Carburetor k 151: device, repair, adjustment

Fuel consumption directly depends on the state of the fuel system, and if there are malfunctions in it, the dynamics of the car also deteriorates, the engine starts to work unstable.

This article will consider the K151 carburetor: device, repair, adjustment, tuning features, as well as the main problems and their symptoms.

Carburetor device K-151

V fuel system the carburetor of the K-151 model performs the function of preparing the air-fuel mixture in the composition necessary for operation car engine at various loads - at idle, at medium or maximum speed. This knot applies to passenger cars"Volga", IZH, on commercial vehicles "Gazelle", "Sobol", off-road vehicles UAZ. There are various modifications of "one hundred and fifty-first", and depending on its model, a letter is added to the name at the end, for example, the GAZ-3102/31029 and GAZ-3302 Gazelle cars are equipped with the K-151S carburetor. Also, depending on the K-151 model, the jets can be installed in different sections - much depends on the characteristics and volume of the engine.

The 151 series carburetor consists of the following systems and elements:

- main body (middle part) with a float chamber;

- corps throttle valves- the dampers are rotated due to the drive associated with the accelerator (gas) pedal;

- the upper cover of the float chamber - it contains a locking mechanism that does not allow the chamber to overflow with gasoline, as well as an air damper necessary to start a cold engine and warm it up;

- the main metering system - is the main one in the preparation of the fuel-air mixture (FA), consists of channels of a certain section, two fuel and two air jets;

- systems idle move, which is necessary for stable ICE operation on idle- it includes a bypass channel, adjusting screws (quality and quantity of fuel assemblies), jets (fuel and air), economizer valve with a membrane mechanism;

- accelerator pump - it allows the car to drive without failures with sharp acceleration, consists of additional channels in the main body, a ball valve, a membrane mechanism and a fuel atomizer;

- econostat - the system is designed to enrich fuel assemblies at high engine speeds; it is an additional channel through which an additional portion of fuel enters the intake manifold under the influence of a large vacuum with open throttle valves;

- transition system - it is needed for a smooth increase in speed at the moment the throttle valve starts to open in the secondary chamber; it consists of fuel and air jets.

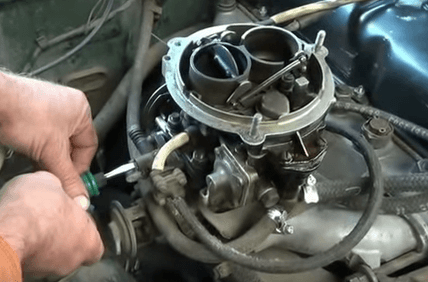

The K-151 carburetor consists of two chambers, the throttle valves in it open sequentially, a filter is installed at the inlet in the fitting - a protective mesh. The unit is also equipped with a return fuel line, through which excess gasoline is discharged back into the gas tank; also, the “return” does not allow creating excessive fuel pressure. The device of the K-151 carburetor itself is quite complicated, and in order to repair and adjust the unit, experience is needed, strict adherence to the repair instructions.

Connecting hoses to the carburetor

Several hoses of two diameters are connected to the K-151 carburetor - if they are mixed up, the engine will not work properly. Connect the hoses in the following order:

Adjusting the carburetor K-151

If, without experience, it is quite difficult for car owners to repair the K-151 unit with their own hands, then it is easier to master the adjustment, the main thing is to understand the principle of operation of the device and follow the instructions. In total, there are several types of adjustments "one hundred and fifty-first":

- idle move;

- air damper position;

- the level of gasoline in the float chamber;

- throttle position.

You should trust experienced carburetors to change the fuel level in the float chamber, but any driver can adjust the idle speed independently. We carry out the procedure as follows:

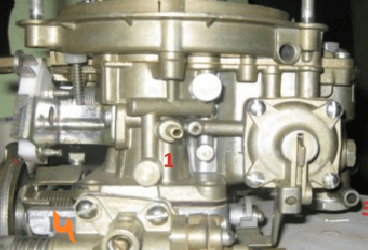

If the engine speed is increased, it should be reduced using the screw that adjusts the position of the throttle valves. This screw often boils tightly, and it is impossible to turn it in any direction (in the figure below under the number 4, under white paint).

There is one "tricky" way that makes the adjusting element turn - you need to install a flat screwdriver in its slot and gently hit it several times with a hammer (you need to feel the effort, otherwise you can break parts of the carburetor). The screw will "come off" and begin to rotate on the thread. If the "trick" is not successful the first time, it should be repeated. It is important not to rush and be patient, then everything will work out.

