Any boy, and many girls, as a child, dream of a small car that they could drive. Such a thing is quite expensive, so there is a rather weighty argument to assemble a car for a child yourself. In addition to saving, when building such a toy, you can also involve a child in the process, which will significantly expand his horizons.

There are not so many tools and materials required to assemble the map model discussed below, and the assembly process is quite simple. The author decided to build a car in a retro style.

Materials and tools for creating homemade products:

- bicycle wheels;

- pine boards and beams;

- oak to create a chassis (beams, boards);

- 24V electric motor with controller;

- battery for 24V (or two for 12V);

- two long screws for fastening;

- saw;

- good glue for wood;

- drill with drills;

- materials for interior trim (leather or leather substitute);

- headlights, taillights and other elements to create realism (optional);

- screws, nails and more.

Card making process:

Step one. Development of car design and construction in general

It all starts with a rather boring event - thinking over the structure and design of the car. After all, if you improvise when assembling, it is unlikely that you will be able to assemble something reliable and beautiful; it is better to work out most of the details in advance.

Among other things, it is important to remember that in such a car, its weight will play a key role, since the car runs on electricity. The heavier the car is, the more powerful the engine is needed and, as a result, the greater the battery capacity. The weight of the car will also need to be added to the weight of the child.

If you plan to put headlights in the car, then this will also be an additional power consumption.

Having decided on the design, you need to sketch it on paper, estimating the dimensions. It is important to take into account the length of the child's legs, his height, and weight. All this determines the amount of consumable materials for homemade products. You also need to select the desired diameter of the car wheels.

On the the final stage you need to estimate how much power will be transmitted to the wheels of the car, with what maximum speed he will drive and how far he can travel. In general, the slower the vehicle travels and the lighter it is, the less energy the product will consume.

The author's choice fell on a 350-watt engine with a gearbox that lowers the rpm to 600. This configuration is enough for the go-kart to move at a speed of 25 km / h, which is more than enough.

To achieve balance, the engine and battery are placed on opposite sides of the vehicle. The author put the batteries in the front and the engine in the back. To save money, you can buy a brush motor. From the author, he gives out 2500RPM, which is a lot and you need to lower the speed using a gearbox. Also, the gearbox allows you to get good traction of the car when low revs.

Step two. Assembling the car frame

The author makes the frame out of wood, it's simple and ingenious. It is very convenient to work with a tree, it is light and cheap. The widespread pine is used here as wood. It is flexible, lightweight and fits the frame perfectly. But to create a pendant, something stronger is already being used, this is oak.

As a connection, the author recommends using combinations of glue with self-tapping screws or nails. Should one unit fail and a chain reaction of the destruction of the frame will begin, so everything must be done reliably.

Step three. We build a building

The outer skin is easy to make using plywood and can be used to make the nose, including the bonnet, as well as sheathe the rear. It is not recommended to make plywood doors, as they are responsible for safety. Here you need to take something thicker so that the child does not fall out of the car when making a sharp turn.

Step four. Paint the car

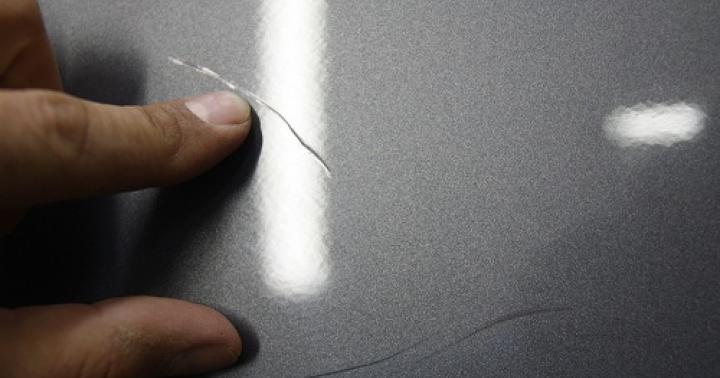

Before painting, it is advisable to grind the body thoroughly so that it is as smooth as possible. If there are holes in the material, they must be repaired with wood putty, otherwise they will become clearly visible after painting. It is convenient to paint with a spray gun. In extreme cases, a roller or brushes are suitable for painting, but it is better to paint with a roller, since it leaves a more uniform layer of paint.

It is also advisable to pre-dilute the paint, so it will lie smoother and dry faster. If desired, you can apply several layers and even paint the car with varnish.

Step five. Suspension assembly and axle installation

The hardest part here is creating the front suspension. After all, the wheels must turn, and as a result, all these turning nodes must be created and securely fastened. Of course, it is best to do everything from metal, but the author most of all succeeds in doing everything from wood, so here they are made of wood. Nevertheless, this suspension does an excellent job even when leaving the road.

When creating the rear axle, the author decided to follow the path of least resistance. The engine torque is transmitted to just one wheel, so there is no need to make a differential. This transmission is sufficient when driving on a firm, level road.

If the axle is made solid, that is, the movement is transmitted to two wheels at once without a differential, then when turning, a very large load will go to the engine and the battery will quickly sit down.

Rotation is transmitted by means of a chain transmission. The "power" wheel must be fastened securely, as it carries the greatest loads while driving. If not properly secured, it can pull out.

It is also important to ensure that the vehicle has a good brake system... It is not safe to brake with only one wheel, as at speed the car will skid a lot and it can roll over. Since the wheels are bicycle, you can also use the braking system from the bicycle. More simple solution will be installing a lever that brakes the car by friction against the wheel.

Step six. We install the engine and electronics

Since the motor is used quite powerful, rather thick wires will be needed to withstand a current of 28A at 24 V. You can calculate the required wire cross-section using a well-known formula. It is important to understand that the thinner it is and the longer it is, the greater the heat loss will be when driving a car. To bother in this matter, you can use the power cables from the car.

As a power supply, the author used two 12V batteries of 18Ah capacity, as a result, two of them weigh about 9 kg. These batteries are the cheapest, but they are not the best suited for powering such homemade products. But you can choose any battery, it all depends on the amount of cash costs. On the batteries that the author chose, his son rides for several hours, so they are quite enough.

To prevent the engine from draining the battery immediately, it is imperative to install a controller. You will also need to make the gas pedal. The controller should gradually increase the voltage depending on the degree of pressing the gas pedal. Required spare parts can be found in Chinese scooters.

Step seven. We decorate the car and detail

At the last stage of construction, you will need to add a number of elements to make the car as realistic as possible, to bring it closer to the invented style. Here you can install whatever you want, it can be headlights, a radiator, an antenna, a chest for things in the back and more.

For upholstery of seats and interior parts, you can use leather, leather substitutes, various films, fabrics and other materials.

Making a car with your own hands is a task worthy of a real man. Many ponder, some take, only a few bring it to completion. We decided to tell the stories of machines made, as they say, on the knee. We'll talk about the work of professional body shops, including type A: Level or ElMotors, another time.

The case of the masters of the East

Most of the homemade people are in the so-called developing countries. Afford expensive car not everyone can, but everyone wants to. And copyright in these countries is viewed, shall we say, in a peculiar way, not in a European way.It's easy to find a video on the web about a whole factory of self-made supercars in Bangkok. These are ten times cheaper than the original. Now it is no longer working: apparently, the German journalists who filmed the video about the self-made people did them a disservice, and the local authorities started thinking about the missing licenses of the “craftsmen” and the safety of the cars they riveted. Of course, these crafts were not specially crash tested.

It is interesting that, in principle, the Thais could withstand supercars - they made space frames from metal profiles and pipes and “dressed” them in fiberglass bodies. In most cases, home-builders simply take old cars, cut off the "extra" body panels and hang their own. This technology is used, for example, this replica Bugatti Veyron from India. An ambitious project, right by the saying "to love - so the queen, to steal - so a million." The author and owner used an old Honda Civic as the basis. And he tried - outwardly, the copy turned out to be worthy: it's not for nothing that the audience is so attentively examining it.

Another Indian, former actor, current social reformer, concocted a parody of the Veyron from a Honda Accord. It turned out creepy. Another one took the Tata Nano as a basis. Let me remind you that this is officially the cheapest production car in the world with peculiar proportions. Very weak and slow. However, the author of this project is clearly not devoid of a sense of humor, because Veyron, on the contrary, is one of the most expensive, powerful and fastest production cars.Landfill Supercars

The Chinese do not lag behind their Thai and Indian colleagues. The young worker of the glass factory Chen Yanxi did not begin or parody someone else's design, but made his own, author's. And even though his car looks decent only from a distance, and it drives only 40 km / h (the installed electric motor no longer allows it), I don't want to laugh at Chen. Well done, that went his own way. More often it happens otherwise.

Three years ago, 26-year-old Chinese property manager Li Weilei was so impressed with Christopher Nolan's "The Dark Knight" Batmobile Tumbler that he built it. It took him and four friends 70,000 yuan (about $ 11,000) and only two months of work. Lee took the steel for the body from the landfill, shoveling 10 tons of metal. To offset the cost, he now rents out his Toggle Switch for photography and video filming, for just $ 10 a month. But renters must be ready to roll the replica manually. The car cannot drive, since it has neither power unit, no functional steering. In addition, in the PRC, only cars produced by certified manufacturers are released on the roads.

Another Chinese craftsman, Wang Jian from Jiangsu province, made his own "copy" of the Lamborghini Reventon from an old Nissan minivan and Volkswagen sedan Santana. And he also dragged metal from the landfill. I spent 60,000 yuan ($ 9.5 thousand) on this case. By the car carburetor engine, it smokes mercilessly, it lacks an interior and even glass, but the author himself likes the result, and the neighbors believe that Jian's car quite accurately copies the Lambo. The author claims that he is able to accelerate to 250 km / h on his supercar. Nobody risks reassuring him.

As you can see, most DIYers love to copy Ferrari and Lamborghini. Externally. Inside this car, designed by Mr. Meath from Thailand, stands motorcycle engine Lifan with a volume of a quarter liter.

The funniest and most touching creation is by the Chinese farmer Guo from Zhengzhou. He made a Lambo for ... his grandson. The car has children's dimensions - 900 by 1800 mm and an electric motor that allows it to accelerate to 40 km / h. A battery of five batteries lasts for 60 km. Guo spent $ 815 on his brainchild and six months of work.

A Vietnamese auto mechanic from Bakjiang province has created a kind of Rolls-Royce, using a "seven" for this. I bought it for 10 million dong (about $ 500). I spent another 20 million on "tuning". Most of the money went to metal, electrodes and a Rolls-Royce grille, ordered from a local workshop. It turned out rough. But the guy became famous. A real Rolls-Royce Phantom in Vietnam is worth about VND 30 billion.

Samavto-2017

In the vastness of the former USSR, the traditions of self-construction are also strong. In the Soviet years, there was a movement called "samavto", which united enthusiasts homemade cars and motorcycles. And there were a lot of them, because in those years it seemed that it was easier to assemble a car with your own hands than to buy - despite the total shortage of spare parts and bureaucratic obstacles. And what interesting projects were born in those years! JNA, Pangolina, Laura, Ichthyander and others ... Yes, there were people. However, they stayed.

Several years ago I wrote about the brainchild of a Muscovite Yevgeny Danilin called an SUV that resembles the Hummer H1, but significantly surpasses it in cross-country ability.

Immediately I remember my old acquaintance with Alexander Timashev from Bishkek. His workshop ZerDo Design in the 2000s created a whole series of interesting homemade products, the first of which was the "Barkhan", also a kind of Hammer based on the GAZ-66. Then there was the Mad Cabin, a type of American hot rod made from the cab of the ZIL-157 army truck - Zakhara. ...

The "Frenzied Cab" was followed by homemade products in retro style - the so-called replicars, speedster and phaeton. And for them, Kyrgyz craftsmen made not only bodies and interiors, but even frames.

Residents of the Moscow region have collected and put up for sale a unique home-made car. The prototype of the convertible was Mercedes Stirlitz, however, the craftsmen only found details from the Zhiguli. But ingenuity and golden hands helped.

As a real rarity, under a layer of dust this convertible will wait six months for warmth in the garage. And its designers and owners calculate the number of sunny days in the Moscow region during which the car will not be idle. The idea to create a car with an open body came about by accident.

The image from the cinema and the desire to have a convertible. Since modern convertibles cost crazy money, I had to make something out of the old that is pleasing and attractive to the eye and something that would be unusual for modern convertibles.

- Valery Zemisov.

The work went on for about seven years. Moreover, even now the car requires improvements: they decided to improve the gearbox. So there will be a big renovation in the coming winter.

Driving performance can be determined while rolling it out of the garage. The car is heavy, three of us have to push. And, perhaps, not too maneuverable. The designers were inspired by the fashion of the 30s of the last century. By the way, we went not as fast then as now. Therefore, the engine was installed here from an old Niva, which belonged to one of the designers.

When we checked in, we were surprised what kind of Mercedes it was, according to the documents it was a Zhiguli. When you go, many turn around, show "super"!

- Valery Zemisov.

The most unusual thing about the car is the fiberglass body. The inflated wings were cast in our own workshop. The rest of the details are from the entire global automotive industry, and something was even borrowed from yachts.

All this is homemade. Klaxons and these corrugations. The engine of the Niva stands, the chassis is from a Mercedes. Salon from Chrysler, something was done by hand. Decoratively made of wood, just like the awning itself was ordered

- Valery Zemisov.

As a result, the cost of the parts alone is more than a million rubles. It is impossible to calculate the time spent on work. Now the car is put up for sale for one million seven hundred thousand rubles. But social media users were skeptical about the idea of selling the original convertible. Since it does not represent any historical value. While the car occasionally leaves for weddings or photo shoots, and spends most of the time in the garage.

Cats took a fancy. Everyone likes it, including the cats. Cats climb, they love to crawl, to warm up, to walk on a soft

- Valery Zemisov.

However, the owners do not lose hope that there will be someone as enthusiastic as they are and will bring the project to perfection.

I bring to your attention a prefabricated wooden model of a retro car MG TC, from the British company MG Cars specializing in the production sports cars.

The work is difficult, but you should not be afraid of it. This wooden model of a retro car consists of 42 elements. Such a model will serve as a good interior decoration and will take its rightful place on your shelf.

1945 MG TC Roadster

Plywood car

In order to assemble such a retro car with your own hands, you will need the following tools and accessories:

Preparation of the workplace

As usual, the first thing you need to do is equip your workplace where you will work. The rules are not complicated: there should be no unnecessary things on the table, the entire tool should be in its place and be at hand. Not everyone has their own desktop and you probably already thought about creating it. Making a table is not difficult - it is more difficult to choose a place for it in the house. A good option- this is an insulated balcony on which you can start working on your craft at any time. If you have a specially equipped room with a workbench, then you are lucky. You can read about the preparation of the table in a separate article where I tried to describe in as much detail as possible the entire process of its creation. After you have completed the process of creating a workplace, you can proceed directly to your future crafts.

Plywood selection

Estimated dimensions of a car model made of plywood (10 cm x 26.5 cm x 10 cm.) The drawing is based on the A3 format, the parts can be fitted on two sheets of plywood 38x23 cm in size, the thickness of the plywood should be from 2.5 to 3 mm. Before transferring the drawing to plywood, sand the workpiece with a coarse sandpaper, and finish with a fine one. It is more convenient to sand with a wooden block wrapped in sandpaper. Sand the finished plywood along the layers, not across. A well-sanded surface should be even, perfectly smooth, glossy-matt in the light and silky to the touch. Pay attention to the location of the fibers, knots, dents and other defects. Quality and color.

