Systems and transmissions

The constant improvement of the chain as a mechanism made it possible to create the bicycle as it is now. Thanks to the chain drive, there was no need to sit on top of the wheel, and for better balance, the cyclist could comfortably sit between two wheels of equal size. It was the development of various gears that contributed to the effective control of vehicles. Now cyclists could easily conquer any climb, even with the greatest incline, and also enjoyed high speeds.

Transmission elements

Use of moving mechanisms

In the 15th century, Leonardo da Vinci worked to develop the idea of teeth and a mechanical chain working together. Surprisingly, this idea sounded long before the design of the first bicycle and only four centuries later found practical application. For the transmission to function effectively, the force created by the rider's legs must be correctly transferred to the rear wheel of the bicycle. The design must be created in such a way that the effort when rotating the pedals does not create discomfort for the rider.

To achieve this, engineering and technological developments were introduced and durable materials were used, which allowed chain transmission to become a common mechanism by the end of the 19th century.

Advantages of a chain drive

The drive itself, without gears, functions very effectively on slopes and flat surfaces. But at the same time, a cyclist, starting from a flat surface without a gear switch or starting an ascent with the wind moving towards him, is forced to pedal while standing, spending considerable effort on this. The driving speed drops to a minimum. The chain drive with gears allows the rider, regardless of the terrain or wind direction, to pedal throughout the ride at a rhythm that is convenient for him. On the first high-wheel bicycles, the pedals were placed on the wheel itself, meaning one revolution of the wheel was equal to a full rotation of the pedal.

The gear ratio can be changed by the cyclist himself at his request. For example, when conquering a steep slope, the rider can, in which the pedals will rotate easier and more often, but the wheel itself will rotate more slowly. That is, there will be an easy transfer. Heavy gear is selected when it is necessary to cross flat terrain or when going downhill: several rotations of the wheel occur per full turn of the pedal. In the transmission, the large sprocket is in front, the small one is in the back. To spin a wheel, a certain force is required, and the more force you create, the more revolutions the wheel will make.

Required number of teeth

Exploratorium scientist Paul Dougherty explains gear ratios using a personal bicycle as an example. This method allows you to determine the number of driving (front) and driven (rear) teeth. For example, Paul suggests considering a gearing option where the gear ratio is 54:27. Based on this ratio, it becomes clear that the number of teeth on the front sprocket is 54, and on the rear sprocket – 27, that is, with a full rotation of the front sprocket, 54 teeth pass around the circle of the drive sprocket. At the same time, the driven sprocket makes 54:27 = 2 revolutions, that is, the rear wheel turns twice. This ratio can be reduced to 2:1. But if the driven sprocket has 11 teeth, then in this case the gear ratio will be closer to 5:1.

It is worth paying attention to the fact that for every full revolution of the drive sprocket, the driven cassette rotates twice as much.

France Twist and Penny Farthing

Paul Dougherty claims that this method of calculating gear ratios is one of many similar ones. In the UK, the gear ratio is calculated based on the diameter of the large wheel of bicycles called penny farthings. It was stated above that Paul Dougherty used a 2:1 ratio. That is, when transforming, it was necessary to double the diameter of the rear wheel. This means that a chain drive with a 2:1 ratio on a 27-inch rear wheel would be considered a 54-inch. So, having determined the circumference of the wheel, we multiply it by the gear ratio. That is, if we use Paul Dougherty’s method with a gear ratio of 2:1 and a driven wheel circumference of one and a half meters, we obtain the driving wheel circumference. It is equal to three meters. This method, unlike the English system, helps to determine the distance traveled or understand how far you have gone.

The metric system was used in France. Metric is the decimal system of units (SI), which is based on the use of the gram and the meter. Today the SI system is called upon throughout the world. In this system, the conversion consists of a product or division by the number 10, that is, in a decimal fraction the decimal point is simply shifted.

When it comes to threads, the metric system indicates its pitch and diameter. The thread pitch is the distance between the threads. Take, for example, the popular M5 thread size, which is used for cable anchor bolts, for fastening a bottle cage, in the mounting holes of the wing or trunk, speed switch levers, is designated M5.0X0.8, that is, the diameter is 5 mm, and the distance between thread turns is 0.8 mm.

