The safety of the driver and passengers depends on the condition of the pads. The car owner must know when to change the brake pads. Of course, the service life of these consumables depends largely on the quality, driving style and conditions. But to maintain braking efficiency, they need to be closely monitored. Let's look at what affects the life of the pads, how to replace them yourself.

Resource brake pads

The wear rate of these elements largely depends on the material from which they are made, as well as on the quality of the friction linings, the condition of the brake system cylinders, and driving style. Experienced mechanics in car services, as well as car enthusiasts, know how long pads can be used. Well, as for the resource, it is approximately determined by the mileage of the car. How much to change the pads can also be found in the documentation for the car. Lining wear also depends on the type of brake. For example, for disk systems, the average resource can be from 50 to 80 thousand kilometers.

Interestingly, for the resource is about the same, although the load on the rear axle is lower. The service life also depends on the conditions in which the car is used, on the driving style, as well as on the experience of the driver. If you accelerate intensively and often brake, then such driving greatly reduces the resource. Often, guys and girls who have just got behind the wheel of their car forget about it and can drive with the handbrake on. This does not have the best effect on the resource of parts of the brake system. Long braking on long descents does not have a very good effect on the state of the pads. How often to change pads? You can replace according to the level of wear. But it is better to carry out the installation as recommended by the manufacturer of a particular car. This procedure should be carried out on a run of 60 thousand kilometers. In practice, it turns out that on this run the pads can be either already worn out or still in normal technical condition.

We diagnose the condition

In service stations, diagnostics are performed by measuring the thickness of the friction lining.

To do this, the car is installed on a flat floor. One of the sides of the car is raised with a jack, or the car is immediately placed on a lift. Then the wheel is dismantled, and with the help of a caliper, the thickness of the pad and disc is measured. If the thickness of the pads is less than 2 mm, then replacement is necessary. Also during the diagnostics, the condition of the disk or drum is checked. If the thickness is less than a certain level, then the part must also be replaced.

Diagnostics without service stations and measuring instruments

To understand when to change the brake pads, you can do without a trip to the service. You can understand that the time has come, and the lining has become unusable, using a visual inspection. By the highlighted marks, you can easily understand that the friction lining is already very worn out. Also, experts recommend monitoring the level of brake fluid in the expansion tank. If it has decreased significantly, or the block has worn out and requires urgent replacement. Do not delay with repairs - this is your safety. You can check when to change the brake pads and in a different way.

To do this, you need to accelerate the car to about 80 km / h, and then perform emergency braking. The beating on the pedals will tell you about the wear of the elements of the brake system. But here the disk is worn out. A signal that the consumables of the brake system need to be replaced soon may be a change in the braking process and the behavior of the pedal. For example, if the car slows down more sharply or slower than usual, then it is worth considering. Characteristic dust with chips may form on the surface of the discs. If, in the process of reducing the speed, the grinding of metal on metal is clearly audible, then it is recommended to pay attention to the thickness of the installed lining and the very presence of the friction layer.

Pad condition monitoring system

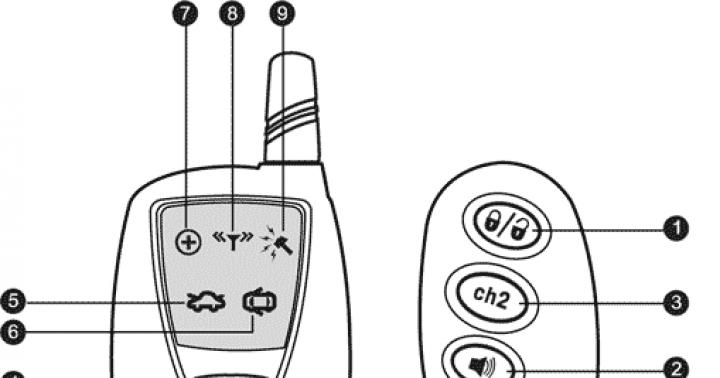

Many modern cars have electronic systems.

