I liked small chips for simple chargers. I bought them from us in a local offline store, but as luck would have it, they ended there, they were taken from somewhere for a long time. Looking at this situation, I decided to order them for myself in small bulk, since the microcircuits are pretty good, and I liked them in work.

Description and comparison under the cut.

It was not in vain that I wrote in the headline about the comparison, since during the journey the dog could grow up mikruhi appeared in the store, I bought several pieces and decided to compare them.

The review will not have a lot of text, but quite a lot of photos.

But I'll start, as always, with how it came to me.

It came complete with other different parts, the mikruhi themselves were packed in a bag with a latch and a sticker with the name.

This microcircuit is a charger microcircuit for lithium batteries with a charge end voltage of 4.2 Volts.

It can charge batteries up to 800mA.

The current value is set by changing the value of the external resistor.

It also supports the function of charging with a small current if the battery is heavily discharged (voltage is lower than 2.9 Volts).

When charged to a voltage of 4.2 Volts and the charging current drops below 1/10 of the set value, the microcircuit turns off the charge. If the voltage drops to 4.05 Volts, then it will again go into charge mode.

There is also an output for connecting an indication LED.

More information can be found in, this chip has a much cheaper one.

Moreover, it is cheaper with us, on Ali the opposite is true.

Actually, for comparison, I bought an analogue.

But what was my surprise when the LTC and STC microcircuits turned out to be completely identical in appearance, both were labeled LTC4054.

Well, maybe even more interesting.

As everyone understands, it’s not so easy to check a microcircuit, it also needs a strapping from other radio components, preferably a board, etc.

And just then a friend asked to fix (although in this context it’s more likely to redo) a charger for 18650 batteries.

The native burned out, and the charge current was too small.

In general, for testing, you must first collect what we will test on.

I drew the board according to the datasheet, even without a diagram, but I will give the diagram here for convenience.

Well, actually the printed circuit board. There are no diodes VD1 and VD2 on the board, they were added after everything.

All this was printed out, transferred to a piece of textolite.

To save money, I made another board on pruning, a review with her participation will be later.

Well, the printed circuit board was actually made and the necessary parts were selected.

And I will remake such a charger, for sure it is very well known to readers.

Inside it is a very complex circuit, consisting of a connector, an LED, a resistor and specially trained wires that allow you to equalize the charge on the batteries.

Just kidding, the charger is in a plug-in box, but here there are just 2 batteries connected in parallel and an LED permanently connected to the batteries.

We will return to the native charger later.

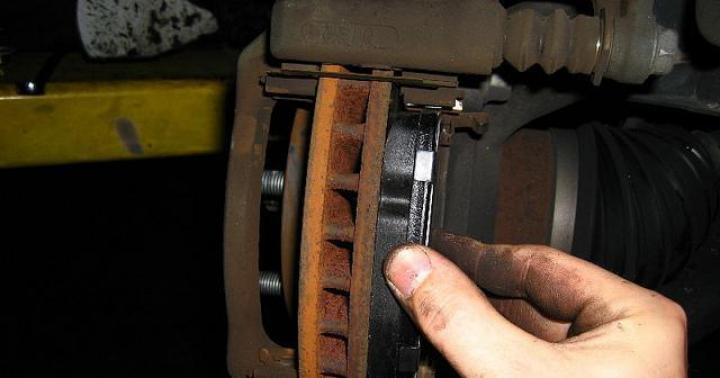

I soldered the scarf, dug out the native board with the contacts, soldered the contacts with the springs themselves, they will still come in handy.

I drilled a couple of new holes, on the middle there will be an LED indicating the device is turned on, in the side ones - the charging process.

I soldered contacts with springs, as well as LEDs, into the new board.

It is convenient to first insert the LEDs into the board, then carefully install the board in its native place, and only after that solder it, then they will stand evenly and evenly.

The board is installed in place, the power cable is soldered.

The printed circuit board itself was developed for three power supply options.

2 options with a MiniUSB connector, but in installation options on different sides of the board and under the cable.

