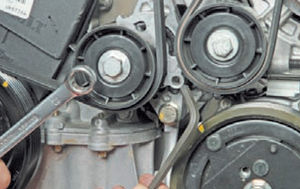

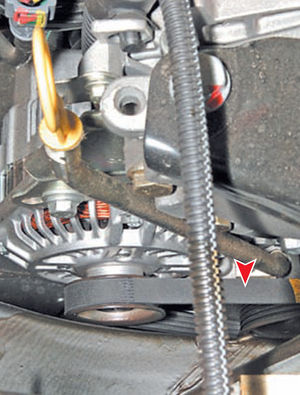

To loosen the belt tension from underneath the vehicle ...

... put a spanner wrench or a “13” head on the tension roller mounting bolt and turn the roller bracket clockwise, overcoming the tension of the tensioner spring, until the hole in the roller bracket is aligned with the recess in the device body (shown on the removed engine for clarity).

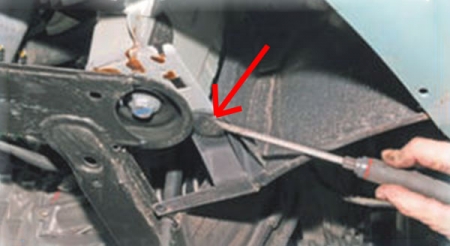

We fix the roller bracket by inserting a 6 mm hexagon or a rod with a diameter of 6 mm into its hole and recess in the tensioner housing.

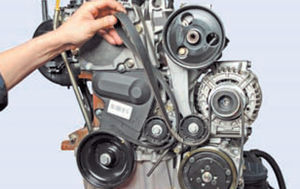

Remove the accessory drive belt.

Marking of the drive belt for auxiliary units of a car with power steering and air conditioning - 5K 1747 (five-strand, 1747 mm long). When replacing the belt, the idler and idler rollers must also be replaced.

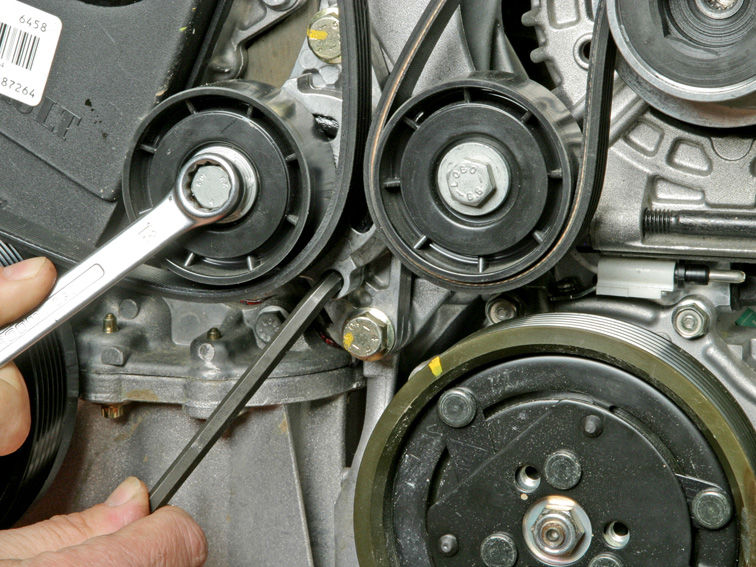

To replace the support roller ...

... with a spanner wrench or a "13" head, unscrew the bolt of its fastening ...

... and remove the bolt with the roller cover.

Remove the support roller.

