The pivot mechanism of the UAZ Patriot car is used to connect the steering knuckle to the wheel hub. This node is one of the main control elements of an SUV, so it is rightly paid close attention to competent car owners. But like all other mechanisms, the king pin wears out over time and then it is already necessary to repair them. Briefly about how to do this, this article will tell.

Sectional mechanism

For an SUV, there are three main types of pivot connection:

- The factory version is a spherical support with plastic liners. The manufacturer produces UAZ on lightweight and cheap components, guaranteeing the reliability of the suspension under moderate operating conditions. Requires periodic adjustment of the gaps, repairs are made as the liners wear out.

- Reinforced hinges with bronze liners - a modification for those who like to "wobble" on potholes and gullies. They are produced in the form of a repair kit by small manufacturers of automotive parts (Vaksoil, Niagara, Autohydraulics, Factor, Sollers, IP Kuznetsov, etc.), designed for heavy road loads. Experienced jeepers immediately rush to change plastic to bronze so that there are no problems with kingpins on country trips.

- - a recent variety that is gaining more and more popularity among UAZ owners. It does not require constant regulation, and with high-quality components and competent replacement, they are quite durable. The disadvantages are the complexity of installation and the impossibility of field repairs.

Bronze liners

The pivots on the Patriot are replaced in case of backlash in the front suspension or for prevention before a difficult trip. One of the results of installing a bearing mechanism is a noticeable improvement in the controllability of the machine. The Altai manufacturer Vaxoil offers a kingpin with a given castor angle of +5 or +8, which also affects driving ease.

The main stages of replacing the pivots on the UAZ Patriot

We will consider only individual operations related specifically to replacing the pivot assembly with our own hands. The remaining preliminary procedures are quite clear and do not require careful analysis.

- it is necessary to unscrew the fastenings of the steering rods to the steering knuckle and release the axle shaft from the hub;

- we unscrew the bolts of the king pins and a special nozzle

Loosen the fixing nut

unscrew the fixing nut. This special wrench is usually included in the delivery of new Waxoil kingpins or sold separately;

- the oil seal of the ball of the rotary mechanism is removed and the fist and ball joint are pulled out;

- the old grease is cleaned out, the used gaskets are replaced with new ones, the threaded connections and fasteners are inspected. If necessary, replace worn nuts and bolts to ensure their reliable operation in the future;

- replacing a plastic liner with a bronze one is simple - the old one is removed, the new one is installed in its place;

- when mounting the bearing kingpin, the old spherical cups are cut off, the surface of the stocking is cleaned, and new bushings are fixed by welding, which must be perfectly aligned to avoid distortions;

Special key

- races of tapered bearings included in the repair kit are pressed into these installation parts;

- then a new lubricant is applied to the mating surfaces and the suspension is assembled in the reverse order;

- the ball joint is guided by the mounting bolts, and the position of the steering knuckle housing must be noted in advance using a core or paint;

- the pivot pins are lubricated before assembly, and in the case of a bearing modification, a conical support is put on the kingpin body, which is pressed in when the fastening nut is tightened;

- after fixing the pivot assembly until the backlash disappears, the control mechanism is adjusted.

The running gear of any car is subjected to serious loads. UAZ is no exception. Moreover, some of the models are taken off-road, where the load on the suspension increases tenfold. On any UAZ, a classic suspension scheme is used - pivot. Over time, these elements fail. How to determine their wear and replace the pivots on the UAZ? Find out the answer in our today's article.

Characteristic

What is a king pin? This is the swivel pivot. Mounted on the steering axle of the car. The pivot pin is used to connect the knuckle to the bridge beam or bearing pins (depending on the design). In the case of UAZ, the kingpin is integrated into the bridge, which can be the leading one when using all-wheel drive.

Symptoms

Damage symptoms do not appear immediately. So, the motorist will notice uneven tire wear.

With even greater development, axial or radial play will appear. In this case, the steering wheel may vibrate at speed. You can diagnose an element as follows:

- Hang out the front axle.

- Check the wheel play without removing it in the radial and axial direction.

- When worn, the UAZ king pin changes to a new one.

Also check the distance between the beam and the fist. The gap should not exceed 0.2 mm.

Why does the UAZ king pin need to be changed on time?

With significant wear, there is a risk of failure of the tie rod ends, springs and silent blocks. The most dangerous outcome is the pin jamming in one direction. If this happens at speed, serious consequences are possible.