In this case, at first I did not know how long the cable would be needed, so I soldered the short one.

I also soldered the wires going to the positive contacts of the batteries.

Now they go on separate wires, for each battery its own.

Here's how it turned out from above.

Now, let's move on to testing.

On the left on the board, I installed the mikruha I bought on Ali, on the right I bought it offline.

Accordingly, they will be mirrored on top.

First mikruha with Ali.

Charge current.

Now bought offline.

Short circuit current.

Similarly, first with Ali.

Now offline.

There is a complete identity of the microcircuits, which, well, cannot but rejoice :) It was noticed that at 4.8 Volts the charge current is 600mA, at 5 Volts it drops to 500, but this was checked after warming up, maybe this is how the overheating protection works, I have not figured it out yet, but the microcircuits behave approximately the same.

Well, now a little about the process of charging and finalizing the alteration (yes, it even happens).

From the very beginning, I thought to simply set the LED to indicate the on state.

Everything seems to be simple and obvious.

But as always, I wanted more.

I decided that it would be better if it was extinguished during the charge process.

I soldered a couple of diodes (vd1 and vd2 in the diagram), but got a small bummer, the LED showing the charge mode shines even when there is no battery.

Rather, it doesn’t shine, but flickers quickly, I added a 47 microfarad capacitor parallel to the battery terminals, after which it began to flash very briefly, almost imperceptibly.

This is exactly the hysteresis for recharging if the voltage drops below 4.05 Volts.

In general, after this revision, everything was fine.

Battery charge, red is on, green is not on and the LED is not on where there is no battery.

The battery is fully charged.

In the off state, the microcircuit does not pass voltage to the power connector, and is not afraid of shorting this connector, so it does not discharge the battery to its LED.

There was also no temperature measurement.

I got a little over 62 degrees after 15 minutes of charge.

Well, this is what the finished device looks like.

External changes are minimal, unlike internal ones. A friend had a 5 / Volt 2 Amp power supply, and it was pretty good.

The device provides a charge current of 600mA per channel, the channels are independent.

Well, it looked like a native charger. The comrade wanted to ask me to raise the charging current in it. It couldn’t stand the native either, where else to raise, slag.

Summary.

In my opinion, for a microcircuit for 7 cents it is very good.

Chips are fully functional and are no different from those purchased offline.

I am very pleased, now there is a supply of mikruh and I don’t have to wait until they are in the store (recently they disappeared from sale again).

Of the minuses - This is not a finished device, so you have to etch, solder, etc., but there is a plus, you can make a board for a specific application, and not use what is.

Well, in a toga, getting a working product made by yourself is cheaper than ready-made boards, and even under your specific conditions.

I almost forgot, datasheet, diagram and trace -

Progress is moving forward, and lithium batteries are increasingly replacing the traditionally used NiCd (nickel cadmium) and NiMh (nickel metal hydride) batteries.

With a comparable weight of one cell, lithium has a large capacity, in addition, the cell voltage is three times higher - 3.6 V per cell, instead of 1.2 V.

The cost of lithium batteries has begun to approach conventional alkaline batteries, the weight and size are much smaller, and besides, they can and should be charged. The manufacturer says 300-600 cycles can withstand.

There are different sizes and choosing the right one is not difficult.

The self-discharge is so low that they lie for years and remain charged, i.e. the device remains operational when it is needed.

"C" stands for Capacity

Often there is a designation of the form "xC". This is just a convenient notation for the charge or discharge current of a battery in fractions of its capacity. It is formed from the English word "Capacity" (capacity, capacity).

When talking about charging with a current of 2C, or 0.1C, they usually mean that the current should be (2 × battery capacity) / h or (0.1 × battery capacity) / h, respectively.

For example, a battery with a capacity of 720 mAh, for which the charge current is 0.5C, must be charged with a current of 0.5 × 720mAh / h = 360 mA, this also applies to the discharge.And you can make yourself a simple or not very simple charger, depending on your experience and capabilities.

Diagram of a simple charger on the LM317

Rice. 5.