Carburetor repair K-151

During the operation of the car, various malfunctions may occur in the carburetor, the main signs of failures in this device:

- increased fuel consumption;

- black smoke from the muffler pipe, it is especially noticeable if you press the gas pedal sharply;

- unstable operation at idle, the engine may also stall on deceleration;

- poor vehicle dynamics;

- dips when picking up speed.

With a faulty carburetor, the engine may not develop speed, and pops and shots in the muffler are often heard in the intake manifold. K-151 is a rather complex unit, and almost any element of it can fail.

There are reasons why the carburetor most often fails:

- jets, fuel and air channels are clogged;

- heating deforms the body;

- the stop valve of the float chamber stops working;

- jets wear out over time.

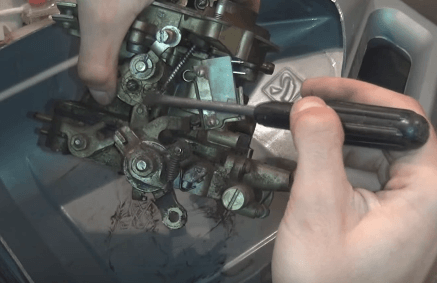

Many repairmen, restoring the carburetor's performance, first of all strive to replace the jets, believing that because of them fuel consumption increases, the engine is unstable. One rather important note is that the jets are very rarely worn, and most often wear occurs when the carburetor is often operated in dusty conditions. The most common reason for poor carburetor performance is clogging, but to clean the unit well, you need to completely disassemble it. Repair of the K-151 carburetor is carried out with the removal of the device, full flushing and purging of all its parts.

Problems with the carburetor when installing gas equipment

Often cars with carburetor engines car owners switch to gas, for example, it is profitable to put LPG equipment on a working Gazelle. But with the constant use of gas in the carburetor, various kinds of problems appear, and one of them is a malfunction of the cold start system on the carburetor.

On many machines in LPG, a spacer for gas for the K-151 carburetor is used, it is located between the main body and the throttle body. Due to the additional insert, the distance between the lower and upper parts of the carburetor increases, so the cold engine starting system begins to work with violations - you have to constantly keep your foot on the gas pedal, while holding the suction. The gas is not fully working suction does not affect the operation of the engine, but the point is that the cold start of the engine, and especially in winter, is carried out on gasoline. Therefore, starting the internal combustion engine with an incompletely closing air damper is quite problematic; even from the vibrations that arise, the fastening of the damper axis is often unscrewed. How to get rid of such an unpleasant problem?

One of the options for resolving the issue is to weld on an additional strap on the air damper rod, which makes it possible to compensate for the difference in the thickness of the standard gasket between the bodies and the gas spacer.

The bar can be made from an electrode with a diameter of 2 mm.

Replacing the carburetor K-151

With severe wear of parts, the carburetor needs to be replaced, most often it changes if the body wears out:

- the lower surface of the middle part is strongly deformed;

- the lid is warped (upper part of the case);

- the seat for the throttle valves in the lower part wears out.

The price of the new K-151 carburetor is quite high (on average 5.5-6.5 thousand rubles), but it is impossible to drive with a faulty device, especially since with high fuel consumption even more money is lost. Changing the K-151 is quite simple, consider the process of replacing it with a Gazelle car:

Accelerator pump repair

If there are malfunctions of the accelerator pump of the carburetor, the engine begins to "choke", with a sharp set of engine speed, a failure occurs. Quite often, the reason for this operation of the internal combustion engine is a clogged "nose" of the fuel atomizer, and the diaphragm of the accelerating pump may also fail.

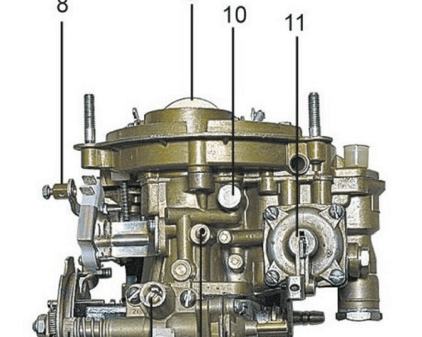

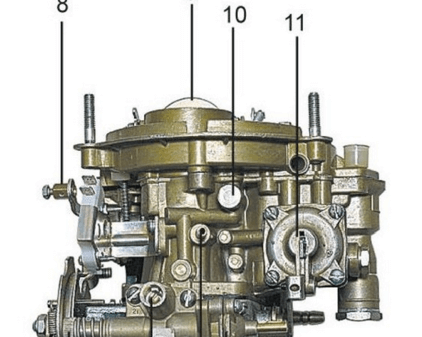

Diaphragm defects are determined by its external inspection; you can easily get to it without removing the carburetor from the engine. To do this, you need to unscrew the four screws of the cover (in the figure below - at number 11), but you need to remove it carefully - it is important not to lose the spring that is inside the assembly.