How to replace the pivots with your own hands?

First, drain the oil from the bridge. If it is black, it cannot be reused. Next, we tear off the wheel bolts and jack up the car. Having hung out the bridge, we proceed to dismantle the caliper and brake shield - they will interfere with us when replacing the pivots on the UAZ.

Next, we screw the M10 bolt into the kingpin. Then we draw out the hat and take out the element in this way. If dismantling with a bolt fails, a steel plate is required. We fix it above the king pin and make a hole M10. Through it we already screw our bolt of the appropriate diameter. We bait a few nuts under the plate and tighten them.

Next, the king pin should come out. At the next stage, we press out the sleeve and take out the washer. With the latter, there are no difficulties, but the first lends itself with difficulty. To press out the sleeve, you need to break the lock with a sharpened nail. We slip the latter under the sleeve and squeeze it in a circle. If the element is tight, you can resort to using pliers. After dismantling, the inner part of the sleeve is degreased and cleaned of dirt.

When replacing the UAZ kingpin, it is important to completely clean the old bushing from grease. Instead, a new one is laid. As such, "Litol-24" is used. Next, install a new kingpin. It is hammered through a wooden block with a hammer. The king pin is not completely pressed in - it is important to exclude the slightest distortions. Otherwise, it will go tight and with a characteristic sound. If this happens, the kingpin is taken out and pressed in again. All other elements are assembled in reverse order.

UAZ pivot adjustment

A mandatory step after replacement is steering adjustment. Otherwise, there may be problems with zhorom rubber and car withdrawal to the side. Adjustment is done with spacers. Start with the top pivot. For the bronze element, 4 spacers 0.5 mm thick each are used. For roller bearing - 5 with the same thickness. Next, we tighten the mechanism and go for a test drive. It is unacceptable for the wheel to heat up. If so, the kingpin needs to be loosened by reducing the number of shims.

Which ones to choose?

In addition to the factory carbon fiber ones (which the owners do not recommend installing in any way), there are several types of kingpins:

- Bearing.

- On a bronze bushing.

The first variety has a complex structure. Such UAZ kingpins combine the lower half with a tapered bearing and a thrust ring, as well as a cage.

The latter is pressed into the steering knuckle housing. A hole for lubrication is provided at the bottom of the UAZ king pin (central and side channels). Judging by the reviews, it is great for asphalt roads - the steering wheel rotates much easier, and the resource is about 100 thousand kilometers. By the way, easy rotation of the steering wheel is provided by reducing the friction force. So, the two halves of the mechanism rotate on the bearing, and not on the ball.

If the UAZ was purchased off-road (which is done in 80 percent of cases), you cannot do without bronze bushings. Such pivots were installed regularly on the UAZ-469. But there are models for modern "Patriots", as well as "Hunters".

Bronze elements are highly resistant to shock loads - such bushings are an order of magnitude stronger than bearing ones. But the steering will be tighter. The cost is almost identical to the previous ones - 1.5 thousand rubles per set. These are excellent pivots for UAZ "Loaf", "Hunter" and 469th. True, like the previous ones, they require regular lubrication and inspection. We describe this procedure in detail below.

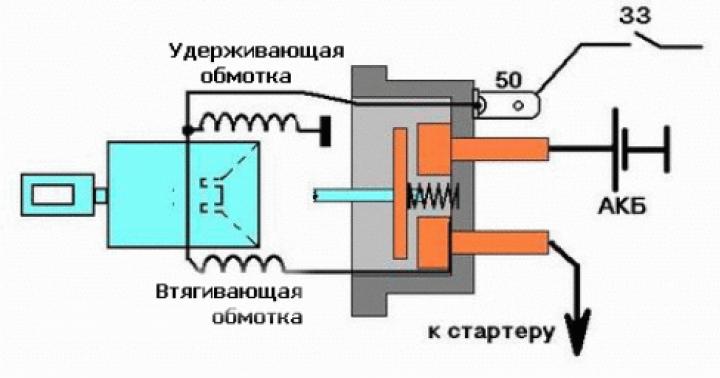

About squirting

This is the name of the procedure for lubricating the bushings of the mechanism. It is produced through a grease fitting using a specialized syringe. A waterproof lubricant is placed inside the latter (for example, Litol-24).

