On wheel bolt lies a huge responsibility for the safe movement of the car and the life of the driver.

How to choose the right wheel bolt

The selection is based primarily on the type of discs that are installed on the car:

- Cast. Longer and thicker bolts are needed to secure them securely. That is, they must have an impressive width, length and thread size. But you can't tell by eye, can you? The solution is very simple - when removing old bolts, count the number of turns they make. The recommended amount is at least six to nine. Absolutely any sample in terms of parameters, while the price for each wheel bolt will be lower than in any auto parts store and will really please, can be found in Matrix-Auto.

- Stamped. Here the situation is the opposite - the characteristics are much less and when buying, you need to determine them as accurately as possible in order to avoid the bolt against the hub and disruption of the normal functioning of the brake elements.

Wheel bolts and another important nuance

A significant moment when choosing them is the thread pitch. It is also not a constant parameter. The meaning of each is indicated by the car manufacturer. Most often, the diameter is twelve or fourteen millimeters, but the step itself is about one and a half.

But this is just an average indicator in terms of frequency of occurrence, it is important to know exactly your indicator exactly.

Material from which the wheel bolt can be made

Basically, two types of raw materials are used - steel (which is usually plated with chromium or molybdenum, nickel) and ferrous metal.

Of course, the best option for car owners, it becomes a combination of aesthetic appearance and stability. Many people choose the chrome-plated price for which is quite acceptable. But recently, the development of the automotive industry has gone far ahead and this established standard has long lost its relevance.

Keeping track of all the innovations, "Matrix-Auto" offers a huge range of bolts of the most varied types of manufacture at the lowest price.

Wheel bolt: perfect appearance

Reliably completing your car, you want it to please the eye as well. This is the ideal wheel mount site that has everything you need:

- Various colors.

- Perfect shine in every detail.

- Simple and harmonious package.

Replace:

http://prntscr.com/biky71

http://prntscr.com/bikycf

Any car owner who is thinking about purchasing alloy wheels should understand what differences there are in the design of nuts and bolts. In particular, the car owner should know the differences from those fasteners that are used in stamped discs. Alloy wheel bolts are not universal. The same applies to fasteners for stamped models - they cannot be interchanged.

To ensure the operation of wheel sets with disks, it is advisable to have a couple of sets of nuts or bolts for them, as well as secret bolts.

