Many modern motorists face the need to adjust the ignition angle (UZ). Sometimes this procedure can cause certain difficulties for a motorist, so a lot of devices have recently appeared on the market to perform this task. For example, you can use a stroboscope to carry out the do-it-yourself ignition installation procedure, which we will discuss below.

[ Hide ]

stroboscope characteristic

So, you have decided to make the ignition settings on your car, but you have no idea how to set and adjust the UOZ. In order for the set angle not to bring discomfort to the driver while driving, you can use a stroboscope for ignition.

circuit diagram

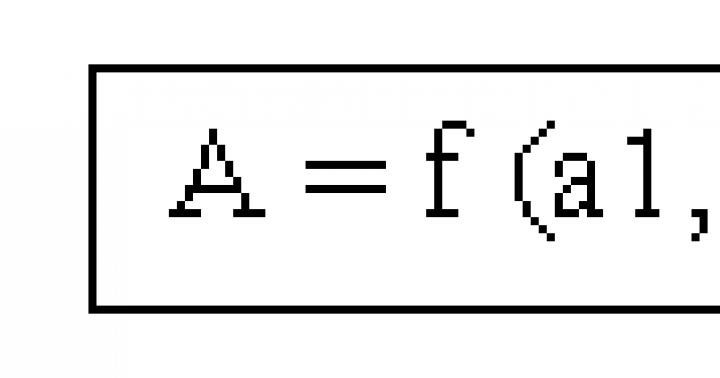

Below is a diagram of the stroboscope. If you do not know how to make a stroboscope on your own with LEDs, you can use this diagram. In the end, you will get the simplest stroboscope, however, the device made will allow you to fully adjust all the necessary parameters.

In the device diagram, it is necessary to distinguish several main parts:

- A power circuit that consists of components - SA1, which is a switch, a diode VD1, and a capacitor C2. A self-made circuit must necessarily include a diode designed to protect other components from erroneous polarity reversal. The capacitor performs the function of blocking impulse noise, helping to prevent malfunctions in the trigger. As for the switch, it can be replaced by a toggle switch, the main thing is that the component can turn the power on and off.

- A homemade stroboscope for installing an ultrasound must include an input circuit consisting of a controller, resistors R1, R2, and a capacitor C1. The controller option in this case is performed by a crocodile clip, which is fixed on the high-voltage cable of the first cylinder. As for the components C1, R1 and R2, they form a simple differentiating circuit.

- Another important component of the stroboscope used is the trigger board, which is assembled using two single vibrators designed to generate a given frequency signal at the output. Capacitors and resistors in this case are frequency-setting components.

- Another component is the output stage, which is assembled on resistors R5-R9 and transistors VT1-VT3. The transistors themselves are designed to amplify the output current of the trigger. Resistor R5 allows you to set the base current of the first transistor. And thanks to the resistor R9, the probability of failures in the operation of VT3 is excluded.

Principle of operation

So, what is the principle of work. The stroboscope for installing the ignition with your own hands is in any case powered by a battery. When the switch closes, the trigger comes into operation. At this time, a high potential is formed on the inverse terminals 2 and 12 in accordance with the scheme, and a low potential is formed on the direct terminals 1 and 13. The capacitors C3 and C4 themselves are powered by resistors.

The signal from the controller, passing through the differentiating circuit, is transmitted to the input DD1.1, which is a single vibrator, which ultimately contributes to its switching. The field of this begins the overdischarge of C1, ending with the switching of the trigger. Ultimately, the one-shot begins to respond to signals from the controller, forming rectangular signals on the first output.

As for the second single vibrator DD1.2, its principle of operation is similar - it allows you to reduce the signal duration by ten times at output 13. This component operates under load from the amplifier stage of transistors that open for the duration of the signal. As for the current passing through these elements, it is limited by resistors R6-R8, its indicator should be no more than 0.8 amperes.