Next, the oiler opens and a hose-tip is screwed into the hole. You need to press in the grease until a new one comes out of the slots. Old grease is usually white and very dry to the touch.

How often should the pins be injected? This procedure is performed every 20 thousand kilometers or once a year. This simple preventive measure will extend the life of the bushings and allow for easier steering. This is noticeable from the first meters of the road.

Finally

The kingpin is both an element of both the running gear and the steering. Therefore, this mechanism must be kept in good condition. With significant output, the owner of an UAZ SUV will experience a lot of problems, one of which is uneven tread wear. Therefore, it is so important to diagnose the malfunction in time and carry out maintenance (syringing of the pivots).

The pivot assembly of the UAZ Patriot car is a kind of large “hinge”, which provides one of the degrees of freedom for the front wheels of the car, which is necessary for its control, that is, for operation.

Usually, when the kingpins are worn, knocking problems are possible, which is associated with the appearance of play between the mating parts. Also, backlash in the pivots is possible in case of damage, from strong blows, or if parts are incorrectly selected during repairs.

Tools needed to replace UAZ Patriot pivots

Flat screwdriver

- Pliers, Wrench for: 12, 14, 17, 19, 22, 24,

- Set of sockets for: 8, 10, 14, 19, 24, 27,

- Special head for 19 (dimensions),

- Kingpin key (drawing),

- Hammer,

- Copper hammer or soft mandrel,

- wooden block,

- montage,

- Locksmith vice (in case of absence, it is allowed to fix the ball joint rotated by 90 degrees in the flange of the axle shaft casing),

- Caliper with depth gauge (columbic), M36x2 tap (needed only in case of damage to the thread in the body of the steering knuckle when turning out the expansion sleeve), Torque wrench up to 30 kgf * m

Spare parts for replacing pivots UAZ Patriot

The number of spare parts is given for the repair of pivot assemblies on two sides of the front axle of the machine.

Cuff 32x50-10 with spring assembly, 2 pcs. (Cat. No. 3741-2304071-01).,

- Steering knuckle cuff, 2 pcs. (cat. no. 3160-2304052),

- Ring SP 134-120-5, 2 pcs. (cat. no. 3160-2304055),

- Insert (plastic or bronze), 4 pcs. (p/n 3160-2304023 or 3160-2304023 bronze),

- Bolt Ml0x1x30 special, 2-3 pcs. (this is due to the fact that during the dismantling process they can be broken) (Cat. No. 290784-P29),

- SHRUS-4M grease - 0.2 kg and Litol-24 - 1 kg, Kingpin, 4 pcs. (cat. no. 3160-2304019 or 3160-2304019 upgraded with grease fitting),

- Thrust washer for the steering knuckle joint, 4 pcs. (cat. no. 3741-2304024),

- Gasket for swing arm (Cat. No. 3160-2304029), 1 pc.,

- Gasket for the kingpin pad (Cat. No. 3160-2304028), 3 pcs.,

- Ball bearing gasket (Cat. No. 31-0121238), 2 pcs.,

- Split pins 3.2x25 (cat. No. 258040-P29) steering nuts, 4 pcs.

The process of replacing the pivots on the UAZ Patriot

Removing bipod traction

Unpin with a screwdriver and unscrew the M14x1.5 nut securing the bipod link pin to the steering knuckle lever with a "22" wrench and remove the bipod link.

The bipod is shown on the bridge in installed form

Removing the brake mechanism

Scheme for removing the UAZ brake mechanism with disc brakes

Turn away bolts of fastening of brake mechanisms to the case of a rotary knuckle a special head "on 19" and remove them.

We unscrew the grease nipples with the king pins, if any.

Removal of fastening of the lever of a rotary fist

We unscrew the M16x1.5 nut with a flange with a kingpin head "24"

On the steering knuckle lever, with a "19" head, unscrew the four nuts M12x1.25 securing the steering knuckle lever

and take out the expansion bushings. The bushings can stick, so you need to put a few blows with a hammer on the end of the steering knuckle lever and then remove it

Removing the pad with gasket

We unscrew the remaining nuts M16x1.5 with a flange with a "24" head and remove the lining with the gasket.

Removing the clamping sleeve

We apply several sharp blows to the kingpins, through a copper spacer or a copper hammer to relieve the tension between the kingpin and the clamping sleeve.

