Nothing brought early cars closer to mass production than the invention of the electric starter: the starting handle was both uncomfortable and unsafe. For more than a hundred years of use, the design of automobile starters has been “licked” almost perfectly, but even now it causes problems. Of these, the most characteristic is clicks under the hood when the engine is started, but the engine does not turn the starter.

Starter design

Regardless of the specific version (reducer / gearless, with or without a stator winding), the electric starter includes a retractor relay. This electromechanical unit performs two functions simultaneously:

- It pushes the bendix and drive gear forward, allowing it to engage with the flywheel ring gear.

- It unloads the contacts of the ignition switch: the current consumed by the starter is large, and the solenoid relay allows you to control the starter with a relatively small current.

The design of the retractor relay is simple: two windings of different power are placed in its case, which draw in (hence the name) the core. A fork is installed on the core, which moves the bendix through the lever, and at the end of the stroke, the core closes the power contacts (“pyataks”) that supply power to the starter directly from the battery.

Two windings are used to reduce current consumption: it takes more force to pull the core in than to hold it in place. As soon as the core of the solenoid relay closes the “pyataks”, the soaking winding is shunted, and only the holding winding works.

Causes of clicks when starting the engine, checking and solving the problem

Retractor malfunctions

Thus, it is not difficult to think of the reasons why the click of the retractor relay may not be accompanied by the starter actuation.

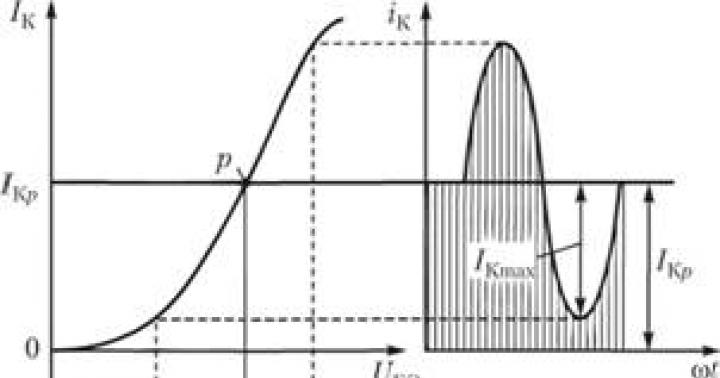

The simplest of them is power problems: a dead battery, oxidized terminals. At the moment when the solenoid relay turns on the starter winding, there is a sharp drop in voltage, and with it, in strict accordance with Ohm's law, and current in the holding winding. The energy of the magnetic field is no longer enough to counteract the return spring of the retractor, and the core moves outward, breaking the starter circuit. Depending on the condition of the car and the battery, this translates into both a single starter click and a “machine-gun burst” of clicks from under the hood.

Therefore, the first thing to check is the battery charge, inspect the terminals on the battery and, if necessary, clean them. Having already guaranteed ourselves the supply of electricity "as intended", we proceed to further verification.

starter core

The starter core can also corny wedge inside the winding due to dirt or rust, which will also cause the starter to click. You don't need to have good mileage to do this. For example, on RenaultFluence and Latitude, the author has repeatedly seen this on a new car. The “repair” here is simple: it is enough to rest a solid object (for example, an extension cord from the tool kit) against the body of the solenoid relay and apply a sharp but not strong blow to it. After that, almost always, the retractor relay restores performance without serious problems in the future and the clicks disappear.

The contacts of the retractor relay have to switch a very large current - for example, a conventional kilowatt electric starter consumes more than 400 amperes at the moment of switching on, the starting current of electric motors is several times higher than the rated one. When the starter is turned off, a spark occurs in the opening contacts, leading to erosion - as a result, at one moment the relay is unable to supply power to the starter windings.

The recipe for treatment here has been known since Soviet times - motorists knew firsthand about cleaning "pyatakov". However, now non-separable retractor relays are often used on cars: in this case, you will have to change the retractor assembly.

If the holding winding breaks or burns out, the motor will not be able to start: as soon as the "pyataks" are closed, the return spring, the elasticity of which is not counteracted by the holding winding, will break the circuit. In this case, the holding winding will work again, and a characteristic high-frequency crack will be heard from under the hood. You can check the condition of the winding even without an ohmmeter by pulling out the starter and connecting it directly to the battery (the body to ground, the positive power terminal to both terminals of the retractor, power and control). If you use a flat screwdriver to “help” the bendix stay in the extended state, then the starter with a faulty holding winding will spin quietly.