This figure is not very large, because:

- the signal itself lasts no more than one second;

- as a rule, the operation of this lasts no more than ten minutes, respectively, overheating of the crystals is unlikely to occur in such a short time;

- modern diodes are characterized by more optimal technical features compared to those used in stroboscope designs ten years ago.

Accordingly, the operation of brighter diode elements will make it possible to largely reduce the load current as a result of an increase in the resistance index. This resistance increases on circuit components R6-R8.

PCB and Assembly Parts

Assembling your own strobe is not a problem. With a small budget, you can use inexpensive parts, if necessary, you can create a more modern device.

- On the board above, KD2999V is used as the diode element VD1, another one can be used, in this case it is important that the diode is with a small forward voltage drop.

- Capacitor devices C2-C4 should be rated at 0.068 uF, and C1 is a high-voltage component with a voltage of 400 volts.

- TM2 is a flip-flop with good noise immunity.

- Transistor components VT1 and VT2 must have a high gain.

- Diode parts HL1-HL9 should have the highest brightness, while their scattering angle should be minimal. The LEDs must be installed on a separate board, while there should be three of them in one row.

After the board for the device is ready, you need to choose a place to install it. For example, it can be a portable light housing, but it must be equipped with a hole in the housing for mounting the R4 regulator. In principle, you can use almost any case, the main thing is that you can easily install a regulator on it. You can learn more about how a home-made strobe for setting the ignition, made on the basis of a laser pointer, looks like from the video (the author of the video is Maxim Sokolov).

Features of device settings

To use the device, it must be adjusted. The tuning strobe must be set up properly to give the most accurate settings. First of all, the tuning resistor R4 is adjusted, which allows you to set the desired visual effect. As you turn the control knob, you will notice that lowering the signal can cause the marks to be underlit, and if the signal is increased, it will blur. Accordingly, during the first adjustment of the ignition timing with your own hands, you should correctly set the most optimal duration of light flashes.

There is one more thing to consider - the length of the cable that runs from the printed circuit board to the controller should be no more than half a meter. For the controller, you can use a 10 cm copper conductor, which should be soldered to the central core of the cable. When the connection is made, it is wound on the insulated part of the high voltage with three turns.

To increase the level of noise immunity, the winding procedure is carried out as close as possible to the spark plug itself. If you do not have copper, then you can use a crocodile clip - this component is soldered to the central core. In this case, the teeth of the crocodile should be slightly bent, otherwise this may damage the insulation.

Stroboscopes are used on cars to adjust the ignition system of the power unit. This device can be purchased at any auto shop. But the device can be made independently. The process of making a stroboscope yourself does not take much time. More on this later in the article.

A stroboscope makes life much easier for its owner.

Thanks to him, even an inexperienced motorist can independently adjust the ignition angle. The work of the stroboscope is based on the stroboscopic effect - a moving object is illuminated by a light flash.

It is beneficial to have such a device, as it makes it possible to independently regulate the ignition without contacting a service center, which saves time and money for the car owner. There are such motorists who prefer factory strobe lights, not trusting home-made ones, but they are no worse than traditional purchased ones.

Why is it difficult to set the ignition without a strobe

It is very difficult to adjust the ignition system with bare hands. The stroboscope allows you to speed up the ignition adjustment time of the vehicle several times. The light in the lamp of this device signals the formation of a spark, which makes it possible to set the correct advance angle.

Factory strobe, pros and cons

Factory devices work flawlessly and efficiently, but they cost decently. But in fact, all such devices have an expensive lamp, the failure of which leads to the acquisition of a new device. It is worth noting that even at the service station, some masters use home-made devices.

Top 5 Most Popular Factory Strobe Lights

The most popular factory-made strobe lights:

The cost of such devices reaches six thousand rubles. With self-manufacturing of a stroboscope, it will cost you about 600-700 rubles. So, saving money is actually ten times stimulating to make such a device with your own hands.

Spare parts and parts for making a stroboscope with your own hands

- LED flashlight.

- Copper wires.