Transferring the drawing to plywood

You need to translate the drawing accurately and accurately: fix the drawing with the buttons or just hold it with your left hand. Check if the drawing fits the dimensions. Arrange the individual parts so that you can use the plywood sheet as economically as possible. There is no need to rush, because your future craft depends on the drawing. To speed up the translation process, you can use the technique of fast translation of a drawing, for this I suggest that you familiarize yourself with the article: You can download a file with a drawing of a car from plywood at the end of the article.

Sawing a car with a jigsaw

There are many rules for cutting, but you need to be based on the most common ones. First, you should cut out the internal elements, then proceed to sawing out the contour. There is no need to rush when cutting. The main thing is to always keep the jigsaw straight at a 90 degree angle when cutting. Saw parts along precisely marked lines. The jigsaw must always move evenly up and down. Also, do not forget to monitor your posture. Try to avoid bevels and irregularities. If you get off the line while cutting, don't worry. Such bevels, irregularities can later be removed with a flat file or "Coarse-grained" skin.

Relaxation

We often get tired when sawing. Fingers and eyes, which are always tense, often get tired. During work, of course, everyone gets tired. In order to reduce the load, you need to do a couple of exercises. You can watch the exercises here. Do the exercises several times in the process.

Assembly diagram

Detailed assembly diagram:

Assembling the parts of the craft in this work is not very difficult, my son, 6 years old, was assembling a model of a retro car, with my tips and not much help. Such exercises develop fine motor skills of hands, imagination, imagination and patience is also trained.

After the parts are assembled into one common craft without any problems, then proceed to gluing them.

To make it more similar, you can add a few strokes in the form of lines using an electric burner. It can be very difficult to beautifully burn out a pattern, but there are not many lines here and it is quite simple to make them. First you need to draw lines with a pencil, then slowly go along these lines with an electric burner. You can read how to work with an electric burner and add patterns in a separate article.

Main types

Side view:

Back view:

Isometric:

Varnishing crafts

Collectible model a retro car, if you wish, you can varnish or paint, it is not necessary to do this, but it will give a lot of individuality to your craft. Try to choose a good quality varnish. Perform varnishing with a special brush, take your time. Try not to leave visible streaks of bubbles and lint from the brush.

Today we want to invite you to make an original gift for a man with your own hands - a retro car. The car can be used as an independent gift or filled with something - sweets, etc.

For work you will need:

- corrugated cardboard, any industrial box can be disassembled;

- corrugated paper - black and white;

- hot glue and a gun to it;

- twisted cord;

- screw caps;

- toothpicks;

- buttons;

- half beads;

- Styrofoam;

- jars from under shoe covers;

- thin plexiglass;

- a piece of mesh;

- acrylic paint as needed;

- every little thing that is at hand.

The main tools are a ruler, scissors, a stationery knife.

We take cardboard, cut out the bottom according to the specified dimensions.

We cut out two sidewalls, I didn't know how to describe the dimensions in more detail, I hope it's clear.

Where the outside will be, attach the covers where the wheels are supposed to be. Circle with a pen.

We glue all the details with white corrugation. if you wish, you can pre-paste over the cardboard with office paper so that it does not shine through. in the places where the lids were circled, it is also necessary to apply glue, it is not scary that it shines through. First you glue the outer part of the parts, then the inner part.

We glue the parts together.

I glued the sides from above to the bottom.

We cut out a detail from the cardboard, try it on, everything sits well. We paste over with corrugation.

Now let's take care of the hood, measure the height in this place.

And here it is necessary to measure. We put the height and length of the hood together and cut out one piece from the cardboard. IMPORTANT! Cut this part and the subsequent ones across the inner veins of the cardboard.

Now you need to make such an incision on the cardboard.

We try on, if the sizes do not match, we cut it.

We measure a piece of Styrofoam on the hood lid, cut out the desired piece and glue the Styrofoam to the cardboard. Foam thickness 2 cm.

Round off the angular edges of the foam on three sides.

Here's what you should get.

We glue the part with white corrugation and glue it to the car body. IMPORTANT: this and the following parts must be pasted across the folds on the corrugated paper.

