The density of the electrolyte in the battery is a headache for car owners who have opted for collapsible batteries. These batteries can be controlled and recharged, but it takes a little science to do so, which is what we're going to do.

What electrolyte density values are considered normal?

The battery is a chemical current source, and the transformations occurring in it are reversible. The design of such devices is simple, they consist of a housing where the electrodes are placed, a separator-converter and a bus. All this is closed with a lid with outlet holes and terminals. But the battery will not work without electrolyte. In lead-acid batteries, this is a solution of sulfuric acid, the density of which is measured in g / cm 3. It is proportional to the concentration of the solution, and the inverse relationship can be traced with respect to the temperature of the liquid. The density test of the alkaline electrolyte will be carried out by those car owners whose car uses nickel-cadmium or nickel-iron batteries.

By the density of the electrolyte, you can determine the condition of the battery. If the value has dropped, then, most likely, some cell is defective, an open circuit has occurred or a deep discharge of the battery has occurred. For the latter case, the reduced density will be in all cells. If the battery does not hold a charge, then you should check the condition of the liquid inside it. During battery operation, water gradually evaporates, as a result, the electrolyte becomes more concentrated, which also negatively affects the state of the unit. This characteristic affects the capacity of the battery and determines its operational life.

It is very important to maintain optimal electrolyte density in the battery, which largely depends on the climatic zone. In regions with a cold macroclimate, it is better to maintain the density of the acidic electrolyte in the range of 1.27–1.29 g/cm 3 . In the middle lane, these figures will change - 1.25–1.27 g / cm 3. In warmer regions, the normal density is 1.23–1.25 g/cm3. Moreover, when pouring electrolyte, it is better to prepare a solution along the lower boundary of these ranges. For an alkaline battery, checking the density of the internal contents should show 1.19-1.21 g / cm 3. Before cooking, it is important to clarify the composition, there are potassium and sodium electrolytes, each of them will have its own proportions in order to achieve the specified value.

Expert opinion

Ruslan Konstantinov

Automotive expert. Graduated from IzhGTU named after M.T. Kalashnikov with a degree in Operation of Transport and Technological Machines and Complexes. Over 10 years of professional car repair experience.

In most cases, the electrolyte is a solution of sulfuric acid and distilled water in approximately 2/1 ratios (60% water and 40% acid). With this ratio, the battery plates are able to accumulate an electric charge. Many people know about the density of the electrolyte, but few know why this parameter changes with discharges and charges. When the battery is charged, water is removed from the electrolyte, respectively, the percentage begins to change in favor of acid. When the battery is discharged, on the contrary, the concentration of acid decreases, on the plates it begins to settle with sulfates. With a deep discharge, the plates will simply overgrow with sulfates, which will no longer be destroyed during the next charge, a process of so-called sulfation occurs. This phenomenon is dangerous in that the density will gradually decrease greatly and charging will no longer help restore battery performance due to excessive sulfation.

You should not experiment with increasing the density, some believe that it is easier to use concentrated sulfuric acid at all, for example, when operating a car at critically low temperatures. You can’t do this, sulfuric acid is one of the most powerful solvents, it can simply corrode lead plates. It is unacceptable to exceed the density by more than 1.35 g / cm 3.

Checking the density of the electrolyte - devices and their operation

Many motorists have come across a situation where, after a long recharge, the electrolyte boils and evaporates, then we fill in distilled water. In this case, the density of the solution is very rarely measured, but in vain. After all, the acid itself also boils away with water, and by adding only distillate, you will get a mixture with a lower concentration, which will negatively affect the performance of the device.

To measure the density of the electrolyte in the battery, you will need a special device - a densimeter. It consists of a glass tube in which a hydrometer is placed, a tip and a rubber pear. We find a filler hole at the battery and immerse the tip of the measuring device in the solution. Then, using a pear, we suck part of the acid into the glass case. We carefully hold the device at eye level - the hydrometer should be at rest, float in the liquid, without touching the walls.

