Complexity

Without toolsNot marked

Alternator type 9402.3701-01 (installed on a Chevrolet Niva manufactured after the fall of 2003), three-phase, with a built-in rectifier unit and an electronic voltage regulator, right-hand rotation (on the drive side).

NOTE

Chevrolet Niva, produced before the fall of 2003, was equipped with a generator type 9412.3701, which was also installed on the injection VAZ 21214, VAZ 2131, VAZ 2123 until the fall of 2003.

NOTE

The alternator mounted on the vehicle used for the photography is driven by a V-belt. Repair work is shown on the example of a multi-ribbed pulley generator. All elements of both generators, except for the pulleys, are absolutely identical.

The alternator armature is driven from the crankshaft pulley by a V-belt or (depending on the version) a V-ribbed belt.

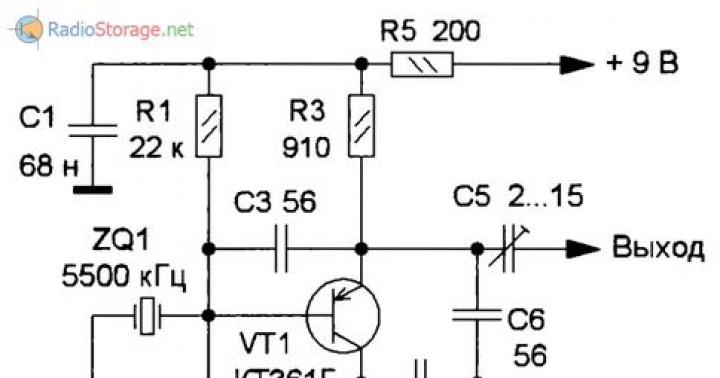

Rice. 9.3. Generator 9402.3701-01: 1 - rectifier block; 2 - bearing sleeve; 3 - rear bearing of the rotor shaft; 4 - contact rings; 5 - protective sleeve; 6 - terminal "B +" of the generator; 7 - gasket; 8 - casing; 9 - voltage regulator with brush holder; 10 - coupling screw; 11 - back cover; 12 - stator; 13 - front cover; 14 - remote ring; 15 - front bearing; 16 - pulley; 17 - washer; 18 - rotor.

Stator 12 (Fig. 9.3) and covers 11 and 13 are tightened with four screws. The rotor shaft 18 rotates in bearings 3 and 15, which are installed in the covers. Power is supplied to the rotor winding (field winding) through brushes and slip rings 4.

The three-phase alternating current induced in the stator winding is converted into a direct current by a rectifier unit 1 attached to the cover 11. The electronic voltage regulator 9 is combined into one unit with a brush holder and is also attached to the cover 11.

Rice. 9.4. Generator system wiring diagram: 1 - battery; 2 - generator; 3 - control lamp of the battery charge, located in the instrument cluster; 4 - mounting block; 5 - ignition switch.

The generator connection diagram is shown in fig. 9.4. The voltage for excitation of the generator when the ignition is switched on is supplied to the output “D +” of the regulator (output “D” of the generator) through the control lamp 3 located in the instrument cluster. After starting the engine, the excitation winding is powered by three additional diodes installed on the rectifier unit of the generator.

The output "W" of the generator on cars of the BA3-2123 family is not used. The operation of the generator is controlled by a warning lamp in the instrument cluster. When the ignition is turned on, the lamp should be on, and after starting the engine, it should go out if the generator is working. The bright burning of the lamp or its glow half-heartedly indicates malfunctions.

Technical characteristics of the generator

HELPFUL ADVICE

If the alternator belt broke on the way, and you forgot the spare at home, a 20 mm wide ring cut from an old car chamber can temporarily replace it. To reduce current consumption when driving a vehicle with a faulty alternator, if possible, turn off the radio, unnecessary lights, heater fan, glass heating, etc.

WARNING

The "minus" of the battery must always be connected to ground, and the "plus" must be connected to the "B +" terminal of the generator. An erroneous reverse connection of the battery will immediately cause increased current through the rectifier block of the generator.

The generator must not be operated with the battery disconnected. This will cause transient voltage surges at the B+ terminal of the alternator, which can damage the alternator voltage regulator and electronic devices in the vehicle's electrical system.

It is forbidden to test the generator’s performance “for a spark”, even by briefly connecting the “B +” terminal of the generator to ground. In this case, a significant current flows through the rectifier unit of the generator and it can fail. You can only check the generator with an ammeter and a voltmeter.

The rectifier unit of the generator is not allowed to be checked with a voltage of more than 12 V or with a megohmmeter, since it has a voltage that is too high for the diodes and they will be broken during the test (a short circuit will occur).

It is forbidden to check the car's electrical wiring with a megohmmeter or a lamp powered by a voltage of more than 12 V. If such a check is necessary, then first disconnect the wires from the generator.

It is necessary to check the insulation resistance of the generator stator winding with increased voltage only at the stand and always with the phase winding leads disconnected from the generator rectifier unit.

When welding components and parts of the car body, disconnect the wires from all terminals of the generator and the battery.

Alternator type 9402.3701-01, three-phase, with built-in rectifier unit and electronic voltage regulator, clockwise rotation (drive side).