Lightweight wheel nuts

Lightweight wheel nuts Key differences

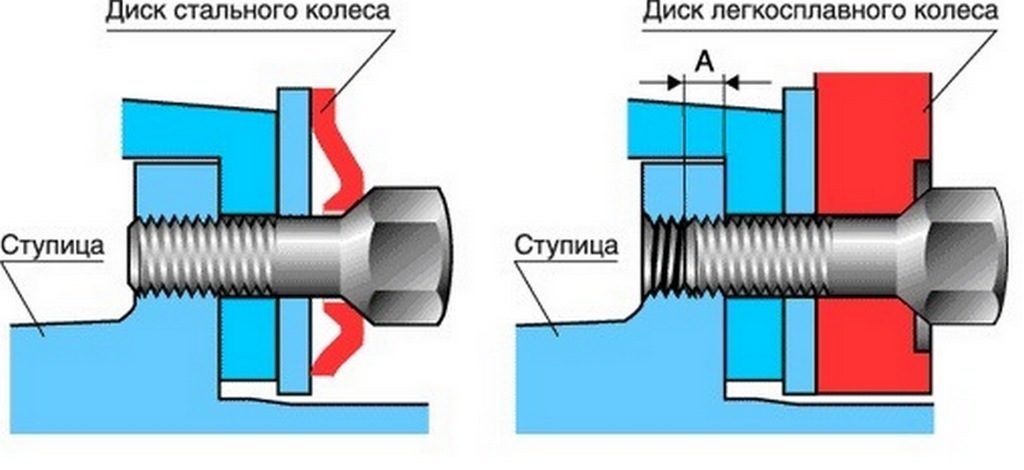

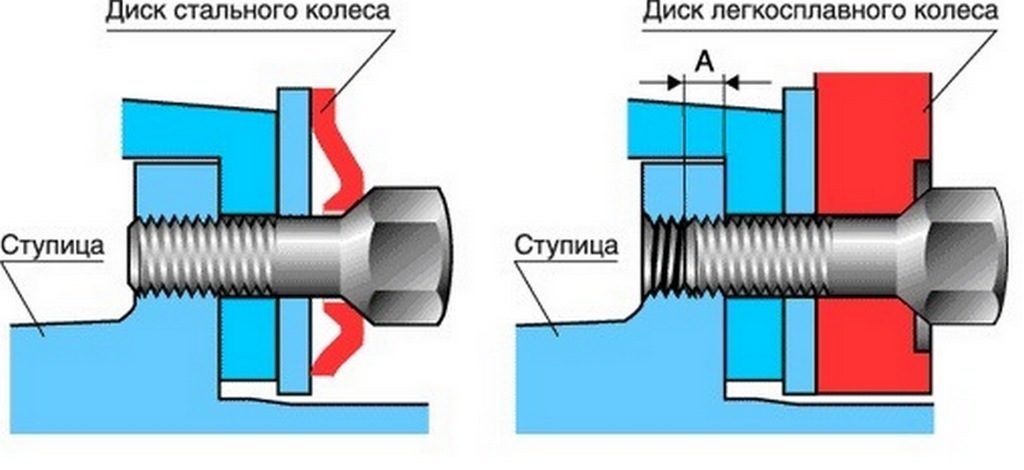

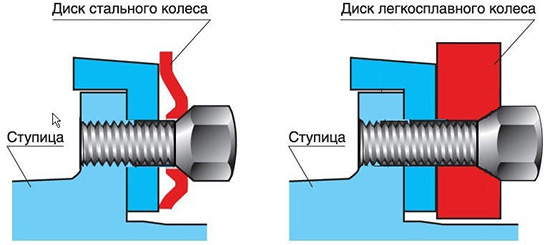

Bolts and nuts for alloy wheels have a special design that directly follows from the wheels themselves. For example, stamped models are usually made of strong steel and have a small thickness that is present at the point of attachment to the automotive hub. Nuts and bolts for them are equipped with a flat cylindrical surface, and for a reliable connection of the bolts, it is enough for them to have a flat head.

Alloy wheels, on the other hand, are made of lighter alloys. They are less reliable. Products for fastening such discs are distinguished by a conical contact surface - it is larger than the same area of a flat head used for stamping.

This is intended to reduce the load on the rims at the mounting points. These elements will also work with forged rims made of aluminum alloy.

Chromed alloy wheel nuts and bolts

Chromed alloy wheel nuts and bolts Thus, the features in tightening bolts and nuts on discs are as follows:

- When using die-cast nuts and bolts and installing them on a cast wheel, the joint will quickly scratch and the hole will soon begin to crumble.

- Alloy wheels will need longer bolts. This is due to the softness of their alloy, which requires a greater thickness of the finished product.

- When tightening the nuts, pay attention to the final length of the bolts in the hub. If the number of full revolutions is less than 6 (about 10 mm), change the studs or install a different model of discs for your own safety.

- Check all bolt and nut specifications to match the disc before installing. The angle of fasteners for standard tapered products should be 60 degrees. It will need to be compared to match the bolt holes. V selected models it may differ from the standards. In addition, you will need to check the threads and the contact surface (fasteners for alloy wheels should have washers that increase the contact area).

You also need to understand that due to the design of alloy wheels from softer alloys, over time, their connection to the hub can be weakened more likely. To avoid this, after every several tens of kilometers traveled, the owner must make sure that the fasteners are well tightened and tighten them if necessary. If it does not fit tightly, the disc will be subjected to cyclic impacts, and the bolts and nuts will continue to loosen.