Chain drive in transmission and its operation

A chain mechanism is a mechanism that connects the pedals to the driven wheel. Thanks to the chain mechanism, the force acting on the pedals is transferred to the rear wheel. Thus, the bicycle is set in motion.

What you should take:

In order to have a minimal idea, as well as understand the essence of chain transmission, you need to prepare the following items:

- several spools of thread. One coil should be either larger or smaller, and the remaining pair should be of the same size;

- rubber bands;

- flat boards of wood;

- a pack of nails.

Spools of thread are fixed on a wooden plane using nails at a considerable distance from each other. They must be strengthened in such a way that when they are connected, the elastic does not stretch, and the coils themselves can move freely and easily. After this, connect the two coils using an elastic band.

Observe how one coil behaves relative to the rotation of the other coil. What is visible? Do they move in unison, with the same speeds and direction of rotation?

In what ways can transmission be investigated:

- It is necessary to make marks on both coils using a special marker, and then turn them. For this, two coils are used, one of which is larger in size than the other. So how does one coil rotate relative to the other?

- Perform one rotation on the elastic band so that it describes a figure eight. How did this circumstance affect the rotation speed and direction of movement of the coils?

- Inspect your bike's chain and derailleurs. Is there a similarity with a bicycle transmission? What's the difference between them?

Diagnosis of the transmission system.

Gears help the cyclist pedal most efficiently, allowing him to easily and quickly conquer the steepest climbs and some obstacles.

What do you need to take to demonstrate how the gears work? What materials should be prepared:

- a bicycle equipped with gears;

- a bar of soap and a roll of tape;

- a sheet of paper and a simple pencil.

Experiment

It is necessary to set the gear so that the drive sprocket is the smallest and the driven sprocket is the largest. Use a piece of tape or chalk to mark the top of the rear wheel. At the same time, the pedals should be fixed. Now you need to make a full revolution of the pedals and count and record the number of rotations made by the rear wheel.

At the next stage of the experiment, place a large star in front and a small one in the back. How many revolutions does the rear wheel make with a full revolution of the pedals? Which of the two combinations is most suitable for conquering a steep climb? Which one is effective for sprinting on flat terrain?

Conducting an experiment with mid-range gears.

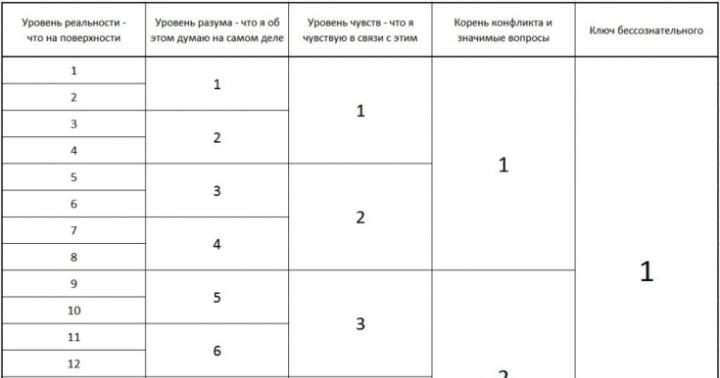

To do this, you need to draw a table where the gear ratios and the number of full wheel revolutions per pedal revolution will be entered. Why, in your opinion, did the development of a mechanism such as a chain drive contribute to the improvement of bicycles?

Cadence

The cadence of the pedals is called cadence. The gear system allows cyclists to maintain the most optimal rhythm of movement (pedaling speed), which makes pedaling very productive. Today, riders have different opinions about what the rhythm of cycling should be. However, the vast majority agree that cadence is most important. From the words of Paul Dougherty: “The human body delivers the greatest amount of energy to pedal in the most efficient manner at a given cadence. I try to keep my cadence between 60 and 90 cycles per minute.". He also notes that most recreational cyclists pedal too slowly, inefficiently, wasting energy in high gears.

The cadence of professional cyclists is very high; for road racers it is in the range of 75–120 rpm. A completely different cadence indicator in mountain biking.