With a pivot key and a "27" head, we unscrew the clamping sleeve a few turns.

Removing the steering knuckle

With a key or a “14” head, we unscrew five M10x1x30 bolts of special fastenings of the ball joint to the flange of the axle housing. Remove the turn limiter.

Tapping with a hammer through a wooden block, we disconnect the flanges so that the mounting blade passes into the connector.

With a mounting spatula, trying not to damage the cardboard gasket, we wring out and finally disconnect the flanges and remove the steering knuckle.

We clamp the steering knuckle with the axle shaft in the yew of the locksmith for the tie rod lever

We measure the overhang of the stop bolt with a caliper and record

With the key "14" we unscrew the bolt M10x1x16.

With the key "17" we loosen the tightening of the locknut and with the key "12" we unscrew the stop bolt

Removal of a clip of a cuff of a rotary fist

With a “10” head, we unscrew the remaining eight bolts M6x12 fastening the holder of the cuff of the steering knuckle and remove it

Removing the ball joint and CV joint

Using a 27" head wrench, unscrew the clamping bushings and remove the kingpin

Having remembered (marking - with punching or paint) the orientation of the ball joint in the steering knuckle, take it out and remove it from the axle shaft

From the steering knuckle we take out the axle shaft with a hinge of equal angular velocities

Removal of liners and cuffs of a semiaxis

We remove the old liners and cuffs of the axle shaft from the ball joint (cuff 32x50-10 with a spring assembly).

Very often, when using low-quality pivot keys, the thread in the steering knuckle housing under the clamping sleeve is damaged.

If the thread is damaged, it must be corrected with a tap M36x2

Troubleshooting parts

We wash all parts in kerosene or diesel fuel and inspect them. Cracks, scuffs and other damage are unacceptable on parts

Installing new inserts

Cuff 32x50-10 with spring assembly, 2 pcs.; Inserts (plastic or bronze), 4 pcs.; Ball bearing gasket (Cat. No. 31-0121238), 2 pcs.; SHRUS-4M; Cold welding;

We install a new cuff of the axle shaft in the ball joint. The orientation of the cuff is carried out along the sealing spring - it must be on the side of the final drive gearbox (i.e., when installing, the spring should "look" at you). Install the gasket on the end of the ball joint.

In cases where there is slight wear or deformation of the kingpin support along the inner hemisphere, it is allowed to use composite materials to fill the damaged areas. In this case, it is necessary to install the pivots and bushings without waiting for the polymerization of the composition.

We install new liners (plastic or bronze) in the pivot bearings on the ball joint and apply SHRUS-4M grease to the inner surface of the liners.

Steering knuckle assembly

We install new thrust washers of the steering knuckle joint in the ball joint and the steering knuckle housing.

Before assembly, apply Litol-24 grease, about 0.5 kg, to the inner surfaces of the steering knuckle housing and ball joint

and insert the axle shaft with a constant velocity joint, on which SHRUS-4M is applied up to 100 grams.

Installing the ball joint

We put a ball joint on the axle shaft, while monitoring the correct orientation of it.

The bottom of the ball joint is determined very simply: on the bottom side of the flange there are three holes, on the top side there are two. We recommend that you notice the orientation of the steering knuckle housings during disassembly, for example, by punching or paint.

We pay attention to this, since the knot is assembled in any combination and you can easily make a mistake.

Pivot lubrication

Lubricate the conical surface and thread of the clamping sleeve, the rubbing surfaces of the king pin with SHRUS-4M grease

Tightening clamping sleeves

We insert the pins into the threaded holes of the steering knuckle housing and wrap the clamping sleeves until the pins stop in the supports. If you have installed kingpins with a channel for lubrication, then for further work it is necessary to unscrew the grease fittings from them with an "8" wrench

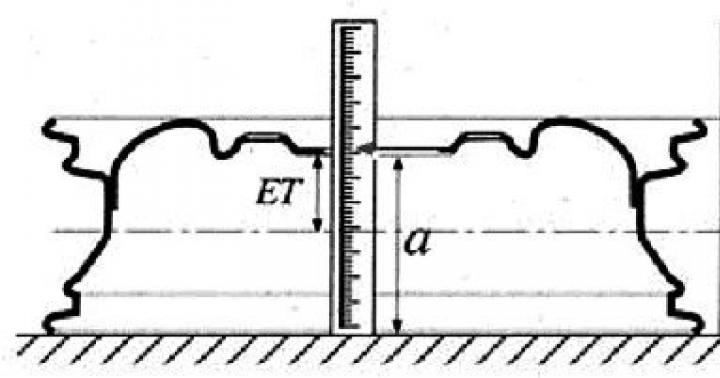

We center the body of the steering knuckle relative to the ball joint with an accuracy of 0.2 mm from the ends of the influxes of the body of the steering knuckle, using a kingpin wrench with a "27" head