If there is no special device, then you can check the density of the electrolyte in the battery with a voltmeter. We connect an autotester to the battery terminals and measure the voltage. It should fluctuate within 11.9–12.5 V. Then we turn the key in the ignition and gain 2.5 thousand revolutions. In this case, the voltage should reach a minimum of 13.9 V, but not exceed 14.4 V. If there is no change, then you just need to charge the device.

How to increase the density of the working electrolyte?

What to do when the density of the electrolyte drops in the battery? Of course, it is necessary to restore it to the desired value. There are several ways:

- recharge the battery;

- completely replace the electrolyte with a new one;

- add more concentrated electrolyte;

- add acid.

We prepare in advance all the necessary equipment: a measuring container, a pear, a soldering iron and a drill. All items must be clean and well dried. We also need distilled water and the electrolyte itself.

You should always try to recharge the battery first. Checking battery voltage. Has the value changed since revs? Then you should charge the device for 10 hours with a current that is ten times less than the capacity. For example, if it is 60 A * h, then a current of 6 A is enough. Then this value is halved and the battery is still left on charge for 2 hours. It is the second mode that evens out the density of the electrolyte. And if the voltage with the engine running rises more than 14.4 V, then you need to fill the battery with water. Then put . If after such events the battery is still quickly discharged, then you need to work with the electrolyte.

To restore the electrolyte density value in a discharged battery to normal, you can completely replace the contents. To do this, pump out the liquid from each can as much as possible, and then drain the residue. To do this, seal all openings tightly and turn the unit on its side. We drill holes at the bottom from the side of each can and drain the electrolyte. It is strictly forbidden to put the battery upside down, as in this position a short circuit may occur, and the surface of the plates will crumble.. After the solution is no longer in the device, thoroughly rinse it with purified water. Be sure to hermetically seal the holes in the bottom of the device and fill it with a new electrolyte.

Typically, the density of the electrolyte in batteries can be increased or decreased by adding a concentrated solution or purified water. First of all, the quality of the conductive substance is checked in each bank separately. If the measurement showed a density of more than 1.18 g / cm 3, then you can simply dilute it with a more concentrated solution. To do this, we select the maximum possible amount of electrolyte, replace half of it with a solution with a higher concentration than we strive to obtain (for example, we need 1.25 g / cm 3), and fill it all back. We shake the battery gently to mix the updated composition well.

A more concentrated electrolyte can be prepared by yourself, then it is better to make 1.40 g / cm 3. Purchased, most likely, it will be 1.27 g / cm 3, then the process of increasing the density may take a little longer.

After a short pause, a density check is carried out. You will find that it has risen, but has not reached the desired figure. Then we repeat the procedure again, only we reduce the dilution step so as not to jump over the target mark. This time, only a quarter of the pumped out liquid needs to be replaced with a more concentrated electrolyte. After each procedure, the measurement will show that we are getting closer to the desired mark on the device. It is difficult to accurately obtain the normal density of the electrolyte in the battery in this way, you will probably miss the desired mark, but by that time it will be enough to add a little bit of clean water, because the dilution step will already be quite small and the goal will be achieved.

When the density of the electrolyte is less than 1.18 g/cm3, acid will have to be added. We carry out all operations in the same order as in method 3. Only the dilution step should immediately be taken small, because the acid has a very high density (about 1.8 g / cm 3), you can jump over the desired mark already from the first dilution. It is very important when preparing all solutions to pour acid into water, and not vice versa, so as not to provoke splashing of the concentrate. Carry out work in a special robe, protect the skin and organs of vision. If liquid comes into contact with the body, immediately flush the affected area with clean water.

All professional motorists know that any car requires care and maintenance. Important in this matter is the maintenance of a very important device - the battery, which ensures the start of your car and the smooth operation of all electrical systems.

In order for the battery to serve for a long time, it must be serviced. As we know, our car battery is filled with electrolyte and it plays an important role in the operation of this device. We wrote about the electrolyte in detail in the article, and now let's talk about how to measure an important parameter of this acid and water solution - density.

