Chainsaw Friendship 4 was developed nearly 40 years ago. However, despite its considerable age, the legendary tool has practically not lost its popularity and today it is actively used by many experienced gardeners. And such a demand for a model is associated not only with its reliability, but also with the fact that its owner can make various homemade products from the Druzhba chainsaw, slightly altering its design and using several additional spare parts.

Chainsaw Friendship 2 - description and characteristics

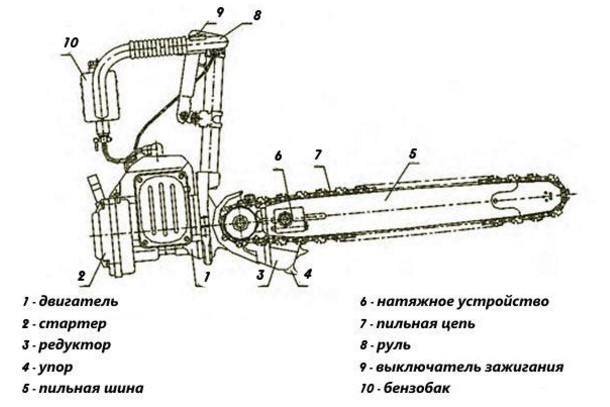

Immediately after its release, this model gained immense popularity among amateur and professional gardeners. It was based on a two-stroke single-cylinder engine capable of rotating at a speed of 3200 rpm and delivering a power of just over 3 liters. with. Compared to previous models, this chainsaw was equipped with a handle and a frame, holding on to which the owner did not burn on the hot engine.

The body of this saw was made of a durable metal alloy. The design also included a mechanical chain brake that would stop the chain on impact or break. Among the minuses, a large mass stands out - the saw weighs 12.7 kg. Specifications tools include:

- Manual saw start type;

- Lack of an automatic oil supply system for the chain;

- Oil tank capacity - 245 ml .;

- Lack of an electronic ignition system;

- Lack of a slewing gear;

- The bus is 45 cm long.

Quite good characteristics of the tool make it possible to improve it and independently turn a Soviet saw into various household equipment.

Chainsaw Friendship 4M Electron - features and design

This model is equipped with the same engine as the previous modification. Nevertheless, its power is already 4 "horses", and the torque is 5200 rpm. The motor is secured with a flange connection, secured with a clamp. Thanks to this, the motor can be removed at any time.

The cylinder of this model is made of durable and lightweight aluminum alloy, and the inner walls are chrome plated for increased wear resistance. The design of the tool includes a slewing gear, thanks to which the saw rotates 90 degrees for more convenient use. Among the advantages should be highlighted the presence of rubber gaskets damping vibration on the handles. Among other technical characteristics of chainsaws of this line, it is necessary to highlight:

- Improved saw starter;

- Fuel tank capacity - 1.5 liters;

- Tank capacity for chain lubrication - 245 ml .;

- The presence of an electronic ignition system;

- Bus 45 cm long;

- The proportion of gasoline and oil for refueling is 1 in 20.

Thanks to the reliable design and several modifications to the carburetor and other components, this model of the Druzhba chainsaw is regularly used today.

The high demand for Druzhba chainsaws is due to a large number of advantages. These include:

- Ability to work under high loads, while showing, at the same time, a fairly high performance;

- A simple device for chainsaws, which makes it possible with your own hands to quickly and permanently eliminate almost any breakdown;

- The presence of sufficiently comfortable high handles, which allows the operator to cut while standing;

- Reduced vibration level;

- Saw parts are located in places accessible to the operator;

- The chain is stationary at idle engine speed, and instantly set in motion when the throttle lever is pressed;

- The ability to use low-octane gasoline for refueling;

- Most models are equipped with an instant brake;

- The saw does not stall if the chain is blocked;

- Smooth and most accurate cut;

- Long service life - if you adhere to the maintenance rules and repair instructions, the tool can last about 25 years.

The only significant disadvantage of the equipment is its heavy weight.

Any of the Druzhba chainsaw models weighs at least 12 kg, which is why even trained specialists are forced to take short breaks.

Due to the simple design of domestic chainsaws, their repair and maintenance is quite simple to perform independently. The main thing is to carefully read the drawings and study the structure of the Druzhba chainsaw.

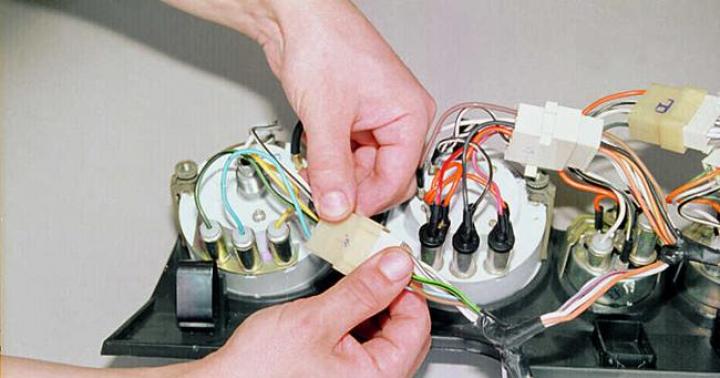

One of the most frequent malfunctions chainsaw lies in the fact that it starts and stalls - the reason for this lies in the increased sensitivity of the contact ignition system. It often fails due to the use of low-quality gasoline and oil. To avoid these problems, you should purchase saws with a non-contact electronic ignition... Moreover, parts for such a system are cheaper and much easier to find on sale.