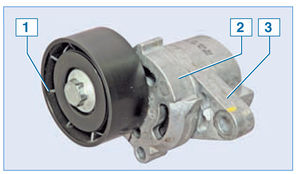

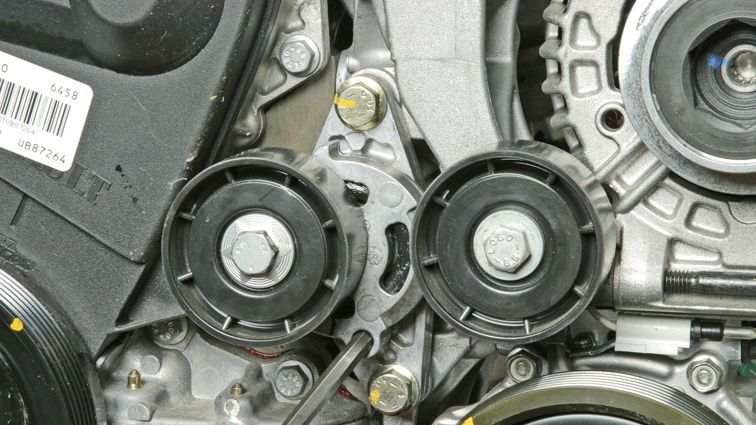

Remove the tension roller in the same way. If it is necessary to replace the tensioner (for example, if the spring breaks) ...

... with the "13" head, unscrew the two bolts securing the tensioner housing ...

... and remove the tensioner assembly with the roller.

Automatic tensioner assembly:

1 - tension roller;

2 - roller bracket;

3 - case

Install the removed parts in reverse order. Before mounting the belt, the idler roller bracket must be turned clockwise and locked (see above).

When installing the belt, we put it on the pulleys and put it under the tension and support rollers in accordance with the drive diagram.

The pulleys for the drive of auxiliary units, the generator, the air conditioner compressor and the power steering pump are six-lane, and the drive belt is five-lane.

... so that it is offset to their outer edge 1, and the inner groove of the pulleys 2 remains free.

After installing the belt, slightly turning the tension roller with the key, remove the retainer. Then turn the head "18" with a ratchet crankshaft clockwise three turns behind its pulley bolt to get the belt in the correct position.

Option 2

Drive circuit of auxiliary units of a Renault Logan car with power steering, without air conditioning:

1 - accessory drive pulley;

2 - tension roller with bracket;

3 - an adjusting bolt;

4 - bolt of the tension roller bracket;

5 - alternator pulley;

6 - pulley of the power steering pump;

7 - belt

The manufacturer recommends checking the belt tension of auxiliary units of a car with power steering and without air conditioning using a special tool (strain gauge tester) at a RENAULT dealer service.

Considering that the belt may have to be changed on the way (for example, when it breaks), far from the service, we will show a method in which you can approximately estimate the belt tension.

Remove the right mudguard in the engine compartment. From the bottom of the car with your thumb, press on the belt in the middle between the pulleys of the power steering pump and crankshaft... With a pressing force of ~ 10 kgf, the belt deflection should be 6 - 8 mm. To tension the belt, loosen the tightening of the two bolts 4 fastening the tension roller bracket and rotate the adjusting bolt 3 clockwise. After tightening the belt, tighten the tension roller mounting bolts.

Excessive belt tension will result in premature failure of the belt and idler pulley, as well as ancillary bearings.

To replace the belt, turn the adjusting bolt 3 counterclockwise a few turns and loosen the tightening of the bolts 4 of the tension roller bracket. After loosening the belt tension, remove it from the pulleys. Marking of the drive belt for auxiliary units of a car with power steering and without air conditioning - 5K 1110 (five-strand, 1110 mm long). When replacing a belt, it is also necessary to replace its tensioner pulley. Install the accessory drive belt in reverse order.

The pulleys for the drive of auxiliary units, the generator and the power steering pump are six-strand, and the drive belt is five-strand.

We put the belt on the pulleys like this ...

... so that it is offset to the inner edge 1 of the pulleys, and the outer groove of the pulleys 2 remains free.

Adjust the belt tension (see above). For an accurate check of the belt tension, you must contact the service.

Option 3

Generator drive diagram on a Renault Logan car without power steering and without air conditioning:

1 - alternator pulley;

2 - the bolt of fastening the generator to the tensioning bar;

3 - tension bar;

4 - the bolt of the lower mounting of the generator;

5 - alternator drive belt;

6 - a pulley of a drive of auxiliary units

To check the tension of the alternator drive belt on a Renault Logan car without power steering and without an air conditioner, press the belt with your thumb ...

… In the middle between the alternator and crankshaft pulleys.