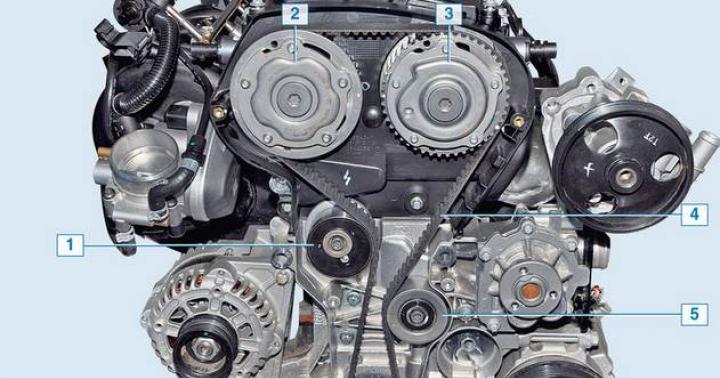

1 - Pin;

2 - Body of the rotary knuckle;

3 - Expanding sleeve;

4 - Kingpin;

5 - Insert;

6 - Hinge of equal angular velocities;

7 - Ball bearing;

A and B - Controlled dimensions, A=B

By successively increasing the torque by 2-3 kgf*m, using a torque wrench (periodically controlling the symmetry with respect to the ends, the deviation should not exceed 0.2 mm), tighten the clamping bushings with a final torque of 20-25 kgf*m.

With a consistent increase in the torque of the clamping sleeve, each time through a soft mandrel, strike with a hammer along the axis of the king pins on both sides.

It is necessary to ensure the accuracy of the symmetry of the installation of the ball joint of 0.2 mm, relative to the ends of the influxes of the steering knuckle housing. Measurements are made using a caliper.

This centering is necessary for the correct operation of the axle shaft seals and to reduce the load on the constant velocity joints.

Please note that after tightening the clamping bushings with a force of 25 kgf * m, the ball joint rotates very tightly relative to the steering knuckle housing, as it should be. The turning force is adjusted separately - by tightening the nuts of the pivots.

Installation of a clip and a cuff of a rotary fist

We stuff Litol-24 into the cavity between the ball joint and the steering knuckle housing.

Then install the cuff of the steering knuckle ..

We install a felt ring (ring SP134-12-5), which must first be soaked in machine oil.

Install the steering knuckle collar. Using the "10" head, we screw it on eight M6x12 bolts. We screw in the locking bolt-stop with a lock nut, set the previously measured height on the caliper and fix it with a "17" key and a "12" key. We fasten the bolt M10x1x16 with a "14" key. We install the gasket, lining and screw the M16x1.5 nut with the flange onto the kingpin.

We install the gasket and the steering knuckle lever, expander bushings and fasten them onto four Ml2x1.25 nuts using the “19” head and screw the M16x1.5 nut with a flange onto the kingpin. This photo shows a variant of the steering knuckle lever for UAZ-374195 cars and its modifications

Installing a steering knuckle with a half shaft

We fasten the steering knuckle with the axle shaft to the flange of the axle shaft housing with five special bolts M10x1x30, two of them were previously dressed to limit the turn, with the key "14" until it stops.

Attention, after a run of 200-500 kilometers, repeat the tightening of the indicated five special bolts M10x1x30

Ball joint adjustment

Pre-tighten the M16x1.5 nuts with a 24 head flange with a torque of 5 kgf * m.

The torque of rotation of the ball joint in any direction relative to the common axis of the pivots must be within 1.0 - 2.5 kgf * m, i.e. holding the body of the steering knuckle with your hands, you must freely turn it around the axis. If this does not happen, tighten the M16x1.5 nuts with a flange on both sides until the desired result is achieved.

The maximum tightening force is 15 kgf * m.

