VW Polo Sedan (2010+). The smell of antifreeze in the cabin

Expansion tank leak

As a rule, the cabin smells of coolant if it leaks from the expansion tank. In most cases, this malfunction is caused by long-term operation of the vehicle or a violation of the technical condition of the car. But, no matter how surprising it is, antifreeze leaks often occur on modern cars. The main cause of antifreeze leakage is the wear of system components or manufacturing defects. Also, the working fluid may leak if the nozzles or other components of the cooling system are incorrectly replaced. Since the coolant tends to erode, the motorist may not notice a slight leakage of the mixture. In this case, a foreign smell in the cabin will indicate a malfunction of the car's cooling system. Visually, it is easier for the vehicle owner to detect a significant leak. In this case, the liquid leaves noticeable stains on the components of the system. If antifreeze or antifreeze rapidly leaves the expansion tank, then this can be determined from the readings of the relevant analyzers or when characteristic smudges appear. When the liquid leaves the system to a small extent, you can feel a sweet smell in the vehicle interior. In this case, it is necessary to promptly start diagnosing the cooling system of the vehicle.

Leaking stove or radiator

Often the reason is that the stove or its radiator is leaking. Since it has a complex structure, it is recommended to change it to a new one, and not to repair it. Leakage can also occur due to loose fitting connections.

If it is not possible to change the stove radiator, then you can continue to drive like this, but it is worth checking the fluid level in the cooling system more often.

Diagnostics

First of all, it is necessary to conduct a visual diagnosis of the cooling system. During the diagnostics, it is necessary to carefully check all the conductors of the system for mechanical damage or leakage. If during the inspection damaged conductors were found, it is necessary to restore the tightness of the cooling system by replacing them.

Also, one of the most common malfunctions of the cooling system is coolant leakage into the engine crankcase. This malfunction can lead to quite serious consequences and significantly disrupt the function of the engine. You can identify this malfunction by visually inspecting the oil tank cap. If the coolant enters the crankcase, a white emulsion appears on the cover. If the coolant flows out, you can notice the formation under the car.

If the inside of the car smells of antifreeze, then the coolant is leaking directly into the passenger compartment. The smell of antifreeze in the cabin indicates a violation of the tightness of the heater radiator. In the event of a radiator leak, some of the coolant leaks directly into the passenger compartment and the driver of the vehicle may smell a characteristic sweet smell.

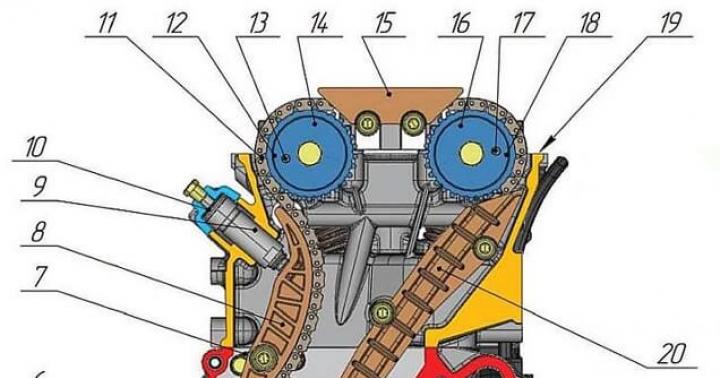

Also, coolant can enter under the drive of the gas distribution mechanism. In this case, it is quite difficult to visually determine the leak, but by diagnosing the space under the timing belt, you can notice characteristic traces of moisture. As a rule, the cause of the formation of moisture under the timing belt is a faulty pump.

As you know, the system of maintaining the temperature regime plays an important role in the correct and long-term functioning of the engine. In the event of a malfunction of the cooling system, the engine is subject to overheating and premature wear of the components. During the operation of the vehicle, the cooling system operates in difficult conditions. The components of the system are constantly under the influence of high pressure and temperature differences. In this regard, the elements of the cooling system are subject to increased wear and require timely diagnostics and regular maintenance.

The smell of antifreeze in the cabin indicates a malfunction of the connecting hoses of the systems and the need for diagnostics. With prolonged use of the vehicle, the rubber components of the system wear out and often become unusable. If the diagnostics showed the maximum permissible wear of the conductors of the system, it is required to replace them without fail. To fix the hoses of the cooling system, it is best to use special metal clamps, which are characterized by a long service life, reliability and do not allow leakage of the working mixture. In addition, it is necessary to pay attention to the condition of the radiator and, if necessary, restore its tightness or replace it.

In the event of a coolant leak, the vehicle's engine is subject to increased wear. In this regard, not paying attention to the condition of the cooling system in a timely manner, you can acquire a large amount of engine repair costs. Timely diagnostics and regular maintenance of the cooling part will allow you to remain confident in the reliability of the engine and increase the life of its elements.

The rear suspension is semi-independent, lever-spring with trailing arms pivotally mounted on the car body and interconnected by a transverse beam. The upper and lower ends of the spring rest on elastic rubber pads. Brackets are welded to the levers, to which, in turn, the rear wheel hubs with rear wheel brake shields are attached. In front, bushings are welded to the suspension arms, into which rubber-metal hinges (silent blocks) are pressed.

The lower ends of double-acting hydraulic shock absorbers are bolted to the suspension arms. The upper ends of the shock absorbers are attached to the body.

Front suspension

The front suspension is independent, MacPherson type lever-spring, with telescopic shock absorber struts, has twisted coil springs, wishbones and a torsion-type anti-roll bar.

The main components of the front suspension are telescopic shock absorber struts, which combine the functions of the telescopic element of the guide mechanism and the damping element of the vertical vibrations of the wheel relative to the body.

On shock absorber struts twisted coil springs, compression buffers with protective covers and upper supports with thrust bearings are assembled. The load on the car body is transmitted through the upper support. The shock absorber strut is connected to the suspension arm through the steering knuckle with a ball joint.

Roll Stabilizer connected to the cross member of the front suspension of the car with two brackets through rubber cushions with shock absorber struts.

Levers front suspension attached to the crossbar through the front and rear hinges (silent blocks). The front wheel hubs are mounted on non-adjustable double row angular contact ball bearings.

Volkswagen Polo sedan front suspension elements: 1 - shock absorber; 2 – a rack of a bar of the stabilizer of cross-section stability; 3 – a bar of the stabilizer of cross stability; 4 - bracket for attaching the stabilizer bar to the subframe; 5 – rotary fist; 6 - hub assembly; 7 - ball bearing; 8 - lever; 9 - subframe; 10 - stabilizer bar cushion.

Cars of this brand are produced with an independent MacPherson brand front suspension, which is a standard solution for the running gear of cars of this class.

Shock absorbers are standard, telescopic. Equipped with springs. They have a cylindrical shape.

Also, the Volkswagen Polo suspension includes front levers and a stabilizer bar. As a rule, only the torsion type model is used.

The original shock absorber struts form the basis of the entire front suspension of the car.

At the same time, they perform two main tasks, firstly, they dampen all vertically directed vibrations on the wheel part, and secondly, they play the role of a guiding element.

On the racks themselves, the upper supports are attached, which have their own bearings, through which the main load is applied to the entire body. The suspension and shock absorbers are connected by transmission to the front levers. They, in turn, are connected exclusively by means of a ball joint and a steering knuckle.

The anti-roll bar is connected to the shock absorber struts, special struts equipped with rubber cushions.

The levers are attached to the cross bar of the front suspension in two places. The connection is made using hinges, which are also called silent blocks. Another important element of the suspension is the hub on which the wheel is attached. The hub itself is mounted on special double-row bearings.

Volkswagen Polo. Checking front suspension wear

In order to timely track the condition of the suspension, as well as all its components and assemblies, you will need either a lift or a standard viewing hole. It is important to consider that during inspection, the front wheels must be hung out. It is worth having a mounting spatula and a set of necessary keys on hand.

First of all, the safety of all rubber covers and casings on the suspension units should be examined. Especially on the ball joint parts. Any even external mechanical damage is not allowed on the suspension.

Then you should make sure that in fact there are no signs of impacts on road obstacles on all suspension units in the front of the car. Carefully inspect all existing arms, struts, and stabilizer bars for damage and any deformation.

Check the condition of the shock absorbers and suspension joints.

Rubber pads should also be inspected for damage. If damage to the rubber is found, the pillows will have to be replaced with new ones.

When checking the rubber components of the suspension itself, first of all note on the:

- No signs of aging rubber

- Absence of any damage, including mechanical.

When inspecting rubber-to-metal joints, be sure that the parts do not show the following signs: the rubber parts are cracking, bulging, or they show obvious signs of aging. Separation of rubber parts from metal components. In these cases, it is necessary to replace the damaged components

.

Sequential check of components and parts of the Volkswagen Polo suspension

Let's take a look at all the necessary actions for a comprehensive inspection of the chassis of the car. Ball bearings. Inspection of rubber boots and check for support backlash.Control inspection, carried out with a special mounting blade, should be pressed on the steering knuckle, while relying directly on the suspension arm itself. In a serviceable node, no play should be observed.

In a similar way, you should check the front and rear silent blocks. Inspect the protective rubber covers of the stabilizer struts. Track the condition of the pillows attached to the stabilizer bars to the cross bar.

Do not forget that no knocks or extraneous sounds should occur during inspection.

It is also worth looking at the protection of the shock absorber strut if you need to tighten the nut on the stem.

How to replace the front suspension lever?

It is not difficult to determine the existing deformation of the lever. If it takes place, then there will be a violation of the angle of installation of the front wheel. This can be eliminated by replacing the assembly, this can be done by hand, using a lift and a set of wrenches. When working under the bottom of the car, be sure to follow all safety rules.

Remove the wheel that shows a change in installation angle. Remove the ball joint from the arm at the front. Unscrew the bolt of the front hinge of the lever attached to the front beam. By analogy, disconnect the rear hinge. Next, disconnect the lever from the cross beam by removing it from the brackets. Direct installation of a new component is carried out in reverse order. If you have no experience or have other questions, contact a car service to get a quality adjustment of all the angles of the front wheels.

How to replace the components and assemblies of the front shock absorbers?

Below we will analyze in detail and point by point all the stages of a complete replacement of the shock absorber strut. To do this, you need to have: a set of wrenches, a set of screwdrivers, a lift or a mounting hole. It is important that the entire front of your car is hanging out.

We unscrew the nut at the hub and all the wheel nuts. Remove the wheel.

Next, open the hood, and fix the wiper blades. We dismantle both levers from the wiper and remove the seal from the hood. Disconnect the air intake grille. Now we take out the hinge from the stabilizer strut by unscrewing the corresponding nut. We take out the brake hose located in the grooves of the holder on the shock absorber strut. We disconnect the spring retainer from the brake hose with pliers and remove the hose from the holder itself on the rack.

Remove the plug from the wheel speed sensor. Next you need to remove the ball joint. We unscrew the nuts on the lever in front. We further derive the tail part of the outer hinge from the groove of the hub and securely fasten the wheel drive to the body. Be careful not to damage the inner hinge!

Without tightening the nuts, install the ball joint bolts in place, in the holes located on the front lever. When this is done, disconnect the steering knuckle from the shock absorber from the strut side. To do this, unscrew the shock absorber strut mounting nut from above, remove the stop.

Open the knuckle terminal with a mounting spatula and remove the rack from there, separating it from the knuckle.

Attention! When installing a new shock absorber strut, all fastening nuts of the assemblies should be replaced with new ones.

Now consider the replacement of individual parts on the shock absorber strut.

1. You will need a spring compressor to remove the strut stem nut. After compressing the spring, unscrew the stem nut and remove the upper stem support.2.Remove the strut support bearing and upper bearing cup.

3. After that, you can remove the spring from the rack and disconnect the protective cover with the compression buffer.

After performing these works, carefully inspect all components for damage and wear of the units, if necessary, replace the corresponding parts. Check the stroke of the shock absorber rod, there should be no bumps, jamming or jamming during the stroke. Also inspect the spring and replace if necessary.

It should be borne in mind that this check of the shock absorber strut is quite approximate, and for a more complete and thorough analysis of the condition of the part, you need to contact a car service.

The suspension in front of the machine is independent, has a spring type with McPherson control arms and telescopic shock absorber struts. The equipment also includes springs with a cylinder shape, transverse levers, a transverse stability stabilizer having a torsion type.

The suspension in front contains the basic units:

- shock absorber struts of a telescopic design, they perform the duties of a part indicating the direction of the nodal connection;

- system damping vertical vibrations of the wheels in relation to the body of the car.

Twisted springs with the shape of a cylinder are attached to the shock absorber struts, next to them are located under the protection covers of the compression buffer and the top support with stop ball bearings. The support at the top is a direct transmitter of the load on the machine body. In addition, the suspension strut is connected to the suspension arm by means of a steering knuckle.

Two brackets that go through the rubber cushions act as a connector for the anti-roll bar and the transverse suspension rib at the front of the car.

The levers located on the suspension in front are attached to the cross member with the help of silent blocks in front and behind. The wheel hubs in front are mounted on angular contact ball bearings, which are not adjustable.

Suspension failure factors ahead and methods to overcome them

During the operation of the Volkswagen Polo, signs of suspension malfunctions in front of the car may appear. Consider the probable causes of their manifestation and methods for overcoming them.

Occurrence of extraneous noise or knocking when moving the machine

Insufficiently strong connection of the car body and the brackets securing the stabilizer bar or the struts of this stabilizer and the arm located at the bottom of the suspension. To eliminate it, it is enough to tighten securely weak thread connections.

Wear of stabilizer parts made of rubber and racks to it. Requires replacement of spent items.

Wear of the part of the shock absorber strut support at the top made of rubber. It is necessary to change the support of the shock absorber strut, located at the top.

Wear of the ball joint at the bottom or hinges of the steering rods. Replace used hinges.

Wear of the wheel bearings or loosening of the hub mounting screw. Change the ball bearing, tighten the hub screw.

Breakage of the suspension spring in front of the car. Replace spring.

Breakage of the shock absorber compression buffer. Change the compression buffer.

Wheel imbalance in the front of the car. Carry out wheel balancing.

Loss of straightness when moving on a horizontal roadbed

- Tire pressure varies. Adjust the tire pressure to the manufacturer's recommended value.

- The longitudinal inclination of the axis of rotation of the wheels ahead is broken. In the Volkswagen Polo, the angle of the longitudinal inclination of the axis of rotation of the wheels in front of the car is not designed. In cases of detection of such violations, tighten all nodal connections and fasteners. Replace used parts with new ones. If necessary, carry out repairs on the car body.

- The camber angle on the wheels in front of the car is broken. Recommendations correspond to the previous point.

- Uneven sagging of springs. Change the deformed spring.

- Tire wear varies greatly. Change your used tire.

- The rigidity of the wheel tire bead is unequal. Move the tire to the opposite side of the machine.

Excessive or uneven wheel tread wear

- Toe-in and wheel mounting angles in front are not correct. Adjust the toe and diagnose the factors that led to the discrepancy between the wheel angles.

- Excessive wear of ball bearings, steering rods and suspension bushings in front. Replace the elements that are out of order.

- Wheel imbalance. Carry out balancing.

- Hull deformation or suspension nodal connections are deformed. Perform body repairs and replace faulty suspension components.

- The shock absorber strut does not work properly. Change shock absorber.

Diagnosis of suspension parts in front of the car

Checking the operation of the suspension elements is carried out from below the machine. Install Volkswagen Polo

on a special lift or over a viewing hole. The wheels in front must be in suspension. For inspection, take a set of keys and a mounting blade.

When diagnosing the technical condition of the car, it is imperative to check the protection covers of the ball suspension bearings. They cannot contain mechanical deformations.

Conduct a study on the manifestation of cracks or the effects of touching obstacles on the road. Can be deformed:

- car body;

- nodal connections;

- suspension elements.

Study the position of rubber-metal hinges, rubber pads, suspension hinges carefully and in detail. Pay attention to the settling of the supports at the top of the suspension shock absorber struts. If gusts of the rubber surface are detected, rubber bulges, surfaces are trimmed from the end, an urgent replacement of used parts is necessary.

Absolutely not allowed:

- Rubber elements - indicators of obsolescence of rubber, the presence of acquired defects.

- Rubber-metal hinges - indicators of rubber obsolescence, cracks, protrusion of the rubber mass, tearing of the rubber mass from the metal base.

Elements that are out of order must be replaced immediately.

Diagnostic algorithm

Examine the appearance of play in the ball bearings. Install a mounting spade between the steering knuckle and the suspension arm, lean on the lever, make an attempt to swing the steering knuckle. Did you find a significant gap? Change the ball joint.

Using a mounting spatula, examine the hinge arms located at the front and rear. After placing an emphasis on the cross member, swing the suspension arm. The play that appeared in the hinges in front and behind indicates the need for an urgent change of silent blocks.

Inspect the hinge covers at the top and bottom of the stabilizer bar.

Examine the stabilizer strut hinges for gaps.

Swing the stabilization bar by hand, study in detail the pillows attached to the cross bar. If you detect knocks, then an urgent replacement of the pillows is necessary.

Examine the surface of the shock absorber strut boot.

Check the tightness of the shock absorber rod fixing screw.

We remove and dismantle the suspension shock absorber strut in front of the Volkswagen Polo

To replace the shock absorber strut, take the necessary set of tools: a set of keys, a hex key "No5", pliers, a mounting shovel.

Work execution algorithm:

- Lock the Volkswagen Polo with a handbrake and place supports against rollback under the wheels at the rear of the car.

- While the machine is at the bottom, loosen the wheel mounting screws and the wheel hub nut.

- Lock the hood cover in the same way with the stop in the raised position.

- Fix the mounting screws of the ball joint in the holes of the suspension arm and screw on the fasteners. You don't need to pull them out completely.

- Install the shock absorber strut in the reverse order according to this algorithm.

Now raise the car from the front, position and fix the stops securely, unscrew the hub screw, unfasten the screws securing the wheel, and dismantle the wheel itself.

Dismantle the glass cleaner arms and the grille of the air intake box.

Using the appropriate wrench, carefully turn the strut pin mounting screw and pull the pin out of the shock strut bracket.

Disconnect the brake hoses from the retaining grooves of the shock absorber strut. To do this, using pliers, unfasten the spring-type retainer. The brake tube comes out freely from the retaining member of the strut.

Pull the sleeve leading the wheel speed sensor out of the retaining element on the shock absorber strut.

Unclip the wheel speed sensor wiring harness.

Loosen the ball and arm mounting screws at the front of the machine and pull them out of the holes.

Pull the tail part of the hinge from the outside from the hub hole of the wheel in front. Attach the wheel drive to the body of the car. Do not allow the hinge located inside to be bent.

Without turning the head of the tightening screw, unscrew the fixing screw of the steering knuckle and shock absorber strut. Pull out the fastening screw.

Remove the screw cap on the top of the shock absorber strut.

While holding the shock-absorbing rod from scrolling, unscrew the fixing screw of the shock absorber strut, remove the stop.

Unclench the knuckle connection terminal with a mounting shovel and pull out the rack.

- shock absorber strut mounting screw at the top;

- fasteners (bolt and nut) of the shock absorber strut and suspension knuckle in front of the machine;

- mounting screws of the ball bearing and suspension arm in front;

- mounting screws of the anti-roll bar;

- wheel hub screw in front of the car.

Repair of the suspension shock absorber strut in front of the Volkswagen Polo

Often, do-it-yourself repair of a strut shock absorber does not give the desired result. We will deal with the change of shock absorber, suspension springs, support and strut bearing. You can change them yourself.

Work execution algorithm:

- Carefully examine the dismantled elements for cracking, gusts. Replace used items if necessary.

- Inspect the shock absorber carefully. If cracking of the surface, deformation of the body, streaks of oily liquid are found, change the used element.

- Perform installation work in the reverse order of this algorithm.

Remove the shock absorber.

To compress the spring, insert a special puller and press the spring.

Hold the shock absorber rod (it must not be turned) and unscrew the shock absorber rod screw.

Remove the strut mount, strut bearing from the stem, and strut cup at the top.

Remove the spring from the shock absorber rod, the protection cover that clamps the buffer.

It is also necessary to inspect the shock absorber strut. Place it in a vertical position and lower and raise the shock absorber rod several times. Movements should be smooth and there should be no jamming and extraneous noise. If problems are found, the shock absorber strut must be changed.

The spring must be replaced in the presence of cracking and deformation of revolutions.

Replacing the ball mount in front of the Volkswagen Polo

In situations where the change of the ball bearing is beyond doubt, it can be replaced in accordance with the presented algorithm. In this case, the algorithm will show the replacement of the ball wheel support on the left, and on the right, the replacement is performed similarly.

Work execution algorithm:

Replace all removed fixing screws with new elements.

Lower the car and rock it several times.

Tighten all connecting threads on the Volkswagen Polo while the car is on the ground.

Removing and installing the suspension arm in front of the Volkswagen Polo

If, after diagnosing the silent blocks in front and behind the car, reasons are found for replacing the elements with new ones, then dismantle the suspension arm in front and change the silent blocks.

Work execution algorithm:

- A special device installed in the spring assembly itself will help compress the spring.

- Unscrew the fixing screw of the silent block in front and pull it out of the hole.

- Have the wheel alignment checked and adjusted by a specialist workshop.

Unscrew the mounting screws of the ball and suspension arm support in front of the car and remove the support screws from the holes.

While holding the nut (so that it does not rotate), unscrew the mounting screw of the silent block from behind and remove the mount from the hole.

Remove the control arm bush at the front of the suspension from the cross member bracket.

Remove the arm bushing at the rear of the suspension from the cross beam bracket and dismantle the Volkswagen Polo arm.

Install the nodal connection of the suspension arm in front of the car in the reverse order of this algorithm.

Replacing the elements of the anti-roll bar suspension in front of the Volkswagen Polo

Work execution algorithm:

- Lock the car with a handbrake and put blocks against rollback under the wheels behind the car.

- Raise the Volkswagen Polo from the front and support it with supports. Remove the wheel.

- Remove the pivot pin mounting screw at the top of the stabilizer strut and shock strut bracket.

- Remove the pin from the shock absorber strut bracket.

- By analogy, carry out the dismantling of the fastener below.

- Remove the mounting screw, and pull the pivot pin from the bottom out of the cross member's stabilizer bar hole. Remove the stand.

- Mount the rack in the reverse order of this algorithm.

Algorithm for changing the anti-roll bars

- Lock the car with a handbrake and put blocks against rollback under the wheels behind the car.

- Raise the Volkswagen Polo from the front and support it with supports. Remove the wheel.

- Remove the engine compartment splash guard.

- While holding the hinge pin at the bottom of the anti-roll bar against twisting, unscrew and remove the screw, hinge pin at the bottom of the rack. Remove the strut and anti-roll bar from the opposite side in the same way.

- Rotate the stabilizer up.

- Unscrew the mounting screws of the steering system and suspension cross member and attach the assembly to the car body.

- Remove the rear engine mount bracket.

- Loosen the mounting screws of the ball bearings and suspension arms.

- Place a jack stand under the suspension cross member at the front. Unscrew the fixing screws of the cross beam and the car body. Lower the cross beam down (to the maximum).

- Unscrew the fixing screws of the stabilizer and the suspension cross member. Remove the stabilizer.

- Release the stabilization pads from the mounting brackets.

- Rotate and carefully unclip the stabilization pad. Remove it from the stabilizer. Remove the second pillow in the same way.

- Check cushions for deformation. Replace worn out elements with new ones.

- Mount the stabilizer in the reverse order of this algorithm.

Algorithm for dismantling and installation work of the steering knuckle of the Volkswagen Polo suspension

Tools needed to do the job:

- a set for dismantling the caliper and disc of the brake system of the wheel in front of the car;

- set of keys and socket heads;

- pliers;

- special puller for ball joints;

- mounting spatula.

Work progress:

- Apply the handbrake to the machine and chock the wheels at the rear.

- While the machine is at the bottom, remove the tension of the screw connections of the wheels and the hub nut.

- Raise the machine from the front and set the stops, unscrew the wheel hub screw, the fixing screws and remove the wheel.

- Disconnect and pull out the sensor for fixing the number of wheel revolutions from the knuckle.

- Remove the wheel brake caliper from the front of the car (no need to disconnect the brake hose) and fix it to the side. Can be attached to spring coils. Watch the tension of the hose, it should not be bent.

- Remove the brake disc.

- Unfasten the steering link end switch from the steering lever.

- Without allowing twisting, unscrew the fixing screw of the steering knuckle and shock absorber strut. Pull out the screw.

- Remove the pivot pin from the outside of the wheel hub hole at the front. Attach the wheel drive to the body. There should be no bending of the hinge inside.

- Pull out, using a mounting spatula, the rack from the connection of the knuckle of rotation. Dismantle the steering knuckle complete with hub and shield element of the brake system unit.

- Mount the elements in the reverse order of this.

- Have the wheel alignment checked and, if necessary, readjusted by a specialist workshop.

Changing the front wheel bearing of a Volkswagen Polo

The hub is equipped with an internal ball bearing, which is designed for a long service life. During its operation, additional adjustment and lubrication is not needed. And yet there are factors that affect the reduction in the life of the element. This is an overload of the machine's systems during prolonged movement at high speed, a trip on a poor-quality road surface. To perform the replacement, a special puller or mandrels of the appropriate size are required. It is not advisable to carry out installation with a hammer. The possibility of damage, warping during installation is great. Therefore, it is necessary to use a special tool.

Work progress:

- Dismantle the steering knuckle complete with the hub.

- Using a puller, press the hub out of the ball bearing.

- Pull the ball bearing snap ring out of the steering knuckle.

- Using a mandrel, press the cage out of the ball bearing from the knuckle.

- Thoroughly clean the elements, lubricate the inside of the knuckle and outside of the hub with grease.

- Mount the elements in the reverse order of this.

- Change the ball bearing on the other side of the machine in the same way.

Dismantling of the transverse beam of the front suspension Volkswagen Polo

Work progress:

- Raise the car with a hoist or raise part of the car from the front above the inspection pit.

- Remove the motor mudguard.

- Loosen and remove the strut mounting screw from below, pull the hinge pin out of the stabilizer hole. In the same way, extend the finger from the opposite side.

- Loosen the mounting screws of the suspension support bracket behind the motor and gearbox housing.

- Unscrew the fasteners of the steering system and the suspension cross member in front. Attach the steering mechanism to the body.

- Remove the auxiliary muffler.

- Fix the props under the suspension cross member at the front.

- Loosen the hanger bar fasteners at the front of the machine and body. Do this on both sides.

- Gently move the cross member forward in the direction of travel and remove it completely with a slight drop.

- Install the transverse beam and elements of nodal connections in the reverse order of this.

Before installation work, change the fastening screws of the connections:

- front and rear of the suspension cross member in front of the vehicle;

- ball bearings and suspension arms;

- steering mechanism and transverse beam.

Reading 4 min.

For 40 years now, the craftsmen from Wolfsburg have delighted fans of the famous German series with their refined and extraordinary works in the field of automotive engineering. One of the masterpieces of German fantasy is undoubtedly the Volkswagen Polo, which has earned countless awards over several generations.

Special attention should be paid to the sedan model. This example of the highest art was created especially for our Russian roads. The Germans took into account everything - from climatic operating conditions to the condition of the roadway and the quality of fuel resources.

Huge and meticulous work was done by representatives of the German automaker on the development of the suspension system for the Polo. It was necessary to create a high-quality unit capable of withstanding the extreme road (or, more precisely, "off-road") conditions in Russia.

In 2010, the hard-working Germans presented the Russians with a new miracle - the Volkswagen Polo sedan, which instantly, starting in the fall, scattered through the hands of motorists according to the "hot pies" principle. Not the last violin in the rise in sales was played by the updated suspension.

General view of the device

The era of classic double wishbones is coming to an end. To follow the fashion, manufacturers equip their "brainchildren" with new independent installations, called MacPherson. It came from the name of a famous American engineer from the Ford company.

It was with this suspension that the craftsmen from Wolfsburg equipped the Volkswagen Polo sedan in the front. Its design is simple: the same “swinging candle” principle on which the shock absorber strut works, one wishbone and a spring located above the steering knuckle axis. All the elements that soften the work of the suspension and perform the guiding function are assembled together, representing a compact monolith. Such an absolutely ingenuous scheme made it possible to significantly reduce the weight of the unit compared to the “two-lever” and, accordingly, reduce the cost of materials. Therefore, MacPherson is now installed on almost all modern cars - whether they are compact middle-class models or expensive SUVs.

The Germans also tried with the rear "crossbar". Having carefully studied our roads, they developed a completely new semi-independent suspension based on the fourth Golfik. And this is no longer “what if”. The track of the sedan has increased by about 34 mm, the strength and endurance of the installation components have increased, as well as its carrying capacity and quality of control. In general, the experiment was a success.