Generator Niva Chevrolet 9402.3701-01: 1 - rectifier block; 2 - bearing sleeve; 3 - rear bearing of the rotor shaft; 4 - contact rings; 5 - protective sleeve; 6 - output "B +" of the generator; 7 - gasket; 8 - casing; 9 - voltage regulator with brush holder; 10 - coupling screw; 11 – back cover; 12 - stator; 13 - front cover; 14 - remote ring; 15 - front bearing; 16 - pulley; 17 - washer; 18 - rotor.

Connection diagram of the Chevrolet Niva generator system

1 - rechargeable battery; 2 - generator; 3 – the control lamp of a charge of the accumulator battery located in a combination of devices; 4 - mounting block; 5 - ignition switch.

The generator connection diagram is shown in the figure above. The voltage for excitation of the generator when the ignition is switched on is supplied to the output “D +” of the regulator (output “D” of the generator) through the control lamp 3 located in the instrument cluster. After starting the engine, the excitation winding is powered by three additional diodes installed on the rectifier unit of the generator.

The output "W" of the generator on cars of the VAZ-2123 family is not used. The operation of the generator is controlled by a warning lamp in the instrument cluster. When the ignition is turned on, the lamp should be on, and after starting the engine, it should go out if the generator is working. The bright burning of the lamp or its glow half-heartedly indicates malfunctions.

Specifications of the generator for Niva Chevrolet

- Maximum recoil current (at 13 V and 6000 min -1), A - 80

- Limits of regulated voltage, V - 13.2-14.7

- Gear ratio engine-generator - 1:2.16

Removal and installation of the Chevrolet Niva generator

Before starting to remove the generator, it is necessary to drain it - remove the minus terminal of the battery.

Disconnect the block with the wire from the output "D" of the generator

Remove protective cover

Unscrew the nut and disconnect the wires from the contact bolt (terminal "B +")

Loosen the bolt nut securing the alternator to the tension bar

Take out the bolt

Loosen the nut of the alternator lower mounting bolt.

Remove the alternator drive belt, how to remove the Shiva Chevrolet alternator belt is shown in the figure

Remove the bolt and use the mounting spatula to remove the generator from the bracket

Remove the generator from the Chevrolet Niva.

The installation of the generator on the Chevrolet Niva is carried out in the reverse order of its removal. After installing the generator, adjust the tension of the generator drive belt.

Do-it-yourself Niva Chevrolet generator repair

To disassemble, repair and assemble a generator on a Chevy Niva, you will need: 10 keys, Phillips and flat-blade screwdrivers, an ohmmeter (autotester), a control lamp.

Chevrolet Niva generator device:1 - nut; 2 - washer; 3 - pulley; 4 - front cover; 5 - remote ring; 6 - rotor; 7 - stator; 8 - back cover;9 - casing; 10 - gasket; 11 - protective sleeve; 12 - rectifier unit with a capacitor; 13 - brush holder with voltage regulator.

Press out the three latches securing the rear cover of the generator

Remove the plastic casing of the generator

Remove the two screws securing the Chevrolet Niva voltage regulator

Remove the voltage regulator with brush holder

Disconnecting the wire from the terminal of the regulator

Remove the four screws securing the rectifier unit and the screw securing the Chevrolet Niva capacitor

Bend the three leads of the stator winding so that they make it possible to remove the rectifier unit

Remove the rectifier with capacitor

To replace the capacitor, unscrew the nut of the contact bolt, remove the washer and spacer. Remove the capacitor lead from the terminal bolt.

Turn out four coupling screws (screws are tightened by the big moment). Spring and flat washers are installed under the screw heads

Using a screwdriver, remove the generator cover from the side of the slip rings. Clamp the generator rotor in a vise (not too hard so that the rotor does not turn) and unscrew the pulley mounting nut. Remove spring washer and pulley.

Remove the alternator thrust washer

Remove the Chevrolet Niva generator rotor from the cover on the drive side

Remove the distance ring from the rotor shaft

Inspect slip rings. If they have scuffs, scratches, scratches, wear marks from brushes, etc., the rings must be ground. If damage to the rings cannot be removed with sandpaper, you can grind the rings on a lathe, removing the minimum layer of metal, and then grind

Check the resistance of the rotor winding with an ohmmeter (tester) by connecting it to slip rings. If the ohmmeter shows infinity, then there is a break in the windings and the rotor needs to be replaced

Check with a test lamp if there is a winding short circuit on the rotor housing. To do this, turn on the test lamp in a 220 V alternating current network (you can use a rechargeable battery and a 12 V lamp). Connect one wire to the rotor housing, and the second - in turn to each ring. In both cases, the lamp should not light. If at least in one case the lamp is on, then a short circuit occurs and it is necessary to replace the rotor

Examine the stator. On the inner surface of the stator there should be no traces of armature touching the stator. If there is wear, the bearings or alternator covers must be replaced.

