I think this topic will be relevant to those who use more than two cars. As a rule, one is operated in the winter, the other in the summer. That is, one of them season in the year is in the garage or in the parking lot. And while he's standing there, we don't know how his battery feels. No, of course you can "feel" it periodically with a voltmeter or buy a ready-made indicator, of which there are many on the same Ali-express (for example, inserted into the cigarette lighter). But I wanted to make my own indicator that would show intermediate values of the residual battery charge. Well, for example, more than 75%, 75%, 50% and 25% of the charge. And I would like to be so lazy to take care of the health of the battery so that once again I don’t climb under the hood of the car and unpack the charger unnecessarily.

For a long time I was looking for acceptable schemes on the internet. Collected some. But that's not it. Then the hysteresis of the indication operation is such that it would be better if it did not exist, this indication is easier and more reliable to measure with a tester. Either the settings float and there is no stability, then in general the brightness of the LED changes smoothly depending on the voltage on the battery and go and find out what is on it. And then I found one scheme on some Portuguese site. It's simple to obscene and it seems like it should work. It is built on the operational amplifier UA741. Here she is:

In it, I only changed the value of the zener diode from 6.2 V to 7.5 V. Operations are clear. The LED lights up at the desired setting (adjustable by trimming resistor R2). R2 is better to use multi-turn, since it is not easy to set the desired voltage to them. The sensitivity in the actuation zone is very gentle and the almost invisible turn of the adjustment screw takes the desired voltage to the side.

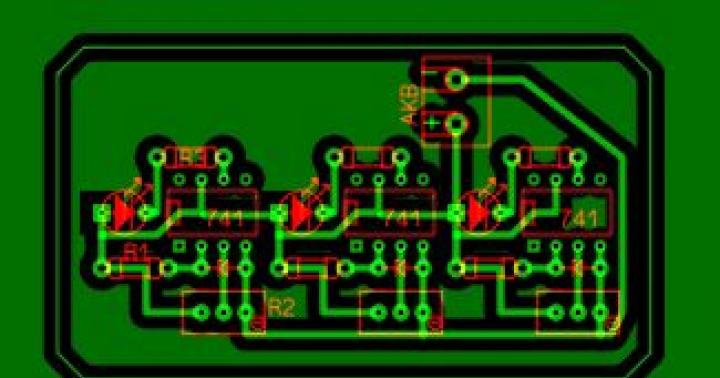

It is necessary to adjust using an accurate adjustable laboratory power supply with a digital voltmeter showing tenths (or better hundredths, I turned on the digital tester in parallel) of a volt. Since I wanted to see the degree of battery charge in the gradations indicated above, I assembled a circuit of three such blocks. Here's a picture of the print:

When the battery is fully charged, the voltage on it is higher than 12.7 V, while not a single LED is on and everything is fine (photo 1).

The first block lights up the green LED when the voltage at the battery terminals is less than 12.5 V, which corresponds to about 75% of the battery charge (photo 2).

The second one lights up a yellow LED when the voltage is below 12.2V, which is about 50% charged (Photo 3).

Well, the third, red, lights up at a voltage below 11.7 V or about 25% of the remaining battery charge (Photo 4).

The voltage settings I used for AGM batteries (I have these on cars). For ordinary acid ones, they can be changed to others. The board was placed in a small (40 mm x 70 mm) case. An additional small-sized switch was placed on the case in the break of the positive wire for convenience, so as not to remove the clamps from the battery terminals when measurements are not required and so that the device does not consume at the same time, although a small (about 20 mA, mainly determined by the current of the burning LEDs) current from the battery . A double red-black wire with clamps at the ends is connected to the battery from the device (Photo 5).

The device is permanently connected to the battery terminals of the car standing in the garage. When necessary, going into the garage, without unnecessary "dances" I turn on the switch on the device, observe what color the "bulbs" are lit and see if my battery is healthy or needs to be "treated".

This simple device will notify you of the discharge of a 12-volt (for example, car) battery with the sound of a buzzer. An audible signal will indicate that the battery is low and needs to be recharged. The comparator threshold is approximately 0.2 volts.

The circuit is assembled on only three transistors and is available for repetition even by novice radio amateurs.

In standby mode, the current consumption is about 3 mA, and when the buzzer is on, it is about 4 mA.

The diagram of the device is shown in the figure:

The left side of the transistor circuit T1 is a comparator that determines the voltage threshold below which the battery should not be discharged. The right side of the transistor circuit T2 is a sound generator, and T3- amplifier.

The state of battery discharge can be approximately estimated based on the data in the table:

| Voltage, V | Charge,% |

| 12,6-12,9 | 100 |

| 12,3-12,6 | 75 |

| 12,1-12,3 | 50 |

| 11,8-12,1 | 25 |

| 11,5-11,8 | 0 |

When the 12 volt power supply is connected, the device starts working immediately, but if this does not happen, then, perhaps, an error was made somewhere in the installation.

Regulator R1 it is necessary to make the sound of the buzzer disappear when the battery is charged, then the buzzer will turn on if the voltage drops by about 0.2 volts.

Schema validation comes down to simple steps.

Disconnect the collector of the transistor T1 from the circuit by connecting the power, and make sure that the sound generator is working. The tone of the sound can be changed (if not satisfied) by selecting the value of the capacitor C1. After that, we restore the connection of the collector T1 according to the scheme.

After that, you can proceed to setting up a comparator assembled on a transistor T1. To do this, turn on the power, measure the voltage at the zener diode with a voltmeter ZD1: it should be 5 volts. Next, slowly turn the potentiometer slider R1 and get a sound signal. With a smooth turn in the opposite direction of the engine of this potentiometer, the sound should disappear.

For the final adjustment, it is desirable to power the circuit from a regulated DC source with a voltage of up to 15 volts. We connect a digital multimeter in parallel with the power supply in voltmeter mode, set the voltage on this voltmeter corresponding to the limit level of battery discharge (according to the table above) and adjust R1 we achieve the disappearance of the sound signal. Fixing the engine R1 in the found position. Then, on the power source, we begin to smoothly lower the voltage until the buzzer sounds and make sure that it is about 0.2 volts lower than it was previously set.

At what level of undervoltage should the sound alert be triggered, each user can set the regulator R1 individually.

On the basis of this circuit, you can make a load plug for testing batteries under load, if you supplement the circuit with a powerful wire resistor, with a resistance of about 1.2 ohms, in parallel with the power wires of the circuit. Such a load plug will allow you to check the degree of battery voltage drop when a current of about 10A flows, the allowable drawdown level is set, as before, with a potentiometer R1.

In the circuit as a transistor T2 only the specified type of transistor 2SC945 should be installed. T1 And T3 can be replaced with analogues, for example 2SC1213, 2N2222 or similar domestic KT315, KT503. zener diode ZD1- any low-power stabilization voltage of 5 volts. Buzzer- a conventional electrodynamic emitter with a winding resistance of about 50 ohms (such are used on computer boards).

How tightly Li-ion batteries have entered our lives. The fact that they are used in almost all microprocessor electronics is already the norm. So radio amateurs have long adopted them and use them in their homemade products. This is facilitated by the significant advantages of Li-ion batteries, such as small size, large capacity, a large selection of designs of various capacities and shapes.

The most common battery is 18650, its voltage is 3.7 V. For which I will make a discharge indicator.

Probably, it’s not worth telling how low their discharge is harmful to the crane batteries. And for batteries of all varieties. Proper maintenance of rechargeable batteries will extend their life several times and save you money.

Charging indicator circuit

The circuit is quite versatile and can operate in the range of 3-15 volts. The response threshold can be adjusted with a variable resistor. So the device can be used for almost any battery, be it acid, nickel-cadmium (nicd) or lithium-ion (Li-ion).

The circuit monitors the voltage and as soon as it falls below a predetermined level, the LED will light up, signaling a low battery discharge.

The circuit uses an adjustable one (link where I took it). In general, this zener diode is a very interesting radio element that can make life easier for radio amateurs when building circuits based on stabilization or threshold operation. So take it into service, especially when building power supplies, current stabilization circuits, etc.

The transistor can be replaced by any other NPN structure, the domestic analogue of KT315, KT3102.

R2- adjusts the brightness of the LED.

R1 is a variable resistor with a rating of 50 to 150 kOhm.

The value of R3 can be added up to 20-30 kΩ to save power if a high gain transistor is used.

If you do not have an adjustable TL431 stabilizer, then you can use a proven Soviet two-transistor circuit.

The operating threshold is set by resistors R2, R3. Instead, one variable can be soldered to allow adjustment and reduce the number of elements. Soviet transistors can be replaced with BC237, BC238, BC317 (KT3102) and BC556, BC557 (KT3107).

The circuit can be assembled on the board or surface-mounted. Put on a heat shrink tube and blow it with a hot air gun. Attach with double sided tape to the back of the case. I personally installed this board in a screwdriver and now I don’t drive its batteries to a critical discharge.

You can also connect a buzzer (tweeter) in parallel with a resistor with an LED, and then you will definitely know about critical thresholds.

The most common driver problem is the lack of a dashboard in the car. This problem creates some discomfort, due to the fact that the driver notices a discharged battery late, especially if the indicator is high. It is worth paying attention that such a device for indication is assembled quite easily.

You can measure the battery charge yourself with a voltmeter. Today, voltmeters are very expensive, and since it is not much we bypass it, because for us it is only important the value to which the charge can reach.

It is worth paying attention to the fact that the device with which the battery charge will be measured can be made by hand and without a voltmeter.

Below is a system for creating, an LED lamp is taken as an indicator. When the voltage drops and the battery charge is low, the LED lamp lights up, which serves as an indicator for recharging.

Looking at the diagram, you can be sure that it will not be difficult to assemble it. Any element of the system is easy to buy. How transistors can be used:

- KT 315B

- KT 3102

- S9012

- S9014

- S9016

As an LED lamp, you can purchase any, as long as its operating voltage is in the range of 15–20 V.

The main and indispensable element of the system is the variable resistor R2, with its help the limit is set at which the indicator is triggered, despite the fact that the circuit says to take it with 1.5 kOhm, it is necessary to take a more powerful one within 20 kOhm. Because if we take R1 \u003d 20 kOhm, then there will be little such resistance in order to open the VT1 key.

If you take a battery with an ordinary charge of 12 V or more, then the transistor VT1 will open and shunt the indicator LED lamp HL1. When the battery voltage drops, then VT1 will decrease over time until it closes, after turning it off, VT2 opens and the HL1 LED lamp lights up, this serves as a signal that the battery charge is low. For such a scheme, it is possible to connect any signaling threshold.

As a board, you can use material from a PC or an old TV. This system is small and handy.

To set up the system, you need a device for power supply with which the resistor will be adjusted and limits set for the alarm to be set.

If necessary, you can make several such circuits with different sensitivity thresholds for more accurate measurements.

A simple monoblock car amplifier on the TDA1560Q External USB socket in car radio

What could be sadder than a suddenly dead battery in a quadrocopter during a flight or a metal detector turned off in a promising clearing? If only you could know in advance how much the battery is charged! Then we could connect the charger or put in a new set of batteries without waiting for sad consequences.

And this is where the idea is born to make some kind of indicator that will give a signal in advance that the battery will soon run out. Radio amateurs all over the world were puffing over the implementation of this task, and today there is a whole carriage and a small cart of various circuit solutions - from circuits on a single transistor to fancy devices on microcontrollers.

Attention! The circuits given in the article only signal a low voltage on the battery. To prevent deep discharge, you must manually turn off the load or use.

Option number 1

Let's start, perhaps, with a simple circuit on a zener diode and a transistor:

Let's see how it works.

As long as the voltage is above a certain threshold (2.0 Volts), the zener diode is in breakdown, respectively, the transistor is closed and all current flows through the green LED. As soon as the voltage on the battery starts to drop and reaches a value of about 2.0V + 1.2V (voltage drop at the base-emitter junction of transistor VT1), the transistor starts to open and the current begins to be redistributed between both LEDs.

If we take a two-color LED, then we get a smooth transition from green to red, including the entire intermediate range of colors.

The typical forward voltage difference in two-color LEDs is 0.25 volts (red lights up at a lower voltage). It is this difference that determines the region of complete transition between green and red.

Thus, despite its simplicity, the circuit allows you to know in advance that the battery has begun to run out. As long as the battery voltage is 3.25V or more, the green LED is on. Between 3.00 and 3.25V, red begins to mix with green - the closer to 3.00 Volts, the more red. And finally, at 3V, only pure red is lit.

The disadvantage of the circuit is the difficulty in selecting zener diodes to obtain the required response threshold, as well as in the constant current consumption of the order of 1 mA. Well, it is possible that color blind people will not appreciate this idea with changing colors.

By the way, if you put a transistor of a different type in this circuit, it can be made to work in the opposite way - the transition from green to red will occur, on the contrary, if the input voltage rises. Here is the modified schema:

Option number 2

The following circuit uses the TL431 chip, which is a precision voltage regulator.

The threshold is determined by the voltage divider R2-R3. With the ratings indicated in the circuit, it is 3.2 Volts. When the voltage on the battery drops to this value, the microcircuit stops shunting the LED and it lights up. This will be a signal that the full discharge of the battery is very close (the minimum allowable voltage on one li-ion bank is 3.0 V).

If a battery is used to power the device from several cans of a lithium-ion battery connected in series, then the above circuit must be connected to each bank separately. Like this:

To set up the circuit, we connect an adjustable power supply instead of batteries and by selecting the resistor R2 (R4) we achieve the ignition of the LED at the moment we need.

Option number 3

And here is a simple diagram of a li-ion battery discharge indicator on two transistors:  The operating threshold is set by resistors R2, R3. Old Soviet transistors can be replaced with BC237, BC238, BC317 (KT3102) and BC556, BC557 (KT3107).

The operating threshold is set by resistors R2, R3. Old Soviet transistors can be replaced with BC237, BC238, BC317 (KT3102) and BC556, BC557 (KT3107).

Option number 4

A circuit based on two field-effect transistors, consuming literally microcurrents in standby mode.

When the circuit is connected to a power source, a positive voltage at the gate of the transistor VT1 is formed using the divider R1-R2. If the voltage is higher than the cutoff voltage of the field-effect transistor, it opens and pulls the VT2 gate to ground, thereby closing it.

At a certain point, as the battery discharges, the voltage removed from the divider becomes insufficient to unlock VT1 and it closes. Consequently, a voltage close to the supply voltage appears at the gate of the second field device. It opens and lights up the LED. The glow of the LED signals us about the need to recharge the battery.

Transistors will fit any n-channel with a low cutoff voltage (the lower the better). The performance of the 2N7000 in this circuit has not been tested.

Option number 5

Three transistors:

I think the diagram needs no explanation. Thanks to the large coefficient amplification of three transistor stages, the circuit works very clearly - between the burning and not burning LED, a difference of 1 hundredth of a volt is enough. The current consumption with the indication on is 3 mA, with the LED off - 0.3 mA.

Despite the bulky appearance of the circuit, the finished board has rather modest dimensions:

From the VT2 collector, you can take a signal that allows the connection of the load: 1 - enabled, 0 - disabled.

Transistors BC848 and BC856 can be replaced by BC546 and BC556, respectively.

Option number 6

I like this circuit because it not only turns on the indication, but also cuts off the load.

The only pity is that the circuit itself does not turn off the battery, continuing to consume energy. And she eats, thanks to the constantly burning LED, a lot.

The green LED in this case acts as a reference voltage source, consuming a current of about 15-20 mA. To get rid of such a voracious element, instead of a reference voltage source, you can use the same TL431, turning it on according to the following scheme *:

* Connect the TL431 cathode to the 2nd pin of the LM393.

Option number 7

A circuit using so-called voltage monitors. They are also called supervisors and voltage detectors (voltdetectors). These are specialized microcircuits designed specifically to monitor voltage.

Here, for example, is a circuit that lights up an LED when the battery voltage drops to 3.1V. Assembled on BD4731.

Agree, it couldn't be easier! The BD47xx has an open collector output and also self-limits the output current to 12 mA. This allows you to connect an LED directly to it, without limiting resistors.

Similarly, you can apply any other supervisor to any other voltage.

Here are a few more options to choose from:

- for 3.08V: TS809CXD , TCM809TENB713 , MCP103T-315E/TT , CAT809TTBI-G ;

- at 2.93V: MCP102T-300E/TT , TPS3809K33DBVRG4 , TPS3825-33DBVT , CAT811STBI-T3 ;

- MN1380 series (or 1381, 1382 - they differ only in cases). For our purposes, the open drain option is best suited, as evidenced by the additional number "1" in the chip designation - MN13801, MN13811, MN13821. The response voltage is determined by the letter index: MN13811-L is just 3.0 Volts.

You can also take the Soviet analogue - KR1171SPhh:

Depending on the digital designation, the detection voltage will be different:

The voltage grid is not very suitable for monitoring li-ion batteries, but I don’t think you should completely discount this microcircuit.

The indisputable advantages of circuits on voltage monitors are extremely low power consumption in the off state (units and even fractions of microamperes), as well as its extreme simplicity. Often the whole circuit fits right on the LED pins:

To make the discharge indication even more visible, the output of a voltage detector can be driven by a flashing LED (eg L-314 series). Or to assemble the simplest "blinker" on two bipolar transistors yourself.

An example of a ready-made circuit that notifies of a dead battery using a flashing LED is shown below:

Another circuit with a blinking LED will be discussed below.

Option number 8

A cool circuit that triggers the blinking of the LED if the voltage on the lithium battery drops to 3.0 Volts:

This circuit causes a super-bright LED with a duty cycle of 2.5% to flash (i.e. long pause - short flash - pause again). This allows you to reduce the current consumption to ridiculous values - in the off state, the circuit consumes 50 nA (nano!), And in the blinking mode of the LED - only 35 μA. Can you suggest something more economical? Hardly.

As you can see, the operation of most discharge control circuits is to compare a certain reference voltage with a controlled voltage. In the future, this difference is amplified and turns on / off the LED.

Usually, a transistor stage or an operational amplifier connected according to a comparator circuit is used as an amplifier for the difference between the reference voltage and the voltage on a lithium battery.

But there is another solution. Logic elements - inverters can be used as an amplifier. Yes, this is a non-standard use of logic, but it works. Such a scheme is shown in the following version.

Option number 9

Schematic on 74HC04.

The operating voltage of the zener diode must be lower than the trip voltage of the circuit. For example, you can take zener diodes for 2.0 - 2.7 Volts. Fine adjustment of the threshold is set by the resistor R2.

The circuit draws about 2 mA from the battery, so it must also be turned on after the power switch.

Option number 10

This is not even a discharge indicator, but rather a whole LED voltmeter! A linear scale of 10 LEDs gives a visual representation of the battery status. All functionality is implemented on just one single chip LM3914:

Divider R3-R4-R5 sets the lower (DIV_LO) and upper (DIV_HI) threshold voltages. At the values indicated in the diagram, the glow of the upper LED corresponds to a voltage of 4.2 Volts, and when the voltage drops below 3 volts, the last (lower) LED will turn off.

By connecting the 9th output of the microcircuit to the "ground", you can transfer it to the "point" mode. In this mode, only one LED corresponding to the supply voltage is always lit. If you leave it as in the diagram, then a whole scale of LEDs will glow, which is irrational from the point of view of efficiency.

as LEDs you need to take only red LEDs, because they have the smallest direct voltage during operation. If, for example, we take blue LEDs, then when the battery is down to 3 volts, they most likely will not light up at all.

The chip itself draws about 2.5 mA, plus 5 mA for each LED lit.

The disadvantage of the circuit can be considered the impossibility of individually setting the ignition threshold for each LED. You can set only the initial and final values, and the divider built into the microcircuit will divide this interval into equal 9 segments. But, as you know, towards the end of the discharge, the voltage on the battery begins to drop very rapidly. The difference between batteries discharged by 10% and 20% can be tenths of a volt, and if you compare the same batteries only discharged by 90% and 100%, you can see the difference in a whole volt!

A typical Li-ion battery discharge graph below clearly demonstrates this circumstance:

Thus, the use of a linear scale to indicate the degree of battery discharge does not seem to be very appropriate. We need a circuit that allows you to set the exact voltage values at which one or another LED will light up.

Full control over the moments when the LEDs are turned on is given by the diagram below.

Option number 11

This circuit is a 4-digit battery/battery voltage indicator. Implemented on four op-amps that are part of the LM339 chip.

The circuit is operable up to a voltage of 2 Volts, consumes less than a milliamp (not counting the LED).

Of course, in order to reflect the real value of the spent and remaining battery capacity, it is necessary to take into account the discharge curve of the battery used (taking into account the load current) when setting up the circuit. This will allow you to set the exact voltage values corresponding to, for example, 5%-25%-50%-100% of the residual capacity.

Option number 12

And, of course, the widest scope opens up when using microcontrollers with a built-in reference voltage source and having an ADC input. Here the functionality is limited only by your imagination and programming skills.

As an example, we give the simplest circuit on the ATMega328 controller.

Although here, to reduce the dimensions of the board, it would be better to take the 8-foot ATTiny13 in the SOP8 package. Then it would be totally awesome. But let this be your homework.

The LED is taken three-color (from the LED strip), but only red and green are involved.

The finished program (sketch) can be downloaded from this link.

The program works as follows: every 10 seconds the supply voltage is polled. Based on the measurement results, the MK controls the LEDs using PWM, which allows you to get different shades of glow by mixing red and green colors.

A freshly charged battery gives out about 4.1V - the green indicator is lit. During charging, there is a voltage of 4.2V on the battery, while the green LED will blink. As soon as the voltage drops below 3.5V, the red LED will flash. This will be a signal that the battery is almost dead and it is time to charge it. In the rest of the voltage range, the indicator will change color from green to red (depending on the voltage).

Option number 13

Well, for a snack, I propose the option of reworking the standard protection board (they are also called), turning it into an indicator of a dead battery.

These boards (PCB modules) are extracted from old mobile phone batteries almost on an industrial scale. Just pick up a discarded mobile phone battery on the street, gut it and the board is in your hands. Everything else is disposed of properly.

Attention!!! There are boards that include overdischarge protection at unacceptably low voltages (2.5V and below). Therefore, from all the boards you have, you need to select only those copies that work at the correct voltage (3.0-3.2V).

Most often, a PCB board is like this:

The 8205 microassembly is two milliohm field devices assembled in one housing.

Having made some changes to the circuit (shown in red), we will get an excellent indicator of the discharge of a li-ion battery, which practically does not consume current in the off state.

Since the VT1.2 transistor is responsible for disconnecting the charger from the battery bank during recharging, it is superfluous in our circuit. Therefore, we completely excluded this transistor from operation by breaking the drain circuit.

Resistor R3 limits the current through the LED. Its resistance must be selected in such a way that the glow of the LED is already noticeable, but the current consumption is not yet too large.

By the way, you can save all the functions of the protection module, and make the indication using a separate transistor that controls the LED. That is, the indicator will light up simultaneously with the disconnection of the battery at the time of discharge.

Instead of 2N3906, any low-power p-n-p transistor available at hand will do. Just soldering the LED directly will not work, because. the output current of the microcircuit that controls the keys is too small and requires amplification.

Please be aware that the discharge indicator circuits themselves consume battery power! To avoid unacceptable discharge, connect indicator circuits after the power switch or use protection circuits, .

As, probably, it is not difficult to guess, circuits can be used and vice versa - as a charge indicator.