Due to the softness of the disc metal, it is necessary to regularly check the tightness of the bolts on cast discs.

Due to the softness of the disc metal, it is necessary to regularly check the tightness of the bolts on cast discs. Types of fasteners

Depending on the shape of the landing area, wheel bolts for alloy wheels are:

- with a round clamping part.

- with a cone-shaped clamping surface. They can have an indent at the end of the clamp of 1.3 mm (head) or be without indent.

Depending on the size, the bolts are divided into:

- short (more often used to secure stamped disc models);

- long (suitable for alloy wheels).

Long bolts for car alloy wheels

Long bolts for car alloy wheels There are a number of other criteria that help you find out which products are right for you:

- diameter;

- threaded pitch;

- material of manufacture (aluminum, steel, titanium);

- coatings (chrome of different shades, zinc).

There are also products on the market with a variety of finishes that can match, for example, a shiny disc surface or body color. Despite the well-established opinion that chromium spraying prevents the formation and development of corrosion better than other coatings, the practical use of nuts and bolts shows that the service life of products made of ordinary ferrous metal is no less. Considering that in the early years any detail will retain its original appearance, it is not worth choosing nuts or bolts, guided by aesthetic requirements.

Chrome Plated Nuts for Alloy Wheels

Chrome Plated Nuts for Alloy Wheels "Locks" are a special type of mounts for cast disks. They protect the wheels of the car from intruders. The security bolts, thanks to the location invisible to thieves, reduce the risk of theft to a minimum.

Their peculiarity is the unusual shape of the nut. From the outside, the product is equipped with a moving sleeve. Thanks to this, the nut can be removed with a separate wrench, and the adjustable wheel can no longer be removed. For each "secret" in the set comes with an individual key, which is kept only by the owner.

McGard Security Bolts and Nuts

McGard Security Bolts and Nuts Tightening the alloy wheels

After selection, before installing the bolts and nuts in the sockets for planting, you will need to lubricate them with graphite grease. Due to this, when the elements come into contact with the disc, they will be able to scroll, providing a more secure fit and will not be locked due to frictional force.

If during installation you encounter a problem of mismatch in the size of the bolts on the wheel rim, then it can be solved by purchasing eccentric bolts (having a movable cone). For example, if the PCD size in the discs is 97 mm, and 99 mm is required, the eccentrics will compensate for this value due to the cone that is on the product. The presence of a minimum distance between the inner fit and the outer diameter of the element will provide the ability to move, indicated on the product by the word Variation.

When you select connections for alloy wheels, pay attention to the size of the threaded surface of the products that are screwed into the hub. If the number of turns is less than 10 mm or 6 turns, you should buy a product bigger size, since short bolts significantly reduce the reliability of the wheels.

Already purchased, new tires are ready for installation, little remains to be done - to install all this on the car and go ahead, surprise and brag ... All this is so, but in fact it turns out not everything is so fast and simple, even this, at first glance , a trifle like wheel bolts can spoil all your plans regarding the installation of "new things" on your swallow. Why - you ask? Yes, because the bolts from stamping do not fit, moreover, not all bolts are the same and are not suitable for every car. And this means that you are again faced with a choice, you again need to look for the necessary information about which bolts are better, where to buy them and how to actually choose them. So that you do not "rack" your brains and waste your precious time, he will solve this problem for you! We will show you how, what and where, and we will only give you a choice based on the information received. Well, as they say, fewer words - more action. Go!?

It may seem to some that the wheel bolts do not play any important role, so you can buy the first ones that come across and install them on your car. However, not everything is so simple, and these bolts are not that unimportant, but quite the opposite. After all, think about it, they fasten the wheel, more precisely, and without a reliable fastening, as you understand, there can be no question of any traffic safety. And this is already a serious claim for problems on the road.

What are these same wheel mounts?