The starter itself may also be faulty - the solenoid relay normally supplies power, but there is no sense in this. Most starters have a permanent magnet stator, and they only have windings on the rotor. Worn commutator brushes or lamellas will cause the starter motor to fail to turn under normal power. Frequent long attempts to start the motor can also cause problems: overheating of the stator and / or rotor winding will cause damage to the interturn insulation, then a short circuit and burnout of the winding.

The "grandfather" method of checking is very simple, and with sufficient accessibility of the starter from under the hood, it will not even require the removal of the starter. Carefully close the power contacts on the solenoid relay housing with a screwdriver or a wrench (attention - do not touch the "ground"!). In this case, the power to the starter winding will go directly without the participation of the solenoid relay. In addition, this method is safe, since without the solenoid relay operating, the starter will not engage with the flywheel, and there will be no risk of accidentally starting the car in gear.

If the starter turned on directly turns without problems, then the retractor is to blame. The second "old-fashioned way" of the final check is rough, but no less effective in garage conditions: you need to try to slow down the bendix of a working starter with a strong object (usually the flat side of the hammer is pressed against the gear). If the starter stops at the same time, there is a clear lack of power, indicating either an interturn circuit or a failure of one of the windings, if several of them are connected in parallel in a particular starter.

The use of widely used multimeters is ineffective: even the resistance of their measuring probes is often comparable in itself to the resistance of a separate winding. The only thing you can count on is the possibility of the rotor ringing to ground in search of short circuits. To do this, one probe is fixed on the core of the rotor, the second in turn must be touched to each individual lamella (contact plate) of the rotor. There should be no closures to the case here.

Mechanical problems

Rarely, on cars with high mileage, it is possible to simply stick the bendix into the tooth of the crown. Initially, both the flywheel ring gear and the bendix teeth have lead-in chamfers that allow the gears to mesh even if the bendix tooth does not exactly hit the gap between the flywheel teeth. Wear over time leads to blunting of the lead-in chamfers, while a situation is possible when the bendix tooth rests against the flywheel tooth, preventing the solenoid relay core from reaching the end of the stroke and closing the power contacts.

You can “revive” the car simply: either close the terminals on the solenoid relay to each other so that the rotor turns to another position, or, if there is no convenient access to the starter, turn the crankshaft itself by the generator or hydraulic booster pulley using an end head and a ratchet. But this is an “emergency” method - you should not postpone repairs, since such problems will continue in the future.

Video: How to check the starter, clicks but does not turn

Seal

One of the main components of the ignition system is the starter. If problems arise in the operation of this mechanism, the car owner may encounter difficulty in starting the engine or inability to start it in principle. For what reasons, what to do in such cases? The answers to these and other questions are given below.

[ Hide ]

Why won't the starter turn?

For what reasons the starter may not work, why can't you start the engine? As practice shows, most often the reason why a node on a diesel or gasoline engine can be “silent” is the lack of power to the device. There is a possibility that such a problem is due to a lack of power in the on-board network of the machine, respectively, the unit may not start due to a dead battery. In the event that the battery is completely discharged, this will lead to the fact that the node simply cannot start (the author of the video on the principle of the starter is Mikhail Nesterov).

If you are faced with such a problem that when you turn the key in the ignition switch, you cannot start the engine, then first you should diagnose the battery performance. Most often, the discharge problem occurs in the cold season, due to frost, the electrolyte freezes in the system. It is also possible that the reason lies in the disconnection of the terminals or their oxidation.

In this case, there is no need to panic, the problem can be solved as follows:

- first of all, disconnect the battery and remove the terminals from the terminals of the device;

- using an iron construction or toothbrush (you can also use fine-grained sandpaper), clean the leads to the devices, as well as the terminals;

- further, check the presence of electrolyte in the battery banks - to do this, unscrew the caps and make sure that the liquid completely covers all the banks without exception, add distillate to the system if necessary;

- then the battery charge is checked, this will require a voltmeter or multimeter, if necessary, recharge the battery;

- after that, check the integrity of the wires in the area from the battery to the starter mechanism;

- if everything is normal, then reinstall the terminals and securely fix them.