Check for an open in the stator winding. To do this, turn on the test lamp in a 220 V alternating current network (you can use a rechargeable battery and a 12 V lamp). Alternately connect a test lamp between all terminals of the winding. In all three cases, the lamp should be on. If the lamp does not light up, there is a break in the winding. Replace stator or winding

Check if there is a short circuit in the stator windings to the housing. To do this, turn on the test lamp in a 220 V alternating current network (you can use a rechargeable battery and a 12 V lamp). Connect the lamp to the stator winding terminal, and the wire from the current source to the stator housing. If the lamp lights up, then there is a short circuit: it is necessary to replace the stator or winding. Inspect the drive side alternator cover assembly with bearing. If during rotation of the bearing you feel play between the rings, rolling or jamming of the rolling elements, damaged protective rings or there are traces of lubricant leakage, and cracks are found in the cover, especially in the places where the generator is attached, it is necessary to replace the cover assembly with the bearing (the bearing in the cover is rolled) . Check the ease of rotation of the bearing from the side of the slip rings. If during rotation of the bearing there is play between the rings, rolling or jamming of the rolling elements, the protective rings are damaged or there are traces of grease leakage, the bearing must be replaced. To do this, use a puller to press the bearing off the rotor shaft and press on a new one using a suitable mandrel, applying force to the inner ring of the bearing. Inspect the generator cover from the side of the slip rings. If cracks are found, the cover must be replaced.

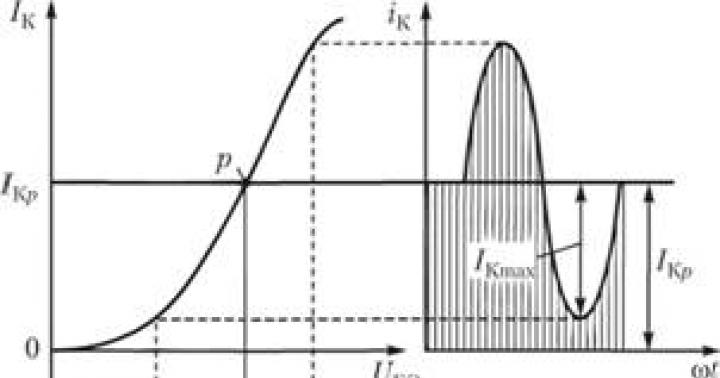

Scheme for testing the voltage regulator (regulator relay) Niva Chevrolet

1 - control lamp; 2 - output "mass" of the voltage regulator; 3 - output "DF" of the voltage regulator; 4 - voltage regulator; 5 - output "D +" of the voltage regulator; A - to the power source.

Check the condition of the capacitor. Damage to the capacitor or loosening of its mounting on the generator (deterioration of contact with the ground) is detected by an increase in radio interference when the engine is running. The capacitor can be checked with a megger or tester. If there is no break in the capacitor, then at the moment the probes of the device are connected to the terminals of the capacitor, the arrow should deviate in the direction of decreasing resistance, and then gradually return back. You can check the rectifier unit both on the removed generator and without removing the generator from the car. The check procedure is the same. For clarity, the test circuits are shown on the removed generator. To check on the car, disconnect the wires from the battery and the generator, and also remove the block with the wire from the voltage regulator terminal.

This is how the rectifier bridge diodes of the Chevrolet Niva generator are located: 1 - positive diodes (with a red mark on the case); 2 - negative diodes (with a black mark on the case); 3 - additional diodes.

Diagnostics of the diode bridge Niva Chevrolet

Check the rectifier diodes with a 12V test light and battery. To check the short circuit in the positive and negative diodes, connect the "+" batteries through a test lamp to the "B +" terminal of the generator, and the "-" batteries to the generator housing. The lamp should not burn; if it is lit, it means there is a short circuit. The block needs to be replaced.

To check the positive diodes, connect the "+" of the battery through a test lamp to the "B +" terminal of the generator, and the wire coming from the "-" of the battery to one of the screws securing the stator winding output. The lamp should not burn; if it is lit, it means that there is a short circuit in the positive diodes. The block needs to be replaced.

To check the negative diodes, connect the "+" of the battery through a test lamp to one of the screws securing the stator winding output, and the wire coming from the "-" of the battery to the generator housing. The lamp should not burn; if it is lit, it means that there is a short circuit in the negative diodes. The block needs to be replaced.

To check additional diodes, connect the “+” of the battery through a test lamp to the contact of the voltage regulator connector block, and the wire coming from the “-” of the battery to one of the screws securing the stator winding output. The lamp should not burn; if it is lit, it means that there is a short circuit in the additional diodes. The block needs to be replaced.

The real favorite among SUVs in the modern automobile market of the country is the Niva Chevrolet car. It combines the excellent qualities of both a touring SUV and a car for family trips. Due to its light weight and short overhangs, the Chevrolet Niva can drive off-road and fords. He easily overcomes steep slopes.

But the electronics system is one of the most vulnerable places in a car. With regular inspection of electrical components, with the timely removal of dirt and moisture from them, repairs will not be required even throughout the entire operation of the car.

Generator operation

The Chevrolet Niva generator is responsible for the reliable and high-quality operation of the electronics system. The owner should identify possible malfunctions in time and carry out high-quality repairs, since the functioning of all lighting fixtures depends on its good condition. It also affects battery life. Continuous current supply is provided by the generator.