The wheels are fastened with both bolts and nuts, the second option is less common in our country than among the same Americans or Japanese, so today we will focus on wheel bolts, not nuts. Bolts can be different: shape, size, configuration and color, in addition, bolts from different manufacturers may differ in thread and metal composition from which they are made. As a rule, bolts are made of metal, less often titanium or aluminum. As for color, they are most often popular chrome wheel bolts or nickel-plated counterparts, however, both are not particularly resistant to corrosion.

How to choose wheel bolts?

Regarding the color and appearance, everything is individual here, that is, everyone decides for himself, which cannot be said about the size (length, diameter, thread). If you care about the appearance of the bolts, it is better to buy wheel bolts corrosion-resistant, such as chrome-plated or stainless steel. Although it is not important just appearance and other parameters that the bolt has. Such parameters, as I said above, include: diameter and pitch of the thread, length of the bolt.

Fundamental rules:

- The wheel bolt should not make more than 8-9 turns. There should not be less, otherwise you risk losing a wheel or wheels;

- The bolt pitch should not be less than 1.5 mm;

- The thread diameter must be at least 12 mm.

The main difference between "stamping" wheel bolts and "casting" bolts is the width as well as the depth of the mounting hole well. The wells of the cast discs are deeper, so it is not possible to use the old bolts for the metal discs.

In addition, the more expensive and beautiful chrome bolts should be treated appropriately, if carelessly (frequent loosening and brute force) will lead to chrome peeling or rusting. Instead of beauty, it is better to give preference to practicality and reliability, these parameters play a more important role, so it is worth considering.

How do you choose the right bolt length?

- The first way ... Best of all, of course, buy wheel bolts according to the code indicated by your manufacturer, however, you can go the other way and just try on the bolt.

- Second way - fitting on site. I mean buy bolts and check if they fit or not. Although the method has the "right to life", it does not always work, as a rule, it concerns "beautiful" bolts, which the seller simply will not give for fitting.

- Method three - mathematical. We unscrew the old bolt, count the number of revolutions, then divide the resulting number by the length of the bolt. As a result, you will be able to find out the required bolt length that you need to compensate for the height of the cast disc well.

Thread. Everything is much simpler here. We unscrew the old bolt in order to eliminate the error and try on the new bolt to the new one, choosing the necessary option.

Note: Did you know that any wheel bolt or nut, regardless of the material from which it is made, is designed for 30-40 cycles "unscrew-tighten". After the resource is exhausted, the wheel nuts or bolts are recommended to be replaced, otherwise there is a high probability of damage to the threads.

When choosing a bolt, pay attention to the color of the bolt; there should be no "blue" on it, which indicates that the bolt is overheated. The wheel bolt must be made of quality material and properly hardened. A bad bolt can add unnecessary problems to you, for example, when the bolt breaks off inside the hub. For those who are still unlucky, we recommend reading one of my previous articles on. Moreover, breaking the bolt during tightening is far from the worst scenario. Imagine a situation where a bolt bursts while driving at speeds above 50-80 km / h.

That's all for me, I hope the knowledge gained will be enough for you to do right choice... And the last thing before choosing and buy wheel bolts, do not be lazy to consult the seller on this issue, indicating to him the make and model of your car, as well as who will install your alloy wheels.

Everyone knows that for fixing wheels on many domestic cars bolts are used, in particular, on the "nine".

Without exaggeration, the life of the driver and passengers depends on wheel fasteners. Therefore, you need to choose bolts for wheels, for a VAZ 2109 in all seriousness and it is better to purchase them from official dealers car manufacturers. Only correctly selected wheel bolts guarantee reliable wheel fixation.

What are the wheel bolts

Consider what a VAZ 2109 wheel bolt is.

Standard fasteners have:

- hex head;

- conical clamping part;

- threaded part.

Moreover, the edges of the head turn into a cone. M12 thread with a pitch of 1.25 and a thread length of 22 - 24 mm. The thread pitch is a very important parameter. If you tighten the bolts with a different pitch, you can spoil the thread in the hub, then you will have to change it.

Such hardware is used for wheels with stamped discs. If cast (light-alloy) wheels are used, then for the VAZ 2109 the wheel bolt must be longer (27 - 33 mm). Chromium plated with a tapered rotating washer is often used. This washer, located under the head, protects the disc surface when the bolt is tightened. Its threaded part must fully enter the hole in the hub, but no more, so that during the rotation of the wheel, the bolts cannot touch stationary parts.

It is worth emphasizing that it is impossible to put old hardware from stamping on new alloy wheels. In this case, the bolts under load can easily unscrew and the wheel will fall off on the go. I don't even want to talk about the consequences.

The clamping part of the bolt can be spherical, but must coincide with the profiles of the holes in wheel rim to keep the wheel centered.

Wheel bolts for VAZ 2109 are made with a hex head for a wrench 17 or 19. There are also lightweight hardware with a hollow head for a hex wrench. There are also bolts in which the head has an internal 10-ray star. For such, you need a non-standard key.

To widen the track of the car, bolts and spacers that are longer up to 40 mm are used.

How to avoid stealing wheels

To protect the wheels from theft, some people use "sekretki", as they are called. This is a bolt that cannot be unscrewed with standard tools, but only with an individual special wrench available only to the owner of the car.

Various methods of protecting such fasteners are used. For example, the head of a bolt can be made in the form of an irregular polygon or even an arbitrary figure, one of the profiles is sometimes shifted to the side. A perforated profile with holes of various diameters and depths is also used. By the profile, the reliability of the lock cannot be determined; here it is more important to use the products of trusted and reliable manufacturers.

Usually, in order not to ruin the secret bolt, tighten it with less effort. Because of this, such bolts on the wheels in the VAZ 2109 are placed one on each wheel. Unfortunately, in our country there are still people who like to “strip” your car, so the topic of secrets is still relevant.

All these secrets make it difficult for lovers of easy money to remove the wheels, they make it difficult. Because if you have time, you can unscrew everything, but the thieves have little time.

Therefore, in order to most effectively protect the wheels, it is worth following a few rules.

- It is better to buy expensive secrets, this helps to avoid the overlap of products. Because in the production of unique locks, the cycle repeats after some time, and there is a certain chance of repetition of parts. And in expensive products, such coincidences are excluded.

- If you buy alloy wheels, it is better to choose those whose locks would be "recessed" inside the disc, and not be on the surface. They are more difficult to unscrew.

- It is worth purchasing bolts with a flat pattern at the top of the head, which is not wrench sharpened. (For example, an asterisk or a heptahedron). That is, the drawing should be as unusual and flat as possible.

The price on the Internet for ordinary wheel bolts is from 14, and for "secret" from 160 rubles.

Sometimes motorists use bolts for a VAZ 2109 wheel with an offset center. They are easy to find in online stores. Such bolts are used if there are no original discs and others have been installed with slight differences. Eccentric bolts allow you to align all the holes and screw the wheel securely.

The bolts are made from different materials. This is steel with an admixture of molybdenum or steel coated with nickel, chromium, etc., sometimes even titanium is found. Coated bolts have a nice appearance. But don't think that this is the best choice. The problem is that all bolts are prone to corrosion. And the technology of nickel or chromium plating with sufficient resistance has not yet been created. After a year, the coated bolts will inevitably lose their beauty. And therefore appearance bolts are practically unrelated to their operational data. The most important are strength, thread pitch, length and type of bolt head.

To change the wheels with your own hands, you need to know how to properly unscrew and tighten the wheel bolts. To do this, it is worth looking at photos and videos. There are many such materials on the Internet. There are also instructions on the network for tightening bolts using a torque wrench. It is especially important when installing new bolts after approximately 50 km of driving, to check the tightness of all bolts. Most likely, some of them will have to be tightened!