- Capacitors c1.

- Specialized clamps.

- Low frequency diode V2.

- Resistors 0.125 V.

- Thyristor KY112A.

- Relay with index RWH-SH-112D.

- Meter cord.

Such parts and spare parts can be purchased at any electronics store or radio market. The body of the device is small. You can even use the base of an old flashlight.

Strobe circuit

There are a lot of schemes on the Internet on how to create a simple strobe yourself. Most of them are easily and quickly assembled without requiring significant financial investments.

Do-it-yourself stroboscope assembly, step by step, the easiest option

Sequencing:

- Drill a hole for the power cable.

- Observing the polarity, solder the clamps to the ends of the wires.

- The sensor can be installed on the right or left.

- We solder the copper wire to the main core.

- Isolate all contacts.

This invention is used to test the operation of the regulator and the spark plug.

Timer-based strobe, pros and cons

To independently make a device using a timer, you need to make more efforts than for a conventional stroboscope. The key advantage of such a device is constant light pulses, which do not depend on the voltage of the battery. A stroboscope such as a tachometer is used. To do this, you need to switch the regulator.

LED stroboscope, pros and cons

The basis of such devices is the 155AG1 chip, which requires pulses with negative polarity to run. In such circuits, it is necessary to use resistances R1, R2, R3. They limit fluctuations in the input signal. This circuit will be powered by a battery. The duration of the pulses is able to provide capacitance C4 with resistor R6. According to the classic settings, this value will be equal to 2 ms.

How to use homemade strobe lights

For the correct functioning of a home-made device, it must be checked. From the existing device, you need to set the lead angle:

- First, we warm up the power unit and leave it to function at idle.

- Connect the device to the battery.

- We wind the copper sensor around the core of the cylinder.

- Next, you should orient the light source according to a special indicator on the body.

- We are looking for a fixed point on the flywheel.

- To make the two points match, rotate the ignition housing and keep it in the desired position.

The key point in self-manufacturing of this device is the correct assembly of the electrical circuit. That is why, before starting manufacturing, it is imperative that you first make a detailed diagram that will help to avoid errors when assembling the device.

Do not forget about safety precautions. Any strobe operates under voltage. The internal elements of the device must not be allowed to touch its body, especially metal.

It is desirable that the variable resistor be protected by a plastic handle. A well-insulated power cord must have a plug. All parts must be mounted on a special board made of insulating material. Parts are mounted according to a special scheme, but their location is not important. It is necessary to carefully fasten all the elements.

If you like to do your own car maintenance, then to reduce the cost of buying a tool, you can make a do-it-yourself ignition strobe.

What is a stroboscope

A stroboscope is a device for observing objects that make fast, repetitive movements. To do this, it illuminates a moving object with bright flashes of light, repeating with a frequency equal to the frequency of the movement of this object. In this light, a moving object appears to be stationary. In a car engine, using a stroboscope, you can determine the ignition timing. To do this, you need to synchronize the flashes with ignition pulses in the first cylinder, and direct the light to the TDC marks and the ignition timing settings, illuminating the crankshaft pulley with a risk.

Prefabricated strobe lights usually have an inertia-free flash lamp as the flash emitter, allowing you to make adjustments to the ignition timing even in bright sunlight. However, it has a short service life and is not always on sale. Therefore, with the advent of LEDs with a light intensity of more than 2000 mcd, it has become more convenient to use them when making a stroboscope with your own hands. To convince of the significant superiority of the parameters of the luminous flux of the new LEDs, we recall that for the AL307, with the same current consumption, the luminous intensity is only 10–16 microdegrees.

(scheme for video materials in the description under the video)

materials

The strobe circuit proposed for making with your own hands is simple and does not require complicated settings. To make a simple stroboscope for adjusting the ignition timing with your own hands, you will need the following tools, parts and materials:

- Pocket flashlight with a large enough compartment for batteries.

- LEDs KIPD21P-K - 9 pcs.