Although it has small dimensions, the generator has great strength. In order not to cause a breakdown and the car regulator does not fail, the owner must follow the rules for operating the car.

Particular attention should be paid to the Chevrolet Niva. Malfunctions that led to a failure in its operation can be determined on automotive diagnostics. And the repair depends entirely on the degree of complexity of the breakdown.

Malfunctions that happen in the operation of the generator

The Niva Chevrolet generator, the photo of which is provided in our article, may have the following malfunctions:

- the pulley is damaged or completely worn out;

- current-collecting brushes are worn out;

- rectifier failure;

- failure of the voltage regulator;

- worn collector;

- worn or completely destroyed bearing;

- Charging wires are damaged.

The owner of the car needs to be familiar with the main causes that occur. In addition, you need to know how to eliminate these breakdowns, as well as preventive measures to prevent them.

Generator "Niva Chevrolet"

Depending on the type of current, generators are either direct or alternating current. The owners of the named car sometimes do not know, but what generators are used for this model? "Chevrolet Niva" was provided with an electromechanical alternating current device. A diode bridge is built in here - a rectifier. To provide work to electrical consumers, it converts alternating current into direct current. The diode bridge with the generator is one mechanism, they can be located both in the case and in the cover of the generator.

The operation of the latter is affected by the speed of the car and the speed of its engine, since the generator is connected by a belt to its crankshaft. In order to adjust the output current, it is installed. In addition, integrated voltage regulators are built into modern generators.

The Chevrolet Niva generator may be prone to the following malfunctions:

- electric;

- mechanical.

If the malfunction is mechanical, then it includes a breakdown of the mount, housing, faulty condition of the clamping springs, bearings, belt drive, or other breakdowns that are not related to the electrician.

With the first type of malfunction, winding breaks, burnout or wear of the brush are possible, the rotor can pierce, and a short circuit occurs between the turns. The diode bridge and the relay-regulator may be out of order.

Sometimes there are signs indicating that the Chevrolet Niva generator is out of order, but completely different breakdowns can cause this problem.

Signs of a malfunctioning generator

As a rule, there are several signs of a generator malfunction:

- When the engine is running, the battery discharge indicator lamp flashes or is constantly on without interruption.

- Car headlights are dim in color, and when the engine is running, the horn rattles or is completely quiet.

- The battery loses its charge quickly.

- With an increase in the number of revolutions, the brightness of the headlights changes significantly.

Alternator belt "Chevrolet Niva"

In order not to get into an unpleasant situation, it is necessary to ensure that the Chevrolet Niva generator belt is in working condition. So, the presence of mechanical damage to the pulley can lead to damage to the belt, as a result, it can break.

Alternator Belt Replacement

To change the Chevrolet Niva, you need to use the following tools:

- screwdriver;

- jack;

- a set of keys.

In a Chevrolet Niva car, the alternator belt is replaced as follows:

- Remove the connector from the crankshaft position sensor.

- Unscrew and remove the bolt that secures the sensor.

- The nut attaching the generator needs to be slightly loosened and moved to the block. With the alternator displaced, its belt will loosen and be removed without problems.

- Using a jack installed on the side where the generator is located, raise the machine by engaging first gear.

- Pull on the belt so that it moves away from the pump pulley. Turn the wheel so that the pulley passes over the pulley.

- Then remove the belt from the other pulleys.

- The new one must first be put on the alternator pulley and the crankshaft pulley, and only then put on the pump pulley.

- Turn the wheel until the belt is on the pulley.

- Put the generator in place, and pulling the belt, attach it with a nut to the bracket.

- Install the crankshaft position sensor.

The process of replacing the alternator belt is completed.

generator roller

Belt tension affects the operation of the generator. And the Chevrolet Niva generator roller regulates it. During the operation of the car, it is necessary to ensure that the roller is in good condition. If there is the slightest suspicion of a breakdown, the Niva Chevrolet must be repaired.

How to replace the tension roller

The generator roller device is quite simple. The bearing is its main part. When loosening or slowing down the belt, it is necessary to check the bearing itself by turning it by hand. A working roller has a quiet rotation, there are no jerks and biting. If the roller is in a faulty condition, it is necessary to replace it, which is possible even in the garage, with a minimum set of tools.

Install a pry bar or other tool that can prevent the movement of the crankshaft so that the clutch disc is locked. By loosening the bolt that secures the roller, relieve the tension on the belt. Having completely unscrewed the axial bolt, the tension roller is removed. Then a new roller is installed and the belt tension is adjusted.

After replacing the roller, you need to re-inspect and check its operation. The user manual has detailed instructions regarding the problem described.

Generator brushes

Worn-out brushes of the Chevrolet Niva generator can lead to a voltage drop in the electrical system of the car. This is considered one of the main and frequent causes of this type of malfunction. But since the generator has a simple design and is easy to get to, even an inexperienced motorist can replace its brushes.

The main signs of a bad brush are:

- drawdowns occur in tension;

- weak headlights at night, blinking;

- the radio is turned off, etc.