What is a hydrometer

First, a few words about density, density is the specific gravity of the acid that is mixed with distilled water, relative to the entire volume of the solution. Simply put, this is the acidity of this mixture.

The density is measured with a hydrometer, the principle of which is based on the law of Archimedes, according to which a buoyant force acts on a body immersed in a liquid, the value of which is equal to the weight of the liquid displaced by this body.

The density of the liquid under study, in our case, the electrolyte, can be determined by the depth of immersion of the hydrometer, i.e. the volume of liquid displaced by it, and the weight of the hydrometer.

Hydrometer design for electrolyte

Hydrometers are different, it all depends on the density of which liquid you will measure. Since this information site is about batteries, we are of course interested in a device that is popularly called a “car hydrometer”. The design of a car hydrometer is quite simple. It consists of:

- glass or plastic tube

- rubber pear

- Pipettes

- Hydrometer

A rubber pipette with a long nose is attached to one end of the glass tube to reach the battery plates. Why rubber, so as not to damage the plates and battery separators.

A hydrometer is inserted into the inside of the tube, which is a hermetically sealed glass tube, inside of which a ballast weight is laid at one end (metal, or maybe some other substance, can serve as a weight). From the other end, this tube flows into a glass rod of a smaller diameter on which a measuring scale is applied.

On the other side of the glass tube-case, a rubber pear is attached, with the help of which we pump the electrolyte from the battery into our hydrometer and back into the battery jar.

There are, of course, devices for measuring density and a slightly different design. For example, the float “Density Indicator”, inside the cavity of which there are several plastic floats of various colors.

It works on the same principle as the hydrometer described above, on the same laws of physics. In the same way, the electrolyte is pumped into the device using a rubber bulb and pop-up floats show the density of the solution. However, the accuracy of measurements with such a “Density Indicator” leaves much to be desired, the floats sometimes float up, sometimes they don’t, although the electrolyte is the same.

Safety precautions when measuring electrolyte density with a hydrometer

Before you start measuring the density of your battery electrolyte with a hydrometer, you should remember that you are working with acid and basic safety measures must be observed.

Be sure to wear goggles to protect your eyes, rubber gloves and an apron. Contact with electrolyte on exposed skin and eyes will cause chemical burns.

If the electrolyte gets on the skin or eyes, immediately rinse these places with plenty of running water for 15-20 minutes, then you can wash the burnt areas with soapy water or a solution of water with soda at a concentration of a teaspoon per 200-300 ml of water, by these actions you will lower the concentration chemical substance. Treatment of affected areas of the skin does not cancel the call for an ambulance or an urgent visit to the hospital.

How to measure density with a hydrometer

To measure the density of the electrolyte in the battery, it is necessary to withstand the conditions on which the readings of our measurements depend:

- The battery must be charged

- It is impossible to measure the density immediately after charging, you need to wait 3-5 hours.

- The hydrometer readings should be corrected depending on the temperature of the electrolyte.

The most accurate data will be at a solution temperature of 27 degrees C. If the temperature is lower, you need to subtract 0.004 fractions of a unit for every 6 degrees C, if higher, add the same value.

Before unscrewing the caps of the battery cans, carefully wipe the surface of the battery so that dirt does not get inside, this can serve to reduce the life of your product.

The measurement procedure itself is quite simple. We assemble the hydrometer: we attach a pipette to the body-tube, place a densimeter in the body, and close the body on the other side with a rubber pear.

We measure the density in each jar in turn. To do this, we lower the pipette nose to the plates and draw an acid solution into the hydrometer body using a rubber bulb. You should not collect a lot of electrolyte, the densimeter may rest against a pear and the readings will be inaccurate, if there is not enough solution, then the densimeter will not float. It is necessary to collect such an amount of acid solution that the densimeter floats without interference.