Photo gallery "Main malfunctions of the mechanism"

1. Blown windings of the mechanism  2. Mechanical damage to the solenoid relay

2. Mechanical damage to the solenoid relay

If there is no voltage in the on-board network, then when you try to start the power unit, a strong click may be heard. If the minimum charge remains in the battery, then by turning the key in the ignition switch, the engine crankshaft will scroll weakly several times. If the problem is with the voltage, then the battery needs to be charged, there are no other options.

Now directly about the malfunctions of the mechanism, according to which it may not grasp and respond to the turn of the key:

- Failure of the relay or damage to the control wire. It is necessary to diagnose these elements, if necessary, replace the failed components.

- Lack of contact, in particular, it is necessary to diagnose the connection of the power wire. When the motor is turned on, a high current is supplied to the starter assembly, which is approximately 200 amperes. In the event that the contact is too weak, then instead of 200 amperes, only 10 or so can flow to the mechanism. And this, in turn, will be enough to click the retractor relay, but this will not be enough to start the internal combustion engine. In this case, it is recommended to diagnose all connections, if necessary, clean all contact surfaces.

- Malfunctions in the operation of the solenoid relay, such a malfunction is also accompanied by clicks at startup. The device can turn on directly if you want to solve the problem, in particular, bypassing switching. There are three outputs on the solenoid relay, two of them are large, one is the input from the battery, and the second goes to the mechanism itself. In this case, you need to try to close these terminals, for this you can use a jumper, a wrench or a screwdriver. Please note that the tool with which you will close should in no case touch the car body, that is, any metal components located in the engine compartment.

In the event that, as a result, the mechanism began to work, even with a bang, the reason lies precisely in the relay, it must be replaced. It is impossible to start the motor using this method, since the drive gear of the mechanism will not be able to engage with the flywheel. As for the retractor relay, the reason is most likely related to the burning of the contact surfaces, a dielectric layer of metal oxides could form on them. The problem of such a plan is solved by cleaning the contacts or replacing the relay, the second option being more preferable. - The next reason why the unit may turn off and not supply the voltage necessary to start the motor may be the wear of the brushes. If the reason is the operability of the brush assembly, then the mechanism will in any case have to be removed and disassembled. If the brushes are worn out, then after disassembly you will see it immediately. It must be borne in mind that, depending on the design features of the device, when the brushes are worn out, the relay may also not work, that is, it may not click.

- In addition, the inoperability of the mechanism may also be due to the failure of the windings, as evidenced by the characteristic smell, as well as the color of the elements. Of course, it is possible to determine the malfunction of these components as a result of removing and disassembling the mechanism. Sometimes it is impractical to change the windings, but it is better to replace the entire assembly. All starter elements usually wear out evenly, so if you replace one of the parts, then most likely you will have to change others in the near future (the author of the video is the Garage 91 Gomel channel).

How to get out of the situation and start the engine?

Location of terminals for shorting the starter directly

What to do if you cannot start the engine due to a malfunction of the starter assembly?

There are several ways to solve this problem:

- Replace or repair the mechanism. The repair procedure consists in dismantling the device and replacing the failed components. To accomplish this task, you need to know where the node is located in your car. When dismantling, you can see all the failed parts and change them for new ones. As we have already said, it would be more expedient to completely replace the entire mechanism than to repair it.

- If you need to go urgently, but the engine does not start, then as an option, you can try to start it from the pusher. The essence of this method is to push the vehicle until it can develop the optimal speed at which the starter mechanism will work. As a rule, it is enough to disperse the car up to 20-30 km / h, while it is desirable to set the second or third gear and turn on the ignition. When the car accelerates, jump into the passenger compartment of the car, depress the clutch and, releasing it, press the gas. If you did everything right, the engine will start. Please note that this method should never be used on cars with automatic transmissions, as this can lead to failure of the box.

- As mentioned above, you can try to close the mechanism directly. To do this, you will need to close the appropriate terminals on the device, and put the gear lever in neutral.