Usually, when passing technical inspection, small elements of the generator are rarely checked. Therefore, worn brushes can remind you of themselves unexpectedly. But before deciding that the replacement of the Chevrolet Niva generator brushes is necessary, you need to find out if there are any other malfunctions that can cause such symptoms. And only after making sure, you can disassemble the generator housing.

Alternator brush replacement

When replacing the brushes, the voltage regulator is removed together with them as an assembly. In this case, the negative is removed and the wires that come from the generator casing are disconnected.

Then the wiring harness is disconnected. From their tips with a positive terminal, it is necessary to remove the rubber cap that performs protective functions. Then, from these wires, you need to unscrew the nut with which they were attached to the generator unit, and remove them.

After disconnecting the spring clips of the generator, you should remove its black casing, made of plastic. Using a Phillips screwdriver, unscrew the fasteners of the voltage regulator. Get it complete with brushes. Then disconnect the block of wires from it.

Replace alternator brushes and reinstall in reverse order.

If the length of the brush rods is less than 0.5 mm, they must be replaced. But if the brushes are in working condition, and the Niva Chevrolet generator does not supply a charge, it is necessary to check the operation of the voltage regulator and the circuit from the regulator to the brushes.

Reasons to replace the generator

One of the reasons when replacing a generator on a Chevrolet Niva is simply necessary is damage to the windings. If this happens, then either a rewind is needed, or you will have to purchase a new generator. Maybe the repair will cost a little cheaper, but no one will give you guarantees about the quality of the rewind and the uninterrupted supply of current to the battery.

Removing the generator

For this process, you need to take a Phillips screwdriver. In addition, you must resort to using a car tester or ohmmeter, a 10 key and a test lamp.

To change the generator, it must be removed from the engine compartment. First, disconnect the wire and negative battery terminal. Next, disconnect the block with wires and the output of the generator, and take out the protective cover from there. Then, unscrewing the nut, disconnect the wires on the generator contact bolt. Then unscrew the bolt that secures the generator to the tension bar, and pull it out. It is also necessary to unscrew the bolt-shaped mount at the bottom of the generator.

Then you should remove the belt. After removing all the bolts, the generator must be removed from the bracket using a mounting spatula. To install a new one, you need to go through the whole process in reverse order.

Having replaced the described electromechanical device, it is necessary to inspect its drive belt and adjust its degree of tension. But before changing the old Chevrolet Niva generator to a new one, you need to make sure that the replacement is really necessary. There are times when repairs can be done by yourself, without resorting to the help of specialists.

In order to avoid confusion, it should be noted how the generator covers are correctly positioned. Next, you need to remove the plastic protective cover by unfastening the three latches on it. The voltage regulator and brush holder are removed together. In order to release the rectifier unit and the capacitor, it is necessary to disconnect the wires from the regulator terminal. The stator winding has three terminals. And in order to perform an operation to remove the rectifier unit and capacitor, you need to bend these conclusions a little. Prying with a flat screwdriver from the side where the slip rings are located, remove the cover from the generator.

Clamping the generator rotor in a vice, unscrew the mount from the pulley. Then take out the spring washer, pulley and thrust washer. Then the rotor and the distance ring are carefully pulled out and their condition is checked. If there are traces of damage, scratches and a noticeably worn condition on the ring, it must be sanded with a regular sandpaper. If the result is poor, the ring is ground on a lathe with the removal of a small layer of metal.

Having connected the rotor with slip rings, the resistance of its winding is checked with a tester. If the wiring is broken, the meter will show an infinite reading. For this reason, the rotor must be replaced.

To check whether the rotor winding closes or not, you need to turn on the test lamp in the network through which 220 V alternating current flows. One lamp wire is connected to the rotor, each ring is connected to the second one in turn. If the lamp lights up, the rotor needs to be replaced.

Complexity

Tool1 - 3 h

Tools:

- Open end wrench 10 mm

- Ratchet wrench

- Head for 8 mm

- Head 10 mm

- Head 13 mm

- Head 24 mm

- Mounting blade

- Marker

- Phillips screwdriver, medium

- Screwdriver flat medium

- Bench vice

- Tester

- 2-arm puller

- Calipers

- torque wrench

Parts and consumables:

- Capacitor (if needed)

- Generator Rotor (if needed)

- Alternator bearings (if required)

- Generator covers (if required)

- Rectifier unit (if necessary)

- Accumulator battery

- Lamp

- wires

Note:

Below is a detail to understand the relative placement and functional relationship of the parts of the generator.

Generator details 9402.3701-01:

1 - screw;

2 - washer;

3 - pulley;

4 - front cover;

5 - remote ring;

6 - rotor;

7 - stator;

8 - back cover;

9 - casing;

10 - pad;

11 - protective sleeve;

12 - rectifier unit with capacitor;

13 - brush holder with voltage regulator.

1. Remove the alternator from the vehicle as described.

2. Mark the relative position of the generator covers.

3. Wring out three latches and remove a plastic casing.

4. Use a Phillips screwdriver to remove the two screws securing the voltage regulator.

5. Disconnect the wire from the regulator terminal and remove the voltage regulator with the brush holder.

6. Unscrew the four screws securing the rectifier unit and the screw securing the capacitor using a Phillips screwdriver.

