The reliability of a metal door is determined not only by the material of the door leaf, the number of locks or the method of installing hinges, but also by the type of door frame on which this leaf is hung.

The right choice and correct installation door frames are the first step towards home safety. Therefore, this issue cannot be ignored. What are the advantages and disadvantages of doors with a metal frame of one type or another?

Today, a steel door frame can be one of the following varieties:

1. From the corner. As you can see from the name, this is just a metal corner with dimensions from 50x50x5 mm to 63x63x6 mm, superimposed on the doorway. The main advantage of this type of construction is that it practically does not take up space. That is, the dimensions of doors with a frame almost coincide with the dimensions of the canvas.

This is important in the case of a narrow opening. Due to the thickness of the metal (5-6 mm), the corner box is well protected from the power release: the crossbars of the lock simply cannot break it.

Unfortunately, a door with such a box is almost impossible to properly seal, thereby providing the necessary heat and sound insulation properties. Therefore, the scope in this case is limited non-residential premises: warehouses, attics and so on.

2. Profile frame for the door... It is made of rolled rectangular shaped tubes with a sheet thickness of 2 mm. In economical options, one pipe with a cross section from 40x25 to 40x40 mm is used, but this is permissible only for doors of medium weight. For more solid structures, it is necessary to take profile pipes with a cross section of 60x40 mm.

The most reliable are double boxes welded from two profiles at right angles. The section of the second pipe (the so-called vestibule) is usually 50x25 mm. In addition to high reliability, such designs provide excellent thermal insulation, since they allow the use of seals of a wide variety of options. There is only one drawback: the door frame will reduce the working part of the doorway by the size of the vestibule, that is, 50 mm on each side.

3. TO bent profile box(it is bent-welded). Manufactured on special bending machines with subsequent welding. It is a various type of construction with platbands. Due to its complex shape, the curved profile box gives even more more possibilities for the installation of seals that provide thermal insulation.

Recently, bent-welded structures have become very popular also because boxes with the so-called "continuous counter-removal" have appeared. But there are also enough disadvantages in this case.

Firstly, the thickness of the door frame reaches very indecent values, and it may be necessary to expand the doorway before installing it.

Secondly, they are usually made from a sheet with a thickness of 1.5 mm (the use of a two-millimeter steel sheet significantly complicates the technology and leads to a sharp rise in the cost of the finished structure), and this is not enough to withstand the power extraction. But it is from him that the "continuous counter-removal" should protect.

What is solid countermeasure?

For a very long time, all manufacturers who care about the quality of their products have used anti-removable elements in the manufacture of steel doors. They are simply steel pins that, when closed, enter the holes made in the door frame, and thus prevent the door leaf from being removed when the hinges are cut off.

"Solid counter removal" differs from the pins in that a ledge is made along the entire height of the door at its end, which enters a special groove of the box from the side of the hinges. It is believed that this method protects even when the anti-release pins no longer hold up. However, if such an effort is applied to the door, then the metal of most boxes from the bent profile will not be able to withstand it. It will simply be cut by the bolt of the lock and the door will open from the keyhole side, not the hinge side.

The height, width and thickness of the doorway - its standard dimensions - are regulated in SNiP, and may differ depending on the materials from which the walls are made. Also, the thickness of the door frame depends on the material of the doors themselves - they are metal or wooden. In houses of the old fund and new buildings, these sizes can differ significantly by themselves, and it also happens that the residents themselves decide to make repairs and install non-standard doors.

What are the standards

Based on the parameters of the average person, standard parameters have been developed for the entrance and interior doors, so that their use is comfortable and does not present any difficulties in movement.

In this case, the permissible discrepancies in the parameters of the walls must be observed, because the dimensions for the entrance and interior structures differ.

The standard parameters are:

- The height should be within 2 meters. Whether it is a metal door or not, it does not matter: the size is taken from the standard height of a person on the grounds that he should pass freely under it. Another reason for setting such a standard is the height of the ceilings.

- The width of the entrance and interior doors has different parameters. At the entrance, this indicator is increased and varies in redistributions of 80-100 cm. The gold standard is 90 cm, and for interior rooms it is 70-80 cm, but at the same time, the dimensions of the people who will live in the house are taken into account.

When designing a building, standard SNiP standards are taken into account for setting the dimensions of doorways. In brick buildings, the width is 1.76 - 0.63 m, in monolithic 1.75 - 0.62, and the height is 2.25 - 1.87 m.

Since most manufacturers' door frames are designed for wall thicknesses of 12.8 cm, it is necessary to create slopes in the main walls. Wall thickness is not regulated in any way by standards, since it does not represent the main characteristic and there is no single standard for the thickness of partitions between rooms.

How to make calculations

The method is suitable for metal and other doors. For the calculation, the formula is taken:

Width = canvas + 26 mm + left, right frame bar;

Height = 38 mm + sash + box timber.

Standard dimensions of the box for an interior door: 2100 mm - height; 70 mm - width; 30 mm - thickness.

There may be slight differences depending on the manufacturer.