With a pressing force of ~ 10 kgf, the belt deflection should be 6 - 8 mm. To tension the belt, remove the right mudguard of the engine compartment

We loosen the tightening of bolt 4 of the lower fastening of the generator and bolt 2 of fastening the generator to the tension bar. Moving the generator away from the engine block with a mounting blade, we tighten the belt. Tighten the generator mounting bolts.

Do not overtighten the belt! Excessive belt tension leads to premature failure of both the belt itself and the generator bearings.

When replacing the belt, weaken its tension (see above) and remove the belt from the crankshaft and alternator pulleys. The marking of the alternator drive belt on a car without a power steering and without an air conditioner is 4RK 718 (four-strand, 718 mm long).

Install the alternator drive belt in reverse order and adjust its tension. For an accurate check of the belt tension, you must contact the service.

Mileage 55,000 on the odometer, 5 years have passed and the belt whistled in subzero temperatures during the first minutes of engine operation. It would seem that the mileage is small, but it is large in engine hours.

Resolved, changing the belt and two rollers.

Sanctions and speculators have raised prices in the country. Including for s \ h. Paying 1300 rubles for 1 video is not willing. I want to save some money.

Total bought the original belt. RENAULT 8200598964 For 1.6 + Power Steering + Air Conditioning.

And two rollers T36413. They are not original and cost 700 rubles alone. Videos as they write on the forum should be metal.

This video goes like a bypass. However, it is also suitable as a tensioner, only the old washers should be left.

Here is a comparison photo.

In total, we get the original video for half the price of the original.

The whistle was gone.

P / S When I was about to remove the wheel, the bolts rusted and the spanner wrench burst at 17. Naturally, the regular one began to bend. I went to the tire fitting to knock it down with a wrench, but drove into the store and bought a key for 160 rubles. Very good. Does not bend. I jumped on it with my 85 kg.

It will be about the first generation Logan sedans. These machines, produced before 2016, could have been, but there were also configurations without power steering. And the Renault Logan accessory belt could have one of three configurations: 1747 mm, 1110 or 718 mm. The longest belts are fitted with air conditioning. They have power steering too.

Replacement video on a motor with power steering and air conditioning

Accessory drive

An engine pulley, mounted on a shaft, transmits power to one or more other pulleys. It all depends on the configuration - it may contain power steering with air conditioning (Fig. 1) or only power steering (Fig. 2). In the version without power steering, the belt transmits the force to the generator.

The tension roller is present in the first two versions. For the third case, the following is provided: the force, that is, the tension, is adjusted after loosening the screw 5 (Fig. 3).

Replacing the belt of Renault Logan auxiliary units is an operation for which you need to have special equipment. Fine adjustments can only be made in a workshop! However, the latter does not apply to "expensive" configurations, where there is an automatic tensioner (Fig. 1, detail 2).

The regulations for all configurations are the same. According to him, the inspection and check of the condition of the belt is performed every 15 thousand km. And the replacement is carried out after 60 thousand kilometers. And even if the external condition is good, the replacement is performed anyway.

Parts numbers in the catalog

Everyone knows that the Renault Logan accessory belt is designated as follows:

- 7700111671 or 8200833541- belt "5K 1747" for complete sets with power steering and air conditioning;

- 8200841132 or 8200061673- belt "5K 1110" (power steering without air conditioning);

- 8200211651 or 6001548021- "4PK 718" (generator only).

On the left are the numbers from the Renault catalog. “5K” here means “five strands”, and the numbers 718, 1110 and 1747 are the length of the belt.

As for tensioners, you can buy a roller with an automatic tensioner (see photo) or just a roller. Legend:

- 8200277606 or 7700102872- roller + tensioner;

- 8200849831 - roller + bracket (non-separable unit);

- 8200104754 - video clip.

Analogues of different firms

5 K 1747:

- 30692 (ASAM);

- QZ5PK1747 (QUARTZ);

- 5 PK 1750 (CONTITECH);

- 58425 or 8653-10381 (GATES).

5K 1110:

- 27526 (ASAM);

- 1 987 947 926 (BOSCH);

- 050 005 1110 (MEYLE);

- 8653-10205 (GATES).