7. Bend the three leads of the stator winding so that they make it possible to remove the rectifier unit.

8. Remove the rectifier unit with the capacitor.

9. To replace the capacitor, unscrew the nut of the contact bolt, remove the washer and spacer. Remove the condenser wire end cap from the terminal bolt.

10. Loosen the four clamping screws (the screws are tightened with a large torque). Spring and flat washers are installed under the screw heads.

11. Using a screwdriver, remove the generator cover from the side of the slip rings.

12. Clamp the generator rotor in a vise (not too hard so that the rotor does not turn) and unscrew the pulley mounting nut. Remove spring washer and pulley.

13. Remove the thrust washer.

14. Remove the rotor from the cover on the drive side.

15. Remove the distance ring from the rotor shaft.

16. Inspect slip rings. If they have scuffs, scratches, scratches, wear marks from brushes, etc., the rings must be ground. If damage to the rings cannot be removed with sandpaper, you can grind the rings on a lathe, removing the minimum layer of metal, and then grind.

17. Check the resistance of the rotor winding with an ohmmeter (tester) by connecting it to slip rings.

Note:

If the ohmmeter shows infinity, then there is a break in the windings and the rotor needs to be replaced.

18. Check with a test lamp if there is a winding short circuit on the rotor housing. To do this, turn on the test lamp in a 220 V alternating current network (you can use a rechargeable battery and a 12 V lamp). Connect one wire to the rotor housing, and the second - in turn to each ring.

Note:

In both cases, the lamp should not light. If at least in one case the lamp is on, then a short circuit occurs and it is necessary to replace the rotor.

19. Examine the stator. On the inner surface of the stator there should be no traces of armature touching the stator. If there is wear, the bearings or alternator covers must be replaced.

20. Check for an open in the stator winding. To do this, turn on the test lamp in a 220 V alternating current network (you can use a rechargeable battery and a 12 V lamp). Alternately connect a test lamp between all terminals of the winding.

Note:

In all three cases, the lamp should be on. If the lamp does not light up, there is a break in the winding. Replace stator or winding.

21. Check if there is a short circuit in the stator windings to the housing. To do this, turn on the test lamp in a 220 V alternating current network (you can use a rechargeable battery and a 12 V lamp). Connect the lamp to the stator winding terminal, and the wire from the current source to the stator housing.

Note:

If the lamp lights up, then there is a short circuit: it is necessary to replace the stator or winding.

22. Inspect the drive side alternator cover assembly with bearing. If during rotation of the bearing you feel play between the rings, rolling or jamming of the rolling elements, damaged protective rings or there are traces of lubricant leakage, and cracks are found in the cover, especially in the places where the generator is attached, it is necessary to replace the cover assembly with the bearing (the bearing in the cover is rolled) .

23. Check the ease of rotation of the bearing from the side of the slip rings. If during rotation of the bearing there is play between the rings, rolling or jamming of the rolling elements, the protective rings are damaged or there are traces of grease leakage, the bearing must be replaced. To do this, use a puller to press the bearing off the rotor shaft and press on a new one using a suitable mandrel, applying force to the inner ring of the bearing.

24. Inspect the generator cover from the side of the slip rings. If cracks are found, the cover must be replaced.

25. Check the voltage regulator. Connect a 12 V test lamp to the brushes. Apply a voltage of 12 V "+" to the terminal, and "-" to the "mass" of the brush holder. In this case, the control lamp should light up.

26. Then apply a voltage of 15-16 V - the lamp should go out. If the lamp lights up or does not light up in both cases, then the regulator with the brush holder is faulty and must be replaced.

27. Check the ease of movement of the brushes in the brush holder and their protrusion. If the brushes protrude from the brush holder by less than 5 mm, replace the voltage regulator with the brush holder. If chips or cracks are found on the brushes, also replace the regulator.

28. The health of the capacitor can be checked with a megger or tester (on a scale of 1-10 MΩ). Connect the tester probes to the capacitor terminals. Before connecting, the device shows infinity. At the moment of connection, the resistance decreases, and then returns again to infinity. In this case, the capacitor is good. A defective capacitor must be replaced.

29. You can check the rectifier unit both on the removed generator and without removing the generator from the car. The check procedure is the same. For clarity, the test circuits are shown on the removed generator. To check on the car, disconnect the wires from the battery and the generator, and also remove the block with the wire from the voltage regulator terminal.

Alternator rectifier bridge diode location:

1 - positive diodes (with a red mark on the case);

2 - negative diodes (with a black mark on the case);

3 - additional diodes.

30. Check the rectifier diodes with a 12V test light and battery. To check the short circuit in the positive and negative diodes, connect the "+" batteries through a test lamp to the "B +" terminal of the generator, and the "-" batteries to the generator housing. The lamp should not burn, if it burns, then there is a short circuit. The block needs to be replaced.

31. To check the positive diodes, connect the “+” of the battery through a test lamp to the “B +” terminal of the generator, and the wire coming from the “-” of the battery to one of the screws securing the stator winding output. The lamp should not burn, if it burns, then there is a short circuit in the positive diodes. The block needs to be replaced.

