To be honest, the task of removing the engine from the frame of the "Ant" is still a job ... As for me, it's easier to pull off a diesel engine from a tractor than from this rattler ... This is, of course, a joke. But seriously, removing the engine from "Ant" is much more difficult and longer than from any other Soviet motorcycle.

Instruments

- Flat screwdriver

- Open-end wrenches for 8, 10, 12, 13, 14 and 17

- Pliers and stuff ...

Preparation

If after removing the engine you are planning it, then it is better in advance while it is on the frame. And one more thing: since in any case we will have to crawl under the scooter and unscrew something there - look for yourself some old sweatshirt or pea jacket for bedding

Withdrawal

Whatever one may say, but the winding lever will only interfere with us - we unscrew it

Unscrew the two nuts on the muffler knee attachment flange

The muffler, which will prevent us from removing the engine, is attached to the frame with two bolts. We unscrew the bolts and remove it together with the knee or disconnect it in place and remove it separately - no difference

We unscrew the checkpoint drive rod and throw it on the ground

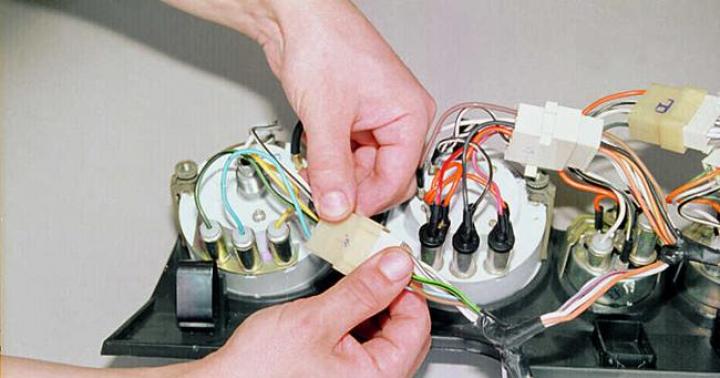

Disconnect the breaker contact wire from the coil

Disconnect the ground wire. The earth wire is located at the bottom of the engine just behind the knee of the muffler. Fastened to the engine with a 10

We remember the location and unscrew the dinostarter wires from the relay-regulator. After unscrewing the terminals - remove the wiring harness from the frame

The engine is attached to the frame at three points: one at the very bottom, the other two - front and rear. We unscrew the bolts that secure the engine to the frame. For greater convenience, the bolts on the engine can be left on and instead of them, only the brackets can be unscrewed from the frame

Just a couple of months ago, an old client asked to capitalize the engine of his "Ant" for the season. He is not greedy for money - he promised to buy everything that is needed for repairs. Agreed, the client brought it for repairs. piston, crankshaft, motor chain and almost all bearings were worn out.

The client insisted on buying a new one crankshaft... They are now in abundance in any store - I don’t want to take them, but they still have the same quality ... I resisted for a long time and as a result the client found a used engine from which I pulled the crankshaft. Of course, it was slightly podushatan, but the bearing of the lower connecting rod head was intact and safe, and we didn't need more.

Instruments

- Large flat screwdriver

- Heads for 14, 17, 22

- Pliers

- Clutch basket puller

- Sealant

- A wish

Preparation

Before installing the crankshaft, it is advisable to check it for runout. And it doesn't matter whether a new crankshaft or a used one, you need to check it otherwise, given the current "quality" of spare parts, you can repair the engine and then suffer long and tediously with it. We put the crankshaft on the prisms and check the runout, the norm: no more than 0.03 mm. If you don't have an indicator, take the crankshaft to a good turner

Build errors

In most cases, the right main bearing of the crankshaft, due to an assembly error, fails almost in the first season after repair. The engine that we are now repairing with you is no exception. The bearing has practically crumbled and in any case needs to be replaced with a new one.

The error lies in the fact that when installing the flange on which the dinostarter stator is attached, the oil channel through which grease flows to the main bearing and the oil seal is smeared.

In order for the main bearing to leave at least several seasons - cut the gasket under the flange a little along the contour of the oil channel and when you put the flange in place - do not smear anything with sealant there.

And one more thing: in order to avoid self-loosening of the bolts securing the stator flange of the dinostarter to the crankcase, and they turn off very often - apply a little thread lock to the thread. If possible, use a medium-strength lock - "blue".