To determine the serviceability of the pump accelerator sprayer, it is necessary to remove the housing air filter, turn the throttle valve by hand and see if the fuel flows through the accelerator "nose". If the spray is clogged, you can try to blow it out, but this will require removing the carburetor cap. If the spout is not blown out, it should be replaced; the work on replacing it is also performed without removing the entire assembly. We replace the sprayer of the accelerating pump as follows:

Replacing the needle valve in the float chamber

If the engine consumes a lot of fuel, one of the reasons for this phenomenon may be a faulty needle valve in the float chamber - it is not tight, and too much gasoline enters the chamber. In some cases, the valve completely ceases to hold fuel, then the carburetor is completely filled with gasoline, and the car will not start. Replacing the needle valve is very simple:

http://avtobrands.ru

1. The fuel level in the float chamber is adjusted with the carburetor cover removed. However, it is possible, without disconnecting the trigger rod, to unscrew the cover fastening screws, lift it and, after removing the gasket, turn the cover to the side, as far as the gaps in the rod attachment points will allow.

Pump up gasoline into the float chamber with a lever manual paging fuel pump until the level stabilizes. The distance from the fuel level to the upper plane of the carburetor body should be 21.5 mm.

When the fuel level is below the specified one, it is necessary to bend up the tongue 1 of the float, which rests on the shank of the stop valve needle. Bend the tongue down at a higher level. After each bending of the tongue, it is necessary, by unscrewing the drain plug of the float chamber, to drain the gasoline from it and, by screwing the plug into place, re-pump the gasoline with the manual priming lever of the fuel pump.

2. Adjust the starting system you can directly on the car, completely warming up the engine and connecting a tachometer to it. Starting the engine with the air filter removed and lightly pressing the accelerator pedal, completely close the air damper with its drive handle. Then use a screwdriver blade to slightly open the air damper as far as the linkage will allow. Rotation frequency crankshaft the engine should be 2500–2700 min –1. If it differs from the indicated one, it is necessary, after loosening the lock nut on the adjusting screw abutting against the profile lever, to tighten or unscrew this screw. After completing the adjustment, tighten the lock nut securely.

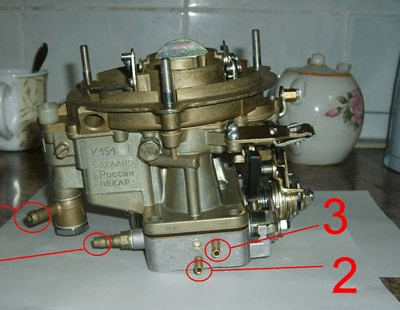

3. Adjust the idle system on a warm engine with a tachometer connected to it. To do this, with the engine running, set the quality screw 2 to the position at which the maximum idle speed is ensured. Then, using the screw number 1, set the frequency increased by 100–120 min –1. Then tighten the quality screw until the speed decreases by 100–120 min –1. This method of adjustment allows you to keep within the emission standards. However, a more accurate adjustment is recommended using a gas analyzer.

Examination

Check the operation of the accelerator pump with the carburetor cover removed after adjusting the fuel level.

With a sharp opening of the throttle valves, an even strong jet of gasoline should come out of the sprayer of the accelerating pump, reaching the channels of the throttle valve body without touching the walls of the diffusers. An uneven and curved jet indicates a partial clogging of the spray channels. If there is no jet at all, make sure that the fuel supply screw of the spray gun and the pressure valve located in it are clean and in good working order. If they are working properly, you should check the cleanliness and serviceability of the diaphragm mechanism of the accelerating pump, disassembling it, as described above.

Fuel consumption directly depends on the state of the fuel system, and if there are malfunctions in it, the dynamics of the car also deteriorates, the engine starts to work unstable.

This article will consider the K151 carburetor: device, repair, adjustment, tuning features, as well as the main problems and their symptoms.