- Chip K561TM2 (two two-stage D-flip-flop). Russian analogues: K176TM2, 564TM2; imported analogue - CD4013 / HEF4013.

- Transistor KT315B - 2 pcs. (VT1, VT2); KT815A - 1 pc. (VT3).

- Trimmer resistor SPZ-196 or SP5-1 with a resistance of 33 kOhm.

- Fixed resistors 5.1 Ohm - 3 pcs., 3 kOhm - 1 pc., 15 kOhm - 1 pc., 20 kOhm - 2 pcs., 330 kOhm - 1 pc., with a power of at least 0.125 W.

- Diode KD213 or any other average power with U arr. max not less than 16 V.

- Non-polar capacitors KM-5, K73-9 or others. C1 must have an operating voltage of at least 200 V; the rest must be at least 16 V. 0.068 uF - 3 pcs., 47 pF - 1 pc.

- Any toggle switch to turn on the power of the device.

- 1 m shielded wire (for example, antenna).

- 3 crocodile clips.

- A small piece of foil textolite 1 mm thick.

- Stranded double insulated copper wire - 1.5 m.

- Glue gun.

- Soldering iron, solder, flux.

Device design

The body of the stroboscope will be a flashlight. The circuit is assembled by surface mounting. The finished circuit is poured with hot plastic from a glue gun, and after the fill has hardened, it is placed in the flashlight battery compartment. The power and signal cables are brought out through holes drilled in the housing. Solder the clamps to the ends of the power wires, indicating the polarity. Connect the antenna cable to the stroboscope input. Solder the alligator clip to the central core of the input cable. After connecting the stroboscope to the motor of the car, it will be used to input synchronization pulses of the high-voltage ignition wire. To make this possible, it is enough to put it on the insulation of the high-voltage ignition wire of the first cylinder of the car engine. The synchronization pulse will go through the capacitance formed by the central core of the ignition wire and the clamp. That is, a simple homemade capacitive sensor will consist of an alligator clip worn on a high-voltage wire.

It is most convenient to make a light emitter by mounting a group of LEDs close to each other in the center of a disc made of foil textolite. It should be installed so that the LEDs, passing through the hole for the light bulb in the reflector, are as close as possible to the location of the filament. You can attach the textolite to the reflector using a glue gun.

Nutrition

The power supply of the device comes from the on-board electrical network of the car. Diode VD1 protects the device from accidental connection of reverse polarity power. The synchronization pulse from the capacitive sensor through the circuit C1, R2 is fed to the input of the trigger DD1.1, included as a standby multivibrator. A high-level pulse starts the waiting multivibrator, the trigger switches, and the capacitor C3, charged in the initial state, begins to recharge through the resistor R3. After about 15 ms, this capacitor will recharge so much that the voltage at the R input resets the flip-flop again.

So the waiting multivibrator responds to each positive pulse from the capacitive sensor, producing synchronously with the input rectangular output pulse of a high level of constant duration (15 ms), which is determined by the values of resistor R3 and capacitor C3. The sequence of these pulses from the non-inverting output of the DD1.1 trigger is fed to the input of the second standby multivibrator, assembled in a similar way on the DD1.2 trigger. The pulse duration of the second node reaches 1.5 ms and is determined by the parameters of the resistor R4 and capacitor C4. The output voltage of the second trigger opens the triodes VT1 - VT3, and current pulses of 0.7 to 0.8 A pass through the LEDs.

So the waiting multivibrator responds to each positive pulse from the capacitive sensor, producing synchronously with the input rectangular output pulse of a high level of constant duration (15 ms), which is determined by the values of resistor R3 and capacitor C3. The sequence of these pulses from the non-inverting output of the DD1.1 trigger is fed to the input of the second standby multivibrator, assembled in a similar way on the DD1.2 trigger. The pulse duration of the second node reaches 1.5 ms and is determined by the parameters of the resistor R4 and capacitor C4. The output voltage of the second trigger opens the triodes VT1 - VT3, and current pulses of 0.7 to 0.8 A pass through the LEDs.

Some subtleties

Despite the fact that the current value is much higher than the allowable for these LEDs (the maximum allowable direct pulse current is only 100 mA), one should not be afraid of overheating and failure. Because the duration of the pulses is short, and their duty cycle in normal mode is not less than 15. The brightness of the flashes of nine LEDs allows you to use the device even during the day.

The editors of the magazine "Radio" reports that in order to make sure that the device is working, it was tested.

The LEDs successfully carried a pulsed current of 1 A for an hour, and even a slight overheating of them was not detected. Usually, the operating time with the device does not exceed 5 minutes, and the current passing through them in this design is somewhat less.

The purpose of the waiting multivibrator on the DD1.1 trigger is to protect the LEDs from failure when the crankshaft speed increases. Usually the device is operated at a crankshaft speed close to idling (from 800 to 1200 rpm). Since the duration of the flashes is constant, with an increase in the crankshaft speed, the duty cycle of the current pulses through the LEDs will decrease, and, as a result, the heating of the latter will increase. Therefore, the duration of the pulses of the waiting multivibrator on the trigger DD1.1 is chosen such that when the crankshaft speed reaches 2 thousand rpm, the duty cycle of its output pulse sequence approaches 1. With a further increase in the speed, and with it the input pulses, the they synchronize the output pulses, and the node begins to generate a sequence of pulses of the average frequency, which is much less dangerous for the LEDs.

Device setup

It has been experimentally established that the duration of flashes should be from 0.5 to 0.8 ms. With a shorter flash duration, when setting the advance angle with a strobe, there is a great feeling of lack of light. If the duration is longer, then the moving mark seems to be smeared. It is easy to choose the required duration with your own hands without measuring, but guided only by visual sensations. It is regulated using a tuning resistor R4. The scheme does not need any more settings.

Using the instrument

To set the lead angle (moment) with your own hands, the device illuminates the installation marks of the car engine idling. One of them is located on the rotating parts of the car engine (on the crankshaft pulley or on the flywheel). The second mark is fixed, it is located either on the cover of the front of the cylinder block of the car, or on the gearbox housing. If in the light of the device the movable mark seems to be standing opposite the fixed one, the ignition of the car is normal and does not require adjustment of the timing (angle) of the advance.

If the marks do not match, to adjust the timing of the lead, you need to change the position of the distributor accordingly. To delay the ignition moment, you need to turn the distributor in the direction of rotation of the slider, and to make it earlier, in the opposite direction. If the sparking in your car is controlled by a microprocessor, look for a faulty sensor or entrust this problem to professionals.

To accurately set the ignition on the engine, it is necessary to use special devices - stroboscopes. They can be purchased at car dealerships or made by hand. In the second case, you will save a decent amount and make the most suitable device for your car model.

Features of factory strobe lights and the principle of their operation

Precisely adjusting the ignition without using a strobe is quite difficult. Such a device significantly speeds up the tuning process, the lamp signals the appearance of a spark, which allows you to correctly set the ignition timing. Despite the fact that factory instruments work efficiently and accurately, many motorists are in no hurry to buy them. The main deterrent can be called the high price of strobe lights. Most models use an expensive gas discharge lamp, replacing it is equivalent to buying a new device.

The device itself can be made by hand, using simple and affordable materials. There are several good manufacturing schemes that will help you save on buying factory counterparts. For example, you can see the prices for the most popular strobe lights that are on sale:

- Multitronics C2 - 900-1000 rubles.

- AstroL5 - 1300 rubles.

- Focus F1 - 1700 rubles.

- Focus F10 - 5600 rub.

Homemade devices are made from flashlights, LEDs or a laser pointer. At a low cost (about 500 rubles), the device will work no less reliably and efficiently.

Instructions for the manufacture of the device for installing the ignition

The easy way

There are many different schemes on the network, almost all of them are easy to assemble and do not require large expenditures on materials. Consider one of the most popular schemes for creating a stroboscope at home. From the details we need:

- transistor KT315;

- thyristor KU112A, 0.125 W resistors;

- any flashlight on diodes (diodes should be 6 or more);

- capacitors C1;

- low frequency diode V2;

- relay with index RWH-SH-112D;

- 1 meter power cord;

- special clamps;

- copper wire about 10 cm.

All parts can be purchased at the radio market or in a specialized store. As a housing for the device, you can use an old flashlight or a flash from a camera.

Assembly diagram of a car strobe in a housing from an old flashlight

You can use such a device not only to install the ignition. They can check the candle, adjust the operation of the regulator.

Homemade stray using a timer

A stroboscope based on timer devices has a more complex circuit. Its main advantage is stable light pulses that do not depend on battery voltage. The device can also work in tachometer mode, for this you just need to change the position of the regulator.

Timed strobe lights can also be used as a tachometer

Tip: It is better to use diodes from the KD521 series in the circuit. If you have not found a domestic-made timer, you can take a foreign analogue NE555.

Scheme for manufacturing a device on LEDs

Such a device is based on the 155AG1 chip; it is triggered by pulses with negative polarity. The circuit uses resistances R1, R2, R3, which limit the amplitude of the input signal. The required pulse duration is set by capacitance C4 and resistor R6. At default settings, this is 2 ms. The vehicle battery will be used as a power source.

LED strobe lights are highly reliable and can be used even in bright daylight

Video: how to make a stroboscope with your own hands

How to set up homemade

To test the device in practice and set the ignition timing, do the following:

- We warm up the engine and leave it to idle.

- We connect a homemade stroboscope to a power source.

- We wind the copper sensor on the core of the first cylinder.

- We direct the light source to a special mark, which is applied to the body.

- We find a fixed point on the flywheel pulley.

- In order for the two points to converge, it is necessary to rotate the ignition housing and then fix it in a certain position.

In practice, homemade strobe lights are in no way inferior to factory ones. The main thing is to correctly assemble the circuit and check the operation of the device. Homemade stroboscopes are quite inexpensive and can be easily repaired if necessary.

Car owners with solid experience know the value of a correctly set initial ignition timing and the correct operation of the vacuum and centrifugal ignition timing controllers. If the ignition timing is set incorrectly (by the way, even a seemingly minimal deviation of 2-3 degrees can play a significant role), this can cause increased fuel consumption, loss of power and overheating of the power unit and even reduce its operational life. Therefore, the ability to check and adjust the ignition system is a very valuable skill for drivers, although these processes are quite complex.

If the car owner nevertheless decided to implement this operation, then the first tool that will come in handy for him will be a stroboscope for setting the ignition, designed to simplify the process of servicing the above system.

How does a stroboscope for ignition work?

The ignition strobe is a very simple and affordable device that can be obtained at any specialized store, and besides, it will greatly facilitate your life as a car owner. After all, with such a device available, even a novice driver will check and adjust the initial ignition timing in a matter of minutes, as well as check the centrifugal and vacuum regulators for any damage.

This device works on the principle of the stroboscopic effect, the essence of which is explained something like this: if an object that moves in the dark is illuminated with a short bright flash, it will seem visually frozen in the position in which the flash caught it.

The principle of operation of this device lies in the stroboscopic effect, the essence of which can be explained approximately as follows: if an object moving in the dark is illuminated with a bright and at the same time short flash, then it will begin to visually appear frozen exactly in the position in which the flash caught it. For example, if you illuminate a wheel with flashes that rotates at a frequency equal to its rotational frequency, you can visually capture it. This is easily noticeable due to the position of a certain mark.

To set the ignition timing, start the engine at idle, and use a strobe light on the previously discussed marks. One of them, called the movable one, is located on the crankshaft, although it can be on the generator drive pulley or on the flywheel, and the other on the engine housing. Flashes occur simultaneously with the moment of sparking in the glow plug of the cylinder.

Both marks should be visible during flashing. Moreover, the following conditions apply here: if the marks are located exactly opposite each other, then the ignition timing will be the most optimal, and if the movable mark shifts, then the position of the interrupter-distribution mechanism must be corrected until the marks match.

Both marks should be visible during flashing. Moreover, the following conditions apply here: if the marks are located exactly opposite each other, then the ignition timing will be the most optimal, and if the movable mark shifts, then the position of the interrupter-distribution mechanism must be corrected until the marks match.

The main element of the stroboscope is a pulsed stroboscopic lamp of the inertialess type. This mechanism is designed in such a way that flashes occur at the moment a spark appears in the candle of the first cylinder. The result of this will be the location of the alignment marks, along with other elements of the motor, rotating synchronously with the crankshaft, as a result of lighting them with a strobe lamp, they seem to be motionless. Thanks to this, it is possible to control the correct setting of the initial ignition timing.

From all that has been described and said above, an idea is already emerging about the characteristics of the operation of a stroboscope for ignition. At the same time, we will explain its device: after connecting the leads to, the voltage converter will work, which is a symmetrical type multivibrator. The initial voltage is distributed further from the transistor-based dividers, which begin to open slightly, but one of them always does it much faster than the other.

And this affects the behavior of another transistor, which as a result of this closes, which is explained by applying a blocking voltage from the windings to its base. Then the transistors begin to open one after another, and this causes one or another transformer winding to be connected to the battery in turn. At the moment, a voltage with a rectangular shape and a frequency of about 800 Hertz appears in the secondary windings. Its value is directly proportional to the number of turns in the winding.

At the moment of origin of direct sparking, the high-voltage impulse of the first cylinder is supplied to the electrodes, which are located on the strobe lamp, by means of capacitors and a special spark gap plug from the distribution socket. With all this, the energy accumulated by the capacitor is converted into light from the flash of the lamp. After the capacitors are discharged, the lamp goes out, but they receive a charge from the resistors up to a voltage of about 450 volts. In this way, preparations for the next outbreak are completed.

At the moment of origin of direct sparking, the high-voltage impulse of the first cylinder is supplied to the electrodes, which are located on the strobe lamp, by means of capacitors and a special spark gap plug from the distribution socket. With all this, the energy accumulated by the capacitor is converted into light from the flash of the lamp. After the capacitors are discharged, the lamp goes out, but they receive a charge from the resistors up to a voltage of about 450 volts. In this way, preparations for the next outbreak are completed.

Resistors also serve to prevent shorting in the windings at the moment the lamp flashes. The purpose of the diode is to protect the converter transistor if the stroboscope is connected in the wrong polarity. Thanks to the spark gap, it is ensured that the necessary voltage of the high-voltage pulse is obtained in order to prevent the lamp from igniting. In this case, neither the distance, nor the pressure in the combustion chamber, nor the candles play any role. Thanks to the spark gap, uninterrupted operation of the stroboscope is ensured even with shorted electrodes in the spark plug.

As you can see, the principle of operation of a fairly simple-looking mechanism is rather complicated. But that doesn't mean that it can't be sorted out. It is also important to understand how to set the ignition with a strobe and try to carry out this process yourself.

Characteristics of the stroboscope for ignition installation

The stroboscope is endowed with a certain set of characteristics that distinguishes it from other devices, making it truly unique and necessary. Among the uniqueness, for example, we can name the following: the power source for the stroboscope can be its own batteries and the on-board car network. This automatically raises the question of which method is the best - autonomous power or at the expense of the car's network.

The stroboscope is endowed with a certain set of characteristics that distinguishes it from other devices, making it truly unique and necessary. Among the uniqueness, for example, we can name the following: the power source for the stroboscope can be its own batteries and the on-board car network. This automatically raises the question of which method is the best - autonomous power or at the expense of the car's network.

Let's just say that this given is absolutely not fundamental, but still the first method limits you from the need to pull wires behind the device. Another distinguishing characteristic of a stroboscope is the value of the minimum flash frequency that it produces.

It should be similar with the speed, rotating at maximum speed. The most common stroboscopes with a frequency of 50 Hz. As a rule, the stroboscope cannot function for a long time, carrying out flashes, and this is due to the special design of the lamps. Often, it is able to work correctly continuously for no more than ten minutes. These indicators are indicated in the instructions for the device. In order to avoid unforeseen situations, the stroboscope and, first of all, its lamps, must be given rest for a duration equal to the time of its operation in one session.

Ignition adjustment with a stroboscope

So, if you have this unique tool for setting the ignition, then you should not put everything on hold, but it's time to start checking and adjusting the ignition. Each distributor has two adjustment systems - centrifugal and vacuum correctors. During operation of the power unit, the ignition timing is not constant, which is affected by the number of revolutions and load. This is necessary for the optimal process of combustion of fuel, and optimally means powerfully and as economically as possible. So let's start our test. Go.

So, if you have this unique tool for setting the ignition, then you should not put everything on hold, but it's time to start checking and adjusting the ignition. Each distributor has two adjustment systems - centrifugal and vacuum correctors. During operation of the power unit, the ignition timing is not constant, which is affected by the number of revolutions and load. This is necessary for the optimal process of combustion of fuel, and optimally means powerfully and as economically as possible. So let's start our test. Go.

1. Warm up the engine and adjust the idle speed to normal or slightly lower. Remove the vacuum tube that goes from the distributor vacuum to the carburetor. In this mode, check and adjust the setting of the initial ignition timing. Detailed information about this can be found in the manual for your vehicle.

2. By increasing the engine speed to two thousand, you will also have to observe an increase in the voltage angle by about seven degrees, if this does not happen, then there is a problem with the centrifugal regulator. The main reason, often, may be the jamming of the centrifugal mechanism, which often happens as a result of its oxidation. In addition, the springs of the mechanism often break.

3. It will be more difficult to check the operation of the vacuum ignition timing controller due to the fact that its work is related to work. The main condition for the correct operation of the vacuum regulator is the absence (at idle) of a vacuum in the tube that runs between the vacuum and the carburetor. It should only occur with an increase in engine speed.

The timely appearance of a vacuum in the tube is checked by the tip of the tongue to the end of the tube, which is connected to the vacuum distributor of the distributor. If the carburetor is not able to ensure the timely appearance of a discharge in the tube, then the vacuum corrector simply cannot function normally, even if the distributor mechanism is fully operational.

The timely appearance of a vacuum in the tube is checked by the tip of the tongue to the end of the tube, which is connected to the vacuum distributor of the distributor. If the carburetor is not able to ensure the timely appearance of a discharge in the tube, then the vacuum corrector simply cannot function normally, even if the distributor mechanism is fully operational.

With the correct operation of the carburetor and timely discharge, respectively, proceed to check the performance of the vacuum cleaner itself. Connect the vacuum tube back to the distributor and illuminate the mark with a strobe. With increasing speed, the mark will go twice as high as before with a disconnected tube.

The total advance angle includes three values: the initial ignition advance angle, the additional advance that is created by the centrifugal regulator, and the additional advance from the vacuum cleaner. It can reach up to 30 degrees. It all depends on the operating mode of the power unit, its model and the characteristics of the distributor.

Ignition distributors have their own specific predetermined performance characteristics. To determine their parameters accurately and their compliance with the standard can only be determined on special stands. In the case you are doing, you can only determine whether this or that scheme works or not. Of course, an experienced professional can visually determine how correct the characteristics of the distributor are, and if something happens, adjust them, but this is not so simple and this requires some experience, which is gained over many years of practice.

And the last thing we want to say on this topic. If one of the ignition timing correction systems or both do not work, then the car noticeably loses in accelerating dynamics, “dips” may appear and fuel consumption may increase.