If there is no spark on the Druzhba chainsaw, and the saw candles are constantly flooded with oil, then you will need to check the carburetor. To fix the problem, bend the gas valve inward to avoid further flooding of the saw plug.

It is also easy to adjust the carburetor of the Friendship chainsaw. To do this, the fuel screw will need to be tightened to the very end, and then loosened by 3 full turns. Then close the propeller completely and immediately back it off 2 full turns.

Many beginners do not know how to set the ignition on the Friendship chainsaw. The answer to this question should be sought not in the ignition system itself, but in the flywheel. In order for the saw to start and work properly, both the flywheel and the key must be "native", that is, the installation of elements from other equipment on the chainsaw is unacceptable. As for the ignition itself, there is no need to carry out any manipulations with it - the system is initially configured optimally from the tool manufacturing plant.

As is the case with other models of garden equipment, the use of a domestic chainsaw requires careful study of its operating instructions. She will give an idea about the features of the instrument and its capabilities.

The basis of most homemade products from the domestic chainsaw is its universal drive and ratio reducer. They can be used for the manufacture of various equipment that will be used for the purpose of cutting metal and stone, cleaning the territory, pumping water and for solving other problems.

The basis of most homemade products from the domestic chainsaw is its universal drive and ratio reducer. They can be used for the manufacture of various equipment that will be used for the purpose of cutting metal and stone, cleaning the territory, pumping water and for solving other problems.

It will be possible to realize the full potential of the chainsaw using various attachments and accessories. The basis of any home-made upgrades and alterations is the principle of motor power take-off: the device necessary for the owner is connected to the output shaft of the saw.

The power of the engine makes the applications of the motor practically unlimited. An important role is also played by the convenient design of the clutch, which protects the elements and assemblies of the tool from overload and breakage. Equipment made on the basis of a saw will be distinguished by its tightness, so that it can be operated in different positions.

Below we will consider the features of making simple and more complex devices that will significantly help in housekeeping. All of them are created on the basis of the legendary domestic chainsaw.

Simple homemade products - even a beginner can handle

Among the simplest in design equipment based on a chainsaw, a fairly large list of inventory can be distinguished. It includes:

- - it is based on a bearing assembly and a shaft. At one end of the device, you need to attach a driven pulley that rotates with V-belt... On the other side, a mandrel for cutting elements is attached. Such a tool can be used to cut metal, brick, stone and other building materials;

- - to make a device, a chainsaw motor and a gearbox with a gear ratio of 2 to 1 are attached to the boat. The design will also need to be supplemented with a propeller with blades, 21 cm in diameter.

- If the engine consumes 1 liter of fuel per hour of operation, the boat will move at a speed of 20 km / h;

- The winch from the Druzhba chainsaw - for its manufacture, the tool drive is taken. It is possible to increase the pulling force of the winch by using an additional unit with a separate drive.

- The finished device can be equipped with hooks, anchors and straps.

The simple design and manufacturing principle allows even a beginner to make the necessary equipment for the household.

More complex equipment - manufacturing principle

More experienced farmers who are perfectly familiar with the chainsaw can make more sophisticated equipment. This inventory includes:

- A sawmill from a tool is made using a metal frame. Further, the chainsaw itself is motionlessly attached to it. The workpieces are directed towards the rail. Another manufacturing option is to use an adapter that attaches to the base of the tire.

- You should also use the guide, which will correct the direction of movement of the installed adapter. The guide must be installed on the board fixed to the cutting log. Such a device will help to cut the log into several parts, spending a minimum of effort;

- Moped - an old bicycle is taken as its basis, to the frame of which a chainsaw motor is attached.

- The design of the moped also includes a gear train. If you used a mountain bike as a basis, then you will also need a gearbox to move on such a moped;

- A snowmobile with your own hands from a chainsaw Friendship - every more or less experienced owner of a chainsaw can assemble this unit. This requires a transmission system of two gears, through which the power of the motor will be transmitted to the skis.

- For a more stable operation of the technique, you will need to adjust the carburetor. If, for some reason, the unit does not start immediately after assembly, then the reason for this should be sought in the candle. Most likely, it will need to be replaced with a better quality part.

Domestic chainsaw and homemade products from it helped to save money on the purchase of household equipment for more than a dozen craftsmen. It is the ability to use the tool when creating various equipment, its power and reliability, that made the domestic chainsaw a truly universal working unit.

The mass production of the Druzhba chainsaw began in 1955 in Perm, and already in 1958, at an exhibition in Brussels, the product was awarded the Gold Medal. The saw was named "Friendship" in honor of the 300th anniversary of the reunification of Ukraine with Russia, which was celebrated in 1954, but some sources mention the joint development of Soviet and Chinese specialists, immortalized in the name.

Any saw you purchase from authorized dealer and got on Russian market official way, must have instructions in Russian. We strongly recommend that you familiarize yourself with it before you start using it. Before starting the chainsaw, it is imperative to install and adjust the saw headset (bar, chain and sprockets), otherwise the clutch will immediately fly off the saw.

