Today we can’t live without electronics. It is an integral part of any modern device or gadget. At the same time, all devices, sadly, cannot work forever and periodically break down. One of the fairly common causes of failure of a number of electrical appliances is the failure of an electrical element such as a diode.

You can check the serviceability of this component yourself at home. This article will tell you how to test a diode with a multimeter, as well as what these elements are and what the measuring device itself is.

Diode diode discord

A standard diode is a component of the electrical network and acts as a p-n junction semiconductor. Its structure allows current to pass through the circuit in only one direction - from the anode to the cathode (different ends of the part). To do this, you need to apply “+” to the anode and “-” to the cathode.

Note! Electric current in diodes cannot flow in the opposite direction, from the cathode to the anode.

Due to this feature of the product, if you suspect a breakdown, it can be checked with a tester or multimeter.

Today there are several types of diodes in radio electronics:

Types of diodes

- Light-emitting diode. When an electric current passes through such an element, it begins to glow as a result of the transformation of energy into a visible glow;

- protective or regular diode. Such elements in the electrical network act as a suppressor or voltage limiter. One of the varieties of this element is the Schottky diode. It is also called a Schottky barrier diode. Such an element, when connected directly, gives a low voltage drop. In Schottky, instead of a p-n junction, a metal-semiconductor junction is used.

If ordinary parts and LEDs are used in the vast majority of electrical appliances, then Schottky ones are used mainly in high-quality power supplies (for example, for devices such as computers).

It is worth noting that testing a conventional diode and a Schottky diode is practically no different, since it is carried out according to the same principle. Therefore, there is no need to worry about this issue, because the operating principle of both Schottky and conventional diodes is identical.

Note! Here it is only worth noting that Schottkis in most cases are found double, located in a common building. Moreover, they have a common cathode. In such a situation, you can not solder these parts, but check them “on the spot”.

Schottky diode

Being a component of an electronic circuit, such semiconductor elements often fail. The most common reasons for their failure are:

- exceeding the maximum permissible direct current level;

- excess reverse voltage;

- poor quality part;

- violation of the device operating rules established by the manufacturer.

Moreover, regardless of the cause of loss of performance, failure can be directly caused by either a “breakdown” or a short circuit.

In any case, if there is an assumption that the electrical network has failed in the semiconductor area, it is necessary to diagnose it using a special device - a multimeter. Only to carry out such manipulations you need to know how to check the diode using it correctly.

Multimeter

A multimeter is a universal device that performs a number of functions:

- measures voltage;

- determines resistance;

- checks wires for breaks.

Multimeter

Using this device you can even determine the suitability of the battery.

How is the check carried out?

After we have figured out the semiconductors of the electrical circuit and the purpose of the device, we can answer the question “how to check the diode for serviceability?”

The whole point of checking diodes with a multimeter is their one-way electrical current carrying capacity. If this rule is observed, the element of the electrical circuit is considered to be functioning correctly and without failures.

Conventional diodes and Schottky diodes can be easily tested using this device. To check this semiconductor element with a multimeter, you must do the following manipulations:

Examination

- you need to make sure that your multimeter has a diode test function;

- if there is such a function, we connect the probes of the device to the side of the semiconductor from which the “ringing” will be carried out. If this function is absent, then we transfer the device using the switch to the value of 1kΩ. You should also select the mode for measuring resistance;

- the red wire of the measuring device must be connected to the anode end, and the black wire to the cathode end;

- after this, you need to observe changes in the forward resistance of the semiconductor;

- draw conclusions about the presence or absence of voltage

The unit can then be switched to check for leaks or high circuits. To do this, you need to change the location of the diode output. In this state, it is also necessary to evaluate the obtained values of the device.

Diode bridge

Sometimes there is a situation when you need to check the functionality of a diode bridge. It looks like an assembly consisting of four semiconductors. They are connected in such a way that the alternating voltage supplied to two of the four soldered elements becomes direct. The latter is removed from the other two terminals. As a result, the alternating voltage is rectified and converted into constant voltage.

Essentially, the principle of verification in this situation remains the same as described above. The only feature here is the determination of which output the measuring device will be connected to. There are four connection options that you should call:

- conclusions 1 – 2;

- conclusions 2 – 3;

- conclusions 1 – 4;

- conclusions 4 – 3;

By checking each output, you will get four results. The obtained indicators should be evaluated according to the same principle as for an individual semiconductor.

Analyzing the results

When checking diodes (regular and Schottky) with a multimeter, you will get a certain result. Now we need to understand what it could mean. Signs that indicate the health of the semiconductor include the following:

- when connecting a part of the electrical circuit to the device, the latter will output the value of the available direct voltage in this element;

Note! Different types of diodes have different voltage levels, which is why they differ. For example, for germanium products this parameter will be 0.3-0.7 volts

- when connected in the opposite way (the probe of the device to the anode of the product), zero will be recorded.

Reverse check

If these two indicators are met, then the semiconductor is working adequately and the cause of the failure is not in it. But if at least one of the parameters does not correspond, then the element is considered unusable and must be replaced.

In addition, it should be borne in mind that it is not a breakdown, but a “leakage” that is possible. This unpleasant defect can appear during long-term use of the device or poor-quality assembly.

If there is a short circuit or leakage, the resulting resistance will be quite low. Moreover, the conclusion must be made based on the type of semiconductor. For germanium elements, this indicator in this situation will range from 100 kilo-ohms to 1 mega-ohm, for silicon - thousands of mega-ohms. For rectifier semiconductors, this figure will be many times greater.

As you can see, it is not so difficult to assess the performance of semiconductors in any electrical device on your own. The above principle is suitable for testing diode elements of various types and types. The main thing in this situation is to correctly connect the measuring device to the semiconductor and analyze the results obtained.

Proper soldering of LED strips

Proper soldering of LED strips

How to make a paper lamp with your own hands

How to make a paper lamp with your own hands

In many devices operating from a 220 V network, a diode bridge is installed. This is a device consisting of four (for a single-phase network) or six (for a three-phase) semiconductor silicon diodes. It is needed to convert AC to DC. An alternating current is supplied to its input, and the output produces a pulsating voltage of constant sign. These circuit elements often fail, pulling the fuse along with them. Let's figure out how to check the diode bridge for serviceability in different ways.

What you need to know about diode bridges

First, we will look at what they are and what is inside a diode bridge. These circuit elements are available in two versions:

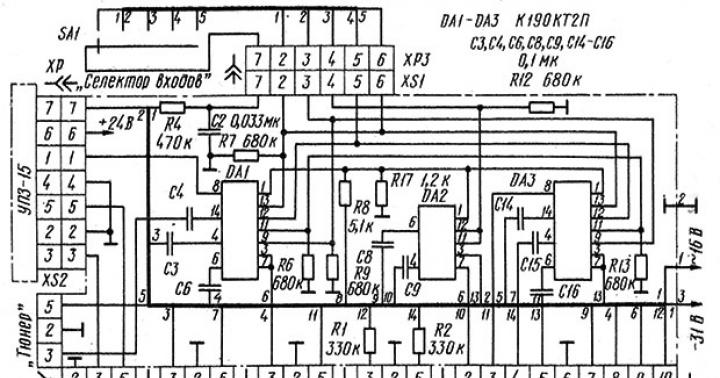

In any case, the rectifier single-phase diode bridge consists of four semiconductor diodes connected to each other in a series-parallel manner. Alternating voltage is supplied to two points at which the anode and cathode are connected (opposite poles of the diodes). Constant voltage is removed from the connection points of like poles: plus from the cathodes, minus from the anodes.

In the diagram, the connection point for alternating voltage is indicated by the symbols AC or “~”, and the outputs with constant voltage are “+” and “-“. Draw this diagram for yourself, it will be useful to us when checking.

If you imagine a real diode bridge and combine it with this circuit, you get something like:

Location of the diode bridge on the board and precautions

Diode bridges are installed in power supplies, both pulse and transformer. It is worth noting that in pulse units, which are now used in all household appliances, the bridge is installed at the 220V input. At its output, the voltage reaches 310V - this is the amplitude voltage of the network. In transformer power supplies they are installed in the secondary winding circuit, usually with a reduced voltage.

If the device does not work and you find a blown fuse, do not rush to turn on the device after replacing it. Firstly, if there are problems on the board, the fuse will burn again. This power supply must be turned on via a light bulb.

To do this, take a socket and screw a 40-100 W incandescent lamp into it and connect it to the phase wire to connect to the network. If you are going to frequently repair power supplies, you can make an extension cord with a socket installed in the gap in the power wire to connect the lamp, this will help save your time.

If there is one on the board, when connected to the network, a high current will flow through it, a fuse or a track on the board, or a wire will blow, or the machine will be knocked out. But if we insert a light bulb into the gap, the resistance of the spiral of which will limit the current, it will light up at full intensity, maintaining the integrity of all of the above.

If there is no short circuit or the unit is working properly, either a slight glow of the lamp or its complete absence is acceptable.

The simplest and rough check

We need an indicator screwdriver. It costs a penny and should be in the toolbox in every home. You just need to first touch the 220V input of the rectifier, if the indicator on the phase wire lights up, then voltage is present, if not, the problem is clearly not in the diode bridge and you need to check the cable. If there is voltage at the input, check the voltage at the positive output of the rectifier; at this point it can reach up to 310 V, the indicator will show it to you. If the indicator does not glow, the diode bridge is open.

Unfortunately, we won’t be able to find out anything else using an indicator screwdriver. You can find out about that from our article.

Testing the diode bridge with a multimeter

Any part on the board can be desoldered for testing or ringing without desoldering. However, the accuracy of the check in this case is reduced, because perhaps a lack of contact with the board tracks, with visible “normal” soldering, the influence of other circuit elements. This also applies to the diode bridge; you don’t have to desolder it, but it’s better and more convenient to desolder it for testing. A bridge assembled from individual diodes is quite convenient to check on the board.

Almost every modern multimeter has a diode test mode, usually it is combined with an audio continuity test of the circuit.

This mode displays the voltage drop in millivolts between the probes. If the red probe is connected to the anode of the diode and the black probe to the cathode, this connection is called forward or conductive. In this case, the voltage drop across the PN junction of the silicon diode is in the range of 500-750 mV, which you can see in the picture. By the way, it shows a test in resistance measurement mode, this is also possible, but there is also a special diode test mode, the results will be, in principle, similar.

If you swap the probes - red to the cathode, and black to the anode, the screen will show either one or a value of more than 1000 (about 1500). Such measurements indicate that the diode is working; if the measurements differ in one of the directions, then the diode is faulty. For example, if the continuity test is triggered - the diode is broken, there are high values in both directions (as with reverse switching on) - the diode is broken.

Important! Schottky diodes have a lower voltage drop, about 300 mV.

There is also an express check of the diode bridge with a multimeter. The procedure is as follows:

- We place probes at the input of the diode bridge (~ or AC), if the continuity test works, it is broken.

- We put the red probe on “–”, and the red one on “+” - a value of about 1000 appears on the screen, swap the probes - on the screen 1 or 0L, or another high value - the diode bridge is working. The logic of this test is that the diodes are connected in series in two branches, pay attention to the diagram, and they conduct current. If the positive power supply is applied to – (anode connection point), and the power supply minus is applied to “+” (cathode connection point), this is what happens during dialing. If one of the diodes is broken, current may flow through the other branch and you may make erroneous measurements. But if one of the diodes is broken, the voltage drop across one diode will be displayed on the screen.

The video below clearly shows how to check a diode bridge with a multimeter:

Full check of the diode bridge

You can also check the diode bridge with a multimeter according to the following instructions:

- We set the red probe to “–”, and touch the black terminals in turn to which the alternating voltage “~” is connected, in both cases it should be about 500 on the device screen.

- We put the black probe on “–”, touch the red terminals “~ or AC”, the multimeter screen shows one, which means the diodes do not conduct in the opposite direction. The first half of the diode bridge is working.

- The black probe is on “+”, and with the red one we touch the AC voltage inputs, the results should be the same as in point 1.

- We swap the probes, repeat the measurements, the results should be the same as in step 2.

The same can be done with a “tseshka” (a Soviet-made universal measuring device). How to check a diode bridge with a dial multimeter is described in the video.

To check an LED and find out its parameters, you need to have a multimeter, a “Tseshka” or a universal tester in your arsenal. Let's learn how to use them.

Continuity of individual LEDs

Let's start with a simple one, how to ring an LED with a multimeter. Switch the tester to transistor testing mode - Hfe and insert the LED into the connector, as in the picture below.

How to check the LED's functionality? Insert the anode of the LED into connector C of the area marked PNP, and the cathode into E. In PNP connectors, C is the positive terminal, and E in NPN is the negative terminal. Do you see the glow? This means the LED has been checked; if not, the polarity is wrong or the diode is faulty.

The connector for testing transistors looks different, often it is a blue circle with holes, this will be the case if you check the LED with a DT830 multimeter, as in the photo below.

Now let's talk about how to test an LED with a multimeter in diode testing mode. First, take a look at the test diagram.

The diode test mode is indicated by a graphical representation of the diode, more details about the designations in. This method is suitable not only for LEDs with legs, but also for testing smd LEDs.

Checking the LEDs with a tester in the continuity mode – shown in the figure below, and you can also see one of the types of connector for testing transistors, described in the previous method. Write in the comments about which tester you have and ask questions!

This method is worse, a bright glow of the diode appears from the tester, and in this case, a barely noticeable red glow.

Now pay attention to how to check the LED with a tester with an anode detection function. The principle is the same, with the correct polarity, the LED will light up.

Infrared diode test

Indeed, almost every home has such an LED. They have found wide application in remote controls. Let's imagine a situation where the remote control has stopped switching channels, you have already cleaned all the keyboard contacts and replaced the batteries, but it still does not work. So you need to look at the diode. How to test IR LED?

The human eye does not see the infrared radiation in which the remote control transmits information to the TV, but your phone's camera does. Such LEDs are used in night illumination of video surveillance cameras. Turn on the phone's camera and press any button on the remote control - if it is working, you should see flickering.

The methods for checking an IR LED and a regular one with a multimeter are the same. Another way to check if an infrared LED is working is to solder a red LED parallel to it. It will serve as a visual indicator of the operation of the IR diode. If it flickers, it means signals are being sent to the diode and the IR diode needs to be replaced. If the red does not flicker, then the signal is not being received and the problem is in the remote control itself, and not in the diode.

In the remote control circuit there is another important element that receives radiation - a photocell. How to check a photocell with a multimeter? Turn on resistance measurement mode. When light hits a photocell, its conductivity state changes, then its resistance also changes downward. Observe this effect and make sure it is working or broken.

Checking the diode on the board

How to check an LED with a multimeter without desoldering? In the principles of its verification, everything remains the same, but the methods change. It is convenient to check LEDs without soldering using probes.

Standard probes will not fit into the connector for transistors, Hfe mode. But it will fit sewing needles, a piece of cable (twisted pair) or individual cores from a multi-core cable. In general, any thin conductor. If you solder it to a probe or foil PCB and connect probes without plugs, you will get such an adapter.

Now you can test the LEDs with a multimeter on the board.

How to check the LEDs in a flashlight? Unscrew the lens unit or front glass on the flashlight, carefully unsolder the board from the battery pack if the length of the conductors does not allow it to be easily examined and studied.

How to ring an LED lamp?

Any electrician has “ringed” an incandescent lamp many times, but how to check an LED lamp with a tester?

To do this, you need to remove the diffuser; it is usually glued. To separate it from the body you need a mediator, or a plastic card, it needs to be inserted between the body and the diffuser.

If you can’t do this, try warming the gluing area a little with a hairdryer.

How now to check an LED light bulb with a multimeter? In front of you will be a board with LEDs; you need to touch their terminals with the tester probes. Such SMDs light up dimly in diode testing mode (but not always). Another way to check serviceability is to test the battery with a Krona battery.

The crown produces a voltage of 9-12V, so check the diodes short sliding touches to their poles. If the LED does not light up with the correct polarity, it needs to be replaced.

Checking the LED spotlight

First, take a look at which LED is installed in the spotlight, if you see one yellow square, as in the photo below, then you won’t be able to check it with a tester, the voltage of such light sources is high - 10-30 Volts or more.

You can check the performance of this type of LED using a known-good driver for the appropriate current and voltage.

If many small SMDs are installed, checking such a spotlight with a multimeter is possible. First you need to disassemble it. In the case you will find a driver, moisture-proof gaskets and a board with LED. The design and testing process are similar to the LED lamp described above.

How to check LED strip for performance

There is a whole article on our website about that, here we will look at express verification methods.

I’ll say right away that it won’t be possible to illuminate it entirely with a multimeter; in some situations, only a slight glow is possible in Hfe mode. Firstly, you can check each diode individually, in the diode test mode.

Secondly, sometimes it is not the diodes that burn out, but the current-carrying parts. To check this, you need to put the tester into continuity mode and touch each power terminal at different ends of the area being tested. This way you will identify the intact part of the tape and the damaged one.

The red and blue lines highlight the stripes that should ring from the very beginning to the end of the LED strip.

How to test an LED strip with a battery? The power supply for the tape is 12 Volts. You can use a car battery, but it is large and not always available. Therefore, a 12V battery will come to the rescue. Used in doorbells and remote controls. It can be used as a power source when ringing problem areas of the LED strip.

Other verification methods

Let's look at how to test an LED with a battery. We will need a battery from the motherboard - size CR2032. The voltage on it is about 3 volts, sufficient to test most LEDs.

Another option is to use a 4.5 or 9V battery, then you need to use a resistance of 75 ohms in the first case and 150-200 ohms in the second. Although from 4.5 volts, checking the LED is possible without a resistor with a short touch. LED's safety factor will forgive you for this.

Determining the characteristics of diodes

Build a simple circuit to measure the characteristics of an LED. It is so simple that you can do it without using a soldering iron.

Let's first look at how to find out how many volts our LED is with a multimeter using such a probe. To do this, carefully follow the instructions:

- Assemble the diagram. At the open circuit (in the diagram “mA”), set the multimeter in current measurement mode.

- Move the potentiometer to the maximum resistance position. Smoothly reduce it, watch the diode glow and the current increase.

- Find out the rated current: Once the brightness stops increasing, pay attention to the ammeter reading. Typically this is about 20mA for 3, 5 and 10 mm LEDs. After the diode reaches its rated current, the brightness of the glow remains almost unchanged.

- Find out the LED voltage: connect a voltmeter to the LED terminals. If you have one measuring device, then exclude the ammeter from it and connect the tester to the circuit in voltage measurement mode in parallel with the diode.

- Connect power, take voltage readings (see connection “V” in the diagram). Now you know how many volts your LED is.

- How to find out the power of an LED with a multimeter using this diagram? You have already taken all the readings to determine the power, you just need to multiply the milliamps by the Volts and you will get the power expressed in milliwatts.

However, it is extremely difficult to determine the change in brightness by eye and bring the LED to the nominal mode; you need to have a lot of experience. Let's simplify the process.

Tables to help

To reduce the likelihood of burning a diode, determine by its appearance which type of LED it is similar to. There are reference books and comparison tables for this; rely on the reference rated current when carrying out the characterization process.

If you see that at the nominal value it clearly does not produce the full luminous flux, try to briefly exceed the current and see if the brightness continues to increase as quickly as the current. Monitor the heating of the LED. If you supply too much power, the diode will begin to heat up intensely. Conventionally, a normal temperature will be at which you cannot hold your hand on the diode, but if you touch it it will not leave a burn (70-75°C).

To understand the causes and consequences of performing this procedure, read.

After all the work done, check yourself again - compare the readings of the devices with the table values of the LEDs, select the closest suitable parameters and adjust the circuit resistance. This way you are guaranteed to determine the voltage, current and power of the LED.

A 9V Krona battery or a 12V battery is suitable to power the circuit; in addition, you will determine the total resistance for connecting the LED to such a power source - measure the resistance of the resistor and potentiometer in this position.

Checking a diode is very simple, but in practice there are different situations, so many questions arise, especially for beginners. An experienced electronics engineer will determine the parameters of most LEDs by their appearance, and in some cases, their serviceability.

In the process of repairing household appliances or other electronic devices: monitor, printer, microwave, computer power supply or car generator (for example, Valeo, BOSCH or BPV), etc. there is a need to check the integrity of the elements. Let's talk in detail about testing diodes.

Given the diversity of these radioelements, there is no uniform method for testing their performance. Accordingly, each class has its own way of testing. Let's look at how to test a Schottky diode, photodiode, high frequency, bidirectional, etc.

As for testing devices, we will not consider exotic testing methods (for example, a battery and a light bulb), but will use a multimeter (even such a simple model as DT-830b will do) or a tester. These devices are almost always at home with a radio amateur. In some cases, you will need to assemble a simple circuit for testing. Let's start with classification.

Classification

Diodes are simple semiconductor radioelements based on a p-n junction. The figure shows a graphical representation of the most common types of these devices. The anode is marked “+”, the cathode – “-” (shown for clarity; in the diagrams, a graphical designation is sufficient to determine the polarity).

Accepted notationsTypes of diodes shown in the figure:

- A – rectifying;

- B – zener diode;

- C – varicap;

- D – microwave diode (high voltage);

- E – reversed diode;

- F – tunnel;

- G – LED;

- H – photodiode.

Now let's look at verification methods for each of the listed types.

Checking the rectifier diode and zener diode

The protective diode, as well as the rectifier diode (including the power diode) or Schottky diode, can be checked using a multimeter (or use an ohmmeter); to do this, we switch the device to the continuity mode as shown in the photo.

We connect the probes of the measuring device to the terminals of the radio element. By connecting the red wire (“+”) to the anode and the black (“-”) wire to the cathode, the multimeter (or ohmmeter) display will display the threshold voltage value of the diode being tested. After we change the polarity, the device should show infinitely high resistance. In this case, we can state that the element is in good condition.

If, when connecting back, the multimeter registers a leak, it means that the radio element has “burnt out” and needs to be replaced.

Note that this testing technique can be used to test diodes on a car generator.

Zener diode testing is carried out according to a similar principle, however, such a test does not allow one to determine whether the voltage is stabilized at a given level. Therefore, we need to assemble a simple circuit.

Designations:

- PSU – adjustable power supply (displaying load current and voltage);

- R – current-limiting resistance;

- VT – Zener diode or avalanche diode under test.

The verification principle is as follows:

- we assemble the circuit;

- set the multimeter mode, which allows you to measure DC voltage up to 200 V;

- turn on the power supply and begin to gradually increase the voltage until the ammeter on the power supply shows that current is flowing through the circuit;

- connect the multimeter as shown in the figure and measure the stabilization voltage.

Varicap testing

Unlike conventional diodes, varicaps have a p-n junction with a variable capacitance, the value of which is proportional to the reverse voltage. Checking for open or short circuits for these elements is carried out in the same way as for conventional diodes. To check the capacity, you will need a multimeter that has a similar function.

To test, you will need to set the multimeter to the appropriate mode, as shown in photo (A) and insert the part into the connector for capacitors.

As one of the commentators on this article correctly noted, it is indeed impossible to determine the capacitance of a varicap without using the rated voltage. Therefore, if there is a problem with identification by appearance, you will need to assemble a simple attachment for a multimeter (I repeat for critics, a digital multimeter with the function of measuring the capacitance of capacitors, for example UT151B).

Designations:

The device requires configuration. It is quite simple, the assembled device is connected to a measuring device (a multimeter with a capacitance measurement function). Power must be supplied from a stabilized power source (important) with a voltage of 9 volts (for example, a Krona battery). By changing the capacitance of the substring capacitor (C2), we achieve a reading on the indicator of 100 pF. We will subtract this value from the device reading.

This option is not ideal, the need for its practical use is questionable, but the circuit clearly demonstrates the dependence of the varicap capacity on the rated voltage.

Checking the suppressor (TVS diode)

Protective diode, also known as limiting zener diode, suppressor and TVS diode. These elements come in two types: symmetrical and asymmetrical. The former are used in alternating current circuits, the latter - in direct current. If we briefly explain the principle of operation of such a diode, it is as follows:

An increase in input voltage causes a decrease in internal resistance. As a result, the current in the circuit increases, which causes the fuse to trip. The advantage of the device is its fast response, which allows it to absorb excess voltage and protect the device. Response speed is the main advantage of a protective (TVS) diode.

Now about the verification. It is no different from a regular diode. True, there is an exception - Zener diodes, which can also be attributed to the TVS family, but in essence they are a fast zener diode operating according to the “mechanism” of avalanche breakdown (Zener effect). But the performance check reverts to a regular dialing test. Creating triggering conditions leads to failure of the element. In other words, there is no way to check the protective functions of a TVS diode; it’s like checking a match (whether it’s good or not) by trying to light it.

High Voltage Diode Testing

It will not be possible to check the high-voltage diode of a microwave oven in the same way as a regular one, due to its features. To test this element, you will need to assemble a circuit (shown in the figure below) connected to a 40-45 volt power supply.

A voltage of 40-45 volts will be enough to test most elements of this type; the testing methodology is the same as for conventional diodes. The resistance value R should be in the range from 2 kOhm to 3.6 kOhm.

Tunnel and reverse diodes

Considering that the current flowing through a diode depends on the voltage applied to it, testing consists of analyzing this dependence. To do this, you will need to assemble a circuit, for example, such as shown in the figure.

List of elements:

- VD – tunnel type diode under test;

- Up – any galvanic power source with a discharge current of about 50 mA;

- Resistances: R1 – 12Ω, R2 – 22Ω, R3 – 600Ω.

The measurement range set on the multimeter should not be less than the maximum diode current, this parameter is indicated in the datasheet of the radio element.

Video: Example of checking a diode with a multimeter

Testing algorithm:

- the maximum value is set on variable resistor R3;

- the element under test is connected, observing the polarity indicated on the diagram;

- By decreasing the value of R3, we observe the readings of the measuring device.

If the element is in good condition, during the measurement process the device will show an increase in current up to I max of the diode, after which a sharp decrease in this value will follow. With a further increase in voltage, the current will decrease to I min, after which it will begin to grow again.

LED testing

Testing LEDs is practically no different from testing rectifier diodes. How to do this was described above. We check the LED strip (more precisely, its smd elements), infrared LED, as well as laser, using the same method.

Unfortunately, a powerful radio element of this group, which has a higher operating voltage, cannot be tested using the indicated method. In this case, you will additionally need a stabilized power source. The testing algorithm is as follows:

- We assemble the circuit as shown in the figure. The power supplies are set to the operating voltage of the LED (indicated in the datasheet). The measuring range on the multimeter should be up to 10 A. Note that you can use the charger as a power supply, but then you need to add a current-limiting resistor;

- measure the rated current and turn off the power supply;

- set the multimeter mode, which allows you to measure DC voltage up to 20 V, and connect the device in parallel to the element under test;

- turn on the power supply and remove the operating voltage parameters;

- We compare the data obtained with those indicated in the datasheet, and based on this analysis we determine the performance of the LED.

Checking the photodiode

With a simple check, the reverse and forward resistance of the radio element placed under the light source is measured, after which it is darkened and the procedure is repeated. For more accurate testing, you will need to remove the current-voltage characteristic, this can be done using a simple circuit.

To illuminate the photodiode during testing, you can use an incandescent lamp with a power of 60 W or more as a source of illumination or bring the radio component to a chandelier.

Photodiodes sometimes have a characteristic defect, which manifests itself in the form of a chaotic change in current. To detect such a failure, it is necessary to connect the element under test as shown in the figure, and measure the amount of reverse current for a couple of minutes.

If during testing the current level remains unchanged, then the photodiode can be considered working.

Testing without desoldering.

As practice shows, it is not always possible to test a diode without desoldering it when it is on the board, like other radio components (for example, a transistor, capacitor, thyristor, etc.). This is due to the fact that the elements in the circuit can give an error. Therefore, before checking the diode, it must be desoldered.

How to test a diode with a multimeter

Usually, power rectifier diodes fail because significant forward current passes through them. The cause of diode malfunctions may be their overheating, disruption of thermal contact with the radiator or an increase in ambient temperature, failure of other circuit elements that caused an increase in the permissible voltage on the diode, or poor quality of their performance.

Failure of the rectifier diodes can cause an increase in the supply voltage to the circuit components and cause additional malfunctions. Diode failure can be expressed in a short circuit between different semiconductors of the p-n layer, lack of contact between them (break) and the appearance of a leakage current.

A diode is a semiconductor whose operation is based on the properties of the pn junction. The operation of the element is that in the forward direction anode (+) - cathode (-) current passes through the semiconductor junction, since its resistance is only a few tens of Ohms, and in the opposite direction cathode - anode (inverted diode) there is no current, i.e. because the transition resistance is quite high.

Using this property of p-n semiconductors, it is not difficult to check the performance of the diode with a multimeter. Some multimeters have a diode test mode, which is marked with a diode symbol. When the red probe of the device touches the anode of the semiconductor, and the negative cathode with another probe, then on the screen of the measuring device, if the element is in good condition, the voltage at the junction will be displayed, in the case of germanium diodes from 0.3 to 0.7 V, and from 0.7 to 1 B for silicon semiconductors.

Diode test mode on a multimeter

The difference in the forward voltage drop of these semiconductors depends on the different junction resistances. If you turn the probes over and touch the positive anode with a black probe and the negative cathode with a red probe, the display will display a voltage drop close to zero (in the case of a working element). If the multimeter does not have such a test mode, then the functionality of the element is checked in resistance mode.

Place the multimeter switch in the resistance measurement position of 1 Kom, and then apply the red probe to the anode of the element, and the black probe to the cathode. The device screen should display the direct junction resistance value for a working diode from tens to hundreds of ohms, which depends on the type of semiconductor. If the semiconductor material is germanium, then the direct junction resistance is lower than that of silicon elements.

If the probes are turned over, then the resistance of the pn junction will be high (if the semiconductor is in good condition) from several hundred Kohm to Mohm. When the reverse junction resistance is noticeably lower, then we can talk about unacceptable leakage current and a faulty element.

How to check an LED, Zener diode, Schottky diode with a multimeter

LEDs are tested in the same way as power diodes - for resistance. When connecting the device probes directly to the LED, the display will show a small resistance. In this case, the LED may have a dim glow. If you change the probes, the transition resistance will be high.

The Schottky diode is tested using the method of testing a conventional diode. The zener diode is also tested in different positions of the electrodes. But this is not enough to test zener diodes. The multimeter can show acceptable resistance values in both directions of the transition, and the stabilization voltage will differ from the required value.

A simple zener diode test circuit

To check the stabilization voltage, you need to assemble a simple circuit with a current-extinguishing resistance. The power supply voltage is usually taken 2 - 3 V higher than the stabilization voltage of the zener diode. As an example, let's take a D814B zener diode with a stabilization voltage of 9 V and a stabilization current of 5 mA. The limiting resistor can be approximately calculated using the formula:

R = U1-U2/I = 12 -9/0.005 = 600 Ohm.

I – rated current of the zener diode.

Having placed such a resistance in the zener diode testing circuit, measure the stabilization voltage on the zener diode; it should be 9 V, taking into account the deviation + 0.5 - 1 V, that is, the stabilization voltage should have a value of 8 - 9.5 Volts.

How to check a diode bridge with a multimeter

A simple diode bridge consists of four diodes assembled in a bridge circuit and is designed for primary rectification of alternating voltage. In the case of a rough check of the diode bridge, you can measure the junction resistance of individual diodes as usual. But then the leakage current cannot be checked.

To check this important parameter, you need to disconnect any semiconductor electrode from the electrical circuit. It is possible to check the presence of leakage current in individual power diodes without disconnecting them from the circuit, using the difference in temperature of the semiconductor cases. A faulty semiconductor will have a higher case temperature than healthy elements.

For this method of testing diodes for leakage current, it is important that they are free-standing and without radiators. It is not always possible to check the temperature difference by hand (with the power source turned off). Therefore, it is better to measure the temperature with a multimeter sensor that has this mode. You can roughly check the diode with a multimeter without desoldering it from the board in the usual way, and in most cases this is quite enough.