- Similar to the pusher method is the towing method. The only difference is that instead of pushing the car manually, another car will be used to pull your car on a cable. The principle of implementation is similar.

Good afternoon. Many motorists are familiar with the situation when the starter clicks, but does not turn. As for evil, such situations occur at the most inconvenient moment, for example, at gas stations or when leaving for work.

In today's article, we will tell you how to determine the malfunction and, if possible, start the car to get to the place of repair.

Before telling the troubleshooting algorithm, let's look at the starter device. For clarity, watch this video:

As you can see, the starter is a conventional DC motor and relay. When you turn the key in the ignition and hear a click, it is the retractor relay that clicks (the coil and contacts at the top of the screen in the video). If the starter does not rotate, but clicks, the following options are possible:

- dead battery.

- failed starter relay

- burnt contact nickels in the retractor relay.

- worn starter brushes.

- starter anchor stuck.

- no power plus is supplied to the starter (because if there is no mass, there will not even be clicks of the retractor)

Below we will analyze each of these malfunctions in detail, and tell you in which malfunctions it will be possible to start the car on the spot, using the existing starter, in order to get to the service.

The battery is heavily discharged- the most common cause of clicks when turning the ignition key.

This error looks like this:

In our video, you can see that at the start, at first, the starter barely turns the engine, and then it just cracks .... With a strong discharge of the battery, the starter will not even try to crank the engine, but will immediately make nasty clicks.

The fact is that the battery voltage is not enough even to trigger the solenoid relay!

Solutions to the problem:

- light a cigarette from another car ( .

- start the car from a pusher / tug (if it is with a manual transmission).

- take off and

Your starter is good!

Starter relay failure.

Relay failure manifests itself as a soft click when the key is turned.

In this case, you can start the car with a simple screwdriver. It's done like this:

Attention! If you are not confident in your abilities, do not do it. It is better to contact a specialist or call a tow truck. If you make a mistake when starting this way, the vehicle may move unintentionally or fire due to a short circuit.

- put on the parking brake.

- using a screwdriver, we close two contacts on the solenoid relay (as in the video).

- after starting the engine, remove the screwdriver and go to the place of repair.

Burned contact nickels in the retractor relay.

This malfunction manifests itself in the form of loud clicks when the key is turned to the start position and the key is released. In some cases, the starter may operate.

Here is a video example of such a malfunction:

How to quickly diagnose contact nickels?

Everything is extremely simple - open the hood, take a screwdriver, and bridge these two terminals:

If a spark jumps during the jumper, and you hear the sound of the electric starter rotating, you can be sure that you have burnt contact pads.

In this case, the car can be started with a screwdriver!

How to start a car with a starter when contact nickels are burned?

Attention! If you are not confident in your abilities, do not do it. It is better to contact a specialist or call a tow truck. If you make a mistake when starting this way, the vehicle may move unintentionally or fire due to a short circuit.

In order to start the car when the contact nickels burn out, it is necessary to simultaneously bridge all three contacts on the solenoid relay.

The closure of two contacts under the nuts is necessary for the rotation of the armature, and the closure of the control contact in order for the overrunning clutch (bendix) to engage with the flywheel.

The order of starting the car in case of failure of contact nickels:

Vehicle with manual transmission:

- put on the parking brake.

- turn on neutral gear.

- open the hood and prepare a flat screwdriver.

- turn the key in the ignition switch to the ignition on position.

- after starting the engine, remove the screwdriver and go to the place of repair.

Vehicle with automatic (+variator and robot) transmission:

- we install a car parking brake (for a robot and a variator).

- open the hood and prepare a screwdriver (maybe two).

- turn the ignition to the on position, press the brake, move the gear selector to the park (P) position.

- using a screwdriver, we close all three contacts on the solenoid relay (sometimes one screwdriver is not enough and you have to take two).

- after starting the engine, remove the screwdriver and go to the place of repair.

The starter brushes are worn out.

The malfunction manifests itself in the same way as the burning of the contact nickels (loud clicks when the ignition key is turned), the only difference is that when the brushes are worn, the starter will never rotate.

It is checked in the same way when the contacts of the retractor relay are bridged with a screwdriver.

like in this picture:

Starter spinning does not start, sincerely not observed.

How to start a car?