Carburetor device K-151

In the fuel system, the K-151 model carburetor performs the function of preparing a fuel-air mixture in the composition necessary for the operation of an automobile engine under various loads - at idle, at medium or maximum speeds. This unit is used on light cars "Volga", IZH, on commercial vehicles "Gazelle", "Sobol", off-road vehicles UAZ. There are various modifications of "one hundred and fifty-first", and depending on its model, a letter is added to the name at the end, for example, the GAZ-3102/31029 and GAZ-3302 Gazelle cars are equipped with the K-151S carburetor. Also, depending on the K-151 model, the jets can be installed in different sections - much depends on the characteristics and volume of the engine.

The 151 series carburetor consists of the following systems and elements:

- main body (middle part) with a float chamber;

- throttle bodies - the dampers are rotated due to the drive associated with the accelerator (gas) pedal;

- the upper cover of the float chamber - it contains a locking mechanism that does not allow the chamber to overflow with gasoline, as well as an air damper necessary to start a cold engine and warm it up;

- the main metering system - is the main one in the preparation of the fuel-air mixture (FA), consists of channels of a certain section, two fuel and two air jets;

- the idle system, which is necessary for the stable operation of the internal combustion engine at idle - it includes a bypass channel, adjusting screws (quality and quantity of fuel assemblies), jets (fuel and air), an economizer valve with a membrane mechanism;

- accelerator pump - it allows the car to drive without failures with sharp acceleration, consists of additional channels in the main body, a ball valve, a membrane mechanism and a fuel atomizer;

- econostat - the system is designed to enrich fuel assemblies at high engine speeds; it is an additional channel through which an additional portion of fuel enters the intake manifold under the influence of a large vacuum with open throttle valves;

- transition system - it is needed for a smooth increase in speed at the moment the throttle valve starts to open in the secondary chamber; it consists of fuel and air jets.

The K-151 carburetor consists of two chambers, the throttle valves in it open sequentially, a filter is installed at the inlet in the fitting - a protective mesh. The unit is also equipped with a return fuel line, through which excess gasoline is discharged back into the gas tank; also, the “return” does not allow creating excessive fuel pressure. The device of the K-151 carburetor itself is quite complicated, and in order to repair and adjust the unit, experience is needed, strict adherence to the repair instructions.

Several hoses of two diameters are connected to the K-151 carburetor - if they are mixed up, the engine will not work properly. Connect the hoses in the following order:

Adjustment

If, without experience, it is quite difficult for car owners to repair the K-151 unit with their own hands, then it is easier to master the adjustment, the main thing is to understand the principle of operation of the device and follow the instructions. In total, there are several types of adjustments "one hundred and fifty-first":

- idle move;

- air damper position;

- the level of gasoline in the float chamber;

- throttle position.

You should trust experienced carburetors to change the fuel level in the float chamber, but any driver can adjust the idle speed independently. We carry out the procedure as follows:

If the engine speed is increased, it should be reduced using the screw that adjusts the position of the throttle valves. This screw often boils tightly, and it is impossible to turn it in any direction (in the figure below under the number 4, under white paint).

There is one "tricky" way that makes the adjusting element turn - you need to install a flat screwdriver in its slot and gently hit it several times with a hammer (you need to feel the effort, otherwise you can break parts of the carburetor). The screw will "come off" and begin to rotate on the thread. If the "trick" is not successful the first time, it should be repeated. It is important not to rush and be patient, then everything will work out.

Repair

During the operation of the car, various malfunctions may occur in the carburetor, the main signs of failures in this device:

- increased fuel consumption;

- black smoke from the muffler pipe, it is especially noticeable if you press the gas pedal sharply;

- unstable operation at idle, the engine may also stall on deceleration;

- poor vehicle dynamics;

- dips when picking up speed.

With a faulty carburetor, the engine may not develop speed, and pops and shots in the muffler are often heard in the intake manifold. K-151 is a rather complex unit, and almost any element of it can fail.

There are reasons why the carburetor most often fails:

- jets, fuel and air channels are clogged;

- heating deforms the body;

- the stop valve of the float chamber stops working;

- jets wear out over time.

Many repairmen, restoring the carburetor's performance, first of all strive to replace the jets, believing that because of them fuel consumption increases, the engine is unstable. One rather important note is that the jets are very rarely worn, and most often wear occurs when the carburetor is often operated in dusty conditions. The most common reason for poor carburetor performance is clogging, but to clean the unit well, you need to completely disassemble it. Repair of the K-151 carburetor is carried out with the removal of the device, full flushing and purging of all its parts.