When you need to order doors, you should find out the exact parameters of the doorway to determine the width of the frame together, and also determine the need for extras.

Non-standard parameters

Very often, the owners of premises decide to change standard sizes doorways in order to give the home and the interior more individuality and sophistication.

- Input. Metal ones are more often made standard, and for exclusive wooden ones, the owners will never refuse to increase the dimensions of the doorway when the parameters of the building allow it - to move it or move it apart. If the width increases to 120-150 cm, as a rule, a double door is installed. Increasing the height parameters is usually done to install additional inserts above the canvas.

- Interroom. They can be either increased or decreased. For areas such as the kitchen and living room, the decision is made in favor of increasing the doorways. This is especially true for the installation of sliding doors. For bathrooms, they are usually shortened.

When changing the parameters of the door frame, the increase in the floor height must be taken into account.

This will be influenced by the following factors:

- Laminate flooring. In this case, the values vary within 1.5-2 cm;

- Linoleum changes values within 0.5-1 cm;

- Cork floor, porcelain stoneware and tiles - 3-5 cm.

Tips for choosing a door frame for a non-standard opening

There is a set of rules that greatly simplify the task of selecting the correct door frame for non-standard openings.

When the standard parameters change, you need to take into account the parameters of the space for the box, wooden beam and all other fastening elements. The height of the finished floor must be taken into account, and in the case when a coating is ordered, it is necessary to take into account what discrepancies will occur in this case.

Clearly about the dimensions and measurements in the following video:

You also need to take into account the thickness of the door frame elements, all possible gaps between walls, jambs. This is necessary to make further adjustments.

The width of the canvas is always less than the opening for the entrance doors, ranging from 10 cm.

It is imperative to take into account the height for installing the sill, even if these are metal doors - it will also require some space, which must also be taken into account when measuring parameters for choosing a door frame. If it is supposed to allocate a separate entrance and its insulation, then it is not recommended to greatly reduce the opening. In this case, the installation of a step is required.

If the height of the opening is not enough, but it is still necessary to allocate a separate entrance with insulation, then sometimes you need to say goodbye to the idea of installing a step. Here you need to use an individual approach.

Even when a complete redevelopment of the premises is carried out, it is necessary to comply with GOST standards so that the correct distribution of loads on the walls occurs.

Choosing doors in industrial buildings, schools, hotels, offices, shopping centers, clinics, hospitals and other high traffic areas has always been a hassle. Now, with the advent of metal framed wooden doors, the choice is clear.

What are the advantages of doors with a metal frame

The choice between metal doors and wooden doors has always been extremely difficult. On the one hand, metal ones are more reliable and fire resistant, more burglary. However, their high price was perplexing with a limited budget. On the other hand, wooden doors are more environmentally friendly and inexpensive, but in cases of high traffic they wear out quickly. With the advent of wooden doors on a metal frame, this problem has been solved.

Wooden doors with a metal frame have absorbed all the best:

The cost is only slightly higher than the cost of traditional wooden doors;

Exquisite appearance natural wood is preserved;

Ecological cleanliness at the highest level;

Increased service life.

Lifetime

A metal box for wooden doors is a real find! It was the box that was subjected to wear and tear in the first place, which made the installation of wooden doors in rooms with high traffic of people impossible! In turn, the metal box is, roughly speaking,« unkillable» ... Due to this, wooden doors can be easily installed in public places and allow NS t save a lot.

Wooden doors with a metal frame in the interior

Due to the richness of colors and shades of natural wood, such doors allow you to create unique finishes and implement any design tasks. The metal box does not fall out of the picture: as a rule, it has a powder coating and colors that are as close as possible to the color of the selected wood species.

Wooden doors with a metal frame are stylish, modern, economical, reliable and durable!

The door frame is a fixed part of the door block, which is attached to the walls of the doorway; it is a frame structure to which the door leaf is attached using hinges.

The main functions of the door frame are

- Practical - covers the doorway in the wall, the door leaf is attached to it;

- Heat and sound insulation;

- Aesthetic;

- Protective - a properly selected door frame profile will protect the door from burglary.

Equipment

The door frame is frame structure, additional elements of which are:

- - necessary to mask the cracks between the box and the wall / partition;

- Sealant- used to improve the sound insulation of the door;

- Additional elements- close the end walls of the doorway. They are installed together with the entrance and interior doors in cases where the width of the door frame is less than the wall thickness of the doorway. In addition to the aesthetic function, addons strengthen the box, prevent it from loosening. They are produced both in a standard design (with a processed or untreated edge), and telescopic, which have grooves at the ends for a lock connection with the frame and platbands.

Also, the box can be equipped with anti-detachable pins and strips, these devices prevent the door leaf from being removed when cutting the hinges.

Types and materials

The material for the production of door frames can be solid wood of various species, as well as MDF, chipboard and their combinations. For entrance metal doors, frames are mainly made of steel. In the case of interior doors, the most popular option is chipboard door frames, since it is believed that they show themselves better during operation, while being cheaper than analogues. Boxes are rectangular or rounded in shape.

There are several types of door frames and are usually divided according to the type of design and place of installation.

By type of construction, door frames are:

- Corner- a corner is used, superimposed on the doorway. The main advantage of this type the design is space saving - the dimensions of the doors with the frame almost coincide with the dimensions of the leaf, which is very important in the case of a narrow opening. The disadvantage of the design is low heat and sound insulation, since a door with such a box is almost impossible to properly seal.

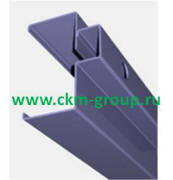

- Profile- are made from a bent profile and make it possible to use various seals for better heat and sound insulation. At the same time, their installation requires significant space, which may require additional expansion of the doorway. An additional option for this type of boxes is the installation of a "solid counter-removal". This solution is a special protrusion along the entire height of the end of the door, which, when closed, enters a special slot in the box, while providing maximum protection against burglary. As a standard, such boxes have a strip on the inside, and on the outside there is a quarter for a seal or cashing.

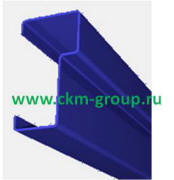

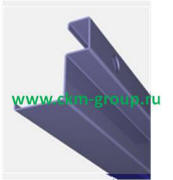

- Bent-welded- these door frames are made of a profile pipe, due to which they are endowed with increased strength and are used for steel doors, since they allow you to create two contact contours. They have excellent sound insulation performance. Moreover, they can be installed both directly on the doorway and inward.

At the place of installation, door frames are corner, end and covering:

- corner box- a box with an outer casing on the hinge side, intended for installation "on the opening".

- inner (end) box- installed inside the opening without the use of platbands, usually mounted to an already finished surface;

- covering box(crimp, telescopic) - this type of design is often used when installing premium doors. Platbands are mounted both from the outside and from the inside, which makes it easier to prepare for installation - behind the platbands you can hide surface irregularities or the remains of polyurethane foam.

The choice of a door frame should be approached carefully, taking into account such factors as the width of the opening, features of operation, aesthetic moments, a comfortable level of heat and sound insulation, as well as the financial component.

Doors with a metal frame are used in the design of: hotels; hospitals; industrial premises; shopping centers; office buildings, train stations. The door block leaf is made with the following types of coatings:

| HPL plastic | CPL plastic | PVC film | Veneer | Ral coloring | ||

Possible options for filling the canvases.

|

|

|

|

|

|

|

Cellular filling |

Tubular chipboard F otv. 28 mm. RW 28 db |

Tubular chipboard Ф hole 18 mm. EI 30 RW 28 db |

Solid chipboard |

Solid chipboard |

Combined chipboard |

- A special filling is made of extruded chipboard, which provides additional sound insulation or fire-resistant properties of the door block.

- RW, db- noise reduction index in db.

- EI, min - fire resistance limit in minutes.

The door metal frame is made of thick steel 1.2 mm ... The metal box for doors has a collapsible design for ease of transportation and preservation of presentation. A welded structure is available on request. The door block with a metal frame is completed with a seal. Doors up to 800 mm hung on two hinges, more than three. The metal box is painted by powder spraying according to RAL. The box is produced in three versions: corner; block; coverage (see below). The additional part of the metal box or the girth is installed after the installation of the main unit.

The main advantages of doors with a metal frame: reliability in operation; ease of installation; impervious to moisture.

Wooden doors with a metal frame can have different purposes, respectively, and different designs.

Examples of execution of doors with a metal frame:

- Door block with lightweight leaf, filling of the leaf with honeycomb cardboard.

- Door block with reinforced door leaf, filling of the door leaf with extrusion chipboard. It is used for rooms with increased cross-country ability, as well as in rooms for which increased requirements for sound insulation are imposed. Depending on the materials used to fill the leaf, doors with a metal frame can have the following sound insulation values: RW -28; 32; 36; 42 db.

- The door block is fireproof, the door leaf is filled with a fire-resistant chipboard plate. Fire resistance EI-30 / EI-60.

- The door block is pendulum or reversible. Depending on the purpose, the canvases can be both lightweight and reinforced. For this type of swing door with a metal frame, reversible hinges with a door closer are used, which are arranged in the floor. An additional option for swing doors is a leaf guard made of stainless steel or brass sheet.

The color scheme and all kinds of textures make it possible to solve the most sophisticated design solutions, the coating of the canvas can be performed both with a wood grain texture and in monochromatic colors including metallic. The door metal frame has a powder coating, the color is closest to the color of the door leaf, it is also possible to use contrasting colors for the manufacture of wooden doors with a metal frame. The door metal frame can be made in three design options:

- Corner metal box with one-piece metal trim.

- Block metal frame, without platband, for installing the door block inside the doorway.

- Enveloping metal box, with a metal backing part.

The design of the door leaf for doors with a metal frame can be either with or without a rebate, depending on the customer's requirements. Schemes of doors with a metal frame are shown below.

|

|

|

|

Corner metal box |

Girth metal box |

Metal box for canvases with a straight end.

|

|

|

|

|

Block metal box |