Ruthie Matthes, cross-country world champion explains: “In mountain biking, you often go up a very steep climb and then go straight down a fast descent, sometimes without even pedaling. You just balance on the bike, without brakes, as fast as you can. Mountain biking uses a wide range and variety of cadences.”

Trial bike with Driven transmission

The Danish company CeramicSpeed, which produces bearings and bicycle parts, presented a working concept of a bicycle at the Eurobike 2018 exhibition with a high-speed transmission that does not have a chain or switches. The transmission is 13-speed with a lightweight aluminum-carbon fiber shaft that transmits rotation from the drive sprocket to the rear wheel cassette. The developers claim that the efficiency of rotation transmission in the new transmission is 99 percent.

Today there are several options for high-speed bicycle transmissions, the most common of which is a chain with one or two speed derailleurs. In this version of the transmission, rotation is transferred from the drive sprocket to the rear wheel sprocket block via a chain. The design of such a transmission is relatively easy to maintain, although it is not very efficient - when pedaling, part of the power is spent on overcoming friction between the chain and sprockets, between links, as well as on stretching the metal chain itself.

On average, chain drive efficiency is about 70 percent, but can decrease or increase significantly depending on the quality of bicycle components and materials used. For example, expensive professional road bike transmissions can be up to 98 percent efficient. At the same time, the efficiency indicator is not constant and decreases over time as the chain and sprockets become dirty, lubricant is used up and lost.

The new transmission presented by CeramicSpeed is called Driven. It is a type of shaft bicycle transmission and provides the ability to change gears. The driving and driven “stars” are made in the form of disks with hooks on one of the planes, evenly distributed around the circumference. The leader has one ring of protrusions, but can have several. The driven “star” is equipped with 13 rings of protrusions.

The driving and driven disks are connected by a shaft. In the front part, the shaft is equipped with a disk with bearings on the edge, which, with their outer rings, fit into the grooves between the hooks of the drive disk. The same disk is installed at the rear of the shaft. It can move forward and backward along the shaft axis. Thanks to this, it can engage with different rings on the driven disk, due to which the transmission ratio changes, similar to a conventional bicycle chain transmission. Driven has a total of 21 radial bearings.

The developer assures that the transmission is designed to transmit power of more than one thousand watts. For comparison, during a normal race the average power generated by a cyclist is about 250 watts. The Driven transmission is undergoing initial testing. How it will work in rain and when it gets dirty, and whether it will withstand load surges, is still unknown. It is likely that transmission maintenance and repair will be quite difficult and expensive due to the need to flush or even replace the radial bearings.

The presented bicycle with a new transmission is made aerodynamic. Judging by the design of the frame and the shape of the steering wheel, it can be assumed that it is intended for competitions with separate starts, that is, it is designed for semi-professional and professional levels of use. It can be assumed that the use of a bike with a Driven transmission will be prohibited in official races. The fact is that the hooks of the driven “star” can pose a serious danger to cyclists during an accident - during rotation it actually turns into a meat grinder.

In professional road cycling, the use of disc brakes has long been prohibited for safety reasons. Cyclist racers often use rafting to save energy at the expense of the opponent in front. With this technique, one rider walks closely behind the other, and if the distance is not maintained, a collision is possible. It was believed that in such a high-speed collision (in road racing the average speed is usually 35-38 kilometers per hour), cyclists could seriously cut themselves on the brake disc.

In January of this year, German engineer Andrea Mocellin developed a folding bicycle wheel. It is assumed that such a wheel will greatly facilitate the transportation of a bicycle, for example, in the trunk of a car. The rim of the 26-inch wheel, called Revolve, consists of six sections connected by a metal frame. The wheel can be pulled by the central part and folded. The Revolve is attached to the bike using a standard quick release.