Installation of brake mechanisms

In reverse order of removal, see above

We fasten the grease fittings (if they are provided for by the design) with the key "8" to the kingpin. We fasten the fasteners of the brake mechanisms to the body of the steering knuckle with a special head "19" on the bolts.

Installation of rods of the steering trapezoid

Install the steering trapezium linkage, screw the fingers with a "22" wrench and cotter pin the M14x1.5 nut. Reuse of old cotter pins is not recommended.

Install the bipod linkage to the steering knuckle lever, screw the fingers with a M14x1.5 nut with a “22” wrench and cotter it.

Install the wheel. Attention! Before driving the car after completing the repair, press the brake pedal several times to press the front caliper pads against the brake discs.

The excellent off-road qualities of the UAZ Patriot depend not least of all on special hinges (pins) of the steering knuckle, so they need to be changed and adjusted in a timely manner. Next, we will talk about the various types of hinges installed on these cars, their replacement and adjustment features. This will help you replace and adjust the kingpin on the UAZ Patriot with your own hands.

Pivot types

On these SUVs, 4 types of hinges are installed, which differ in the type of bearing:

- plastic cup;

- bronze cup;

- steel ball;

- needle bearing.

At the factory, only plastic and ball joints are regularly installed. A bronze cup is put instead of a plastic one without alterations, therefore such tuning increases the service life of the king pin and is not a change in the design of the car. Installing the bearing joint requires a major alteration of the steering knuckle, therefore it is considered to be a change in the design of the car.

How to remove old hinges

Regardless of the type of hinge, the basic dismantling operations are the same. To replace or adjust the pivots, you will need a level area. In addition, you will need:

- a set of socket and open-end wrenches;

- Screwdriver Set;

- a set of heads and a ratchet;

- torque wrench;

- powerful crank and extension from a piece of pipe;

- clean rags;

- anti-recoil stops;

- low stool;

- helper or helper.

It is important! If you are going to change or adjust the king pin, you must carefully read the safety rules and always follow them:

- never leave the car on a jack, always put a safety prop, which is sold in any auto shop or a wide, even block of wood;

- be sure to support the wheels with wheel chocks;

- never do any work under the car alone - if something goes wrong, the assistant will be able to call for help or help you on his own;

- do not drink alcohol, do not use narcotic or psychotropic substances before repairing the car.

Walkthrough

We have broken the whole process into separate operations that must be performed sequentially. This will help not only in disassembling the steering knuckle, but also in assembling it after installing new or adjusting old hinges:

Removing ball joints

Unscrew the grease fitting or the bolt installed instead of it and 4 nuts securing the bipod to the steering knuckle. With a hammer, lightly tap the bipod near the fist to move it. Remove the 4 cone washers, then remove the bipod and shims underneath. To pull out the hinge parts, you will need a special puller, which can be made from a U-shaped profile 5 mm thick. The width of the profile is slightly larger than the diameter of the outer part of the kingpin. Drill a hole in the center of the puller, the diameter of which is 1-2 mm larger than the diameter of the hole for the grease fitting. Then take a bolt 5–7 cm long with a suitable thread and nut.

Screw the nut onto the bolt, then place the puller over the outer part of the hinge and screw the bolt into the plug through it until it stops. Tighten the nut until the bolt completely pulls out the outer part. If there is no such puller, you can try to pull out the hinge by screwing a bolt with large washers into it and squeezing the washers with two mounts, but this method is less effective. Then remove the ball and pull the ball joint out of the steering knuckle, and then pull out the inner part of the hinge in the same way. Thoroughly clean the places for installing the pivots from the remnants of the old grease.

Dismantling other types of hinges

Other types of pivots are removed in the same way:

- Unscrew the nut of the upper king pin, then, through a soft metal spacer, hit the king pin to facilitate unscrewing the clamping sleeve.

- Using a special key (it is found in many sets of new king pins, and you can also buy it at any car dealer), the clamping sleeve is unscrewed.

- Pull out a finger.

- Unscrew the bolts of the rear plate of the steering knuckle and pull out the ball joint.

- With a screwdriver, pry off and pull out the bearing shell or plastic / bronze cups.

- Thoroughly clean the place of the liner and finger from the old grease.

Installation of new pivots

New ball joints are pressed in using a cylinder head guide bushing tool or a wheel bearing tool. You can use other pullers that will ensure that the upper and lower parts of the hinge are fed exactly parallel to the channel in the ball joint and the steering knuckle. Having installed the kingpin in the ball joint, fill the place under the ball with Litol or a better lubricant.