Assembly

I bought the main bearing like this. It's kind of like ours. There are Chinese counterparts in stores - they are more expensive, but I don’t know how they are in terms of quality ... I try to take, albeit not such a super-duper quality, but at least proven over the years.

The quality of the workmanship is such that there is essentially nothing to complain about. The price is quite lifting - 350 rubles.

Press the inner race of the main bearing onto the right trunnion of the crankshaft. Outside - we fasten the dinostarter stator flange and press it into the crankcase until it rests against the flange.

We install an oil seal, a circlip and a main bearing in the left half of the crankcase. I put a new main bearing. It is closed, but it doesn't matter: we open it, wash out the factory grease and install it in the crankcase.

Lubricate clean engine oil all bearings and sealing lips. And very carefully so as not to accidentally wrap the lip of the oil seal - insert the crankshaft into the left half of the crankcase, and knock out the crankcase guides by 5-6mm.

Degrease the crankcase connector, put in a new gasket and install the other half of the crankcase.

We tighten the bolts and immediately so that nothing gets into the crankcase -. I am installing a new piston, cylinder head and petal valve body. Piston like everything else - don't understand whose production - most likely Rostov, but clearly not Chinese. I didn’t want to get involved with this counterfeit, but the owner didn’t want to wait for the cylinder to be bored and put the foot in the cylinder head and insisted on buying it. You see the prices for spare parts - to contact or not to contact this remake is up to you.

We install the second main bearing in the crankcase and fix it with a retaining ring.

(2

estimates, average: 4,50

out of 5)

(2

estimates, average: 4,50

out of 5) Ant is a three-wheeled cargo moped produced by the Tula plant. The Ant gained popularity due to its versatility and cost. An efficient motorcycle was a way out of the situation when there was no possibility of acquiring a car in Soviet times. The carrying capacity of 250 kg, with a weight of 240 kg, made this transport indispensable in agriculture.

The scooter is distinguished by high maneuverability and cross-country ability, as well as small dimensions. In the garage, it will take up as much space as a heavy motorcycle with a sidecar.

The Soviet motor scooter "Ant", which is still popular, has the following specifications:

The Soviet motor scooter "Ant", which is still popular, has the following specifications:

- Length - 2.68 m.

- Width - 1.25 m.

- Height - 1.07 m.

- Dry weight - 240 kg.

- Carrying capacity - 250 kg.

- The speed is about 30 km / h.

- Gasoline engine, two-stroke, 11 hp.

- 4-speed gearbox + reverse.

- Drum brakes with mechanical drive on each wheel.

Among fans of this brand, there is an opinion that the scooter is not inferior in operational properties to Western counterparts.

Of the advantages of a moped, it is worth noting:

- Small turning radius - 3.5 m.

- The lightness of the motor scooter "Ant", motorcycles predominate in weight.

- Low cost - only used devices are presented on the market.

There are also disadvantages:

- There are a lot of worn-out equipment on the market.

- The engine has high consumption fuel - from 8 liters. for 100 km. But more often this figure is closer to 10 - 11 liters. for 100 km. due to increased wear.

- Frequent breakdowns due to low reliability, especially of the engine.

The owners of Ant have the most questions about the engine. Appetites for fuel consumption want to restrain.

A motor was installed on the Ant, which was different from others produced by the industry. Soviet Union... Innovations in its design fueled the interest in technology of the then ordinary people. And now they are stirring up restorers and collectors. The differences are as follows:

A motor was installed on the Ant, which was different from others produced by the industry. Soviet Union... Innovations in its design fueled the interest in technology of the then ordinary people. And now they are stirring up restorers and collectors. The differences are as follows:

- The presence of an electric starter.

- Forced cooling.

The main difference is the presence of an electric starter. This made it possible to start a moped in the same way as a car.

The cooling fan blows air around the engine casing, removing heat from it. It is worth noting that such a scheme works tolerably well.

The motor structure is simple. But even this does not insure him against breakdowns, which are often associated with age. It is not worth disassembling the motor just like that, but when the following signs appear, you should take up the tools:

- Launch problems.

- Oil leak.

- Lack of traction.

- Increased background noise.

- The winding lever does not return to its place.

Possible breakdowns:

Possible breakdowns:

- Worn oil seals.

- Poor assembly after previous repairs.

- Breakdown of the CPG.

- Worn bearings.

- The recoil spring has burst in the kickstarter.

Note! Front overhaul power plant washing it is optional. It is enough to drain the oil and remove it from the frame.

Cylinder block

Having unscrewed a few bolts, it is required to remove the cylinder head. Pay attention to the worn out cylinder head gasket. Opposite the outlet window, the so-called development should be probed. If a characteristic wave or step is felt, then such a cylinder must be changed or bored.

Overshoot occurs where the piston rings are in contact with the cylinder. Where they work, the metal wears out, so a transition is formed at the border with 2 zones, which reflects the degree of wear.

Examine the piston for wear. Some "Kulibins" manage to modify it with sandpaper.

Clutch

- Removing the clutch cover and kickstarter shaft. Pay attention to the return spring - it often bursts and the kickstarter does not return to its place. You can also check the timing chain tension at this point.

- Analysis of the clutch. To do this, you need to unscrew the nuts and remove the pressure plate from the basket.

- The lock washer must be unbent and a stick inserted under the tooth of the main gear sprocket. Please note that the thread on the crankshaft stub nut is right-hand. The nut needs to be unscrewed.

- There will be another lock washer that needs to be straightened out. We take a puller and fixes the clutch drum. The thread at the clutch nut is left-handed.

- The disc and drum are removed, as well as the clutch basket is removed from the shaft together with the chain and the drive sprocket.

Dinostarter

Dismantle the following items:

- Cooling jacket.

- Ignition interrupter cam, but on condition that the power plant was not altered for magneto. In this case, it is required to fix the dinostarter rotor. This can be done for the cooling fan or by fixing the crankshaft with improvised means.

- The rotor is dismantled using a puller - standard or homemade.

As a result, the rotor is removed.

Spare parts price

Despite the fact that the production of the device has long ceased, to this day you can find new spare parts that are produced by the industry. Some parts are imported, some are assembled. The sets are supplied:

- Clutch discs.

- Power plant and gearbox gaskets.

- Nuts.

- Branch pipes.

- Levers.

The necessary parts can be found on the Internet using store catalogs. The prices for the spare parts of the motor scooter "Ant" are loyal. Here are some examples:

- Clutch disc - 400 rubles.

- Kickstarter shaft - 1100 rubles.

- Front shock absorber - 1600 rubles.

- Gearbox oil seals - 100 rubles.

- Piston - 2500 rubles.

- Reducer - 14,000 rubles.

- Wheel hub - 2000 rubles.

Judging by the prices, the device is more than cheap to repair. This is an important operational property for people in the countryside.

In terms of tuning the Soviet apparatus, Ant what the owners will not come up with. After all, they are often technically savvy people who enjoy spending time in the garage. Several areas can be distinguished:

In terms of tuning the Soviet apparatus, Ant what the owners will not come up with. After all, they are often technically savvy people who enjoy spending time in the garage. Several areas can be distinguished:

- Weight loss. To do this, you need to remove the "extra" equipment. This includes the body kit in the form of fenders, hood and fairings, as well as all electrical equipment. For the transportation of goods in the village in the summer, all this is unlikely to be required.

- Increased recoil from the power plant... To do this, cut off the dinostarter shaft. The operation will add power and dynamism. Recoil during cranking is leveled by trimming the crankshaft.

- Installation of other wheels. 4.5 - 9 in the front, and 7 - 10 in the back. Permeability and speed will increase.

- Improvement piston group... You can buy a piston with three rings and make an additional window in the cylinder for supplying the fuel mixture.

- Magneto and improving the efficiency of the cooling system- this is additional tuning.

The main task when tuning is to increase reliability and to poke around less in details due to breakdowns.

In terms of tuning the engine, some owners went to drastic measures and installed a Lifan 188f engine on the Ant scooter, which has a volume of 400 cubic meters. see. And its power is 13 hp. A distinctive feature of this assembly is a variator and a centrifugal clutch.

The centrifugal clutch is not the best way for freight transport, because when driving over rough terrain on a loaded scooter on low speeds its slippage is possible. And this incapacitates him.