32. To check the negative diodes, connect the “+” of the battery through a test lamp to one of the screws securing the stator winding output, and the wire coming from the “-” of the battery to the generator housing. The lamp should not burn, if it burns, then there is a short circuit in the negative diodes. The block needs to be replaced.

33. To check additional diodes, connect the "+" of the battery through a test lamp to the contact of the connecting block of the voltage regulator, and the wire coming from the "-" of the battery to one of the screws securing the stator winding output. The lamp should not burn, if it burns, then there is a short circuit in the additional diodes. The block needs to be replaced.

34. Assemble the generator in the reverse order of removal. At the same time, orient the generator covers in accordance with the previously made marks. Install the spring washer of the alternator pulley with the convex side to the nut. Tighten the nut to 39-62 Nm (3.9-6.2 kgfm).

The article is missing:

- Tool photo

Chevrolet Niva generator

Design features

Alternator type 9402.3701-01, three-phase, with built-in rectifier unit and electronic voltage regulator, clockwise rotation (drive side).

The alternator mounted on the vehicle used for the photography is driven by a V-belt. Repair work is shown on the example of a multi-ribbed pulley generator. All elements of both generators, except for the pulleys, are absolutely identical.

The alternator armature is driven from the crankshaft pulley by a V-belt or (depending on the version) a V-ribbed belt.

Rice. 9.3. Generator 9402.3701-01:

-

voltage regulator with brush holder;

clamping screw;

back cover;

-

front cover;

remote ring;

front bearing;

rectifier block;

bearing sleeve;

rear bearing of the rotor shaft;

contact rings;

protective sleeve;

output "B +" of the generator;

pad;

Stator 12 (Fig. 9.3) and covers 11 and 13 are tightened with four screws. The rotor shaft 18 rotates in bearings 3 and 15, which are installed in the covers. Power is supplied to the rotor winding (field winding) through brushes and slip rings 4.

The three-phase alternating current induced in the stator winding is converted into a direct current by a rectifier unit 1 attached to the cover 11. The electronic voltage regulator 9 is combined into one unit with a brush holder and is also attached to the cover 11.

Rice. 9.4. Generator system wiring diagram:

accumulator battery;

generator;

battery charge control lamp located in the instrument cluster;

mounting block;

ignition switch

The generator connection diagram is shown in fig. 9.4. The voltage for excitation of the generator when the ignition is switched on is supplied to the output “D +” of the regulator (output “D” of the generator) through the control lamp 3 located in the instrument cluster. After starting the engine, the excitation winding is powered by three additional diodes installed on the rectifier unit of the generator.

The output "W" of the generator on cars of the VAZ-2123 family is not used.

The operation of the generator is controlled by a warning lamp in the instrument cluster. When the ignition is turned on, the lamp should be on, and after starting the engine, it should go out if the generator is working. The bright burning of the lamp or its glow half-heartedly indicates malfunctions.

Technical characteristics of the generator

If the alternator belt broke on the way, and you forgot the spare at home, a 20 mm wide ring cut from an old car chamber can temporarily replace it. To reduce current consumption when driving a vehicle with a faulty alternator, if possible, turn off the radio, unnecessary lights, heater fan, glass heating, etc.

Removal and installation of the generator

1. Disconnect a wire from the plug "-" of the storage battery.

2. Disconnect the block with the wire from the output "D" of the generator.

3. Remove the protective cover,

4. Unscrew the nut and disconnect the wires from the contact bolt (pin "B+").

5. Turn away a nut of a bolt of fastening of the generator to a tension level and

6. remove the bolt.

7. Turn away a nut of a bolt of the lower fastening of the generator.

8. Remove the alternator drive belt.

9. Remove the bolt and use a mounting spatula to remove the generator from the bracket.

10. Remove the generator.

11. Install the generator in the reverse order of removal. After installation, adjust the tension of the alternator drive belt (see "Adjusting the tension and replacing the alternator and water pump drive belt").

Generator repair

You will need: "10" keys, Phillips and flat-bladed screwdrivers, an ohmmeter (autotester), a test lamp.

1. Remove the generator from the car (see "Removal and installation of the generator").

Rice. 9.5. Generator details:

-

front cover;

remote ring;

-

back cover;

-

pad;

protective sleeve;

rectifier unit with a capacitor;

brush holder with voltage regulator

2. Mark the mutual arrangement of covers 4 and 8 (Fig. 9.5) of the generator.

3. Release the three latches.

4. Remove the plastic cover.

5. Remove the two screws securing the voltage regulator.

6. Remove the voltage regulator with brush holder,

7. Disconnecting the wire from the regulator terminal.

8. Turn out four screws of fastening of the rectifier block and the screw of fastening of the condenser.

9. Unbend the three stator winding leads so that they make it possible to remove the rectifier unit.

10. Remove the rectifier unit with the capacitor.

11. To replace the capacitor, unscrew the nut of the contact bolt, remove the washer and spacer. Remove the condenser wire end cap from the terminal bolt.

12. Turn out four coupling screws (screws are tightened by the big moment). Spring and flat washers are installed under the screw heads.

13. Using a screwdriver, remove the generator cover from the side of the slip rings.

14. Clamp the generator rotor in a vise (not too hard so that the rotor does not turn) and unscrew the pulley mounting nut. Remove spring washer and pulley.