Unfortunately, it is impossible to start a car with this starter, it must either be repaired or replaced.

If the machine is equipped with a manual transmission, it may be possible to start with a pusher or towing method.

If the car is equipped with an automatic transmission, it makes sense to call a tow truck or a tow truck.

Stuck starter anchor.

If, by some miracle, the brushes hold out, then when you turn the key to the start position, you will hear a very loud click, and then, for a while, all appliances will go out (you may feel a specific smell)! In the same way, the burning out of the mass is manifested!

In any case, the car itself will not go anywhere. It is necessary to make diagnostics and follow the tow truck / tug to the place of repair or parking.

The starter is not supplied with power plus.

For clarity, look at this picture:

Without a test light or a multimeter, you will not determine this malfunction! And in general, without appliances, it can be confused with brush wear!

As you can see, if the power wire from the battery to the retractor breaks, the starter will not work, but the retractor will click.

If, during a visual inspection of the direct battery-starter wire, you do not see any damage, call a tow truck / tow truck and follow to the place of repair and diagnostics.

That's all I have today. Let the situation when the starter clicks, but does not turn, no longer happens to you. If you have any questions or if you want to supplement the article, write comments!

The starter is a rather complex electromechanical structure, in the event of a malfunction of which the car is unlikely to start. In principle, with the help of some alternative way to make the car go, it may be possible, but this is a story of a slightly different nature. In general, failures often occur in this device, as a result of which the starter clicks, but does not turn, or does not turn at all, and this is already a completely critical situation. What to do in such a case - the answers will be given by subsequent information.

To understand in detail the reasons why the starter clicks but does not turn, you need to pay attention to its internal type device. The design of this mechanism includes such an element as a traction relay, the appearance of which is an ordinary, small-sized cylinder that is attached to the main structure of the starter. This relay has two windings: designed to retract and hold. The main malfunction, as a rule, manifests itself when there is not enough voltage on the holding winding, which is why it is not possible to start the car.

Hence the problem of the appearance of characteristic clicks. All cars have the same principle of operation of this mechanism, therefore the reasons why the starter clicks but does not turn are also similar to each other. The starter can click for several reasons, we will understand them.

Firstly, it should be noted that sometimes this is not associated with any breakdowns, but only with the fact that the car, like all its constituent elements, has not warmed up. If, after the fifth or tenth attempt, the car failed to start, then this is a clear sign of a problem.

If you hear frequent clicks coming from the traction relay, this may be due to a poorly charged battery (in this case, I recommend checking the charging current) or poor contact at the battery terminals.

If only one click of the traction relay is heard, the problem may be burnt power contacts, engine mass, fastening reliability, or a malfunction of the starter itself. In each of the cases when the starter clicks but does not turn, it is recommended that a thorough check of the described mechanism for malfunctions is recommended.

Reasons why the starter does not turn

The analyzed device includes three main elements: the power system, the role of which, first of all, is played by the battery, switching, which is all kinds of connections (that is, relays and wires) and the starter itself. Depending on these basic components of the mechanism, the problems of why the starter clicks but does not turn can vary.

The first reason is the battery. This is perhaps the most common variant of why the starter stopped performing its functional duties, namely, why it stopped turning. The essence of this reason is either a discharged or already faulty battery. If the starter does not turn or even click, then it is recommended to check the battery with another kind of load, for example, turn on the headlights. Also, the contacts in the battery must be well tightened and under no circumstances oxidized. Otherwise, problems can develop into much larger problems, and no one needs this.

The second reason is the relay. Here the matter may lie not only in the malfunction of this element, but also in the control cable. It is not difficult to install exactly; for this, it is only necessary to supply a positive value to the control terminal of the starter (the cable of the smallest cross section is connected to it). If the starter started to turn again, then the reason was in the wiring, relay or ignition switch.

The third reason is bad contacts. In this case, it is necessary to carefully check all connections, especially in the case of a power cable. The main essence of this malfunction is that the starter tends to consume a fairly high level of current from the batteries - about 200 A. And if there is insufficient contact somewhere, much less can be supplied to it from the base 200. As a rule, this will be enough to operate the solenoid relay, but not to start the engine. In this case, a series of characteristic clicks can also occur.