The wheels are attached to the vehicle hubs with bolts or studs with nuts (Fig. 1). In the second case, the studs are rigidly fixed in the hub. The most common wheel fastener thread diameters are 12 and 14 mm, with a pitch of 1.25 or 1.5 mm.

Rice. 1. Varieties of wheel fasteners:

a - a bolt and a nut with a conical clamping part without a head, the edges of the head come out on a cone; b - a bolt and a nut with a conical clamping part and a head; c - a bolt and a nut with a spherical clamping part and a head.

The clamping parts of the wheel bolts and nuts can be tapered or spherical and must necessarily match the profile of the holes in the wheel rim, as they ensure the correct centering of the wheel on the hub. This is especially important when fastening the wheel with nuts. If the wheel is secured only with the ends of the nuts (Fig. 2), the disc may slip out from under them during movement, the wheel fastening will weaken, and the holes and pins will be broken. In the worst case, the car will "lose" a wheel - needless to say, how dangerous it is at high speed?

Rice. 2. Incorrect wheel attachment.

The disk, clamped by the end of the nut, and not by the cone, barely holds and slips when the car is driven.

With bolted wheels, this error is almost impossible. However, it is more difficult to install such a wheel than a nut-fastened one. To help the driver, 1-2 guide pins are screwed into the hubs of such wheels, and if they are not there, the wheel centers the hub belt, which enters the central hole of the disc.

Before installing the wheels, the seating surfaces of the hubs and disks should be cleaned of dirt and a thin layer of plastic or graphite grease should be applied to them. It is not superfluous to lubricate the threads of the nuts (studs) and wheel bolts. It is better to replace bolts and nuts with crumpled edges and damaged threads in a timely manner with new ones, necessarily similar to the standard ones, not only in thread size, but also in strength, i.e. not handicraft, but factory-made.

The rim of an alloy wheel is often always thicker than that of a stamped steel wheel, so longer bolts are used to attach cast or forged wheels (Fig. 3). The length of their threaded part (A) should not be less than the depth of the threaded hole in the hub, but not more, otherwise the bolts, when the wheel rotates, may touch the parts of the stationary brake mechanism.

Rice. 3.Standard bolts are not suitable for attaching alloy wheels: longer ones are needed. Dimension A must be equal to the thickness of the hub flange.

The hardness of the material of light-alloy wheels is lower than that of steel, therefore, the microroughness of the disc in the contact areas with the heads of steel bolts or hubs when the wheel is installed, after a while, crumpled and the connection is weakened. To avoid damage to expensive wheels, we advise you to tighten the mounting bolts some time after installing them on the car.

Bolts or nuts for fastening wheels are usually tightened with a torque of about 10-11 kgf "m, unless otherwise specified in the car's manual. When tightening the bolts, the wheel disc is deformed, the hole profile is broken, and the wheel is no longer held on the hub with the required force. also crush the edges of the bolt head and even break off the head.And when tightening the nut, the stud can turn in the hole in the hub, and then it will be impossible to unscrew the nut without a special tool or car service.

To protect the wheels from theft, so-called "secret" bolts (or nuts) are sometimes used. Typically, less force is used to tighten the security bolt or nut to prevent damage. Therefore, they replace only one bolt (nut) for fastening each wheel. The "secret" fastener is designed to be loosened only with a special, individual key, which is supposed to be held only by the owner of the car.

Structures of this kind are found on the market, and are also made by craftsmen. What should you remember when buying them? Firstly, is the "secret" head really inaccessible for unscrewing - and not only with regular keys, but, for example, with powerful pliers or a hammer and chisel. Secondly, is the original fastener capable of failing from the effects of water and dirt, and most importantly, due to the breakdown of the counterpart - the key. Finally, a particularly bulky bolt can upset the wheel balance.

Prepared based on the materials of the magazine "Za Rulem"