The density readings of our electrolyte can be viewed at the intersection of the hydrometer scale and the surface of the solution. Keep in mind that devices have different scales, some read readings in g / cm3, but there are scales in kg / m3, then in order to get the numbers we are used to, the readings must be divided by 1000.

Depending on the values that you have received, you can decide to adjust the acid solution. How to raise the density of the electrolyte, we wrote earlier in the article.

Some hydrometers have a scale for measuring the density of antifreeze with a hydrometer. Why is it necessary to measure the density of antifreeze? This indicator is mainly needed in winter and in the northern regions of the country. The fact is that by the density of antifreeze we can determine the temperature of its crystallization (freezing), this is very important at low temperatures to ensure the normal functioning of the car engine.

Be sure to rinse the hydrometer after use at least three times and preferably with distilled water. This simple procedure will extend the life of your device for more than one year.

Sold brands of hydrometers in Russia

The choice of brands of hydrometers in the market of our country is quite large, but in fact they represent almost the same devices. The differences are only in the quality of the material used for the manufacture of devices.

Hydrometer IP1

The IP1 hydrometer stands out from the general monotony, which is not made with a standard glass hydrometer, but with a set of plastic sticks, opposite which the density value is written on the case. After filling the cavity of the device with electrolyte, the sticks float and the density value is read on a scale from the one that surfaced last.

The measurement limit of this device is from 1.19 g/cm3 to 1.31 g/cm.

Scale division value 0.02 g/cm.

Hydrometer IP1 - “Density Indicator - 1” is not an entirely accurate device, but it is quite common among motorists, probably due to its low cost (approximate cost in stores is 100 rubles) and compactness.

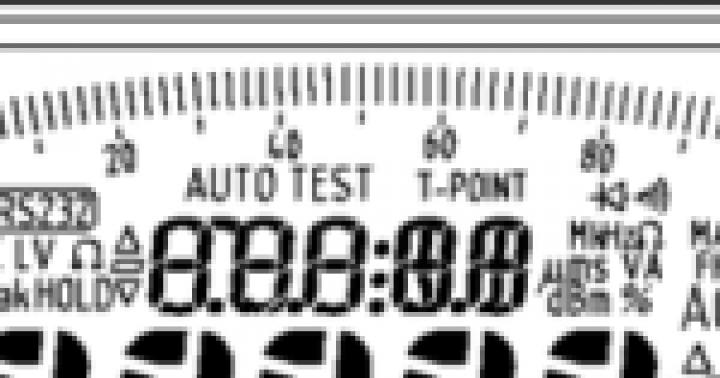

Hydrometer Orion AR-02

Against the background of all this diversity, the products of the Orion AR-02 hydrometer, already familiar to us from a series of chargers, stand out from the company from St. Petersburg LLC NPP ORION SPB.

This is the only device for which I found instructions. She can.

The principle of operation, safety precautions and the measurement process are described above, let's see how the rest of the specimens look in the pictures and some short videos.

Hydrometer for electrolyte Autovirazh AV-9901

Hydrometer for electrolyte Sparta 549125

Most drivers are familiar with the hysterical howl of a starter or a click, or even silence under the hood of a car during engine start. This unpleasant moment is associated with the following malfunctions.

- Car wiring fault. Perhaps the contact has disappeared somewhere, most often this is due to the partial absence of "mass".

- Faulty starter solenoid relay.

- Limit wear of starter bushings.

- Starter winding failure.

- Low voltage in the circuit due to a dead battery.

The latter reason is usually the most likely. The most logical move would be to check the density of the electrolyte in the battery. What does it depend on?

- from the climatic zone.

- From the season.

In order to correctly check the density of the electrolyte in the battery, you need to know its value and have a device called a hydrometer.

It is easy to find out the correct density - there are special standards. Their average indicator is 1.24 - 1.29 kg / dm 3. More precisely:

- cold regions - 1.27 - 1.29 g / dm 3, in summer and winter;

- middle band - 1.25 - 1.27 g / dm 3;

- warm areas - 1.23 - 1.25 g / dm 3.

