Introduction

The economic transformations that have taken place in Russia in recent years have led to fundamental changes in the commodity market. Against the background of the rapid growth of the car park, the number of filling stations has increased several times, and their quality has completely changed. An increasing number of our filling stations began to meet international standards. The capacity of today's gas station network is several times higher than the level of the early 1990s. The number of high-performance fuel dispensers (TRK) has increased and the speed of refueling vehicles has increased. In addition, at modern gas stations and gas stations (gas stations) you can get a whole range of services (oil change, minor repairs, car wash, shop, cafe, etc.).

Increasingly stringent requirements are now being imposed on operating materials (gasolines, diesel fuels, lubricating oils) in terms of quality improvement and economical use. Therefore, knowledge of the composition, properties, areas of application and performance characteristics of petroleum products is necessary for everyone involved in their production, transportation, storage, consumption, and marketing.

The range of petroleum products produced by refineries has changed significantly in recent years. New brands of petroleum fuels with improved environmental properties have appeared. This is achieved by expanding the processes of destructive oil refining, especially hydrocatalytic ones, and the use of effective additives that increase the functional properties of petroleum products.

Gas station history

For the first time, gasoline and other types of fuel, such as household gas, began to be sold in pharmacies; for the owner of the pharmacy, this was an additional source of income and was considered a side business. The first petrol station was a pharmacy in Wiesloch (Germany), where Bertha Benz, the wife of Karl Benz, filled the tank of the first car in which she made her first trip from Mannheim to Pforzheim and back in 1888. In 2008 Bertha Benz installed a memorial plaque to commemorate this event.

Filling station - a complex of buildings with equipment designed to receive, store and issue petroleum products to vehicles, sell oils, greases, spare parts, accessories for vehicles and provide services to owners of individual vehicles.

In our country, motorization of all branches of the national economy is carried out at a rapid pace. The intensive development of road transport should be accompanied by the development of related facilities designed to service cars. This primarily applies to petrol stations. Obviously, without the creation of a sufficient, expediently located, well-planned network of high-performance gas stations, it is difficult to ensure the efficient, economical operation of public road transport and meet the needs of a rapidly growing individual vehicle.

The beginning of the intensive development of the gas station network in our country should be attributed to 1960, that is, to the time when the gas stations were transferred to the oil supply system.

Over the past years, serious qualitative changes have taken place in the system of operation of gas stations, the level of service has sharply increased, and the technical equipment of gas stations has radically changed.

Domestic fuel dispensers, characterized by high reliability and durability, have been created and are being widely introduced.

Prefabricated structures of buildings and premises of gas stations, as well as technological units, have been developed and are being introduced.

Prefabricated gas stations are characterized by great aesthetics.

However, there is still a need to speed up the development of the network of filling stations and further improve them.

Appointment of the gas station

General ideas about gas stations

The main purpose of gas stations is to refuel motor vehicles. The location of the gas station and its production capacity, taking into account the intensity of traffic flows and compliance with the required safety standards - fire, environmental, etc.

Gas station sites should be with asphalt or concrete pavement and provide free access for vehicles to dispensers and drains. In places where oil products may spill near filling islands, the coating must be resistant to oil products.

Gas stations must be equipped with signs indicating the location of a fire reservoir, water intake wells or a fire hydrant, and markers at gas stations with awnings. The territory in the dark must be lit in accordance with existing standards. Special lighting should be given to the lighting of places for refueling and draining oil products. Gas stations must have a landline phone.

Storage of petroleum products at gas stations is carried out in metal horizontal above-ground or buried tanks.

Tanks and their equipment

Rice. 1 general scheme of tank installation

The design of the tank and the technology of its operation must ensure its tightness for 10 years or more. To control the tightness of the tank, it is equipped with appropriate systems that allow timely detection of a leak and taking measures. The tank equipment and its placement should ensure that all necessary technological operations are performed:

Reception (discharge) of oil products is provided by a drain device;

The release of oil products is provided by a dispensing device;

cleaning inside the tank is carried out through a special manhole, which can be made on the cover of the technological neck or separately.

Conventional gas stations have 3-4 types of gasoline and diesel fuel in their set. At the same time, there are several options for filling stations at gas stations: according to the principle, one column - one type of fuel, one point - all types of gasoline and diesel fuel, a mixed option (especially in the presence of gas filling stations). The first option involves driving a car to a strictly defined column, which is not very convenient, because. makes. Therefore, at modern gas stations there is a tendency to the second type.

AGZS are gas filling stations. Usually they are part of gas stations, but due to the special requirements for the refueling process, they are located away from gas stations. Today, with the rise in gasoline prices, the demand for gas filling stations is also growing.

KAFS - container gas station or gas station of modular (container) type. Such a mini-gas station is designed for receiving, storing and dispensing one or two types of fuel in the territory of settlements. Gas stations have an above-ground fuel storage tank. Its technological system is characterized by the placement of gas stations (fuel dispensers) in a single unit with a fuel storage container. Convenient for quick deployment of filling stations

MTAZS is a multi-fuel filling station. Allows you to simultaneously sell two types of fuel (liquid motor fuel and liquefied hydrocarbon gas). There are still few such gas stations, but the fashion for gas equipment should do its job - MTAZS will become a common type of gas station.

Diesel fuel is a liquid product used as a fuel in a diesel internal combustion engine, as well as in gas diesel engines. Usually, this term is understood as fuel obtained from kerosene-gas oil fractions of direct distillation of oil.

Gasoline is a combustible mixture of light hydrocarbons with a boiling point of 30 to 200 °C.

Propane, C3H8 is an organic substance of the alkane class. Contained in natural gas, formed during the cracking of petroleum products.