15. Remove the thrust washer.

16. Remove the rotor from the cover on the drive side.

17. Remove the distance ring from the rotor shaft.

18. Examine contact rings. If they have scuffs, scratches, scratches, wear marks from brushes, etc., the rings must be ground. If damage to the rings cannot be removed with sandpaper, you can grind the rings on a lathe, removing the minimum layer of metal, and then grind.

19. Check the resistance of the rotor winding with an ohmmeter (tester) by connecting it to slip rings. If the ohmmeter shows infinity, then there is a break in the windings and the rotor needs to be replaced.

20. Check with a test lamp if there is a winding short circuit on the rotor housing. To do this, turn on the test lamp in a 220 V alternating current network (you can use a rechargeable battery and a 12 V lamp). Connect one wire to the rotor housing, and the second - in turn to each ring. In both cases, the lamp should not light. If at least in one case the lamp is on, then a short circuit occurs and it is necessary to replace the rotor.

21. Inspect the stator. On the inner surface of the stator there should be no traces of armature touching the stator. If there is wear, the bearings or alternator covers must be replaced.

22. Check for an open in the stator winding. To do this, turn on the test lamp in a 220 V alternating current network (you can use a rechargeable battery and a 12 V lamp). Alternately connect a test lamp between all terminals of the winding. In all three cases, the lamp should be on. If the lamp does not light up, there is a break in the winding. Replace stator or winding.

23. Check if there is a short circuit of the stator windings to the housing. To do this, turn on the test lamp in a 220 V alternating current network (you can use a rechargeable battery and a 12 V lamp). Connect the lamp to the stator winding terminal, and the wire from the current source to the stator housing. If the lamp lights up, then there is a short circuit: it is necessary to replace the stator or winding.

24. Examine a cover of the generator from a drive end in gathering with the bearing. If during rotation of the bearing you feel play between the rings, rolling or jamming of the rolling elements, damaged protective rings or there are traces of lubricant leakage, and cracks are found in the cover, especially in the places where the generator is attached, it is necessary to replace the cover assembly with the bearing (the bearing in the cover is rolled) .

25. Check up ease of rotation of the bearing from slip rings. If during rotation of the bearing there is play between the rings, rolling or jamming of the rolling elements, the protective rings are damaged or there are traces of grease leakage, the bearing must be replaced. To do this, use a puller to press the bearing off the rotor shaft and press on a new one using a suitable mandrel, applying force to the inner ring of the bearing.

26. Examine a generator cover from slip rings. If cracks are found, the cover must be replaced.

Rice. 9.6. Scheme for testing the voltage regulator:

.jpg)

control lamp;

output "mass" of the voltage regulator;

output "DF" of the voltage regulator;

voltage regulator;

output "D +" of the voltage regulator;

A - to the power supply

27. Check the voltage regulator (see Fig. 9.6).

28. Check up serviceability of the condenser. Damage to the capacitor or loosening of its mounting on the generator (deterioration of contact with the ground) is detected by an increase in radio interference when the engine is running. The capacitor can be checked with a megger or tester. If there is no break in the capacitor, then at the moment the probes of the device are connected to the terminals of the capacitor, the arrow should deviate in the direction of decreasing resistance, and then gradually return back.

29. You can check the rectifier unit both on the removed generator and without removing the generator from the car. The check procedure is the same. For clarity, the test circuits are shown on the removed generator. To check on the car, disconnect the wires from the battery and the generator, and also remove the block with the wire from the voltage regulator terminal.

So the generator rectifier bridge diodes are located:

positive diodes (with a red mark on the case);

negative diodes (with a black mark on the case);

additional diodes.

30. Remove the brush holder from the generator.

31. Check the diodes of the rectifier unit using a 12 V test lamp and a battery. To check the short circuit in the positive and negative diodes, connect the "+" batteries through a test lamp to the "B +" terminal of the generator, and the "-" batteries to the generator housing. The lamp should not burn; if it is lit, it means there is a short circuit. The block needs to be replaced.

32. To check the positive diodes, connect the “+” of the battery through a test lamp to the “B +” terminal of the generator, and the wire coming from the “-” of the battery to one of the screws securing the stator winding output. The lamp should not burn; if it is lit, it means that there is a short circuit in the positive diodes. The block needs to be replaced.

33. To check the negative diodes, connect the “+” of the battery through a test lamp to one of the screws securing the stator winding output, and the wire coming from the “-” of the battery to the generator housing. The lamp should not burn; if it is lit, it means that there is a short circuit in the negative diodes. The block needs to be replaced.

34. To check additional diodes, connect the “+” of the battery through a test lamp to the terminal of the voltage regulator connector block, and the wire coming from the “-” of the battery to one of the screws securing the stator winding output. The lamp should not burn; if it is lit, it means that there is a short circuit in the additional diodes. The block needs to be replaced.

35. Collect the generator in an order, the return to removal. At the same time, orient the generator covers in accordance with the previously made marks. Install the spring washer of the alternator pulley with the convex side to the nut. Tighten the nut to 39-62 Nm (3.9-6.2 kgfm).