The density of the battery should be checked at least once every three months. Even a slight deviation from the norm requires an immediate recharging of the battery.

The indicators must be carefully monitored - in order for the battery to work as long as possible and not let the owner down at the most crucial moment. Especially she "does not forgive" negligent attitude towards herself in the winter. The fact is that its capacity is lost in the cold, and sometimes even one unsuccessful engine start leads to battery discharge.

Having the simplest device, it is not difficult to check the battery density at home.

Density - density, but the electrolyte level must be monitored with no less attention, especially in summer, when the battery boils more intensively.

There are a lot of opinions regarding the electrolyte level in the battery:

- Some believe that it is enough to cover the separator grids with this liquid.

- Others believe that the higher the electrolyte level, the better.

- Still others do not look under the battery plugs at all - until the very moment when the starter stops turning, which often causes genuine surprise among such unfortunate owners.

There are batteries that have a mark on the case indicating the electrolyte level. It is not very convenient to use it, and one cannot hope for exact indicators. The proven “old-fashioned” method will help here: a glass tube with an outer diameter of 5–6 mm. On its body in the lower part, marks should be applied indicating the correct electrolyte level (according to the battery's passport data). The tube is lowered into each jar in turn, until it stops against the separator grid. Next, the upper side of the tube is plugged with a finger, and the device is removed from the jar without releasing the finger. The liquid will remain in the tube and the exact level will be visible.

If the level is low, you should gradually pour distilled water into the jar, making a control measurement after each topping up. If the level is too high, which is also not a correct indicator, then using a hydrometer, excess liquid is pumped out. This method is the most reliable.

The need for a charger

This is a very necessary device for keeping the battery in good condition, it is necessary for every car owner to have it. With this device, you can always recharge the battery without resorting to the services of a service station or local "craftsmen".

Having the right device with an ammeter, the driver will perfectly do this himself. The procedure for charging the battery is as follows.

- You need to connect the charger to the battery.

- Turn on the device.

- Set charging current. Its value should correspond to ten percent of the battery capacity. For example: if the battery capacity is 60 A / h, then the current should be 6 amperes, 63 - then 6.3 A / h.

For more information about how it happens and what rules you need to follow, read the article of our author.

Charging time directly depends on the degree of discharge, which is determined by checking the density of the battery with a hydrometer. The scale indicates the percentage of discharge. For example, the battery is 50% discharged and has a passport capacity of 50 Ah. It follows from this that it is necessary to recharge the missing 25 a / h. If you charge the battery with a current of two amperes, then it will take twelve and a half hours, and if the current indicator is four amperes, six hours and 15 minutes. etc.

The principle is simple and understandable, if not for one “but”: each battery has its own unique “burrow”, especially when it is far from new. She takes charge in different ways: faster or slower.

Topping up liquid

Many "clear minds" warmly advise in the event of a strong discharge of the battery to add sulfuric acid to it, which is unacceptable. The acid does not immediately mix with the remaining liquid, and for this it is necessary to charge the battery. In the meantime, the aggressive liquid will intensively corrode the plates, "eating" at the same time the active mass - the powder applied to them.

If you add electrolyte, then the consequences will not be so deplorable, but such a liquid will also have a bad effect on the condition of the battery.

If the density is too high, you need to pump out the liquid with a hydrometer, and then add distilled water. Next, charge with a low current, not forgetting about the periodic control of the density of the electrolyte.

If the electrolyte is to be replaced, a new one must be prepared. For proper preparation, distilled water is first poured into a glass or acid-resistant plastic container, and then, in a thin stream, acid.

When adding acid in small portions, it is often necessary to check the density of the electrolyte, bringing it to the desired value, depending on the region of residence and the season.

Safety

Care must be taken when working with acid or checking battery density.

- Work only in overalls that you do not mind throwing away. Even an electrolyte, not to mention a concentrated acid, easily brings any clothes and shoes into a deplorable state.

- Wear rubber gloves to prevent possible chemical burns. Even measuring the density of the battery is not worth it without them.