The rest of the hinges are set like this:

It is important! Regardless of the type of joint, when installing and tightening, it is necessary to ensure the same distance from the ball joint to the steering knuckle from above and below. Measure the gap with a vernier caliper. The maximum gap difference is 0.2 mm.

After installing the kingpin and fixing the ball joint in the steering knuckle, lubricate the surface of the support with Litol or a better lubricant and install the oil seal, securing it with a metal ring and bolts. Then assemble everything in the reverse order to what was used during the disassembly process. Don't forget to adjust the camber and toe.

King pin adjustment

If there is a slight play on the front wheels due to wear of the hinges, then on machines with ball kingpins, convince one or more gaskets located on the steering knuckle under the bipod, as well as under the plate holding the lower kingpin. As a result of this, the bipod will press harder against the fist and provide a more secure fit. On machines with other types of kingpins, it is necessary to unscrew the upper nut and tighten the clamping sleeve until the play is eliminated.

In the front axle of UAZ Patriot cars there are pivot assemblies and constant velocity joints, which ensure the transmission of torque to the wheels in any of their positions. For the assembly to work properly, you need to know how to maintain and change the kingpin.

In today's article, we will analyze in detail what a kingpin is and where it is located on the Patriot, and I will also give you step-by-step instructions for replacing the adjustment and broach of this part.

What is the "King" on the UAZ Patriot and where is it located

The king pin on a UAZ Patriot car is a special unit responsible for turning the wheel in a strictly limited range.

UAZ pivots have the following functions:

- They act as axles around which the steering knuckle can swing;

- They act as connecting components that combine the ball joint and the steering knuckle into a single unit;

- They act as load-bearing components that provide the necessary rigidity of the pivot assembly, and also perceive the moments of forces arising from the steering knuckle (and it, in turn, from the wheel) that arise during the movement of the car and transfer them to the axle beam.

UAZ pivots, despite their simple design, play an important role in the functioning of the front axle of an SUV, and hence the entire car.

Part Specifications

The king pin is a part in the form of two cylinders of different diameters, machined from a single piece. At the end of the upper (wide) part, in its center, there is a threaded channel for installing a grease fitting. Nearby, with mixing from the center, a channel of smaller diameter with smooth walls was drilled for the installation of a locking pin. An annular recess is provided on the side surface of the lower (narrow) part for the distribution of lubricant. Also, a through longitudinal channel can be made in the pivot for lubrication of the entire assembly.

The king pin is pressed into the body of the steering knuckle with a wide part and is fixed with a steel plate (it is held by four bolts), and turning is prevented by a pin. With its narrow part, the king pin is installed in a bronze bushing pressed into the ball joint housing. The bushing is calibrated in such a way that the kingpin can be rotated in it without jamming. Between the wide part of the king pin and the body of the ball joint, metal spacers are laid, with the help of which the entire pivot mechanism is centered. To facilitate turning and reduce the intensity of wear of parts, the kingpins are installed at a slight angle.

The mechanism works with these pins simply: when performing a maneuver, the steering knuckle deviates from the middle position by means of a bipod, the pins turn with their narrow parts in bushings pressed into the ball bearing housing. When turning, the grease from the channel of the kingpin enters the recess in its lower part, where it is distributed in the space between the kingpin and the bushing - this reduces friction forces and reduces the intensity of wear of parts.

Video: UAZ Patriot king pin - what it is responsible for and what functions it performs

Advantages and shortcomings of the king pin on bearings and on bronze liners

Every newcomer among patriots is concerned about the question of which pivot joints are better to put. Among the jeepers there is no unequivocal opinion on the need to complete the UAZ Patriot with a knuckle with rolling bearings. Replacing the hinge assembly with a bearing one is quite laborious and not cheap.

Advantages:

1. Do not require such frequent checks and tightening. If the tension is maintained, they go for a very long time.

2. Low friction even under heavy tension.

3. Large selection of ready-made kits for sale

Flaws:

1. Difficulty of proper installation (more on that later)

2. Bearing 30203, on which most of the kits are made, seems a bit weak. Although the declared 18kN load capacity should be enough, purely theoretically.