4 PK 718:

- 30678 (ASAM);

- 1 987 947 888 (BOSCH);

- 28769 (FEBI);

- VKMV 4PK718 (SKF);

- 0053039 (FLENNOR);

- 240715 (MAPCO);

- 62 92 8769 (SWAG);

- WG1172509 (WILMINK);

- 8653-10039 (GATES).

One little trick

In any configuration with power steering, you can see 6 streams on the pulleys, not 5.

Complete set: power steering without air conditioner

If the belt of Renault Logan auxiliary units is with 6 streams, nothing bad will happen, but the plant does not use such belts. It would be undesirable to make changes. Therefore, install the belt like this:

- Power steering + air conditioner - let all the streams on the pulleys be occupied, except for the inner one;

- Power steering only (more details) - every stream is used, except for the external one (see fig.).

Preparatory actions

The accessory drive will be covered with plastic shields. And you can remove them by freeing the wheel arch. Therefore, the front left wheel is propped up with a jack and removed. Then the sequence is used:

It remains to dismantle the second shield. As a result, access to the belt will be opened.

All steps to replace

You will need one spanner "13", as well as a socket wrench "13" and "6". They do differently with different trim levels:

Replacing the belt of Renault Logan auxiliary units also includes tension adjustment, unless we are talking about a complete set with air conditioning. In the "expensive" configuration, nothing is adjusted, but you still need to check the tension force.

Checking the tension

We will press on the belt at the points marked in the drawing. In this case, a force of 10 kgf (98 N) is applied. In each case, the belt deflection should be 6-8 mm.

Where to push

Pressing is done with your thumb, pressing with almost full force.

Let the check succeed. Nothing else is required to be fitted with an automatic tensioner. And for configurations without a tensioner, a more accurate test is carried out using a strain gauge. The last requirement must be fulfilled.

Adjustment

A correctly adjusted belt should not emit such as!

Tension adjustment is not possible on air-conditioned versions. Therefore, the machine is replaced or repaired (see below). And where there is no automation, everything looks simpler:

Correctly tighten the belt of Renault Logan auxiliary units if there is no power steering in the configuration - this is the most difficult option. The setting in this case will be phased. It can take 30-40 minutes.

Replacing the rollers and tensioner

In trim levels with air conditioning, you can separately replace:

- Guide roller;

- Automatic tensioner with roller.

The trick is that for the first case, you need to perform a commit (see fig.). And then, when the roller is held in place, the mounting screw can be easily loosened. The spanner key "13" is suitable here.

We fix the roller with a rod d = 5-6 mm

If the machine is removed as an assembly, the locking rod is not needed. Use only a socket wrench that looses the two screws.

The accessory drive belt must be replaced if cracks, tears or peeling of rubber from the fabric base are found on it. Forcibly, regardless of the condition, we replace the belt every 60 thousand kilometers.

There are three options for the drive schemes of auxiliary units, depending on the configuration of the first generation Renault Logan / Sandero car.

Replacing the drive belt for auxiliary units of the first generation Renault Logan / Sandero with power steering and air conditioning

Drive circuit of auxiliary units of a car with power steering and air conditioning:- 1 -

- 2 - tension roller;

- 3

- 4 - alternator pulley;

- 5 - air conditioner compressor pulley;

- 6 -support roller.

To replace the belt, remove the right mudguard in the engine compartment. The sequence of actions is shown in the photo below.

To loosen the belt tension, from the bottom of the car we put a spanner wrench or a "13" head on the tension roller mounting bolt and turn the roller bracket clockwise, overcoming the tension of the tensioner spring, until the hole in the roller bracket and the recess in the device body are aligned (for clarity, it is shown on the removed engine).

We fix the roller bracket by inserting a 6 mm hexagon or a rod with a diameter of 6 mm into its hole and recess in the tensioner housing.

Remove the accessory drive belt.

Marking of the drive belt for auxiliary units of a car with power steering and air conditioning - 5K 1747 (five-strand, 1747 mm long).

When replacing the belt, the idler and idler rollers must also be replaced.

To replace the support roller:

Using a spanner wrench or a "13" head, we unscrew the bolt securing the support roller ...