They take full care of the owner. Special sensors will tell the computer how much to change the brake pads, and he will display this information to the driver. On various models, they may simply indicate that wear is critical and replacement is needed right away.

The device and principle of operation of the sensor

The element is very simple - there is a soft metal core in the overlay. If the level of wear approaches critical, then it becomes the initiator of the circuit. The corresponding signal will be sent to the instrument panel. But even if the sensor is installed, one nuance must be taken into account. It doesn't work correctly every time. Sometimes there are crashes and false positives. This situation is due to the fact that the brakes are often in contact with moisture. The result is corrosion. And because of it, the sensors fail. It is important to know when to change the brake pads by visual inspection - this is much safer.

Before replacement

When installing the pads, it is necessary to diagnose the condition of all mechanisms and components in the system.

Be sure to check the condition of the brake disc. It is enough to measure its thickness with a caliper. It will also not be superfluous to make sure that there are no damages on the surface of the disk, and the element itself is not deformed.

Replacement process

To change the pads at the front, you will need a jack or any support with a lifting function. You also need a wheel wrench and a set of tools. Next - they hang out the front of the car, dismantle the wheel from the right side, take out the brake hose. Then press the piston with a balloon wrench. Do not forget that this will increase the level of the brake fluid. It is necessary to monitor the expansion tank.

How to change rear brake pads

Everything is not complicated here - the algorithm is almost the same for different models and brands of cars. The car is raised with a jack and the desired wheel is dismantled. Then the pins are unscrewed, the drum is dismantled from the hub. This is best done by tapping the drum with a hammer.

Next, the spring is disengaged from the shoe, and the first step is to remove the upper spring. Only after that the bottom. Then remove the front block and the spacer bar along with it. Next, removing the clamping spring from the rear, lower it. After that, the block lever is removed from the hole for the tip. Then the cotter pin is pulled out of the hole, the washer and finger are removed. The next step is to install new pads. The mechanism is assembled in the reverse order. To mount the pressure spring and pads, use the lower spring. She clings to the hook. Then the spring is pulled with a screwdriver and its hook is inserted into the hole on the block. The pistons are moved to the center of the cylinder by bringing the front and rear linings together with mounting blades. Here's how to change the rear pads - it's really easy. Even beginners can handle it.

The safety of movement by car depends on the performance of all its components and assemblies. Particular attention should be paid to the braking system, as it is it that helps to prevent most collisions. Replacing brake discs involves carrying out complex work to repair all parts of the system, as well as filling in a new fluid circulating in it.

Signs of worn discs

The brake system has its own lifespan. If for brake pads it is 20-40 thousand km., then for disks a little more than 100 thousand km. Sometimes replacement of parts may be needed much earlier. The main reasons for premature replacement of parts are:

- Poor quality brake pads.

- Hard braking and drift.

- Aggressive driving style.

- Damage caused by mechanical impact.

- Incorrect installation of parts.

- Using low quality pads.

- Unprofessional boring.

Also, brake discs are often changed during car tuning. It is believed that the disk system is more reliable than the drum system.

The most obvious indication of wear is a decrease in the thickness of the part. You can find out the thickness of the disk using a caliper. One of the main signs of wear is a change in the trajectory of movement during braking and an increase in the braking distance. Dips or sticking of the brake pedal, excessive consumption of brake fluid can also occur due to wear of the brake discs. Sometimes a damaged disc can be a source of vibration or beating in the steering column.

If you suspect a malfunction, you should contact a car service or proceed with the repair yourself.

What to look for when replacing

You need to purchase only discs that have quality certificates and meet international standards. When buying, it is important to select parts in accordance with the make and model of the car. Each machine has a different disc thickness. When purchasing parts, it is important to consider whether it is necessary to use new self-locking bolts. Since, along with the dismantling of the discs, other parts of the system are also removed, experts recommend that the brake fluid and pads be replaced at the same time.

It is necessary to change parts on the same axis at the same time, as overloading may occur. The replacement of disc brakes on the front axle is carried out much more often than on the rear, due to the increased loads on it. You should think about changing parts after the first groove, since turning a second time is unacceptable.

Rating of manufacturers of brake discs

Among the manufacturers of inexpensive spare parts for cars, it should be noted Ferodo, NiBk, Bosh. These brands have established themselves for more than one decade as manufacturers of reliable goods in the budget category. Among the manufacturers from the middle price segment deserve attention:

- Brembo.

- Lucas (TRW).

- Schneider.

Disk replacement process

All work should be carried out on a flat surface free of dust and dirt. The machine must be raised with a jack and fixed in this position with metal props. After the car has been fixed at a certain height, the brake system is dismantled and the piston is pressed in the working cylinder.

The next step in the repair work in the system is the removal of the brake pads. In the case when access to the brake disc is very difficult, the caliper should be dismantled. Usually the disc is connected to the hub with 1-2 bolts, so it is not difficult to dismantle it. The landing plane must be cleaned of dirt and dust, as a new part may not be installed correctly or not fit snugly.

The replacement process using the BMW E39 as an example (video):

The brake mechanism is supplied factory lubricated, so it does not require additional use of lubricants. It is not necessary to wipe the surface of the disk before installation, since a lack of lubrication can affect the fit of the part to the hub. Mounting brake discs requires extreme care. Overtightening the bolts can cause radial runout, as can undertorque. When installing, it is better to use a wrench with a dynamometer. The normal indicator is in the range of 100-120 Nm. After installation, it is better to check the amount of vibration using an indicator. For each brand of car, this indicator is individual and can be found on the Internet. In the case when the indicators are out of the norm, then the bolts should be tightened again.

After installing the brake discs, their working surface must be cleaned of grease. If necessary, the caliper can also be replaced. In the case of installing an old part, it is necessary to make sure that there is no rust or other mechanical damage on the surface of the mating flange. It is better to tighten all fasteners also with a wrench with a dynamometer. Replacement of brake pads is recommended to be carried out together with the installation of other parts of the system.

Pumping and running

Bleeding is needed both when replacing the brake fluid, and when re-equipping the entire system. In the first case, it is usually possible to visit a service center, then in the second case, it is necessary to carry out this manipulation at home. In the absence of the necessary unit, you can use the old fixture, which consists of:

- syringe.

- Tubes.

- plastic container.

To bleed the brakes, you must follow a certain sequence. Right-hand drive cars require pumping in this order:

- Left rear.

- Right front.

- Right rear.

- Left rear.

- Right front.

- Left front.

It often happens that after replacing brake pads and other parts, bleeding is required, but there is no assistant nearby. In this case, you will still need a cap that is identical to the one on the car tank. The syringe must be hermetically installed in the lid and screwed onto the tank with the liquid, having previously typed the solution into a home-made device. At the outlet of the pumped circuit, it is necessary to unscrew the fitting and install a container to collect the flowing liquid. Brake fluid is injected with a syringe.

Vehicle components and parts that are subject to constant wear and tear and work in extreme conditions require periodic replacement. It's no secret that reliable brakes are a must for any vehicle. Let's talk with you about how to change front brake pads and do it right. There is nothing complicated here, so even a beginner will cope with the work. But first things first.

How often to change pads?

Agree, there is not much point in changing new brake pads for several reasons. Firstly, the efficiency of the work carried out is reduced to zero, and secondly, it is money down the drain. Several factors affect the wear of this part. The main one is the manufacturer. Indeed, the wear rate largely depends on the quality of the brake pads. And it, in turn, depends on the manufacturer. Although this does not mean at all that the domestic manufacturer makes bad pads. They just wear out much faster, but are also cheaper. Another factor is driving style. If the driver prefers a relaxed style, then the front brake pads will wear out very slowly. At the same time, aggressive driving leads to their rapid wear and quick replacement.

When is it time to change pads?

If the engine oil must be completely replaced every season or after 8-10 thousand kilometers, then the situation with the brakes is somewhat different. Usually the need for replacement occurs earlier than indicated in the technical data sheet. But even if you drive calmly and rarely, then the pads need to be changed on time. For example, if it is advised to do this once every 5-7 thousand km, then this is how it should be done. In addition, if the thickness of the friction linings decreases to more than 1.5 mm, then such front brake pads must be replaced immediately. If you notice that the surface of the pads is oily, then they need to be changed. This is due to the fact that the adhesion of the pad to the caliper is significantly deteriorating, therefore, the braking efficiency becomes lower. If you began to hear a creak during a stop, then this is a clear signal that it is time to replace the pads.

Preparing for a replacement

Before starting work, you need to acquire the right tool. Everyone has the equipment they need. First of all, you need a jack. In addition, it is necessary to acquire lifting supports. Often, as the simplest analogue, a removed front wheel is used, placed under the front of the vehicle in the crankcase area. You also need a wheel wrench and a set of tools such as screwdrivers, box wrenches, etc. Since changing the front brake pads is quite simple, it will not take you much time. However, if no one has looked there for a long time, some problems may arise. Once you have acquired the right tool and are fully prepared, you can proceed.

Replacing the front brake pads: part 1

We leave the car on the handbrake, it is desirable to knock out a couple of bars under the rear wheels. Next, loosen the front wheel bolts and only then jack up the car. This is done this way because it is much more difficult to break the bolt on a raised wheel. After one side has been raised, we install supports under the car. At the same time, for better access to the brake system, the steering wheel is turned out. At this stage, it is necessary to assess the degree of wear not only of the pads, but also of other elements of the brake system. For example, cracks and aging of rubber on its hoses are unacceptable. They must be replaced as soon as possible. True, if you remove them, you will have to pump the brakes. It would be useful to check the condition of the caliper and discs. If everything is in order, then the front brake pads are replaced. Let's see how to do it.

Changing pads: part 2

At the first stage, clean the brake mechanism from dirt. This can be done in any way available to you, best of all with a metal brush. Look at the brake fluid level in the expansion tank. If it is at the maximum mark, then you need to pump it out a little. This is due to the fact that during the installation of new pads, it can pour over the edge. In addition, incomplete releasing of the wheels is possible. Next, you need to push the piston into the cylinder. Usually the piston is tight, but don't be alarmed, that's how it should be. To make it easier to do the job, use a screwdriver. Insert it between the caliper and the shoe and, leaning on the latter, pull the caliper all the way. Using a chisel or screwdriver, the corner of the lock washer is bent, and the lower bolt of the bracket body is unscrewed with a 13 spanner. The latter rises, and the pads are removed. In principle, we almost managed to replace the front brake pads.

Something else

After you have removed the old and inserted new pads, install everything in reverse order. Front brake pads (VAZ-2107, for example) are installed very simply on a domestic car. But periodically it is recommended to clean the brake mechanism from dirt. This is usually done during each replacement. Also, check the condition of the guide pin boot every time. If it is worn out, then it needs to be replaced. Remember that after you have replaced the front brake pads on the car (Ford, VAZ, etc.), the braking efficiency drops sharply. Then the pads will grind a little, and everything will fall into place. But at first, do not drive and try not to brake too hard.

Occasionally. It is this temporary concept that can be applied when an answer is required to the question of how much to change the brake pads. But, technology does not tolerate an approximate time frame. Some parts and technical fluids of a car have certain time or operational limits, for example, it is recommended to carry out in 1-3 years or 30-40 thousand km. run.

How to change brake pads

With regards to such an important detail as brake pads, timely diagnostics will tell you when to change them. Carried out by you yourself, it is not difficult. Actually, as an independent replacement of brake pads. Replacing the pads with your own hands will always help you to produce Instructions for replacing brake pads, which now exists for any car model. And, even if you don’t have it, then having studied the general ones, you will cope with this task.

Changing brake pads requires certain preparatory procedures that will ensure convenient and high-quality work for dismantling and mounting pads.

Tools and equipment

- Standard wrench set for your car

- Jack

- Lifting support ("goats")

- Hammer

- C-clamp or wheel wrench

Car preparation

- We hang the car with a jack and support. About the observance of security measures, probably, it will be superfluous to talk. These are your hands and fingers. This is your health.

- We remove the wheel, and the front of work appears to us.

- We turn the steering wheel so that it is convenient to get close to the brake mechanism

Direct replacement of brake pads

Before proceeding with the dismantling of the brake pad, swipe the protective cover of the caliper. Depending on the results of the diagnosis of the brake disc, make a decision.

- With the help of the reverse spade-shaped part of the balonnik, we squeeze the piston of the brake caliper. Gently insert the lever between the brake disc and pad. Please note that the level of brake fluid in the reservoir will rise at this point. Take steps to prevent spillage of TJ.

- We bend the edge of the stopper of the bolt securing the brake caliper bracket to the guide pin. Don't forget the brake hose. It must be removed from the bracket in which it is fixed.

- We unscrew the bolt securing the bracket, and fold the brake caliper down.

- We also produce here. If the old pads have uneven wear, then it is necessary to remove the protective rubber corrugations of the guide pins, rinse in gasoline and fill with graphite grease.

- After carrying out these activities, the installation of brake pads is carried out. New pads are highly recommended to be purchased from a store from the same production batch. The marking on the packaging will tell you about it. Thus, there will be no difference in the physical and mechanical properties of the pads.

- We throw on the brake caliper and carry out the installation work in the reverse order.

The efficiency of the brake system largely depends on the technical condition of the pads - elements pressed against the disc or wheel drum when the pedal is pressed. They are equipped with overlays that gradually wear out and at some point become unusable. The actual "life" of parts can be different and depends on many factors. Therefore, every motorist must monitor the brake mechanisms of the wheels and clearly determine when to change the pads. To control the wear of the linings, it is not necessary to go to the service station, you can check it yourself.

The brake shoe is a base made of thick metal with an overlay made of friction material attached to it. The components in it are rubber, graphite and mineral fibers, fastened with technological resins. How often to change these important parts for safe driving is indicated in the car's operating instructions. Typically, car manufacturers recommend the following intervals between replacements:

- on cars of the post-Soviet countries, it is planned to install new parts after 10-15 thousand kilometers;

- on foreign cars, whose spare parts are traditionally of better quality, the interval is from 15 to 25 thousand km;

- a separate category is powerful sports cars, where replacement is made every 5-10 thousand km.

Practice shows that the front brake pads experience a greater load than the rear ones, which is why they wear out faster.

Russian motorists should not rely entirely on the recommendations in the technical data sheet, since many factors affect the wear of the linings:

- The more aggressive the driving style, the faster the working surfaces wear out, because for 1 km of the road you use the brakes twice as often as the average driver.

- machine operating conditions. If you constantly drive on dirt and bad roads, then wear is accelerated due to dirt getting on the brake discs and drums.

- The quality of the material from which the part is made.

- Technical condition of brake drums and discs. When grooves appear on the surfaces of these elements, the linings wear out much faster.

- Permanent transportation of goods.

This raises the question of how much brake pads run in real life. The mileage range is quite wide - from 5 to 45 thousand km, depending on the brand of car and the degree of influence of these factors. That is why it is important to independently monitor the condition of the overlays.

This raises the question of how much brake pads run in real life. The mileage range is quite wide - from 5 to 45 thousand km, depending on the brand of car and the degree of influence of these factors. That is why it is important to independently monitor the condition of the overlays.

Part wear symptoms

In the process of driving, there are several signs by which you can navigate when it is time to change the pads of the front or rear brakes, or even all together. The symptoms are:

- a metallic rattle when pressing the pedal indicates the complete wear of the lining;

- increased stroke of the brake pedal, its vibration when pressed;

- when braking, there is a feeling that the front or rear of the car is being pulled to the side, and on a slippery road the car easily goes into a skid;

- a serviceable hand brake does not work;

- to stop, you need to put more effort on the pedal.

If during braking a metallic rattle and squeak is heard from the side of the wheels, then the question of how much to change unusable parts is no longer worth it. Replacement must be done urgently, since there are no more friction linings and the steel base rubs against the working surface of the disc.

Never bring the brakes to a state of complete wear, otherwise, along with the pads, you will have to replace the discs, which is significantly more expensive.

If you find one or more symptoms that indicate problems with the wheel brake mechanisms, check the condition of the pads. Recommendations for performing diagnostics are as follows:

- If the car is equipped with light alloy wheels with large holes, then nothing will have to be disassembled to inspect the front calipers. If necessary, jack up the machine to align the disc opening with the brake mechanism.

- Wheels with steel rims must be removed. Inspect the front brake pads and evaluate the thickness of the pads. If it is less than 3 mm, the parts should be replaced immediately. With a thickness of 3-5 mm, you can drive another 1-2 thousand km, no more.

- The rear brakes are disc and drum. The former are examined similarly to the anterior ones, while the latter will have to be disassembled. Remove the wheel and release the "handbrake", then unscrew the drum and gently knock it off the hub. Unlike the front pads, the rear pads must be changed at a thickness of 1.5-2 mm.

When, as a result of diagnostics, wear of elements close to the maximum is detected, but replacement is delayed for various reasons, drive carefully and without haste. It happens that a worn out lining comes off completely when you sharply press the pedal.

When diagnosing, pay attention to the working surface of the brake drums and discs. If its development is 2 mm or more (determined by the depth of the groove with a caliper), then the part must be replaced.

Other Reasons to Replace Pads

In addition to the situation with critical wear, it is necessary to change the brake pads in such cases:

- the thickness of the friction material is more than 5 mm, but the lining itself has begun to peel off from the steel base;

- cracks and chips appeared on the surface, the material began to crumble;

- on the parts there are stains of oil or brake fluid that reduces frictional properties;

- when the brake drum or disc has been replaced.

Another reason for replacement is due to the abundance of low-quality fakes in the auto parts market.. New pads purchased at an unreliable outlet, after 1-2 thousand km, begin to creak or squeak terribly, although the working part is still far from complete abrasion. The culprit is the material of the part, whose hardness is comparable to metal, which is why the surface is “licked” and a creak appears. If the elements made of unknown materials are not replaced, the output on the brake discs will increase sharply.

Many modern cars are equipped with special sensors that register a decrease in the thickness of the friction layer and give a signal to the driver when it reaches a critical level. This is also a reason to remove parts with worn linings and install new ones.

True, the sensors are often clogged with dirt and lose their efficiency, so it does not hurt the owner of the car to independently check the condition of the brakes.

True, the sensors are often clogged with dirt and lose their efficiency, so it does not hurt the owner of the car to independently check the condition of the brakes.

The first and very important rule: you can not change the front or rear brake pads one by one. It is necessary to put a set of new elements on the front or rear axle, otherwise, when braking, the car can strongly drift to the side. Even when one lining is worn out, all four must be replaced.. As a temporary option, it is allowed to install 2 new parts on one rear wheel.

When choosing new pads in the store, use the following recommendations:

- Products must match the model of the car and be sold in high-quality packaging with enclosed instructions. The inscriptions on the box are clear and without errors indicating Chinese origin.

- See that the friction material is of the same color, without foreign inclusions.

- The surface pressed against the plane of the disc must be flat. Small chips along the edges and indentations are allowed if they occupy no more than 1% of the total area of the working plane.

- Cracks at the interface between metal and friction material are unacceptable.

Ideally, you should buy original products in their original packaging. This will save you from unpleasant surprises, extraordinary replacements and emergencies during the operation of the car.