- Goggles also do not interfere, especially when preparing the electrolyte, when the risk of getting this aggressive liquid into the eyes is especially high. Some people, out of inexperience, pour water into acid, and not vice versa, as it should be, and as a result, a splash can occur.

- Before charging the battery, you must correctly connect it to the device, without confusing the polarity.

- Do not forget about effective ventilation. If there is no forced exhaust, then a well-ventilated room is quite suitable.

During the operation of the car, it often happens that after one or two days of “idle” it turns out to be either problematic or simply impossible to start. This is due to the battery, or rather its rapid self-discharge. This phenomenon is often observed even after a full cycle of charging the battery with a special charger. If we discard the options for other battery malfunctions, which are not so common, the electrolyte is to blame for this situation, or rather its low density.

Despite the fact that every time after charging the battery it is recommended to control the density of the electrolyte, in practice, not all motorists do this, and as a result the battery is chronically undercharged, especially when making short trips by car. This condition is very dangerous for the battery, as it leads to premature wear. In fact, the problem can be fixed with your own hands, while any serious financial investments will not be required at all.

Preparing a place to check the density of the battery

Before checking the density of the battery, it is necessary to determine the place where all procedures will be carried out. Doing this is not as easy as it might seem. Before checking the density of the battery with a hydrometer, it will be necessary to carry out the entire preparatory maintenance cycle:

- battery cleaning;

- checking and correcting the electrolyte level;

- full charge.

Only after that it will be possible to proceed directly to the density test. Such "difficulties" are necessary because, if you check the density of the electrolyte in the battery immediately after dismantling it from the car, the results will be far from reality. And there are several reasons for this. For example, inappropriate electrolyte level. In addition, the density of a charged battery is always higher, and it is this value that is taken as the norm.

As for the room itself, before checking the density of the battery at home, it is necessary that it meets the following requirements:

- be equipped with excellent supply and exhaust ventilation;

- be safe in terms of fire safety;

- have a reliable power supply.

Preparing for the test

Before you can properly check the density of the electrolyte in the battery, it is important adjust its level and fully charge the battery. Only in this way will the results be correct. After removing the battery and cleaning, it is placed on a wide, flat surface, all plugs are unscrewed. Be careful when working, as the acid can cause deep burns to the skin. After checking the electrolyte level, it is important to correct it. For this, only distilled water is used.

Immediately after this, it is impossible to correctly measure the density of the battery - it needs to be charged. Using a special charger and low current, the battery is left overnight. The current value should not exceed 2 A. Thus, the battery will be fully charged. After the charging time has elapsed, the charger is disconnected from the battery and the battery is left in a quiet state for 6 hours. Only after that you can start checking the density.

Attention! During charging, the caps of the cans must be unscrewed, and it is unacceptable to smoke or carry out work related to the formation of sparks in the room where charging is taking place - when charging, a large amount of hydrogen is released into the air, which can lead to an explosion.

Checking the density of the battery with a hydrometer

Before proceeding to check the density of the battery with a hydrometer, it is necessary to prepare the hydrometer itself, as well as clean electrolyte and distilled water - in case the density is below acceptable values. It's a good idea to have on hand the data sheet of the battery, which indicates the "correct" electrolyte ratios. This is important to know, because the characteristics of the electrolyte are different for each region. The device has already applied a scale designed to assess the density, which greatly facilitates the task of the motorist. Please note that you can only work with protective rubber gloves.

The battery is installed in a convenient place, the plugs are unscrewed. The hydrometer has a special rubber pear, which must be compressed before lowering the device into the battery. By smoothly releasing the pear into the hydrometer, a certain "dose" of electrolyte is collected. You should not be overly zealous, the float should be able to move freely inside the device. After the float "calms down" you can begin to evaluate the result. The "correct" density is considered if the float is in the green zone. If not, a correction is required, since such a battery cannot be used. For more accurate results, you can compare the numbers from the graduated scale of the hydrometer with the data from the data sheet. This procedure is carried out for each of the battery cans. The correct check is shown in the video:

Density correction

In the event that the values are incorrect, the situation must be corrected. It is worth paying attention to a certain point - if the density of the electrolyte in all banks is normal, and in one it is low, the battery cannot be reanimated, it must be replaced.