Often, cars with carburetor engines are converted by car owners to gas, for example, it is advantageous to put HBO on a working Gazelle. But with the constant use of gas in the carburetor, various kinds of problems appear, and one of them is a malfunction of the cold start system on the carburetor.

On many machines in LPG, a spacer for gas for the K-151 carburetor is used, it is located between the main body and the throttle body. Due to the additional insert, the distance between the lower and upper parts of the carburetor increases, so the cold engine starting system begins to work with violations - you have to constantly keep your foot on the gas pedal, while holding the suction. The gas is not fully working suction does not affect the operation of the engine, but the point is that the cold start of the engine, and especially in winter, is carried out on gasoline. Therefore, starting the internal combustion engine with an incompletely closing air damper is quite problematic; even from the vibrations that arise, the fastening of the damper axis is often unscrewed. How to get rid of such an unpleasant problem?

One of the options for resolving the issue is to weld on an additional strap on the air damper rod, which makes it possible to compensate for the difference in the thickness of the standard gasket between the bodies and the gas spacer.

The bar can be made from an electrode with a diameter of 2 mm.

With severe wear of parts, the carburetor needs to be replaced, most often it changes if the body wears out:

- the lower surface of the middle part is strongly deformed;

- the lid is warped (upper part of the case);

- the seat for the throttle valves in the lower part wears out.

The price of the new K-151 carburetor is quite high (on average 5.5-6.5 thousand rubles), but it is impossible to drive with a faulty device, especially since with high fuel consumption even more money is lost. Changing the K-151 is quite simple, consider the process of replacing it with a Gazelle car:

If there are malfunctions of the accelerator pump of the carburetor, the engine begins to "choke", with a sharp set of engine speed, a failure occurs. Quite often, the reason for this operation of the internal combustion engine is a clogged "nose" of the fuel atomizer, and the diaphragm of the accelerating pump may also fail.

Diaphragm defects are determined by its external inspection; you can easily get to it without removing the carburetor from the engine. To do this, you need to unscrew the four screws of the cover (in the figure below - at number 11), but you need to remove it carefully - it is important not to lose the spring that is inside the assembly.

To determine the serviceability of the pump accelerator sprayer, it is necessary to remove the air filter housing, turn the throttle valve by hand and see if fuel flows through the accelerator "nose". If the spray is clogged, you can try to blow it out, but this will require removing the carburetor cap. If the spout is not blown out, it should be replaced; the work on replacing it is also performed without removing the entire assembly. We replace the sprayer of the accelerating pump as follows:

If the engine consumes a lot of fuel, one of the reasons for this phenomenon may be a faulty needle valve in the float chamber - it is not tight, and too much gasoline enters the chamber. In some cases, the valve completely ceases to hold fuel, then the carburetor is completely filled with gasoline, and the car will not start. Replacing the needle valve is very simple:

Maintenance of carburetors K-151V (for engines mod. 4178), K-151E (for engines mod. 4218) and K-151U (for engines mod. 4021.60)

Carburetor K-151V (Fig. 38) - vertical, emulsion, two-chamber, with a falling mixture flow and sequential opening of the throttle valves. The carburetor has a balanced float chamber, two main metering systems - the first and second chambers, an autonomous idle system in the primary chamber with quantitative control of the mixture of constant composition with a forced idle economizer (EPCH), transitional systems of the primary and secondary chambers, an econostat with output to the secondary chamber, a diaphragm accelerator pump mechanically driven from the throttle shaft of the primary chamber and with the output of the sprayer to the primary chamber, a semi-automatic system for starting and warming up the engine with manual control. In addition, the carburetor is equipped with a float chamber ventilation valve.

1 - air damper; 2 - screw; 3 - starting spring; 4 - carburetor cover; 5 - bracket (only for К-151Н); 6 - gasket; 7 - diaphragm of the pneumatic corrector with draft assembly; 8 - gasket; 9 - pneumatic corrector cover; 10 - spring; 11 - screw; 12 - screw-displacer; 13 - ball (inlet valve); 14 - float; 15 - body of the float chamber; 16 - fuel supply union; 17 - washer; 18 - fuel filter; 19 - washer; 20 - fuel-conducting bolt; 21 - cork; 22 - cover of the accelerating pump; 23 - accelerator pump drive lever; 24 - fitting for ventilation of crankcase gases; 25 - secondary chamber throttle valve; 26 - housing of mixing chambers; 27 - screw; 28 - cam; 29 - screw; 30 - throttle damper of the primary chamber; 31 - economizer valve assembly; 32 - screw for adjusting the composition of the mixture; 33 - shut-off element of the EPHH valve; 34 - valve body EPHH; 35 - gasket; 36 - EPHH valve cover; 37 - tube; 38 - screw for operational adjustment of idle speed; 39 - heat-insulating gasket (textolite); 40-heat-insulating gasket (cardboard); 41 - small diffuser; 42 - accelerator pump sprayer; 43 - fuel bypass adjusting screw; 44 - spring; 45 - diaphragm of the accelerating pump assembly; 46 - gasket; 47 - screw; 48 - cork; 49 - washer; 50 - emulsion jet idling; 51 - electromagnet; 52 - thrust; 53 - retainer; 54 - nut; 55 - lever; 56 - fitting; 57 - screw; 58 - ventilation valve cover; 59 - ventilation valve; 60 - spring; 61 - gasket

Carburetor maintenance consists of periodically checking the reliability of the carburetor and its individual elements, checking and adjusting the fuel level in the float chamber, adjusting the low engine speed, cleaning, purging and flushing the carburetor parts from resinous deposits, checking the throughput of the nozzles.

Check the fuel level with the engine off, the car installed on a horizontal platform and the carburetor cover removed. The float chamber is filled with fuel using the manual fuel pump lever.

The fuel level (fig. 39) should be within 20 - 23 mm from the plane of the float chamber connector. To check it, it is necessary to screw in a union with a M10x1-6g thread for connecting a rubber hose. The fitting is screwed into the float chamber instead of the drain plug. The fuel level of the fuel level is determined through a transparent tube with an inner diameter of at least 9 mm.

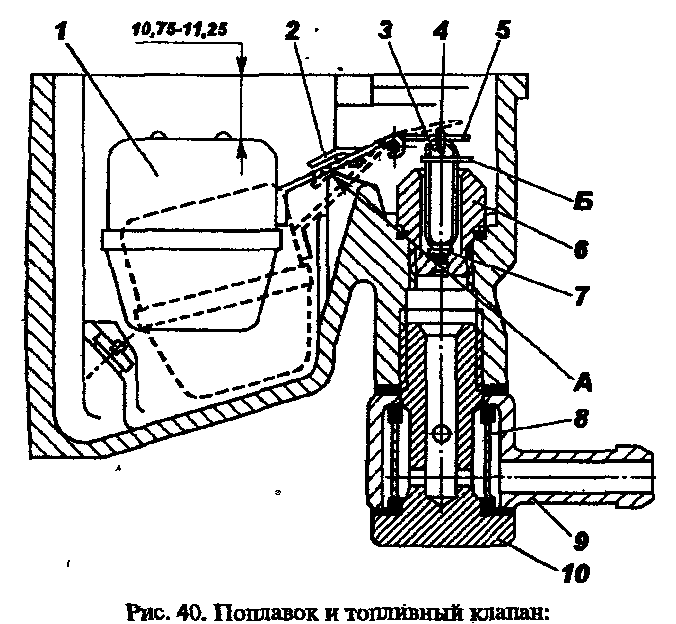

The level is adjusted by bending the tongue 5 of the float loop (Fig. 40) to a size of 10.75 - 11.25 mm between the upper part of the float and the plane of the float chamber connector (the float must be raised to the uppermost position). In the lowest position, the float should not touch the walls of the float chamber, and its tongue 2 should be on the stop A. In this case, the stroke of valve 3 should be equal to 1.5 + 0.5 mm. The valve stroke is adjusted by bending the tongue 2 of the float loop. After adjusting, check the fuel level again and, if necessary, make the adjustment again.

1 - float; 2 - tongue; 3 - fuel valve; 4 - earring; 5 - tongue; 6 - fuel valve seat; 7 - sealing washer (elastic locking element); eight - fuel filter; 9 - fuel line union; 10 - a fuel-conducting bolt

If the adjustment does not give the desired result, it is necessary to check the float mechanism. Usually, the reasons for the increased or decreased fuel level in the float chamber are the asymmetry of the float, its incorrect mass, as well as a sticking or leaking fuel valve. The tightness of the float is checked by immersing it in water heated to 80 - 85 ° C with a time delay of at least 30 s. The mass of the float assembly with the loop after repair should not be more than 13 g. Earring B was directed away from the float.

Adjustment of the minimum crankshaft speed 550 - 650 rpm (700-750 rpm - for engines of model 4218) in idle mode must be carried out with a warm engine (coolant temperature 70 "C) at a working system ignition.

During vehicle operation, the minimum idle speed is adjusted by turning the operating adjustment screw. When unscrewing the screw, the speed increases, when screwing in, it decreases.

If by turning the operating adjustment screw it is not possible to achieve stable engine operation, unscrew the mixture screw until it stops on the restrictor sleeve (pressed onto the screw) and re-adjust the minimum frequency with the screw

Full carburetor adjustment is carried out at a service station (using gas analysis equipment) and must be carried out under the following conditions:

- on a warm engine;

- with adjusted gaps in the gas distribution mechanism

- with serviceable spark plugs and an adjusted ignition timing;

- with the air damper fully open.

Adjustment sequence:

- Adjust the minimum idle speed with the operating adjustment screw.

- Adjust the carbon monoxide (CO) content with the screw of the mixture composition in the range of 1.0 - 1.5%, having previously removed the restricting sleeve. In this case, the content of hydrocarbons (CH) should not exceed 1000 ppm.

- Make sure that the selected position of the screws ensures the normal operation of the engine during gas overloads, for which open the throttle and release it sharply. If at the same time the engine stops or precarious work, it is necessary either to increase the minimum speed by unscrewing the operating adjustment screw, or to enrich the mixture with the mixture composition screw. The maximum allowable CO content is not more than 2%.

- Increase the speed to 2400 rpm. CO content should be no more than 1%; СН - no more than 500 mln.

After the final adjustment, install the restrictor sleeve on the screw of the adjusting mixture and mark its position. Warm up the engine to a coolant temperature of 80 - 85 ° C and check the CO content in the exhaust gases at idle speed. The CO content should not be more than 4.5% at any position of the toxicity screw, which allows the restriction sleeve to be installed. Set the screw with stop sleeve to the marked position.

It is not allowed to adjust the minimum crankshaft speed using the screws slightly open throttle valves.

When checking the operation of the carburetor, pay attention to the operation of the ventilation valve of the float chamber (reliable connection of the wires, absence of jamming and tightness of the valve). A malfunction in the valve leads to an increase in fuel consumption and difficulty in starting a hot engine.

Flush carburetor parts with benzene or unleaded gasoline, then blow with compressed air.

Do not use metal wire to clean the jets and calibrated holes as this will compromise their dimensions and flow.

In order not to scare the jets during installation, you should pay attention to their marking. Each jet is labeled with the nominal flow rate in ml / min. The marking is applied in a percussion manner on the nozzle head (on the side of the slot).

| 1st camera | 2nd camera | |

| Main fuel jet | 225 | 330 (330/380) |

| Main air jet | 330 | 230 (230/330) |

| Idling jet block | ||

| idle tube | 95 (110/95) | - |

| emulsion tube | 85 | |

| Idling emulsion jet | 280 (175/210) | - |

| Idle air jet | 330 (175/330) | - |

| Transition system fuel jet | - | 150 (200/150) |

| Air jet transition system | 270 |

Note... Some jets of the K-151V, K-151E and K-151U carburetors have different flow rates. In brackets it is indicated: in the numerator - for K-151E, in the denominator - for K-151U.

Maintenance of carburetors K-151V (for engines of model 4178), K-151E (for engines of model 4218) and K-151U (for engines of model 4021.60): http://uaz.service-manual.company/sistema-pitaniya / obsluzhivanie-karbyuratorov-k-151v /

About the book: Management. 2003 edition.

Book format: pdf file in zip archive

Pages : 76

Language: Russian

The size: 9.3 mb.

Download: free, no restrictions and no passwords

Carburetor K-151. Device, adjustment, repair.

The book deals with the design and operation features of automobile carburetors of the K-151 family produced by OJSC "PECAR". The main characteristics and parameters of units and systems of the carburetor are given. The features of operation and Maintenance carburetors and related car systems - forced idle economizer and toxicity reduction.

Recommendations for the detection and elimination of typical malfunctions are given. Instructions are given for disassembly, assembly, diagnostics, adjustment and repair of carburetor assemblies and systems. Color illustrations contribute to a better understanding of the material.