Butane (C4H10) is an organic compound of the alkane class. In chemistry, the name is mainly used to refer to n-butane. The mixture of n-butane and its isomer isobutane CH(CH3)3 has the same name. Poisonous, inhalation of butane causes dysfunction of the pulmonary-respiratory apparatus.

Fuel dispensers

Gas stations use fuel, oil and mixture dispensers designed to refuel vehicles with simultaneous measurement of the amount of fuel, oil or mixture dispensed. The dispensers as strict metering devices are equipped with measuring devices, the reading error of which under operating conditions at an ambient and fuel temperature of + -40С should not go beyond: + -0.25% of fuel dispensers for general use.

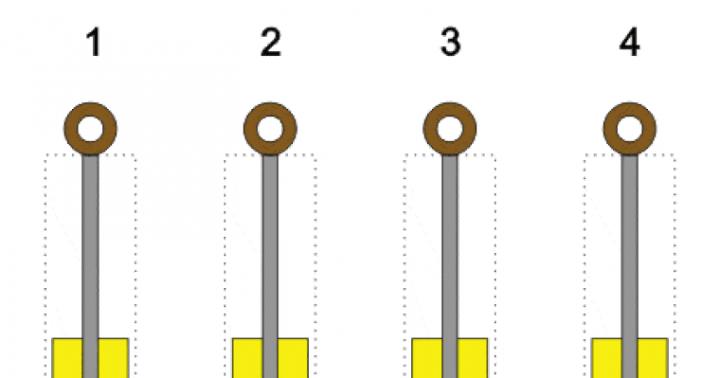

Design software distinguishes the following types of speakers:

· КР - portable with the manual drive;

· KER - stationary with electric drive;

· KEM - stationary with an electric drive and control from a local setting device;

· КА - stationary with the electric drive, automated.

Fuel dispensers, regardless of design and manufacturer, have a pump, a liquid meter, a counting device, a gas separator with a float chamber, a filter, an indicator, a dispensing valve, a check valve and a housing.

Rice. 2 Typical hydraulic diagram of a fuel dispenser

Fuel from tank 1, through intake valve 2, passing through filter 3, enters pump 4.

Filling station operation

environmental protection

The source of environmental pollution at gas stations is the evaporation of oil products, spills of oil products, as well as exhaust gases from motor vehicles.

On the territory of the gas station, it is necessary to periodically check the gas contamination of the surrounding air.

Discharge of untreated sewage into water bodies is strictly prohibited.

The change of filter materials, as well as the removal of trapped oil products and sediment from treatment facilities, must be carried out as necessary.

It is necessary to systematically monitor the cleanliness of sewer wells, prevent flooding of their outlets, at least 2 times a year to clean and conduct an internal inspection of the existing equipment of the sewer network, wells and necessary repairs.

Fire prevention and safety measures

When operating gas stations, fire safety rules must be strictly observed.

It is forbidden to use temporary electrical wiring, electric stoves, reflectors and other electrical appliances with open heating elements in the premises of the gas station.

On the territory of the gas station it is prohibited:

· - to smoke and use open fire;

- wash hands, wash clothes and wipe the floors of the room with flammable liquids;

· - presence of unauthorized persons not related to refueling.

- refuel vehicles whose drivers are in a state of intoxication;

· - refuel tractors with rubber wheels that do not have spark arresters.

· - refuel vehicles, except for passenger cars, in which there are passengers.

When refueling vehicles at gas stations, the following rules must be observed:

· -Motorcycles, scooters, mopeds must be mixed to and from fuel-mixing dispensers and from them manually with the engine turned off, the start and stop of which must be carried out at a distance of at least 15 meters from the dispensers;

· - All operations when refueling vehicles should be carried out only in the presence of the driver and with the engine turned off;

· - Oil products spilled during refueling should be covered with sand, and sand collected in a metal box with a tight-fitting lid;

· - Sand is taken out from the territory of gas station in specially taken away places;

· -After refueling vehicles with fuel, the driver must install a dispensing valve in the dispenser;

The distance between the car standing under the gas station and the next one behind it must be at least 3 meters, and between subsequent cars in the queue - at least 1 meter.

Lightning protection

The facilities of oil supply enterprises must be protected from direct lightning strikes, its secondary manifestations in accordance with the requirements of the Instructions for the lightning protection of buildings and structures RD 34.21.122-87.

When protecting steel tanks with separate lightning rods, the tank bodies must be connected to grounding. It is allowed to connect down conductors of separate lightning rods to these groundings.

The connection of tanks to the ground must be carried out no more than 50 m along the perimeter of the tank base, while the number of connections must be at least two.

For tanks of category II, protection against electromagnetic induction should be made every 25-30 m in the form of metal jumpers between pipelines connected to the tank, cables in a metal case and other extended metal structures located at a distance of 10 m or less from each other.

Installation of jumpers at the joints (joints) of metal pipelines or other extended structures is not required.

Automotive Gasolines

Gasoline is the fuel for carbureted spark ignition engines. To ensure reliable operation of engines in all modes, gasoline must have the following properties: complete volatility to achieve the highest possible combustion efficiency; high detonation resistance; high chemical stability, which predetermines the absence of a tendency to form deposits in the engine fuel system; good compatibility with materials; low corrosive aggressiveness in relation to metals and no impact on rubber products.

Table. Technical characteristics of typical filling stations

Types of petrol stations Number of fillings per day Standard project numbers Typical gas stations with car maintenance points Land area, ha Number of filling stations, pcs. 3-8 (fuel) 4 (oil) 10-12 (fuel) 4 (oil) Number of tanks: For fuel (25m) For oil (5m) For used oils (5m) Consumed electric power, kW: Lighting Heating Water heating Standard project numbers Chemical properties of gasoline

Gasolines are highly volatile and flammable liquids. They contain about 85% by mass of carbon (C), hydrogen (H) and small amounts of oxygen (O), nitrogen (N) and sulfur S. Therefore, when gasoline is completely burned, the exhaust gases mainly consist of water and carbon dioxide. Physical properties of gasoline

The physical properties include: density, viscosity, surface tension, heat of combustion, refractive index, volatility, oxidizability, electrical conductivity, thermal conductivity. corrosiveness, chemical stability, tendency to form deposits in the form of carbon deposits, toxicity. Modern gas station

The automaker MAZDA has received approval from the Japanese authorities to operate the first hydrogen filling station. The new station is designed to refuel all types of vehicles with hydrogen engines, where hydrogen is stored in a gaseous compressed state. The developed modern technologies make it possible to produce environmentally friendly, environmentally friendly refueling on water, which meets the requirements of the EU and RUSSIA. Conclusion petrol filling station A modern gas station is not just a "tank-pump-dispenser" system designed to fill a gas tank. This is a whole complex for the provision of all necessary services on the road. Let's hope that the further development of gas stations will go in the same direction: modern design, modern technologies, modern services and, most importantly, high quality fuel. In the process of completing the course work, I improved my skills in working with the Word text editor, the Paint graphics editor and the Excel spreadsheet. I also mastered the chemical editor CS ChemDraw Pro and learned how to create presentations in Power Point. Bibliography V.G. Verevkin - Reference Informational Handbook. E. I. Zorya - Operations with petroleum products. Traven V.F. Organic chemistry: A textbook for universities: In 2 volumes / V.F. Traven. - M.: ICC "Akademkniga", 2004.

ORGANIZATIONS

TYPES AND PURPOSE OF SERVICE COMPANIES AND

1) Gas stations are designed to provide car owners with fuel, lubricants and technical fluids.

2) A filling station is an enterprise that provides, in addition to refueling, additional services:

Car wash:

Provision of secure parking;

Oil change and minor repairs;

Providing posts for self-service;

Technical assistance;

Meals and rest for drivers and passengers, etc.

3) AGNKS (automobile gas-filling compressor stations) that carry out refueling with compressed natural gas and gas filling stations (automobile gas filling stations) that carry out

refueling with liquefied petroleum gas.

2. SERVICE STATIONS (SRT).

A service station is the main type of a service enterprise where the following services and works can be performed:

Sale and pre-sale preparation of cars;

Washing and cleaning;

Diagnostics, maintenance and repair;

Sale of spare parts and materials;

Additional equipment and tuning;

Temporary storage of cars;

Technical assistance;

Accompanying services.

STOs are classified:

By appointment and location: urban and road;

By size (number of working posts) for:

Small - up to 5 posts;

Medium - 6-15 posts;

Large - 16 or more posts;

By objects and lists of works and services performed on:

Complex;

Specialized in works and services;

Specialized in brands and types of vehicles.

3. DEALER ENTERPRISES (DEALERS).

These are trade and service enterprises that sell, warranty and post-warranty maintenance of cars of a certain manufacturer with which an agreement has been concluded.

Depending on the content of the contract with the manufacturer, dealers may be entitled to:

Trademark (franchising or commercial concession) and manufacturer's brand - "branded service enterprises");

Trade and / or service of cars of this manufacturer.

Enterprises performing maintenance, current and major repairs of units, components and systems of vehicles.

The most widely used specialized workstations for repair:

Electronic and electrical equipment;

Radio equipment and means of protection;

Tires and wheels;

Bodies and cabs (repair, straightening, painting);

Ventilation, air conditioning and climate systems;

Engines and transmission units;

Suspension and running gear.

5. TUNING COMPANIES.

They make retrofitting or structural changes to cars and units.

The most typical works are:

External modernization of the body (change of geometry, installation of fender liner, fairings, etc.);

Internal modernization of the body (re-planning, replacement of seats, installation of partitions, etc.);

Installation of additional equipment and devices (audio-video equipment, airbags, power windows, anti-theft devices, etc.);

Replacement of aggregates and systems (installation of a more powerful engine, automatic transmission, replacement or strengthening of the suspension, etc.);

Upgrading or changing the design of units (forcing or deforcing the engine, installing converters and filters, etc.).

6. SHOPS AND SALES FOR SALE OF CARS.

7. CAR WASHES.

Car washes are divided into:

Automated;

mechanized;

Non-mechanized (manual washing and cleaning).

8. CAR PARKING.

Subdivided: - according to the mode of use into:

Permanent (stationary);

Temporary;

According to the arrangement and design for:

Open and closed;

Manege and with isolated boxes;

Heated and not heated;

Ground, underground and multi-storey;

According to the composition of the services offered:

Single purpose (storage only);

Multi-purpose (storage, washing, minor repairs, etc.).

9 MOTELS AND CAMPSITES.

Motels are intended for short-term rest and accommodation of drivers and passengers on the way and storage of cars.

Campsites are designed for long-term accommodation and recreation of autotourists. They are a well-equipped and protected area with areas for placing cars, residential houses or tents, common household premises.

10. TRADING AND SUPPLY COMPANIES.

Designed to provide service enterprises with vehicles, spare parts, process equipment and materials.

11. TECHNICAL ASSISTANCE SERVICES.

Designed to provide technical assistance at the site of a vehicle failure and transport the vehicle if it is impossible to eliminate the failure to a service company or storage location.

12. OTHER ENTERPRISES AND ORGANIZATIONS.

1) Banks providing car loans.

2) Insurance companies working with service companies that repair cars for "insured events".

3) Companies and bureaus of autotechnical expertise. Bureau of technical expertise carry out:

Determining the actual costs of car repairs as a result of insured events;

Verification of the compliance of the actual repair performed with the payment documentation issued by the service company;

Checking the compliance of materials and spare parts with current requirements, etc.

Figuratively speaking, a gas station is a kind of small distribution tank farm that provides cars with fuel. Therefore, much of what is stated above from the field of design and operation takes place at the enterprises considered below.

Filling station (gas station) - a complex of buildings, structures and equipment, limited by a site site and intended for refueling vehicles (except tracked vehicles) with motor fuel.

The gas station organizes the sale of oils, greases, spare parts, accessories for cars and other vehicles, the acceptance of used oils and small containers from oil products from the owners of individual vehicles, maintenance, as well as the provision of services for the maintenance of vehicles, their owners and passengers.

They are divided into public gas stations, which refuel any cars, regardless of their type of ownership and departmental affiliation, and departmental gas stations, which refuel cars only of certain enterprises, organizations, firms. At the first stations, retail trade in fuel is carried out for money, or through a non-cash payment system. On the second, cashless delivery of fuel is carried out with the implementation of its strict accounting for each consumer (for example, refueling vehicles of a motor transport company).

Public gas stations are usually located in places with the greatest concentration of cars: at parking lots, at intersections of roads, on highways, etc.

Departmental gas stations are usually located on the territory of those enterprises whose cars they fill. When organizing them, the local conditions of these enterprises are used, so their design often differs from the designs of stations with exactly the same general requirements for them.

By the number of services provided, gas stations are divided into gas stations proper, which only refuel vehicles with fuel and oils, and gas stations (gas stations), where, in addition to refueling vehicles with fuel and oils, they carry out maintenance, washing, and stores selling spare parts, packaged petroleum products , cafes and restaurants, campsites and other facilities for the provision of services for the maintenance of vehicles and their owners and passengers. ACPs may only cover a subset of the services listed above.

The following classification of filling stations has been adopted.

A traditional filling station is a gas station with an underground location of fuel storage tanks, the technological scheme of which is characterized by the separation of tanks and fuel dispensers (TRK).

Modular filling station - a gas station with an underground location of fuel storage tanks, the technological scheme of which is characterized by the placement of the fuel dispenser above the fuel storage unit, made as a single factory product.

Modular filling station - a filling station with an above-ground arrangement of fuel storage tanks, the technological scheme of which is characterized by the separation of the fuel dispenser and the fuel storage container, made as a single factory product.

Modular gas stations located outside settlements and enterprises are divided into two types: type A - the total capacity of the tanks is from 40 to 100 m3; type B - no more than 40 m3.

Mobile filling station - a filling station intended for the retail sale of fuel, the mobile technological system of which is installed on a car chassis, trailer or semi-trailer and is made as a single factory product.

Container filling station - a filling station with an above-ground location of fuel storage tanks, the technological system of which is characterized by the placement of the fuel dispenser in a fuel storage container, made as a single factory product.

Container filling stations are divided into 2 types:

Type A - if the total capacity of the gas station tanks is more than 20 m3;

Type B - if the total capacity of the gas station tanks is not more than 20 m3.

Fuel-dispensing point - a gas station located on the territory of an enterprise and intended for refueling vehicles of this enterprise.

Multi-fuel filling station - a gas station on the territory of which refueling of vehicles with two or three types of fuel is provided, among which liquid motor fuel (gasoline and diesel fuel), liquefied gas (liquefied propane - butane) and compressed natural gas are allowed.

Automobile gas-filling compressor station - a gas station, on the territory of which refueling of fuel system cylinders is provided: trucks, special and passenger cars with compressed natural gas used as their motor fuel.

Automobile gas filling station - a gas station, on the territory of which refueling of cylinders of trucks, special and passenger cars with liquefied gas (liquefied propane-butane), used as their motor fuel, is provided.

Stationary gas stations are located in settlements and on highways. In terms of productivity, they are divided by the number of filling stations during peak hours - 57, 100, 135, 170 vehicles per hour.

Container filling stations (KAZS) are located on highways, tourist routes, in car fleets, at industrial and agricultural enterprises, paid parking lots, in garage cooperatives, as well as in other places where vehicles are concentrated.

Mobile gas stations (PAZS) are placed in places of concentration of vehicles, motor boats and boats, agricultural machinery, on tourist routes, the territory of stationary gas stations during the cleaning and repair of tanks.

Delivery of motor fuels to gas stations is carried out by road or, in rare cases, by rail and pipelines. Filling stations are subordinate to oil depots, service plants, industrial associations, joint-stock companies, as well as private enterprises and owners.

The construction of gas stations can be carried out both according to standard projects and according to individual ones. Technical characteristics of typical gas stations are given in Table. 7.1.

Table 7.1 - Technical characteristics of typical petrol stations

|

Types of petrol stations |

Number of fillings per day |

|||||||||||||||||||||||

|

250.500 |

0 o o o |

|||||||||||||||||||||||

|

1. Container filling stations (KAZS) |

||||||||||||||||||||||||

|

1.1 Land area, ha |

0,06...0,13 |

0 ,12 ...0,21 |

||||||||||||||||||||||

|

1.2 Number of filling posts, pcs. |

||||||||||||||||||||||||

|

1.3 Number of tanks: |

||||||||||||||||||||||||

|

For fuel (9 m 3 each) |

||||||||||||||||||||||||

|

For oil |

||||||||||||||||||||||||

|

For used oils |

||||||||||||||||||||||||

|

1.4 Electric power consumption, kW: |

||||||||||||||||||||||||

|

Lighting |

||||||||||||||||||||||||

|

Power |

||||||||||||||||||||||||

|

Heating |

||||||||||||||||||||||||

|

Water heating |

||||||||||||||||||||||||

|

1.5 Reference design |

"Standard solutions for gas filling stations on highways and in settlements" |

|||||||||||||||||||||||

|

2. Typical gas stations (without car maintenance points): |

||||||||||||||||||||||||

|

2.1 Land area, ha |

0,35.0,4 |

0,4,0,5 0 , 0 , |

||||||||||||||||||||||

|

2.2 Number of filling posts, pcs. |

||||||||||||||||||||||||

|

Fuel |

A filling station, or gas station, is a complex of buildings (structures), the main functional purpose of which is to refuel vehicles with motor fuel, oils and special fluids. Modern gas stations are classified according to several characteristics:

Departmental, or fueling points of large enterprises with a significant number of vehicles (cars, tractors, road equipment, etc.), providing them (enterprises) with independence from centralized supplies of motor fuel; Common use. The difference in design, more than other characteristics, affects the functionality of the gas station, which requires a more detailed consideration of this principle of classification. Container filling station (KAZS)The term "container filling station", or CAFS, is understood as a filling complex, the distinguishing feature of which is the placement of a fuel tank and fuel dispensers in a single container. The supervisory control panel is also placed in the container. By definition, gas filling stations consist of several storage containers and a control container and differ from each other only in the type (capacity) of tanks, the number and type of dispensers and the composition of the equipment. The installation of vibration filters at the gas station ensures the purification of motor fuel from water and dirt, which, in turn, guarantees the protection of the consumer's car engines. It is noteworthy that the operation of vibration filters does not require electricity, since the cleaning process takes place at the molecular level. Gas filling stations are most in demand as fuel dispensing points for enterprises and large construction projects or temporary fuel storage points. Modular gas station, or MAZSMAZS is the most popular version of a mobile gas station, combining the high functionality of traditional gas stations with an affordable price. The modular design of filling stations provides the ability to create filling complexes of any configuration that meets the operational requirements.

The main advantages of the MAZS are:

Block gas stationBAZS is a single structure used for filling, long-term storage and distribution of fuel products. The main feature of the block station is the underground placement of tanks and the above-ground placement of fuel dispensers. It (the station) is adapted for the simultaneous finding of three types of oil products (motor gasolines of various grades and diesel fuel). The design of the BAZS is a combination of a double-walled waterproofed tank, a monocolumn for a canopy and the canopy itself. Block filling stations are controlled both by the operator and automatically, in the autonomous loading mode. The electronic equipment installed at the BAZS allows monitoring the density, temperature, volume and level of oil products, as well as the level of produced water. In addition, block gas stations are equipped with automatic fire extinguishing systems that destroy the source of ignition. Block, however, as well as modular filling stations are especially popular with the consumer due to the uniqueness of their economic characteristics - rationality and profitability. Mobile gas stationPAZS is nothing more than a special truck designed to provide consumers with light oil products (kerosene, diesel fuel, gasoline), the density of which does not exceed 0.86 grams per cubic centimeter, in areas with a low density of gas stations. The main function of mobile filling stations is the transportation and metered distribution of motor fuel. Standard equipment Fuel storage tank; Autonomous power source (gasoline or diesel generator); fuel dispenser; Fuel dispensing system equipped with an electronic display showing fuel consumption. PAZS are indispensable in places of large parking lots, on the routes of popular tourist routes, on construction sites and agricultural lands. They are successfully applied when carrying out repair work on the technological equipment of stationary gas stations. The operating temperature range of the PAZS is quite wide and is located in the range from 400C to - dosed 400C. Gas filling stations, or automobile gas-filling compressor stations (CNG filling stations)

The main difference between CNG filling stations and gas filling stations of the usual type, which carry out exclusively the sale of motor fuel, lies in the complex processing of natural gas supplied through the gas pipeline. The technological process of processing consists of the following operations:

The modern network is formed from CNG filling stations of several basic sizes (the unit of measurement is the performance of the station, expressed in conditional fillings during the day): Stationary - 500; Block-container - 250; Modular block-container - 125; Introduction………………………………………………………………..page 2. General position ....................................................................................................... ... Types of filling stations……………………………………………………………… page 4. Scheme of the master plan of gas stations…………………………………………………………………………………………………………………………. The territory of the gas station……………………………………………………….page 7. Appointment of gas stations……………………………………………………….page 10. Underground storage tanks for petroleum products…………….page 11. Gas station operation…………………………………………………….page 15. Filling complexes and stations…………………………….page 16. Provision of related services at filling stations ………………………………page 24. Conclusion…………………………………………………………….page 25. References…………………………………………………… page 26. INTRODUCTION A few years ago, the trade in fuels and lubricants (POL) was widespread in the sphere of a rather narrow circle of enterprises and organizations. However, at present, due to its almost 100% liquidity and high profitability, this type of entrepreneurial activity has become one of the most popular. Many enterprises and organizations that have never been involved in the trade of fuels and lubricants have become involved in this process. Therefore, many organizations have questions related to the peculiarities of legal regulation and taxation of activities for the production and sale of fuels and lubricants. General position 1.1. Filling stations (gas stations) are designed to refuel vehicles (except tracked vehicles) with petroleum products. Some gas stations organize the sale of oils, greases, spare parts, accessories for cars and other vehicles, receive used oils and small containers from oil products from owners of individual vehicles, as well as maintenance and car washing. 1.2. Gas stations are divided into stationary, mobile (PAZS), container (KAZS and block points). Stationary gas stations are located in cities and towns, as well as on highways. Modular gas stations, the technological system of which is designed for filling vehicles with liquid motor fuel only and is characterized by an above-ground arrangement of tanks and separation of the fuel dispenser and fuel storage container. Mobile gas stations (PAZS) are placed in places of concentration of vehicles, motor boats and boats, agricultural machinery, in the field, naturist auto routes, the territory of stationary gas stations during the cleaning and repair of tanks. They are mounted on the chassis of cars and trailers. Modular filling stations, the technological system of which is designed to refuel vehicles only with liquid motor fuel and is characterized by an underground location of tanks and placement of the fuel dispenser above the fuel storage unit. Container filling stations are located on highways, tourist routes, in car fleets, industrial and agricultural enterprises, paid parking lots, in garage cooperatives, as well as in places where vehicles are concentrated. Types of filling stations Block filling station- A filling station, the technological system of which is intended for filling vehicles with liquid motor fuel only and is characterized by an underground location of tanks and placement of a fuel dispenser above a fuel storage unit, made as a single factory product. Modular petrol station- A filling station, the technological system of which is intended for filling vehicles with liquid motor fuel only and is characterized by an above-ground arrangement of tanks and the separation of the fuel dispenser and the fuel storage container, made as a single factory product. Container filling station - A filling station, the technological system of which is intended for filling vehicles with liquid motor fuel only and is characterized by an above-ground arrangement of tanks and placement of a fuel dispenser in a fuel storage container, made as a single factory product. Mobile filling station for liquid motor fuel(PAZS) - a filling station intended for the retail sale of only liquid motor fuel, the technological system of which is installed on an automobile chassis, trailer or semi-trailer and is made as a single factory product. Automotive gas filling compressor station(CNG filling station) - a gas station, the technological system of which is intended only for filling cylinders of the fuel system of trucks, special and light vehicles with compressed natural gas (hereinafter referred to as LPG). Car gas filling station(AGZS) - a gas station, the technological system of which is intended only for filling cylinders of the fuel system of trucks, special and passenger vehicles with liquefied hydrocarbon gas. Mobile gas filling station(PAGZS) - a gas station, the technological system of which is characterized by the presence of a combined block for the transportation and storage of liquefied hydrocarbon gas, made as a single factory product, and a design that does not provide for filling the tanks of this block with fuel on the territory of the gas filling station. Mobile gas filling station- Filling stations, the technological system of which is intended only for filling cylinders of the fuel system of trucks, special and light vehicles with compressed natural gas, is characterized by the presence of a combined block for transporting and storing compressed natural gas, made as a single factory product, and a design that does not provide for filling the vessels of this block fuel at the gas station. Multi-fuel filling station- filling station, on the territory of which refueling of vehicles with two or three types of fuel is provided, among which liquid motor fuel (gasoline and diesel fuel), liquefied petroleum gas (liquefied propane-butane) and compressed natural gas are allowed Delivery of petroleum products to gas stations can be carried out by road, rail, pipeline or water transport. Bulk petroleum products are released into the tanks of motor vehicles and containers of consumers exclusively through fuel and oil dispensers. SCHEME OF THE MASTER PLAN FOR FUEL STATIONS

Gas station territory The location of the gas station is indicated by the road sign "Gas Station". The roadway of the territory of the gas station must have a hard surface and be in good condition, provide free access for vehicles to each fuel dispenser, drain devices, fire reservoirs, places for unloading container cargo. The territory of the gas station is equipped with a sewerage system that provides for the removal and collection of storm and melt water contaminated with oil products from the surface of the roadway, and the localization of spills during the discharge and release of oil products. On the territory of the gas station, places for collecting materials used in the elimination of the consequences of an oil spill are allocated and equipped, as well as places are allocated for the installation of garbage bins. In winter, the passages and driveways on the territory of the gas station are regularly cleared of snow and ice. During the performance of repair work on the territory of the gas station, pits, pits, trenches must be securely fenced. Upon completion of the repair work, the coverage of the territory must be restored. When performing repair work on the territory of gas stations in pits, pits, trenches, the state of the air environment in them is monitored. In case of detection of vapors of oil products, work must be stopped until the pit is completely degassed and the state of the air environment in it is analyzed. In the case of fencing the territory of the gas station, the enclosing structures must be ventilated and made of non-combustible materials. Landscaping of the territory of the gas station with coniferous trees, trees, shrubs and grasses that emit fibrous substances or pubescent seeds is not allowed. On the territory of the gas station, constant mowing and removal of dried grass, cutting down of overgrowth of trees and shrubs, collection and removal of fallen leaves should be ensured. The territory of the gas station at night should have an average horizontal illumination in accordance with building codes and regulations. It is prohibited to carry out any kind of repair work of vehicles on the territory of the gas station, unless it is provided for by the project. On the territory of the gas station, the arrangement of underground premises, underground spaces under buildings and structures, as well as underground structures (tunnels, channels, etc.) is prohibited. Pits for fuel dispensers, cable wells, technological wells must be covered with non-combustible material. Parking of vehicles on the territory of the gas station is prohibited, except for parking lots and parking lots specified by the project.

This complex, like other objects of the network, resembles a cross between an airplane and an airport. The filling station is located at km 33 of the Srednevyborgskoye Highway, at the intersection with the road to the village of Elizavetinka, and is operated by Faeton - Fuel Network No. 1 LLC.

There is a car wash at the station. High-speed equipment of the German company Christ works in several modes and allows you to wash and polish to a shine not only the body, but also the rims of the car, which is a unique service in St. Petersburg. And what is especially valuable - with a minimum of time to bring the car in order. Just a few minutes, and the car shines with cleanliness, the company notes. This automatic car wash is equipped with Christ portals (series 166) - this is the latest high-pressure touchless washing equipment, which significantly reduces the consumption of water and detergents. The car wash uses 90% of recycled water and high-quality systems of local treatment facilities, which makes it possible not to harm the environment and take care of the environment.

Appointment of the gas station General ideas about gas stations The main purpose of gas stations is to refuel motor vehicles. The location of the gas station and its production capacity, taking into account the intensity of traffic flows and compliance with the required safety standards - fire, environmental, etc. Gas station sites should be with asphalt or concrete pavement and provide free access for vehicles to dispensers and drains. In places where oil products may spill near filling islands, the coating must be resistant to oil products. Gas stations must be equipped with signs indicating the location of a fire reservoir, water intake wells or a fire hydrant, and markers at gas stations with awnings. The territory in the dark must be lit in accordance with existing standards. Special lighting should be given to the lighting of places for refueling and draining oil products. Gas stations must have a landline phone. Storage of petroleum products at gas stations is carried out in metal horizontal above-ground or buried tanks. The design of the tank and the technology of its operation must ensure its tightness for 10 years or more. To control the tightness of the tank, it is equipped with appropriate systems that allow timely detection of a leak and taking measures. Underground storage tanks for petroleum products;

1 - drain device; 2 - fuel tank; 3 - receiving valve; 4 - corner anti-explosive; 5 - measuring device; 6 - respiratory valve; 7 - fuel dispenser

1 - trunk; 2 - head; 3 - submersible pump; 4 - breathing valve with a fire fuse; 5 - thermal insulation backfill; 6 - ice lining A schematic diagram of a stationary filling station is shown in fig. 14.16. The oil product delivered to the gas station using tankers is drained through device 1 into fuel tank 2. Here it settles, its quantity is measured through device 5. The oil product is released to consumers using a fuel dispenser 7 connected to the tank by a pipeline on which valve 3, and an angular fuse 4. "Breathing" of the tanks is carried out through valve 6. For storage of petroleum products at gas stations, horizontal and vertical steel tanks with a capacity of 5 to 50 m3 and a wall thickness of 3...4 mm are used. Tanks at filling stations are usually distributed as follows: 75% for gasoline, 15% for diesel fuel and up to 10% for oils. Gas station tanks are designed for excess pressure of 700000 and vacuum - 1000 Pa. Measuring device 5 is used to measure the level of overflow of oil in the tank. It provides the vertical direction of the measuring rail (meter rod). Structurally, the measuring device is a perforated pipe with a diameter of 40 mm with a lid. Quick and tight connection of the nipple with the sleeve of the tanker is provided by a special quick coupling. For storage of petroleum products at gas stations, horizontal and vertical steel tanks with a capacity of 5 to 50 m3 and a wall thickness of 3...4 mm are used. Tanks at filling stations are usually distributed as follows: 75% for gasoline, 15% for diesel fuel and up to 10% for oils. Gas station tanks are designed for excess pressure of 700000 and vacuum - 1000 Pa. Measuring device 5 is used to measure the level of overflow of oil in the tank. It provides the vertical direction of the measuring rail (meter rod). Structurally, the measuring device is a perforated pipe with a diameter of 40 mm with a lid. To connect the dispensers to the tanks, a suction device is used, consisting of a receiving valve 3, an angle fuse 4 and a suction pipeline. The purpose of the intake valve 3 is to prevent the discharge of oil from the suction pipeline into the tank after the dispensing column is turned off. When the pump stops, the pressure in the pipeline and in the tank equalizes and the valve disc, under the action of its own weight, sits on the seat, blocking the cross section. Corner protector 4 prevents the flame from spreading through the suction pipe. To do this, a brass mesh is installed inside the metal case, which simultaneously acts as a filter for the oil product pumped out of the tank. Fuel - dispensers are designed for refueling vehicles with simultaneous measurement of the amount of fuel or oil dispensed. Despite the differences in the designs of dispensers, they all include a pump, a liquid meter, a filter, a dispensing sleeve and a dispensing tap. The pump of the fuel dispenser is intended for pumping fuel from the gas station tank into the tanks of vehicles. Since the tank is below the column, the pump is self-priming. The capacity of fuel dispenser pumps ranges from 20 to 70 l/min. The liquid meter is used to measure the consumption of fuel or oil supplied to consumers. The results of instantaneous measurements are summarized and recorded on the counting device as the total amount of released liquid. The filter is used to remove mechanical impurities from the liquid entering the column. The dispensing sleeve is intended for pumping liquid and connecting the dispenser with a dispensing tap. In dispensing columns, rubber-fabric petrol-resistant sleeves with a diameter of 25 mm for a pressure of 0.4 MPa are used. The dispensing tap is used to quickly cut off the fuel jet when it reaches the maximum level in the car tank, in order to prevent overfilling and related losses. The tank equipment and its placement should ensure that all necessary technological operations are performed: Reception (discharge) of oil products is provided by a drain device; The release of oil products is provided by a dispensing device; cleaning inside the tank is carried out through a special manhole, which can be made on the cover of the technological neck or separately. Conventional gas stations have 3-4 types of gasoline and diesel fuel in their set. At the same time, there are several options for filling stations at gas stations: according to the principle, one column - one type of fuel, one point - all types of gasoline and diesel fuel, a mixed option (especially in the presence of gas filling stations). The first option involves driving a car to a strictly defined column, which is not very convenient, because. makes. Therefore, at modern gas stations there is a tendency to the second type. AGZS are gas filling stations. Usually they are part of gas stations, but due to the special requirements for the refueling process, they are located away from gas stations. Today, with the rise in gasoline prices, the demand for gas filling stations is also growing. KAFS - container gas station or gas station of modular (container) type. Such a mini-gas station is designed for receiving, storing and dispensing one or two types of fuel in the territory of settlements. Gas stations have an above-ground fuel storage tank. Its technological system is characterized by the placement of gas stations (fuel dispensers) in a single unit with a fuel storage container. Convenient for quick deployment of filling stations MTAZS is a multi-fuel filling station. Allows you to simultaneously sell two types of fuel (liquid motor fuel and liquefied hydrocarbon gas). There are still few such gas stations, but the fashion for gas equipment should do its job - MTAZS will become a common type of gas station. Diesel fuel is a liquid product used as a fuel in a diesel internal combustion engine, as well as in gas diesel engines. Usually, this term is understood as fuel obtained from kerosene-gas oil fractions of direct distillation of oil. Benzine is a combustible mixture of light hydrocarbons with a boiling point of 30 to 200 °C. Propane, C3H8 is an organic substance of the alkane class. Contained in natural gas, formed during the cracking of petroleum products. Butane (C4H10) is an organic compound of the alkane class. In chemistry, the name is used primarily to refer to butane. The mixture of butane and its isomer isobutane CH(CH3)3 has the same name. Poisonous, inhalation of butane causes dysfunction of the pulmonary-respiratory apparatus. Fuel dispensers Gas stations use fuel, oil and mixture dispensers designed to refuel vehicles with simultaneous measurement of the amount of fuel, oil or mixture dispensed. The dispensers as strict metering devices are equipped with measuring devices, the reading error of which under operating conditions at an ambient and fuel temperature of + -40С should not go beyond: + -0.25% of fuel dispensers for general use. Design software distinguishes the following types of speakers: · KR - portable with the manual drive; ·КЭР - stationary with the electric drive; · KEM - stationary with electric drive and control from a local setting device; · КА - stationary with the electric drive, automated. Fuel dispensers, regardless of design and manufacturer, have a pump, a liquid meter, a counting device, a gas separator with a float chamber, a filter, an indicator, a dispensing valve, a check valve and a housing. Filling station operation environmental protection The source of environmental pollution at gas stations is the evaporation of oil products, spills of oil products, as well as exhaust gases from motor vehicles. On the territory of the gas station, it is necessary to periodically check the gas contamination of the surrounding air. Discharge of untreated sewage into water bodies is strictly prohibited. The change of filter materials, as well as the removal of trapped oil products and sediment from treatment facilities, must be carried out as necessary. It is necessary to systematically monitor the cleanliness of sewer wells, prevent flooding of their outlets, at least 2 times a year to clean and conduct an internal inspection of the existing equipment of the sewer network, wells and necessary repairs. Filling complexes and stations The requirements of this chapter apply to filling complexes (hereinafter referred to as filling stations) and filling stations (hereinafter referred to as filling stations) intended for refueling ground vehicles with gasoline and diesel fuel during their commissioning, operation, maintenance and repair work. In order to monitor compliance with fire safety requirements, inspect filling stations (gas stations), promptly obtain the necessary reference and technical information for work, the following documentation should be available at filling stations (gas stations): a copy of the approved in the established order master plan of the gas station (gas station), containing the layout of objects on its territory, indicating the distances between them and to the objects closest to the gas station (gas station), as well as the scheme of movement of vehicles on the specified territory; certificates for existing equipment; a plan for the localization and elimination of fire hazardous situations and fires at filling stations (gas stations), agreed with the State Fire Service; a plan-scheme of the nearest water sources indicating the distances to them and the flow rate of water sources; a plan for the evacuation of people and vehicles from the territory of the gas station (gas station), agreed with the State Fire Service; documents defining the responsibility for ensuring fire safety during the operation of filling stations (gas stations); instructions that define the requirements for ensuring fire safety during the operation and maintenance of filling stations (gas stations), developed on the basis of the Manual for the operation of technological systems and equipment of filling stations (gas stations), which is part of the TED; job description of a security guard for a gas station (gas station) (if security of a gas station or gas station is provided), developed taking into account the fire safety requirements for gas stations (gas stations); schedule for routine maintenance; register of routine maintenance; register of maintenance and repair work carried out on the lightning protection systems of filling stations (gas stations); register of petroleum products; equipment repair register; a log of registration of primary and repeated briefings at the workplace on labor safety, industrial sanitation and fire safety; duty or shift (when organizing shift work of filling stations or filling stations) magazine; other documents that, in the opinion of the head (owner) of the filling station (gas station), are necessary for safe operation. Cleaning and pre-repair preparation of equipment that handled fuel or its vapors (tanks, containers, pipelines, etc.) must be carried out by employees of filling stations (gas stations) who have received special training, or by specialized organizations licensed for this type of activity. Technological equipment intended for the use of flammable and explosive substances and materials must comply with the TED, technical specifications (hereinafter - TS) and design documentation, agreed and approved in the prescribed manner. The fuel filling station (hereinafter referred to as TZS) as an assembly must be tested at the factory for tightness by a pressure exceeding the pressure of the corresponding periodic tests (pressure values of periodic tests should be given in the TED for TZS) by at least 20%, as well as for the operation of its systems emergency protection with the execution of relevant acts, which are a mandatory annex to the TED. Technological equipment must have serviceable systems for the prevention, localization and elimination of fire hazardous situations and fires, control and regulation devices that ensure fire safety of the process. It is forbidden to perform technological operations on the equipment in the absence of the specified systems and devices provided for by the TED and TS for this equipment, their shutdown or overdue dates for their verification. Enter keywords. | |||||||||||||||||||||||

The design of the MAZS is characterized by the separation of the storage container and fuel dispensers, made in the form of a single factory product. Manufacturers offer modular filling stations designed for several (up to four inclusive) types of liquid motor fuel.

The design of the MAZS is characterized by the separation of the storage container and fuel dispensers, made in the form of a single factory product. Manufacturers offer modular filling stations designed for several (up to four inclusive) types of liquid motor fuel. i mobile filling stations include:

i mobile filling stations include: The functional purpose of CNG filling stations is to organize the refueling of vehicles with alternative fuel, which is compressed (compressed to a liquid state) natural gas.

The functional purpose of CNG filling stations is to organize the refueling of vehicles with alternative fuel, which is compressed (compressed to a liquid state) natural gas.