What are the modifications of the "Ant" scooter on the video:

The motor scooter Ant was produced at the Tula Machine-Building Plant from 1959 to 1995. Its modification, or, as they say now, restyling, was carried out in 1983 and updated version received the designation Ant 2M 01. The longevity of this unusual three-wheeled vehicle brought, first of all, positive qualities, among which it is necessary to highlight:

- versatility;

- affordable cost;

- simple repair;

- compactness;

- maneuverability.

Motor scooter TMZ Ant was the first cargo copy of motorcycle equipment, mass-produced in the USSR. The presence of a cargo platform allowing to transport 250 kg of cargo at a speed of 60 km / h made Ant very popular. Suffice it to note the areas in which it was applied:

- Transportation within the city, including small consignments of products for restaurants, cafes and canteens.

- Intra-plant transportation, when small batches of certain components were moved between production workshops.

- Transportation of small volumes of building materials, especially in urban environments.

- Carrying out transportation indoors, primarily for agricultural purposes (greenhouses, poultry farms, livestock farms).

For various modifications of the TMZ Muravei scooter, four body options were used:

- open;

- open reduced (installed on the cargo-passenger version);

- awning;

- van.

The most significant drawback should be noted the lack of any comfort for the driver, who was forced to spend almost the entire working day at the wheel of a scooter. It was especially difficult to work in winter, since, unlike two-wheeled mopeds, scooters and motorcycles, the cargo scooter Muravei was operated at state-owned enterprises also in winter.

Device and technical parameters

The device of the motor scooter Ant was quite simple and consisted of the following main parts:

- engine;

- frame;

- transmission and suspension;

- electrical equipment;

- brake system;

- body.

Such a simple design of the Ant 2M 01 scooter and its wide unification with the two-wheeled model Tulitsa (Tula) allowed the owners to carry out repairs on their own.

The TMZ Muravei scooter had the following technical characteristics and operational parameters (the data for the modification of the Muravei 2M scooter are given in brackets):

- Drive - 3x2.

- Carrying capacity- 0.25 t (0.28 t).

- Engine:

- type - gasoline two-stroke,

- ignition - electronic;

- number of cylinders - 1,

- volume - 0.20 l,

- cooling option - forced air,

- power - 11.0 liters. with. (12.5 l. From.),

- carburetor - K-36G,

- fuel - a mixture of gasoline and oil (1/33).

- Dimensions:

- base - 1.78 m,

- length - 2.68 m,

- width - 1.25 m,

- height - 2.16 m,

- track - 1.05 m,

- ground clearance - 0.12 m.

- Transmission:

- type - mechanical,

- number of gears - 4,

- reverse gear - through a reverse gear,

- the way of switching is a foot pedal.

- Total information:

- weight - 0.24 t,

- maximum speed - 60 km / h, (62 km / h),

- volume fuel tank- 13.0 l,

- fuel consumption - 6.2 l, (6.0 l),

- wheel size - 4.00-10.

The main disadvantages of a scooter and its modernization

Motor scooter Ant, like any technique, except for its own positive qualities also had disadvantages. At the same time, the existing shortcomings could be attributed both to the structural, originally incorporated in the device, and to the operational ones arising during the operation of the equipment.

According to the reviews of the owners, structural defects that required alteration or the most frequent repair of a particular unit should include:

- an unsuccessful circuit for the electrical equipment of a scooter, often leading to the failure of components (din-starter, relay-regulator, ignition coil), especially rainy weather;

- unfinished device Gearboxes often with poor-quality factory assembly led to a flight during operation of 2nd or 3rd gear. To eliminate it, the owners had to study the device of the box itself, as well as how to properly disassemble, and then assemble the gearbox after repair;

- not a big difference in the fuel levels between the tank and the carburetor chamber, when there was a small amount of fuel in the tank, it led to operation on a lean mixture or to stop the engine.

The most common operational deficiencies are:

- unstable ignition on Ant requiring frequent adjustments;

- short service life of brake pads;

- loss of hydraulic liquid shock absorbers, requiring disassembly, refueling and assembly of shock absorbers for repair;

- malfunctioning electrical equipment of the din-starter under the influence of dirt, water, dust. The repair was carried out by disassembly-assembly, nickname of the electrical circuit with the search and replacement of the failed element;

- cracks in the frame;

- oil leak in the gearbox.

Very often, the owners, having gained experience in operating the Ant motor scooter, carried out modernization. But before proceeding with the implementation of the changes, the following issues were resolved:

- How much is it?

- What will the modified Ant look like?

- How to find and collect necessary materials for modernization?

- How much will the scooter weigh after the alteration and how will this affect the technical characteristics?

- How long will it take to make the rework?

After receiving positive answers to these questions, work was carried out on the changes. Motor scooter Ant tuning, which made it possible to give it additional properties, boiled down to the following main alterations:

- Tipper installation bodies for the transportation of bulk cargo.

- Design change appearance.

- Installation of a coupling device that allows you to work with various trailed and semi-trailed devices and equipment.

Versatility, cost and maintainability allowed the TMZ Muravei scooter to be compared in terms of production volume and popularity with such the best Soviet models of motor vehicles as a heavy and light road motorcycle for a village.

In Soviet times, this bloodsucker Ant was bought only because of its body. Since nothing of the kind was produced in the USSR in those years. And people had to go to the garden, then feed the farm, so they took him.

The body in Ant is really good; you can easily load 10 bags of mixed feed, 500 kilograms of coal or half a cube of firewood into it and he will boldly trample all this junk home. On the two-seater version, the body was significantly smaller and strongly shifted back due to which the overloaded scooter tipped over backwards on bumps. But on the other hand, the two-seater version could be ridden together.

The tailgate opens like a regular truck

In stock - the body has no extensions. On collective farms, this feature was ignored and the sides were sewn to some unrealistic size.

Control

The steering is standard for Soviet motorcycles: on the right is the throttle, on the left is the clutch lever, but what else is needed? ..

Engine

The Ant's engine is somewhat different from the Soviet engines of that time. The most significant difference lies in the starting system: here it can be carried out using an electric starter (in the 50s it was very cool) or using a manual kickstarter. Not a single Soviet motorcycle of those years had an electric starter at all.

The engine starts with a starter just like a normal car: insert the key into the ignition lock, turn the key all the way to the right and the engine starts

The second difference is the forced cooling of the engine.

The fan drives air through the shrouds to cool the cylinder and cylinder head. Cooling system works tolerably

Mechanical clutch with cable drive from the lever on the steering wheel

The gearbox is mechanical, the shift lever is on the left, right under the driver's foot. The switching algorithm is as follows: the first, second, third and fourth gear is turned up. Neutral is at the very beginning and to engage it you need to push the gear lever down. Controversial decision, but it is done here

Double-shaft gearbox with constant gearing

The engine is as simple as a broom

Transmission

The rear wheels are driven by a chain

The chain transmits torque to the reverse reduction gear and then through the axle shafts and rubber couplings, the torque is distributed between the rear wheels. Characteristic feature of this gearbox is the presence of a reverse

The reverse lever is located on the right side

Electrician

The most problematic part of the Ant has always been considered his electrician, in particular the voltage regulator relay and the dino starter (generator and starter in one person). Dino starter and relay-regulator because of their design features require constant attention and qualified service. If the dinostarter is not serviced on time, then it begins to undercharge the battery literally in the very first season

On older models, the relay-regulator was of a mechanical type

On the latter, more advanced - electronic type

Contact ignition. Contacts are located in the cooling jacket

The ignition coil and condenser are placed on the frame. In terms of repair and maintenance, it is very convenient

Fuel system

The power system consists of a fuel tank, carburetor and air filter

Fuel supply by gravity, feed control - mechanical fuel valve

On the latest scooters, a more advanced K-65G carburetor was installed. In general, the carburetor is very good, if only because it has two systems that facilitate starting in cold weather: a manual enrichment on the steering wheel and a float sink. All these systems together provide a confident engine start in any frost.

To increase traction at the bottom, a petal valve has been introduced into the engine design. The valve is installed in the cylinder and closes the reverse fuel ejection from the crank chamber

Three-channel blowing of the cylinder. Three-channel purge provides better cylinder filling

The cylinder head has a displacer. The displacer itself is a useless thing, but in combination with a three-channel purge and a petal valve, it significantly adds thrust at the bottom.

Brakes

The Ant also has brakes, and you can even try to stop the scooter with them, but only three kilometers before the obstacle. Both brakes are drum brakes with a mechanical drive: front manual with a cable drive, rear foot brake with a drive from the rods