The circuit with the application provides a fairly accurate voltage stabilization, which is set by the potentiometer R2.

Current stabilization is not as critical as voltage regulation, so it is enough to stabilize the current using a shunt resistor Rx and an NPN transistor (VT1). The required charging current for a particular lithium-ion (Li-Ion) and lithium-polymer (Li-Pol) battery is selected by changing the resistance Rx.

The resistance Rx approximately corresponds to the following ratio: 0.95/Imax.

The value of the resistor Rx indicated in the diagram corresponds to a current of 200 mA, this is an approximate value, it also depends on the transistor.

It is necessary to provide a radiator depending on the charge current and input voltage.

The input voltage must be at least 3 volts higher than the battery voltage for normal operation of the stabilizer, which for one bank is? 7-9 V.

Diagram of a simple charger on the LTC4054

Rice. 6.

You can solder the LTC4054 charge controller from an old cell phone, for example, Samsung (C100, C110, X100, E700, E800, E820, P100, P510).

Rice. 7. This small 5-leg chip is labeled "LTH7" or "LTADY"

I will not go into the smallest details of working with the microcircuit, everything is in the datasheet. I will describe only the most necessary features.

Charge current up to 800 mA.

The optimal supply voltage is from 4.3 to 6 Volts.

Charge indication.

Output short circuit protection.

Overheating protection (reduction of charge current at temperatures above 120°).

Does not charge the battery when the voltage on it is below 2.9 V.

The charge current is set by a resistor between the fifth output of the microcircuit and ground according to the formula

I=1000/R,

where I is the charge current in amperes, R is the resistance of the resistor in ohms.

Lithium battery low indicator

Here is a simple circuit that lights up an LED when the battery is low and its residual voltage is close to critical.

Rice. 8.

Transistors are any low-power ones. The ignition voltage of the LED is selected by a divider of resistors R2 and R3. It is better to connect the circuit after the protection unit so that the LED does not drain the battery at all. The nuance of durability

The manufacturer usually claims 300 cycles, but if you charge lithium just 0.1 volts less, up to 4.10 V, then the number of cycles increases to 600 or even more. Operation and Precautions

It is safe to say that lithium-polymer batteries are the most “gentle” batteries in existence, that is, they require mandatory compliance with a few simple but mandatory rules, due to non-observance of which troubles happen.

1. Charge to a voltage exceeding 4.20 volts per can is not allowed.

2. Do not short circuit the battery.

3. It is not allowed to discharge with currents exceeding the load capacity or heating the battery above 60 ° C. 4. A discharge below a voltage of 3.00 Volts per jar is harmful.

5. Battery heating above 60°C is harmful. 6. Battery depressurization is harmful.

7. Harmful storage in a discharged state. Failure to comply with the first three points leads to a fire, the rest - to a complete or partial loss of capacity.

From the practice of many years of use, I can say that the capacity of the batteries changes little, but the internal resistance increases and the battery starts to work less in time at high consumption currents - it seems that the capacity has fallen.

Therefore, I usually put a larger capacity, which the dimensions of the device allow, and even old cans, which are ten years old, work pretty well.

For not very high currents, old cell batteries are suitable.

You can pull out a lot of perfectly working 18650 batteries from an old laptop battery. Where do I use lithium batteries

I have long converted a screwdriver and an electric screwdriver to lithium. I use these tools on a regular basis. Now even after a year of non-use, they work without recharging! I put small batteries in children's toys, watches, etc., where there were 2-3 "tablet" elements from the factory. Where exactly 3V is needed, I add one diode in series and it turns out just right.

I put in LED flashlights.

Instead of the expensive and low-capacity Krona 9V, I installed 2 cans in the tester and forgot all the problems and extra costs.

In general, I put it wherever it turns out, instead of batteries.

Where do I buy lithium and usefulness on the topic

Are on sale. At the same link you will find charging modules and other useful things for DIYers. At the expense of capacity, the Chinese usually lie and it is less than written.

Honest Sanyo 18650