... and remove the bolt with the roller cover.

Remove the support roller.

Remove the tension roller in the same way.

If it is necessary to replace the tensioner (for example, if the spring breaks):

Using the "13" head, unscrew the two bolts securing the tensioner housing and remove it assembled with the roller.

Automatic tensioner.

Install the removed parts in reverse order. Before mounting the belt, the idler roller bracket must be turned clockwise and locked (see above).

When installing the belt, we put it on the pulleys and put it under the tension and support rollers in accordance with the drive diagram.

Attention! The pulleys for the drive of auxiliary units, the generator, the air conditioner compressor and the power steering pump are six-lane, and the drive belt is five-lane.

We lay the belt on the pulleys so that it is offset to their outer edge, and the inner groove of the pulleys remains free.

After installing the belt, slightly turning the tension roller with a wrench, remove the retainer from the roller bracket hole and the recess in the tensioner housing. Then, using the "18" head with a ratchet, we turn the crankshaft clockwise three turns for the bolt securing its pulley in order to achieve the correct position of the belt.

Replacing the accessory drive belt of the first generation Renault Logan / Sandero with power steering without air conditioning

Diagram of the drive of auxiliary units of a car with power steering (without air conditioning):

- 1 - accessory drive pulley;

- 2 - tension roller with bracket;

- 3 - adjusting bolt;

- 4 - the bolt of the tension roller bracket;

- 5 - alternator pulley;

- 6 - pulley of the power steering pump;

- 7 - belt

Remove the right mudguard in the engine compartment. From the bottom of the car, with your thumb, press the belt in the middle between the pulleys of the power steering pump and the crankshaft. With a pressing force of ~ 10 kgf, the belt deflection should be 6–8 mm. To tension the belt, loosen the tightening of the two bolts 4 fastening the tension roller bracket and rotate the adjusting bolt 3 clockwise. After tightening the belt, tighten the tension roller mounting bolts.

Attention! Excessive belt tension will result in premature failure of the belt and idler pulley, as well as auxiliary bearings.

To replace the belt, turn the adjusting bolt 3 counterclockwise a few turns and loosen the tightening of the bolts 4 of the tension roller bracket. After loosening the belt tension, remove it from the pulleys.

Marking of the drive belt for auxiliary units of a car with power steering and without air conditioning - 5K 1110 (five-strand, 1110 mm long). When replacing a belt, it is also necessary to replace its tensioner pulley. Install the accessory drive belt in reverse order.

Attention! The pulleys for the drive of auxiliary units, the generator and the power steering pump are six-strand, and the drive belt is five-strand.

We lay the belt on the pulleys so that it is displaced to the inner edge of the pulleys, and the outer stream of pulleys remains free.

Adjust the belt tension (see above).

For an accurate check of the belt tension, you must contact the service.

Replacing the accessory drive belt of the first generation Renault Logan / Sandero without power steering and without air conditioning

Generator drive diagram on a car without power steering and without air conditioning:- 1 - accessory drive pulley;

- 2 -bolt of the lower mounting of the generator;

- 3 - alternator drive belt;

- 4 - generator pulley;

- 5 - the bolt of fastening the generator to the tensioning bar;

- 6 - tension bar

With your thumb, press on the belt in the middle between the pulleys of the generator and the crankshaft.

With a pressing force of ~ 10 kgf, the belt deflection should be 6–8 mm.

To tension the belt, remove the right mudguard in the engine compartment.

We loosen the tightening of bolt 2 of the lower fastening of the generator and bolt 5 of fastening the generator to the tension bar. Moving the generator away from the engine block with a mounting blade, we tighten the belt. Tighten the generator mounting bolts.

Do not overtighten the belt! Excessive belt tension leads to premature failure of both the belt itself and the generator bearings.

When replacing the belt, weaken its tension (see above) and remove the belt from the crankshaft and alternator pulleys.

The marking of the alternator drive belt on a car without a power steering and without an air conditioner is 4RK 718 (four-strand, 718 mm long).

Install the alternator drive belt in reverse order and adjust its tension. For an accurate check of the belt tension, you must contact the service.