Advice! The easiest way to correct the increased value is to add distilled water to the battery.

If the value is lowered, you will have to work very carefully with acid. Both concentrate and diluted electrolyte can be poured into jars - in this case, acid should be added to the water, and nothing else. After adding the concentrate to the jars, the battery must be left alone for 4 hours. This time is necessary for the density of the entire electrolyte to equalize. After that, it is required to take measurements again with a hydrometer and evaluate the results.

In the set of the motorist, there will not be superfluous a hydrometer for electrolyte and antifreeze AET-1, which is designed to measure the density of the electrolyte in acid and alkaline batteries (Fig. 1) in the range from 1100 kg / m 3 to 1300 kg / m 3 and determine the freezing point of antifreeze (Fig. 2) in the cooling system of a car engine in the range from minus 5°С to minus 40°С, as well as from a device for extracting liquid (electrolyte or antifreeze). The hydrometer is located inside a plastic tank, and when the measured liquid is taken with a rubber bulb, it occupies a certain position, which is read by a person by the level of the meniscus. All parts of the hydrometer are packed in a plastic tube, which is closed with a lid. The cover is made in the form of a small funnel, through which it is convenient to pour the electrolyte into the battery.

1. COMPLETENESS AND TECHNICAL CHARACTERISTICS

1.1. Hydrometer for electrolyte and antifreeze AET-1, pcs... 1

a) electrolyte density measurement range, kg/m 3 ... from 1100 to 1300

- scale division value for electrolyte, kg/m3 ... 10

- permissible error limit, kg/m3 ... ±10

b) range of readings of antifreeze freezing point, °С... from minus 5°С to minus 40°С

- price of division of the scale for antifreeze, ° С ... 5

- permissible error limit, °С... ±5

1.2. Liquid sampling device (electrolyte or antifreeze)

- polymer pipette, pcs... 1

- rubber balloon, piece... 1

- rubber plug, piece... 1

- stopper with a rubber tip, piece... 1

1.3. Passport, piece... 1

1.4. Packing tube, piece... 1

1.5. The weight of the hydrometer with a case and a passport is 135 gr.

1.6. The length of the hydrometer in assembled form, prepared for work - 350 mm.

1.7. The length of the packaging tube assembly is 305 mm.

2. DESIGN AND OPERATION

2.1. The hydrometer is a float, in the upper part of which a paper scale is placed, graduated in units of density kg / m 3 for electrolyte and in degrees Celsius (°C) for antifreeze.

2.2. The liquid sampling device is used to select electrolyte from the battery or antifreeze from the engine cooling system.

2.3. Before starting work, it is necessary to assemble the liquid sampling device, as shown in Fig. 3

With the help of a balloon, electrolyte or antifreeze is sucked into the pipette through the tip of the cork in such an amount that the hydrometer floats freely in a vertical position.

2.4. The line of contact of the liquid with the hydrometer rod corresponds to the density of the electrolyte in kg / m 3 or the freezing point of antifreeze in ° C (Fig. 4).

Measurements should be carried out at a temperature of (20 ± 2)°C.

If measurements are carried out at a temperature other than 20°C, then the following corrections must be added or subtracted to the measurement results (table 1) .

For example: If at a given measurement temperature the correction according to the table has a minus sign, then it is subtracted from the measurement result. If the correction is with a plus sign, then it is added to the measurement result.

Table 1.

2.5. After taking measurements, the hydrometer and the liquid sampling device must be washed with clean water and wiped dry.

Good to know:

Table 2.

3. WARRANTY

Warranty period of operation is 24 months from the date of sale through a retail network.

Produced by: Russia, OOO Citadel, Belgorod, st. Working, 12