3. Less upright under extreme loads

4. They are afraid of getting water.

5. When working without tightness, they quickly fail

6. In advanced cases, an emergency failure is possible with the destruction of the bearing and jamming

The main reasons for the failure of the UAZ Patriot kingpin

Ball pivot assemblies usually fail due to the destruction of the rim of one of the cups that cover the ball. At some point, this rim can simply split, and this happens either from a strong blow (due to hitting an uneven road), or from the so-called metal fatigue. As soon as the rim of the cup collapses, a play of the ball appears, due to which a knock and creak occurs in the pivot assembly. It is possible to understand that it is the king pin that is faulty only by completely disassembling the front steering fist.

If you hear a continuous knock in the front suspension, then you need to replace the pivots on the UAZ

Video: Advantages and disadvantages of Waxoil king pin

Adjusting and broaching the kingpin on the UAZ Patriot - step by step instructions

In the event of small gaps in the pivots on the UAZ Patriot, adjustment is made without complete disassembly of the rotary mechanism. For this you need:

- Fix the UAZ on a flat area, raise the front axle with jacks and remove the front wheels.

- Remove the protective pads and gaskets on the clamping sleeves of the pivot connection.

- Reset the kingpin with a few blows to reduce the preload.

- Using a special wrench, tighten the clamping sleeve until the resulting backlash is eliminated.

- The broach is made at 10-12º, the tightening torque is not more than 30 Nm.

- Adjustment actions must be performed alternately on the upper and lower support.

- After that, the force during the movement of the steering knuckle is checked, which should be free. The clamping sleeves are lubricated, then a gasket with a protective cover is installed.

When Patriot suspension play is significant and simple adjustment does not help, it is necessary to replace the bearings of the ball joint to avoid its final failure. In this case, the front suspension is completely disassembled and the pivot mechanism is subsequently adjusted.

Replacing the king pin on the Patriot with your own hands - step by step instructions

In order to replace the kingpin on a UAZ Patriot car, you must perform the following steps:

- Park the machine on level ground and apply the handbrake.

- Support the rear wheels with wheel chocks, then loosen the front wheel bolts and jack up that side.

- Place a jack stands under the car and remove the wheel.

- Unscrew the two bolts and remove the plate holding the pads, then pull the pads out.

- Loosen the two bolts and remove the caliper bracket.

- Unscrew the two bolts, then remove and hang the brake caliper so that the hose is not stretched or pinched.

- Unscrew the screws securing the brake disc and carefully hitting the back side with a piece of wood, knock it off the hub.

- Loosen and unscrew the steering tip nut and pull out the pin with a puller.

- Disconnect the ABS wire.

- Unscrew the bolts holding the plug on the end of the hub and remove it.

- Unscrew the 6 bolts securing the trunnion and pull it, the CV joint and the axle shaft from the steering knuckle.

- Unscrew the 5 bolts securing the ball joint to the axle flange and remove the wheel rotation limiter.

- Then remove the ball joint, put it on the table and clean it of dirt.

- Remove the 6 bolts securing the ball joint seal and remove the seal.

- Unscrew the grease fitting or the bolt installed instead of it and 4 nuts securing the bipod to the steering knuckle. With a hammer, lightly tap the bipod near the fist to move it.

- Remove the 4 cone washers, then remove the bipod and shims underneath. To pull out the hinge parts, you will need a special puller, which can be made from a U-shaped profile 5 mm thick. The width of the profile is slightly larger than the diameter of the outer part of the kingpin. Drill a hole in the center of the puller, the diameter of which is 1-2 mm larger than the diameter of the hole for the grease fitting. Then take a bolt 5–7 cm long with a suitable thread and nut.

Screw the nut onto the bolt, then place the puller over the outer part of the hinge and screw the bolt into the plug through it until it stops. Tighten the nut until the bolt completely pulls out the outer part. If there is no such puller, you can try to pull out the hinge by screwing a bolt with large washers into it and squeezing the washers with two mounts, but this method is less effective. Then remove the ball and pull the ball joint out of the steering knuckle, and then pull out the inner part of the hinge in the same way. Thoroughly clean the places for installing the pivots from the remnants of the old grease.

Regardless of the type of joint, when installing and tightening, it is necessary to ensure the same distance from the ball joint to the steering knuckle from above and below. Measure the gap with a vernier caliper. The maximum gap difference is 0.2 mm.