Any new chainsaw (as well as a newly installed chain or bar) definitely needs to be processed. To do this, it is advisable to work with a chainsaw at low speeds for 40-45 minutes (this approximately corresponds to the use of a fuel tank), then turn off the engine and check the chain tension. Next, you need to make several cuts, applying weak efforts, and only then proceed to active operation. All this is done to ensure that the sprocket, bar and chain are well warmed up, and oil gets on all lubricated parts of the saw headset.

After the obligatory pre-start check and refueling with fuel and oil, the saw is ready for work, Next, you need to pull out the suction, completely remove the slack in the starting cable and start the tool with a strong jerk of the starter (with a sluggish tension, there is a high risk of flooding the spark plug, which will somewhat complicate subsequent start attempts). If done correctly, the saw starts the first time.

When purchasing a chainsaw, buyers often ask the question of whether it is necessary to put pressure on the chainsaw when cutting. First of all, it depends on the condition of the saw headset, and in particular the chain. When working with a blunt chain, the sawing efficiency drops significantly, and the need to apply force increases. In addition, in this case, the likelihood of a saw failure is higher, since the load on the engine increases. Therefore, with a professional approach to the process, it is recommended to regularly edit the chain (for example, at the end of the working day), and for home use, it is recommended to sharpen it after every 2-3 work sessions.

Be sure to pay attention to the features of the seasonal operation of the tool. If the saw is operating at low temperatures, then it is necessary to provide for the possibility of warming up the carburetor during operation. In addition, it is advisable to first warm up the saw (if it was stored in an unheated room) in order to avoid unwanted consequences due to the presence of condensation

Instructions

With your own hands

Chainsaw cutting system

Proper care of the cutting set is very important for a good one. A blunt chain must not be used, so it must be sharpened periodically. The need for this operation is monitored by outward appearance sawdust. If they are large and square, everything is fine. As soon as fine dust appears, it's time to sharpen the chain. To do this, you need two files - round and flat. It is ideal for this purpose to purchase a special sharpening device in which there is a guide - this will simplify the work. It is even better if you can clamp the tire in a vice. The sequence of actions is as follows:

Cut depth stops, which are located in front of the teeth, are sharpened with a flat file, remembering that the number of movements must be the same for each "cutter".

The cutting edge of each tooth is sharpened with a round file. The number of movements for each tooth should also be the same. Try to move the file strictly parallel to the edge. First, those teeth are sharpened, the edge of which is directed in one direction, then the rest. To remember where you started sharpening, mark it with a marker.

You can do it easier - give the chain for sharpening in metal repair, there is often a special device for this.

Timely sharpening and adjustment of the chain tension increases the safety of work, and also prevents the chain itself from sagging unnecessarily and damaging it. It is better to adjust the saw chain tension before starting work or on an already cooled saw. When heated, the chain lengthens, and when it cools, it shortens accordingly. If this is not taken into account, then the chain may be overtightened, which is fraught with failure of the cutting mechanism. To properly tension the saw chain, loosen the screws securing the side cover. Use a screwdriver to turn the tension screw and tighten the chain while slightly pulling and pulling it along the guide bar. It is advisable to use gloves in this case so as not to injure your hands on sharp teeth. A properly tensioned chain should not sag at the bottom of the bar, but at the same time, you should not use too much force when pulling it.

When finished, you should immediately loosen the saw chain, as it shrinks as it cools and can damage the tire, sprocket and engine bearings.

Before installing a new chain, you must clean the groove of the bar from sawdust and dirt. The presence of dirt in the groove interferes with the lubrication process of the chainsaw, because of this, the bar and chain will overheat during operation. Be sure to check and clean the oil supply hole on the tire. Litol is suitable as a lubricant. If there is no special hole for lubrication, "Litol" is applied directly to the end of the tire. Before starting to work with a new chain, be sure to put it in an oil bath. Pay close attention to the tension of the new chain. Pull it up in the first hour of work as needed. Do not allow the chain to sag during operation.

The chain tension is usually controlled in this way: put the saw on a flat surface, grasp the link located in the center of the bar from above with your hand, and pull it up. The chain should come out of the groove by 3-5 mm.

A chainsaw with a well-sharpened and correctly tensioned saw chain cuts itself, under its own weight. You cannot put additional pressure on her! Remember that sometimes it is more expensive than itself.

Flip the tire periodically to ensure even wear on both sides. The tire wears out on average three times slower than the chain, therefore it is customary to use 2-3 chains when working with one bus and a leading sprocket. When all three chains are worn out, replace the entire saw / bar, drive sprocket, chains /.

The quality of your chainsaw is primarily determined by the saw chain, guide bar and drive sprocket. When carrying out sawing work, they all act as a single saw unit and therefore must be serviced as a single unit. With proper use and maintenance of the saw unit (chain, bar and drive sprocket), it is he who will provide best result sawing. In any chainsaw, it is not the engine that cuts, it is the saw machine that cuts.