The fourth reason is a malfunction of the starter itself. Since this device includes several elements, the reasons for the termination of its operation may lie in them. This is, first of all, a solenoid relay, a brush assembly, as well as windings. As a rule, such problems cannot be eliminated without dismantling the assembly. But you can try to find out the reason for sure.

For the first check, you will need a screwdriver or a wrench, with which you can close two terminals, and do it securely without touching the case and for a short period of time. If, after carrying out these operations, the starter began to rotate (it can do it with a bang), then the matter is probably in the relay.

Symptoms of a malfunction of the brush assembly and windings are similar. If the solenoid relay does not click, and the starter does not start up “straight”, then the matter may lie in the breakdown of these particular elements. And a malfunction of the windings can still give out a smell and color. But again, everything will become known as specifically as possible after its disassembly.

Solutions to the problem

Depending on the previously described problems associated with starter problems, the following solutions can be distinguished:

In the absence of voltage, the malfunction may lie in the ignition key. In this case, voltage must be applied to the bare wire directly from the terminal with a positive value, and if it works, then all that remains is to change the key. This problem is the most elementary, and therefore, at its first successful solution, it will not have properties for repetition.

Finally, it is worth recalling that it is necessary to perform all fault checks if the car's gearbox is in a neutral type position. Otherwise, the car may start to move, and then, quite possibly, in addition to problems with the starter, many more will appear. So keep an eye on your car and its safety, and then he will repay the same.

Video “Replacing the starter solenoid relay”

The recording shows how you can replace the solenoid relay at home.

A starter is a complex electromechanical unit, without which your car is nothing more than a pile of iron. No, of course, you will be able to start the car in some alternative way, but this is a completely different story. Often, the starter, whose task is to start, fails and fails, after which either the starter clicks but does not turn, or the starter does not turn at all, which is even worse.

Reasons why the starter clicks but does not turn

Often the cause is emergency or improper braking, in which the starter, which is hooked with, receives a high current. The starter itself belongs to short-term electric units, therefore, if it is operated for a long time, it may fail, which in most cases manifests itself in the form when the starter does not turn or the starter clicks, but does not turn.

In order to understand why clicks occur and there is no rotation, you need to pay attention to how the starter is arranged.

The starter contains a so-called traction or, as it is also called, a retractor relay, which looks like a small cylinder attached to the base of the starter. The starter relay, in turn, is equipped with a retracting and holding winding. Failure occurs just at the moment when there is a shortage of voltage on the holding winding. The task of the retracting winding is to draw in the core, but it returns to its original position, since the holding winding cannot hold it. This is exactly what happens when you try to start the car by turning the key. And this phenomenon looks to us in the form of clicks, that is, when the starter clicks but does not turn.

As you already know, clicks are emitted by a solenoid relay, there may be several reasons why this happens. Here is a list of the most likely reasons why the starter does not turn, but clicks:

- Rechargeable battery (ACB). Most likely, the battery is simply discharged, or not sufficiently charged, or the terminals have poor contact with high-voltage wires. and try to start the engine again.

- Poor weight of the body with the motor. In this situation, it is recommended to take another mass wire and try again.

The starter does not turn and one distinct click is heard. In this case, I recommend checking the mass of the engine, as well as the fastening of the traction relay to the starter housing. The problem may be bad or burnt contacts on the traction relay. If not, then most likely, the breakdown lies in the malfunction of the starter mechanism itself, here you can not do without its complete disassembly or replacement.

If you are convinced that the reason for the starter clicking but not turning is in the starter itself, here are a few likely reasons why this may be happening:

- It is possible to burn out the power wire connecting the starter winding and the traction relay.

- Critical wear of brushes or starter bushings.

- Breakage of the starter winding or short circuit on the armature winding.

- Deformation or destruction of the fork in the drive.

Summing up

Having noticed problems with the starter, do not delay the repair, otherwise at one inopportune moment it will simply stop turning, and this, according to the "law of meanness", will happen somewhere far from home or when you are in a hurry ... The problem is when the starter clicks, but does not twist, you can decide on your own. The network is full of all kinds of manuals for repairing and replacing the starter with your own hands. However, if you are not sure, it is better to trust professionals, so you can save your time, nerves, and sometimes money.

DIY starter diagnostics and repair video: