The VVT-i valve causes a lot of problems for owners. The rubber rings, in its design, over time shrink into a triangle and press the valve stem. The valve wedges - the stem gets stuck in an arbitrary position. All this leads to the passage of oil (pressure) into the VVT-i clutch. The clutch turns the camshaft. Moreover, on Idling the engine starts to stall. Either the revolutions become greatly increased, or they float. Depending on the malfunction, the system fixes errors 18, P1346 (for 5 seconds, a violation of the timing phases is recorded); 59, P1349 (At a speed of 500-4000 rpm and a coolant temperature of 80-110 °, the valve timing differs from the required by ± 5 ° for 5 or more seconds); 39, P1656 (valve - open or short circuit in the valve circuit of the VVT-i system for 1 or more seconds).

Below in the photos is the installation location of the valve, catalog number, valve analysis and examples of "triangular" rubber rings, date with changed vacuum due to valve wedge. An example of a stuck valve stem and oil filter location.

The system check consists in testing the operation of the valve. The scanner provides a test for switching on the valve. When the valve is turned on at idle speed, the engine stalls. The valve itself is checked physically for sticking of the stem stroke. Replacing the valve is not particularly difficult. After replacement, you need to reset the battery terminal to bring the speed back to normal. Repair of the valve is also possible. It is necessary to flare it and replace the O-ring. The main thing during repairs is to maintain the correct position of the valve stem. Before repairing, it is necessary to make reference marks for installing the core, relative to the winding. You also need to clean the filter mesh in the VVT-i system.

Alexey Knyazev

11.08.2016

Toyota Vitz 1.3 VVT-i car, 4-speed automatic, 1999, 2NZ engine.

It all started with the fact that switching between the third and fourth gears began to fail, the last gear could not turn on in any way, it turned on for 3-4 seconds, I had to press the 4th off button and when the speed was about 80 hands, turn it on. Then the brakes began to disappear, or rather began to turn off vacuum amplifier with sharp braking, and sometimes just on a very hot engine (from 30 minutes of driving). Idle revolutions on a warm engine were kept at about 2000 rpm, while when the brake was released, the car itself accelerated over 40 km / h. The vacuum tank hardly worked, especially at low speed. Moreover, if the car is not very hot (up to 30 minutes drive), then everything is in order. At idle (when it was driven for 2 hours to identify the cause), the problem did not appear. That is, it appeared only after half an hour of active driving. But the behavior at speed: you press the brake pedal, the vacuum cleaner works, you press harder - it turns off abruptly, then, naturally, you start pressing with all your strength with your heel on the floor, and it turns on again. Needless to say, every braking was like driving on a steep safari with sharp jerks. Further, when accelerating at a traffic light, you press the gas pedal, the car does not want to change gear and accelerate, the engine is very, very low revs it was about to stall, but, nevertheless, the gear shifted, and the car started smoothly and reluctantly.

The engine did not give any errors. Diagnostics in a car service (and they tried to understand what was happening for a week) revealed only one thing - somewhere there is air leaking into the engine.

I found the necessary vacuum amplifier in the vastness of Russia and changed it - the problem remained. I changed one ignition coil, with a crack, from 3rd to 4th gear, the gearbox began to shift better, the problem diminished, but did not disappear. I re-read a bunch of forums, and, armed with new knowledge, began to apply the scientific poke method. I checked all the hoses, everything is in order, I checked the adsorber - everything is also in order. I cleaned the MAC-sensor with a steam generator, it became better, but not much. I checked the filter mesh of the VVT-i system - everything is in order. In the end, when, after another portion of repairs, the engine in the parking lot again began to keep revs above 2000, I opened the hood, stood in front of the car, looked at the running engine and thought - what to do ?! And then I remembered that when I tried to remove the VVT-i valve, the magnet was removed separately from the valve. Let me, I think, turn off this valve and see what happens. I take out the connector, and, lo and behold, the engine sneezed a little and started working fine!

It turns out that everything is provided by Toyota engineers, and with the valve off, the engine works as usual, without a variable valve timing system. The throttle response has suffered quite noticeably, but absolutely all the problems have gone, especially the shutdown of the vacuum booster!

Then, when I installed a new valve a month later, I already learned how to determine the moment it was turned on by the sound and behavior of the machine. The old valve turned on abruptly: with a smooth, continuous depression of the gas pedal, at first there were no changes, then it turned on abruptly and the car, as if from a kick in the ass, started. The new valve turned on smoothly, together with the gas pedal recessed, with a slight delay in the position of the pedal. After reading more forums on the Internet, I found out that quite often, if the engine stalls at start, the VVT-i system valve is to blame. True, this is not written on the forums, basically the cry "help", so the problem is massive. Another successful experience - I repaired the 2002 Toyota Corolla in this way (by turning off the valve), stalled at the start.

So there can be many symptoms, but the answer is one. And nowhere on the forums or in articles have I come across information that if this valve is turned off, then you can safely drive. Gasoline consumption, by the way, increases slightly: in the city - by 0.5-1.0l / 100 km, and it also eats a little more on the highway - somewhere by 1l, well, maybe 1.5l, I just couldn't measure it - it was too big the error turned out, but I found out that the flow rate depends quite strongly on the number and intensity of accelerations (more than with a working valve).

P.S. On the Vitz and Corolla, the valve is located behind the generator, on top of the front upper edge of the engine (if you open the hood and stand in front of the car, then on the left), the two-pin connector on the end of the cylinder (this is a solenoid) protruding from the engine housing is covered from above with a plastic engine cover. I have not seen it on other engines, but it is unlikely that the layout has been greatly changed. Well, the valve is used for both Lexus and Toyota the same.

VVTI is a variable valve timing system developed by Toyota. If we translate this abbreviation from of English language, then this system responsible for intelligent phase displacement. Now on modern Japanese engines the second generation of mechanisms was installed. And for the first time, VVTI began to be installed on cars since 1996. The system is a clutch and a special VVTI valve. The latter acts as a sensor.

The device of the VVTI system valve of Toyota cars

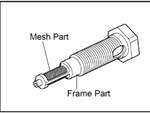

The element consists of a body. In the outer part there is a control solenoid. He is responsible for the movement of the valve. The device also has O-rings and a sensor connector.

General principle of the system

The main control device in this variable valve timing system is the VVTI clutch. By default, the engine designers designed the valve opening phases to obtain good traction at low engine speeds. As the speed rises, the oil pressure also increases, due to which the VVTI valve opens. Toyota Camry and its 2.4 liter engine work on the same principle.

After this valve opens, camshaft will rotate to a specific position relative to the pulley. The cams on the shaft have a special shape, and during the rotation of the element, the intake valves will open a little earlier. Accordingly, close later. This should have the best effect on the power and torque of the engine at high revs.

Detailed job description

The main control mechanism of the system (and this is the clutch) is installed on the pulley camshaft engine. Its body is connected to a star or the rotor is connected directly to the camshaft. Oil is supplied from one or both sides to each rotor petal on the clutch, thereby forcing the camshaft to turn. When the engine is not running, the system automatically sets the maximum dwell angles. They correspond to the latest opening and closing of the intake valves. When the engine starts, the oil pressure is not strong enough to open the VVTI valve. To avoid any shocks in the system, the rotor is connected to the clutch housing by a pin, which will be squeezed out by the oil itself when the lubricant pressure rises.

The system is controlled by a special valve. Upon a signal from the ECU, an electric magnet with the help of a plunger will begin to move the spool, thereby passing oil in one direction or the other. When the motor is at a standstill, this spool is spring-driven to set the maximum dwell angle. To turn the camshaft at a certain angle, oil under high pressure by means of a spool it is brought to one of the sides of the petals on the rotor. At the same time, a special cavity opens to drain. It is located on the other side of the petal. After the ECU realizes that the camshaft is rotated to the desired angle, the pulley channels overlap and it will be further held in this position.

Typical Symptoms of VVTI System Problems

So, the system must change the phases of operation. If any problems arise with it, then the car will not be able to function normally in one or several operating modes. There are several symptoms that indicate malfunctions.

So, the car does not hold idle speed on the same level. This indicates that the VVTI valve is not working as expected. Also, the "braking" of the engine will tell about various malfunctions in the system. Often, with problems with this phase change mechanism, it is not possible for the motor to operate at low speeds. P1349 code may also indicate problems with the valve. If on a warm power unit high idle speed, the car does not drive at all.

Possible causes of valve failure

There are not so many main reasons for valve malfunctions. There are two that are especially common. So, the VVTI valve can fail due to the fact that there are breaks in the coil. In this case, the element will not be able to correctly respond to voltage transmissions. Fault diagnosis is easily carried out by checking the resistance measurement of the coil winding of the sensor.

The second reason why the VVTI valve (Toyota) does not work correctly or does not work at all is a sticking in the stem. The reason for such seizures may be commonplace dirt that has accumulated in the channel over time. It is also possible that the sealing gum inside the valve is deformed. In this case, it is very simple to restore the mechanism - it is enough to clean the dirt from there. This can be done by soaking or soaking the element in special fluids.

How to clean the valve?

Many faults can be repaired by cleaning the sensor. First you need to find the VVTI valve. Where this element is located can be seen in the photo below. It is circled in the picture.

Cleaning can be done with carburetor cleaning fluids. To completely clean the system, the filter is also removed. This element is located under the valve - it is a plug with a hole for a hexagon. The filter must also be cleaned with this liquid. After all the operations, it remains only to assemble everything in the reverse order, and then install it without resting on the valve itself.

How to check the VVTI valve?

It is very easy to check if the valve is working. To do this, a voltage of 12 V is applied to the sensor contacts. It must be remembered that it is impossible to keep the element energized for a long time, since it cannot work in such modes for so long. At the moment of energization, the stem will be pulled inward. And when the circuit breaks, he will come back.

If the stem moves easily, the valve is fully functional. It only needs to be rinsed, lubricated and can be operated. If it does not work as it should, then repair or replacement of the VVTI valve will help.

Self-repair of the valve

First, dismantle the generator control bar. Then remove the bonnet lock fasteners. This will give access to the generator axle bolt. Next, unscrew the bolt that holds the valve itself, and remove it. Then remove the filter. If the last element and valve are dirty, then these parts are cleaned. Repairs are inspection and lubrication. You can also replace the O-ring. More serious renovation is not possible. If a part doesn't work, it is easier and cheaper to replace it with a new one.

Self-replacement of the VVTI valve

Often, cleaning and lubrication does not provide the desired result, and then the question arises complete replacement details. In addition, after the replacement, many car owners claim that the car began to work much better and fuel consumption has decreased.

To begin with, remove the regulating bar of the generator. Then remove the fasteners and gain access to the generator bolt. Cut off the bolt that holds desired valve... The old element can be pulled out and discarded, and a new one is put in place of the old one. Then the bolt is tightened and the car can be operated.

Conclusion

Modern cars are both good and bad at the same time. They are bad in that not every operation related to repair and maintenance can be performed independently. But you can do the replacement of this valve with your own hands, and this is a big plus for the Japanese manufacturer.