Carburetors of the K-151 series are made according to general typical schemes, but in design they are fundamentally different from the widespread carburetors of the Weber, Ozone and Solex types and have practically no common parts with them. The need to create carburetors of the K-151 series is caused by the expansion lineup Gorky and Ulyanovsk Automobile Plants, whose cars are equipped with engines of the Zavolzhsky Motor Plant (ZMZ).

The design of the series of carburetors K-126 and K-131, which were previously installed on these engines, was outdated and did not provide the required performance characteristics engines of the 402 family of cars Gazelle GAZ-3302, 31022, Volga GAZ-3102, 31022, 3110, engines of fashions. 4063 Sable GAZ-2752, 2217 and 22171 vehicles, as well as UAZ-3153, 33036, 39094 and 39095 vehicles.

Modifications of the K-151 series carburetors, depending on the car model for which they are intended, differ in the parameters of some metering elements (diffusers, jets, emulsion tubes), as well as in the design and size of individual units, for example, the presence of an electrically driven float chamber ventilation valve in the carburetor and the backflow fitting of the carburetor of the Sobol GAZ-2752 car, etc.

Compared to the previous models of PECAR carburetors, the K-151 series carburetors provide better mixture formation and accurate metering of fuel in all operating modes, which sufficiently meets the requirements of existing and future standards of exhaust gas toxicity and fuel efficiency.

PECAR OJSC produces the basic carburetor of the K-151 series and its seven modifications - K-151V, 151G, 151E, 151I, 151D, 151P and 151N, intended for installation on four-cylinder GAZ cars, UMZ - UAZ cars and UZAM - Izh cars.

All modifications of carburetors of this family are of the same type: two-chamber two-diffuser with a falling flow of the combustible mixture and pneumatic fuel braking, a balanced float chamber, elements of a closed crankcase ventilation system and sequential opening of the throttle valves. They differ mainly in calibration data and complete sets of additional elements.

Carburetors of the K-151 series are equipped with a single-section float chamber with a hollow brass float; autonomous idle system (АСХХ); main dosing systems in the primary and secondary chambers, the secondary chamber transition system; control vacuum selection systems for the vacuum corrector of the ignition distributor and the exhaust gas recirculation valve (not on all modifications); a valve for shutting off the fuel supply in the forced idle mode (PCH); mechanical drive of the secondary chamber throttle; a diaphragm mechanism for starting and warming up a cold engine with a manual air damper; an econostat; diaphragm accelerating pump.

The basic K-151 carburetor is installed on engines of the ZMZ-402 family with a working volume of 2.45 liters. cars Volga GAZ-24-10, 31029, 3102.3110 and Gazelle GAZ-33021, 33023, 33027, 330273, 2705, 27057.

Modifications K-151V and K-151G are intended for engines of the UMZ-417.10 family with a working volume of 2.45 liters. , 31514, 3741, 3962, 2206, 3303, 3909. They differ from the base carburetor, and from all other modifications of the family, calibration data, the presence of an unbalance valve of the float chamber with an electric drive, the absence of fuel backflow fittings and the selection of the control vacuum for the recirculation system valve exhaust gases.

Both modifications have the same calibration data and differ only in the design of the throttle valve drive: in the K-151V modification, a lever is installed on the throttle axis of the primary chamber for connecting to the accelerator pedal using a linkage system, in the K-151G, instead of a lever, a sector is mounted for connecting a flexible cable.

On engines increased power UMZ-4218.10 with a working volume of 2.89 liters. UAZ-3153, 33036, 39094 and 39095 vehicles install the K-151E modification, which is identical in design to the K-151V modification, but significantly differs from it in the calibration data of the dosing elements of the idle system.

The K-151I modification was developed for the ZMZ-410.10 family of high-power engines with a working volume of 2.9 liters. cars Volga GAZ-31029 and Gazelle GAZ-3302. It differs from the base carburetor in the diameter of the large diffuser of the secondary chamber, the throughput of the emulsion nozzle of the idle system and the delivery of the accelerating pump.

For the family of engines of the new generation ZMZ-406 with a working volume of 2.3 liters. cars Volga GAZ-3110, Sobol GAZ-2752, 2217, 22171 and Gazelle of all modifications, except for GAZ-33021, a modification of K-151D has been developed, which, like the base carburetor, has a fuel backflow fitting, but differs from it in the calibration data of the main systems dosing and idle code.