In this article, we will only talk about one part of the saw unit - the saw chain. Oregon founder Joseph Cox is the inventor of the modern saw chain from various manufacturers around the world. The history of the invention of the modern saw chain says that more than 50 years ago, the American lumberjack Joe Cox, while resting during a break from work, drew attention to the larva of a bark beetle, with extraordinary ease making its way into the solid. The C-shaped shape of the jaws of the bark beetle larva, which allows it to easily gnaw its way both along and across the wood fibers, prompted him a way to solve the problem - to create a saw chain that allows cutting wood with greater productivity and with a more convenient sharpening. And this idea, the very fact of the similarity of the bark beetle's jaws to hooks, he transferred to metal and invented the first hook saw chain. During the production of chains, they were constantly improved. Particular attention was paid, both then and now, to increasing the productivity of the chains, increasing the service life and the grinding period. Saw chains from Oregon have been and remain the benchmark for all other saw chain manufacturers. About 90% of all chainsaw and electric saw manufacturers worldwide use an Oregon chain. So, let's dwell on the basic rules, the implementation of which will allow you to feel the joy of superiority over wood of any hardness when sawing it.

Repair

Starting the engine with separate controls

Cold start:

- pull out the choke lever until it stops (the choke valve is fully closed);

d. move the choke lever to the middle position (the choke valve is open, the high idle position remains on);

- repeat the start-up procedure;

After starting the engine, immediately squeeze and release the throttle trigger - the choke lever automatically moves to the operating position (normal travel).

Starting a warm engine:

- turn the switch to position I (on);

- Pull the choke lever to failure, then move it to the middle position (increased idle speed), or leave it in the normal idle position without touching it;

- when the choke lever is in the high idle position after starting the engine, press and release the throttle trigger;

Stop the engine by moving the switch to position 0 (off).

Starting the engine with combined controls

Cold start:

- while pressing the throttle trigger locking lever, move the air damper control shaft to position III (lowest position), in this case the air damper is completely closed;

- pull the starter cord handle several times until the first flash of fuel in the engine;

- move the control shaft to the middle position II (the air damper is open, the high idle position remains);

- repeat the procedure for starting the engine;

After starting the engine, press and release the throttle trigger; in this case, the control shaft automatically switches to operating position I (normal idling).

Starting a warm engine:

- transfer the control shaft to position I (normal idling mode), or position II (high idling mode);

- carry out the procedure for starting the engine;

- when the control shaft is in the high idle position after starting the engine, press and release the throttle trigger;

The engine should be stopped by setting the control shaft to the uppermost position (position 0).

Attention:

When starting the engine, always select the free play of the starter cord before connecting the winding mechanism to the engine flywheel. The starter handle, extended to the limit, must not be abruptly released.

Risk of damage to components in the starter group.

Remember to check the position of the overrun brake before each start and during operation. The inertia brake must be engaged (the brake lever must be pulled towards the front handle until it clicks).

When the inertial brake is off, the chain on the bar is pulled freely by hand (this operation can only be carried out with work gloves). When the chainsaw is operating with the inertial brake on, the chainsaw body melts in the clutch area and the chainsaw may catch fire. The repairs required in this case will be recognized as non-warranty and will be made only at the expense of the client.

Installing the saw head:

the axis is symmetrical, therefore, it is recommended to periodically turn it over during operation. When installing the chain, make sure that the cutting edge of the tooth points forward.

Attention:

When installing the bar, make sure that the chain tension pin is in the access hole on the bar - there is a risk of damage to the bar cover.

Correct chain tension:

The chain from the bottom adheres tightly to the tire without sagging, from the top in the middle of the tire it freely extends to the height of the link.

Attention:

All carburetor settings affecting the quality of the fuel mixture (screws "L" and "H") must be made at a service center using an electronic engine rev counter - risk of engine damage. The consumer can use only the idle screw, located slightly away from the screws "L" and "H". Its purpose - the saw works on Idling, the chain is not scrolled.

Before long-term storage of the chainsaw, drain the fuel mixture from the tank, start the engine, thus removing the remaining fuel from the carburetor. We hope that the gasoline-powered tool you have purchased will serve you for many years and you will enjoy working with it.

Specifications:

Chainsaw class: household

Engine type: 2-stroke. petrol

Bus length: 45 cm.

Working volume: 45 cm cube.

Motor power: 2.6 kW

Chain pitch: 1.5 / 0.325 inch

Fuel type: Gasoline (A-92) + oil for two-stroke engines

Start type: Manual Fuel tank capacity: 520 ml

Oil tank volume: 260 ml

Chain lubrication: automatic

Weight: 4.5 kg

Warranty: 12 months

Before choosing a chainsaw, you need to have a clear idea of what tasks you will perform with it. To use the tool in logging plans and if the operation will be daily for 6 - 8 hours, in this case you need a professional chainsaw. If the saw will be used only in the country: cut down a few trees, prepare firewood, a regular version of a household chainsaw will do.

That is, the type of tool chosen will depend on the workload during the day, the frequency of use and the amount of work. The professional chainsaw is designed for continuous use and continuous use. This class of saws is usually equipped with an anti-vibration mechanism that makes work easier. The semi-professional version is not intended for continuous work and can withstand 2 - 3 hours of continuous sawing, and it also does not have an additional vibration damping device.

Another type of chainsaws, these are amateur ones, do not have power, but they are the most demanded consumers, this saw is quite capable of satisfying all household needs that arise.

For the manufacture of this type of tool, high-strength, wear-resistant and reliable materials are used. As in all gasoline tools, the main and important unit is the engine, as well as the handle and the tire with the cutting head. Saw-mounted two-stroke gasoline engine with air cooled, uses a gasoline-oil mixture for power supply in the proportion as indicated in the attached instructions. Separately installed chain lubrication reservoir. Cutting speed and performance depend on the volume and power of the motor.

For a long, confident operation of the saw, you need to use only lubricants intended for this brand and timely service the tool. Make sure that there is oil in the chain reservoir and do not run the saw without lubrication, this can lead to overheating and destruction of the bar.

When buying a chainsaw, you should pay attention to the condition of the chain and headset. Timely need to sharpen the chain, with a dull chain you are guaranteed poor performance, and cutting speed, it can also lead to saw failure. After developing your motor resource, you can always spend overhaul, clean, replace worn parts and the chainsaw is ready for use again.

Chainsaw operation begins with the installation of tires and a chain, information on which can be found in. After a short period of time, the saw bar is turned so that the bottom becomes the top, and vice versa. This is necessary for even wear, as the bottom wears out faster. The chain of a gasoline saw should be placed in one direction only (drawing on the cover), since the movement of the chain during cutting goes from top to bottom. Then the casing is installed.

Petrol chain saw STIGA SP400 18 "After installing the guard, tighten the chain clockwise with a wrench. The chain of the chainsaw should not sag, but also not be very tight (about half the height of the tooth can be pulled back). Then the nuts on the casing are attracted. During operation, the chain must be tightened.

Modern chainsaws are equipped with a handle - a brake. The brake must be disengaged (handle towards you). It works automatically (if any emergency situation is created) or at the will of the person operating the chainsaw. If the brake is triggered, you must immediately throw the throttle stick, otherwise you can burn the clutch.

Chainsaws have two tanks. One tank is located closer to the bar for the oil that lubricates the chain. It is better to fill in multigrade oils until the tank is full. The second tank of the chainsaw is intended for a fuel mixture consisting of A-92 or A-95 high-octane gasoline and branded oil at the rate of 20-25 grams of oil per 1 liter of gasoline. Do not mix a lot of the fuel mixture, as the mixture becomes unusable after two weeks. If the mixture remains in the tank, and you do not have to use the tool in the next couple of weeks, then the mixture should be drained, and the saw should be started and allowed to stall by itself after the fuel runs out. This is necessary for the carburetor to be stored dry.

There are two types of starting the chainsaw - cold and hot. What is the difference and why these two types of winding are needed, is indicated in the instruction manual. The first 5 liters of fuel must be discharged in a gentle mode - let the saw cool down after every 10 - 15 minutes of operation. do not require. Sawing is carried out only with full throttle!

Approximately once per hour of operation of the chainsaw, it is necessary to correct the cutting teeth with a template that is included in the delivery (2-3 movements from you).

After finishing the work of the chain saw, it should be thoroughly cleaned air filter(it is located under the top cover). It is necessary to wash the air filter with soapy water and a sponge and dry it.

After finishing the work of the chainsaw, the chain must be loosened or removed, since when it cools it will begin to narrow and may stretch. Better to get two chains and work them one at a time.

After the time specified in the instructions, grease the bearing with high speed grease.

After 5 liters of fuel have been spent on the chainsaw, it is recommended to take the saw to a service center for additional adjustment high revs tool. Usually, this rather simple procedure is performed completely free of charge in service centers and therefore there is no point in neglecting her.

Engine MP-1 designed by ZMKB "Progress" them. Academician A. G. Ivchenko - single-cylinder, two-stroke, carburetor, air-cooled, displacement 94 cm3, power 4 hp. Engine lubrication - oil mixed with gasoline. The motor and the saw unit are made in the form of independent units and are connected to each other using a flange connection, which is fixed with a clamp (which is attached to the saw handles). This arrangement allows you to rotate the saw unit at any angle, and if necessary, quickly replace the failed unit. Due to its functional completeness and ease of attachment, the Druzhba engine was used to drive (Kumir, Sadovod), water pumps (Skif, TsBN-1, TsBN-2, PMP-4), DC generators (GZ- 106A) for charging storage batteries in the field, mechanical winches for forest skidding, in the Kama boat motor, in lawn mowers. This engine was also popular with DIY enthusiasts. In the 60s, attempts were made at the Moscow Aviation Institute to boost this engine and install it on ultralight aircraft. Light helicopters X-3, X-4, X-5 were manufactured, on each of which propeller-driven units of 4 Druzhba engines were installed, operating through a common gearbox on the main rotor. None of the vehicles passed flight tests due to the low reliability of the engines.

Modifications

Over the years of production, the general design of the saw remained the same, however, minor changes were made:

in the 50s - 60s, a modification of the "Friendship" was produced with the attachment of the handles to the fan cover, later the handles were attached to the clamp connecting the engine and the gearbox.

until the end of the 80s, the Druzhba-4A model was produced with a contact magneto and a KMP-100 carburetor - discontinued;

in the late 80s, electronic ignition was used (from the contactless magneto MB-1), the saw received the designation "Friendship-4A-Electron";

in the 90s, a more advanced KMP-100U carburetor was used, the saw received the designation "Druzhba-4M" (manufactured by ZiD) and "Druzhba-Altai" (manufactured by Sibpribormash), saw chains of a modern type were used.

On the basis of the Druzhba saw, a more powerful Ural saw was developed.

On the basis of the Druzhba chainsaw engine, the SD-60 engine was developed to drive stationary installations (generators, pumps), which differed from the prototype with a cast-iron cylinder liner, a float carburetor, a fixed rope starter and a speed regulator.

Advice

Chainsaw repair friendship.

The "Friendship" chainsaw has several standard breakdowns that can be eliminated even by yourself, without asking for help from the master. Such breakdowns include contact ignition and carburetor adjustment. In most cases, you can do it yourself.

At Druzhba, contact ignition is very sensitive to various oils and brands of gasoline. This causes many problems and troubles for many owners of this technique. Pin elements cannot be repaired. If your chainsaw has an old contact ignition, then it is better to replace it with an electric ignition. It does not require adjustment, and therefore reduces the cost of maintaining "Friendship".

When the candles in a chainsaw get wet, you should pay attention to the carburetor - it means that it is overflowing. This problem can be eliminated by slightly bending the petrol valve inward. In this case, the amount of fuel entering the combustion chamber will be significantly limited, and there will be no overflow to the candles.

You need to learn how to regulate "Friendship" yourself, without turning to the master every time. To do this, we carry out a sequence of actions: tighten the fuel screw all the way, unscrew it exactly three turns; Screw in the propeller as far as it will go and loosen it two turns. Most likely, you will need to seal the connection between the carburetor and the cylinder so that there is no "suction" of air, because its appearance can cause the saw to become inoperative. The adapter can be wrapped with a strip of thin sheet metal or sealed with sealant.

And in general, all connections must be airtight - this is the key to long and high-quality work.

All connections must be airtight, because this is the guarantee of the quality work of "Druzhba".

With your own hands

Sawmill from a chainsaw.

Before using any imported chainsaw, it is required to carry out its preliminary running-in. On the one hand, it is needed to extend the life of the engine, because the moving parts during the running-in period must first run in to each other. In addition, during the break-in period, you will be able to acquire certain skills in working with a gas-powered saw. This is important for those users who first read the instruction manual for the Makita chainsaw, friendship, Ural, calm and work with a chainsaw.

The chainsaw must be run in with a minimum load on the engine in a cyclic operation mode: sawing lasts 1-1.5 minutes, then idling for 15-20 seconds. The motor will acquire maximum power after ten full tank fillings have been used up. The engine must not be run in at idle, because the formation of a large amount of carbon deposits provokes piston rings or spark plug failure.

SpecificationsChainsaw "Friendship" - one of the oldest models, which has more than half a century of history. It was developed in 1953, and in 1955 its mass production began at once at two enterprises in Perm and Biysk. The chainsaw won the gold medal at the Brussels Technical Exhibition in 1958.

From the beginning of the 90s, private enterprises began to produce the saw and spare parts for it. The saw got its name in the year of the celebration of the reunification of Russia with Ukraine in 1954. Despite its long history, the technical characteristics of the friendship chainsaw remain acceptable to many consumers.

The chainsaw is equipped with an air-cooled, single-cylinder, carburetor, two-stroke MP-1 engine with a working volume of 94 cubic meters. see The digital value in the name of the chainsaw means horsepower: "Friendship 4" means the power of the chainsaw engine - 4 liters. pp., "Friendship 4E" has an engine with electronic ignition. The engine is lubricated with oil mixed with gasoline. Independent attachment to the flange connection of the power unit and the engine made it possible to position the saw unit both horizontally and vertically. Replacing any unit due to the separate fastening is not a big deal.

It is from the Druzhba chainsaw that the technology of automatic saw chain lubrication originates, which significantly increases the service life of the chain and guide bar, which are universal. This allows the use of saw chains with different pitches, in case of replacement of the guide sprockets and the tactics of the damper device. The saw has an inertial clutch that drives the chain by increasing the engine speed. If you bite the chain or overload the saw, the motor will not stall. satisfy the needs of consumers so much that millions of people have preferred it for many decades.

The weight of the saw, without consumables, is 12 kg. The chainsaw, in the presence of work at low speeds, allows you to use any oil. The engine is capable of "consuming" fuel with a low octane number. The saw is also equipped with an emergency brake for stopping in case of emergency. The Druzhba chainsaw manual contains a complete description, with possible problems that have arisen and how to fix them.

In some European countries, the name of the saw "Friendship" has become a household name. This is the name of any chainsaw. And the two-handed saw in the common people began to be called "Friendship - 2", because of the participation of two people in the process. In addition, the high position of the controls allows the operator to cut in a "standing" position, while, as with modern saws, the normal working position of the operator is the "kneeling" position. The service life of the saw is, on average, 15 - 30 years. The main purpose of the chainsaw: felling wood, crosscutting trees, sawing and harvesting firewood.

Preparation for work.

First, check the chainsaw for chain tension, which should be adjusted, chain slack is unacceptable. Poor chain tension can wear out the tire and sprocket faster than expected, greatly increase the load on the chain saw body and disable the shock absorbers ahead of time.

The chainsaw chain should not touch solid objects, apply the chain brake, move the brake lever away from you so that the chain does not rotate ahead of time. Pull out the throttle control lever, this can be done when the engine is cold. Insert the toe into the back handle. Pull out the starter cord by tugging on the handle until the saw sneezes.

After that, start the chainsaw and move the choke to the working position. Click on the gas and put the chainsaw at idle speed. Pull the brake lever towards you to return to its original position. The chainsaw is now ready for use!

Check the tool brake before starting work. The next step is to set the saw on a flat and solid surface and press the throttle. Do not let go of the chain saw handle, push down on the handle and apply the brake. The brake will be considered OK when the chainsaw is stopped.

Before starting the chainsaw, be sure to check for the presence of chain oil in the tank. If there is no lubrication at high speed, problems with the chain and bar may appear. You can check the presence of grease during operation. When the chainsaw is running at high speeds, it is necessary to direct the tire onto clean paper. If the lubricant flows normally, a strip of oil will be visible on the sheet.

How to cut down trees

Just before felling a tree, read other chainsaws and determine where it will fall. Look at the number of branches, and where the main ones are facing, it is worth considering the direction of the wind and the natural inclination of the trunk. It is necessary to knock down the trunk in the direction where it is more convenient for it to fall. Cut the lower branches of the tree just before felling.

Depending on the thickness of the tree and other features, several methods of felling a tree are distinguished, the most optimal solution is selected only by professional lumberjacks. Before felling a tree, make sure it doesn't damage anything after it falls.

Stand from the trunk of the fallen tree to the left, cut off the branches from it, move from the bottom of the trunk. Try not to use the bow of the chainsaw, work slowly. Lean the chainsaw against your hip or tree trunk and use all parts of the bar for sawing. Lay the petrol saw on one side, with all your weight on the trunk, cut off branches from the top of the trunk. When the branches are cut from the top and sides, the trunk can be turned over and the remaining one can be sawed off.

At the same time, remember that at a certain position of the tree, which rests on one branch, the trunk may move or roll when it is cut. For thick and large branches, it is necessary to saw off in parts, moving from its end. If the branch is too thick, it may need to be filed from several sides.

When you have cut off all the branches from the trunk, you can start sawing the trunk - bucking it. Bucking must be started from the trunk to the top. If the trunk is located on an inclined plane, then when bucking, do not stand below the tree trunk. If the gasoline saw is stuck in the barrel, then it must be removed immediately. Stop the engine and tilt the barrel until you can remove the chainsaw.

Chainsaw care

Power saws should be kept under a shed or in open areas. Before storing the tool, it must be cleaned of sawdust and dirt, the fuel must be drained from the tank, the saw chain must be removed and put into oil. Open areas that are subject to corrosion must be lubricated with a layer of oil. The chainsaw must be preserved for long-term storage.

After working with a gas-powered saw, you must do the following:

Check chain saw tension and lubrication. If you run out of oil, you need to add it to the tank and tighten the chain if it is loose. Let the tool rest and cool down a bit, then fill the saw with gasoline.

Do not forget to check the air filter, which can become clogged with shavings and sawdust during operation. Therefore, it must be removed, purged and rinsed in time. If necessary, it is worth cleaning the filter from dirt.

After every hour when the chainsaw was running, you need to lubricate the driven tire sprocket and immerse it in heated oil.

After 25 hours of operation, dust must be removed from the cylinder windows, combustion chamber, piston grooves, rings and piston crown.

Engine starting

It is necessary to carefully read the instructions for using the stihl chainsaw, friendship, calm, ural, especially the sections that relate to starting a cold and hot engine. The principle of starting the engine is the same in all saws. Differences are only in the placement of the petrol saw controls - the choke lever and the STOP button.

With separate controls

It is necessary to start a cold engine in this way:

turn the switch to the "on" position;

pull out the choke lever all the way;

move the choke lever to the middle position (the choke is open, the increased idle position remains on);

repeat the starting procedure;

after starting the engine, press immediately and release the throttle trigger - the choke lever will automatically move to the operating position.

You need to start a warm engine like this:

turn the switch to the "on" position;

pull out the choke lever until it stops, then move it to the middle position, or do not touch it and leave it in the traditional idle position;

perform the procedure for starting the engine;

when in the position of increased idle speed of the choke lever after starting the engine, press the gas trigger and release it;

the engine can be stopped by turning the switch to position 0 (off).

With combined controls

You can start a cold engine in the following sequence:

simultaneously press the throttle trigger and move the choke control shaft to the lowest position, in this case the air damper is completely closed;

pull the starter cord handle several times until the first flash of fuel in the engine;

move the control shaft to the middle position;

repeat the procedure for starting the engine;

after starting the engine, press and release the throttle trigger, the control shaft in this case will automatically move to operating position I.

Starting a warmed-up engine in accordance with the operating instructions for the chainsaw calm and any other gasoline-powered tool is carried out as follows:

move the control shaft to the normal idle position;

start the engine;

press and release the throttle trigger while the shaft is in the extended idle position.

Safe work rules

It is strictly forbidden to work with an unregulated and faulty petrol saw.

When starting the engine, do not wind the cable around your hand.

When starting the engine, the chain should not touch any objects.

To avoid damage to the chainsaw and accidents when felling a tree, do not cut through the tree. You should leave 3-4 centimeters of the hinge.

Turn off the chain when moving from one tree to another.

Work on installing the chainsaw chain and adjusting its tension level with the engine off, wearing a protective helmet and gloves.

After refueling the saw with oil and fuel, carefully remove oil and fuel residues from its surface, wipe it dry.

It is forbidden to cut down a tree over which another hangs, as well as to cut down heavily overhanging or inclined trees in view of the danger of such an operation for the lives of the sawers.

When felling a tree, only the sawer and his assistant can remain at the chainsaw, other people should be at least 50 meters away from the working tool. The assistant warns the sawer with a voice or signal that the tree is about to fall.

Before the end of the sawing, the sawer and an assistant must carefully monitor the direction of the fall of the tree, moving quickly to the side with the saw, but not against the butt of the tree.

Crossings through the moving chain are prohibited. If you run away or break the chain, immediately release the gas and turn off the engine. The saw chain may only be put on the bar when the engine is not running.

When refueling the gasoline saw according to the operating instructions for the huskvarna chainsaw, goodluck, ural, calm and others, do not smoke.

It is strictly forbidden to refuel the chainsaw at a distance of less than 20 meters from an open flame.

The carburetor should be adjusted to ensure the least contamination of the exhaust gas inhalation zone and stable idle speed of the engine, in which the saw chain does not move along the tire.

When carrying it over a long distance, the engine of the chain saw should be turned off and tightly covered with a special cover.

Felling of trees using a petrol-powered saw must be done exclusively in a prepared cutting area, where dangerous hanging and dead trees have been removed.

Prices / Order

Firms

The choice of a benopila is both simple and complex at the same time. That is why the answer to the question of which chainsaw to choose cannot have a definite answer. In order to choose a reliable chainsaw, you need to take into account such factors as the types of work for which it is intended, the time during which you are going to work and even the complexion of the person (or people) who will work with this tool. Despite the variety of models and manufacturers producing chainsaws, we will try to tell you which chainsaw is best to buy in each specific case.

The choice of a chainsaw depending on the class.

Before figuring out which chainsaw is better, clearly define what you are going to use this tool for, since the cost of a chainsaw is primarily determined by its power and ability to work more or less long - that is, from the class of the chainsaw.

Is the best choice of chainsaw for summer cottages. They work with such a chainsaw from time to time and for a short time. With such a saw, you will find a minimum of functionality, however, with the help of such a saw, you can cut enough firewood in order to cook kebabs or start a fire in the fireplace.

It is assumed that a household chainsaw is used by its owner no longer than 40 minutes a day. The resource of such a chainsaw is from 400 to 1000 hours. But the townspeople who are not accustomed to loads will like their relatively compact size and low weight. These qualities compensate for the low power of a household chainsaw. Choosing a household saw, you will get a reliable assistant for various simple tasks around the house and garden.

The best models in this class are chainsaws: Stihl MS 180; Husqvarna 235 X-TORQ; Echo CS 350WES

Semi-professional chainsaws - if you intend to perform more complex work or use a chainsaw in the construction or expansion of a house, then when deciding which brand of chainsaw to choose, opt for semi-professional models of chainsaws.

These tools should not be used for an entire working day without stopping, but they are capable of more than their household counterparts. They are capable of logging in the volume of one household. Sometimes professionals also use such saws - for example, when pruning knots in felling sites.

You can choose a semi-professional chainsaw on our website among the models: Stihl MS 250; Stihl MS 270; Echo CS-4200ES; Echo CS-5100 ES

Professional chainsaws are a tool for lumberjacks. They are powerful, reliable and can work for years for 8 hours a day without interruption. In order to provide a long working resource - 1300 - 2000 hours - the best chainsaws are made of durable and wear-resistant materials, which provides them with a longer "run" without major repairs.

Choosing a chainsaw depending on the availability of service

No matter how reliable your chainsaw is, you need to remember that sooner or later any tool needs maintenance or repair. Therefore, when answering the question of which chainsaw to choose, it is imperative to take into account - is there a branded service center in the place where you live.

The easiest way is to choose a chainsaw, focusing on whether there is an instruction in Russian in the package. This guarantees that the delivery of the tool was "white" and that all the manufacturer's warranties apply to the purchased chainsaw, and it is also possible to use the services of a service center.

In addition to repairs and maintenance, the chainsaw needs to “correct” the chain from time to time. It is on the state of the chain that the working qualities of the chainsaw depend. A professional tool is often edited on a weekly basis.

Choosing a chainsaw depending on power and weight.

These two technical characteristics of a chainsaw are closely interconnected. That is, the increase in power entails a simultaneous increase in mass. You need to understand that for a household chainsaw, great power is not an important selection criterion. Reliability and light weight are more important to the layman. You can simply not cope with a powerful pilof.

For professional chainsaws, the range of capacities is quite large, since the choice of a chainsaw in this case depends on the type of work and even for the season. For example, there are chainsaws, the design of which allows one-handed operation.

Additional options when choosing a chainsaw.

Nice "little things" like an anti-vibration system are necessary for those who hold a chainsaw in their hands for a long time. For the proper service of chainsaws, it is important that the chainsaw has an air filter to protect it from dust contamination.

It is especially important that the chainsaw is equipped with a reliable brake - after all, this is one of the most dangerous tools.

The length of the saw bar must be consistent with the power of the saw; it is not necessary to install bars larger than the length indicated in the passport.