Now we take on the trunk. We also cut a piece of cardboard across the veins. We measure the bottom of the trunk.

The top of the trunk and of course the height as measured by the hood. And the length is an arc. You can measure it with a ruler or use a tailor's centimeter - it doesn't matter. The difference can then be cut off.

Fit in, the height is the same. We remove the part and work with it further.

We begin to cut the cardboard between each vein about half of the part.

It is hard to explain further, I think from the photo it is clear that you need to try on the car body and finish cutting the cardboard into strips as shown in the photo. Turn the part over and make one notch on the back.

We glue the part with corrugation and glue it to the body.

Here's a crocodile turned out.

We trim the edges with a cord. In front we glue the loop, as in the photo, for the future bead.

We also glue the loop at the back.

If you wish, you can glue such a side, but you can do without it.

We leave the body and take up the wheels. You will need 8 caps and a black corrugation.

We fold the two covers in one direction to each other. One side of the wheel is concave, the other convex.

We apply the corrugation in this way and begin to pull on the edge of the covers.

We closed the paper, we also coat it with glue inside.

On the concave side of the wheel, we try to push the paper all the way, as in the photo.

If there are such holes in the middle, we glue it with a circle of corrugation.

And in this way we glue two small drops to the wheel. The distance between the needles is not important.

This is how it happened.

For the center of the wheel, I choose the buttons without legs. In extreme cases, the legs can be cut or broken.

We glue the buttons in the middle and surround everything with a cord.

I decided to glue more half-beads here.

Putting the wheels aside and grabbing the seats. We cut out 4 squares of 4.5 cm from the foam. The size may vary, it is better to try on in place, leaving a small gap. Foam thickness 1.5 cm.

We rounded the edges like this on three sides, glue it over with black corrugation and a cord.

We glue the seats in place first, then the backs.

We glue the finished wheels in place.

Now let's get to the wings. cut out two strips of cardboard about 45-47 cm long and 4 cm wide. And again across the veins on the cardboard.

I always try on the position of the wing by eye.

This is how it should turn out. Measure the width of the nut - 2 cm. Draw a line from the nut to the very end of the wing.

Cut off the unnecessary part. Here's what you should get. Along the edges 4 cm, nut - 2 cm.

We glue it with black corrugation, glue it to the body. You can pre-sketch with a simple pencil the places for gluing.

We glued the wings, edged them with a cord.

We take a piece of thin plexiglass. if this is not the case, you can use dense polyethylene, a plastic folder, etc.

We try it on to the hood, cut out the desired piece, and surround it with a cord.

We glue the parts like this.

Now to the car.

From these details I made a steering wheel - improvised means. I am showing it just as an example, not as a sample. It's hard for me to even describe them.

A ready-made steering wheel.

Cut the leg obliquely and measure it in place before gluing.

The lever was made from a piece of a wooden skewer and a tip from an umbrella needle.

We glue the parts into place, the lever between the seats fits well.

Let's move on to the face. I pasted the net and edged it with a cord.

It's the same on the hood.

On the trunk, you can decorate as you go, the main thing is that the composition does not interfere with the function of opening the trunk.

We simulate a door cord.

We cut out such a detail from cardboard, glue it over with a corrugation and glue it here.

Cut out one more detail to fit the printed license plate, slightly larger than the license plate.

We glue in place like this.

For rear bumper cut out about such a detail, the length and width are approximate as you like.

We try it on to the body under the rear wheels and cut it like this.

We glue it to the bottom like this.

We glue the same part with the number as in the front.

We take the jars from the shoe covers, open them, wrap the base with black corrugation, close the lid, paint the lid or select the lid to match the color of the car.

We glue the "headlights" into place. We insert a bead into a toothpick and glue it to the hood above the loop.

I made a klaxon out of these two parts, I also post the photo as an example.

She wrapped the ball with polysilicon, and the socket with a metallized corrugation, connected everything and glued it to the body. The door handle was imitated with a wooden bead. I cut it in half and glued the halves to the doors.

Well, that's it! Mechanical engineering is over! Now admire!