Vasily Sychev

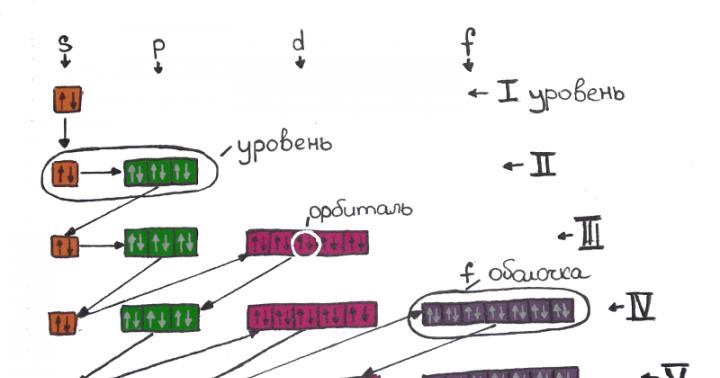

Transmission and gear system. General information

This is a group of components that ensures the transmission of force from the gears of the system to the gears of the ratchet or cassette using a chain. The front and rear derailleurs regulate the angular velocity ratio of these gears.

Gear shift

The number of gears or speeds is determined as follows:

NUMBER OF FRONT GEARS x NUMBER OF REAR GEARS.

During strong jumps, the chain can fly off, so jumping cyclists refuse to change gears. On other MTB and road bikes, the number of rear sprockets depends on the level of equipment. On road bikes, sometimes there is no smallest chainring in the system, because it gives the lowest speed.

So, we figured it out. Bicycle with 21 speed has 3 front sprockets and 7 rear But is it possible to use all these speeds? The answer is no! I'll explain why. All the stars in the front are parallel to each other, and the same is true in the back. When transferring 17(small star in front and small in back) the chain will be very bent.

| Driving in such (oblique) gears wears out all transmission components much faster. |

Gear shift technique

When changing gears, you press the shifter handle (or turn the gripshift), then turn the pedals without effort, and then release the shifter handle. The pedals must be turned idle, otherwise the chain will be tense and it will be difficult for the derailleur to move it, it may bend.

If you don't know how many gears your bike has, how to use them correctly or how many gears you actually need, please don't worry about it - you're not alone. Therefore, in our today’s publication, which is not at all standard for automotive material, we will try to explain in simple words to all interested readers how the gear shift system works on bicycles, what useful facts it is advisable to know about it, and why these bicycle gears are somewhat similar to automobile transmission. And so, let's take a closer look at all these switches, sprockets, chains, it is with their help that you set your bike in motion. Of course, if you have one.

Understanding the basics of bicycle gearing and how changing the size of your front and rear cassette chainrings will affect your pedaling will help you select the most appropriate gear ratio for your fitness and enable you to adapt to challenging trail conditions.

If you got a car before you got a bicycle, the task of choosing a two-wheeled sports equipment or a vehicle for recreational walks may not be as simple as it might seem at first glance. This goal is actually absolutely non-trivial.

Not only that, when choosing a bicycle, you must first decide on the direction of its use, the so-called riding style, since there are so many of these styles these days that you can simply get confused. There are simply a great many of them! This can be riding on the highway on a racing or semi-professional bike, or riding cross-country on cross-country bikes, as well as various extreme types of cycling or simply using walking city models, both for men (boys) and for women (girls) of any age.

For each of these models and areas of use of a bicycle bike, a transmission of various types will be used, i.e., from the simplest single-speed (according to the same principle of operation as was once installed on the Ural bicycle and similar simple “old bikes”) and up to various multi-speed versions of chain drives. Why do we need these multi-chain shifters on bikes, how do they work, and what type of drive is best? Let's take a look together.*

*We will specifically touch only on the basics of a bicycle transmission. Namely, peripherals, such as belt drives, all-wheel drives, and such types of transmissions as we mentioned above. , we will not touch upon this topic specifically now.

Bicycle Gearing: The Basics

How many speeds does my bike have?

Let's start studying the bicycle transmission from its very basics, namely? From the number of speeds. How to determine or calculate how many speeds there are on a bicycle? This problem is for the first grade of the cyclist school. It is very easy to calculate the number of speeds on a bike; to do this, simply multiply the number of sprockets at the rear by their number at the front. Thus, if you have in front Three Stars(some cyclists call this element “chainring”, the essence does not change), and a cassette is installed at the rear 10 stars, then your bike has 30-speed transmission. In other words, we will say that each of these ten rear sprockets can be used in combination with each of the three front sprockets when driving.

This simplest algorithm is suitable for calculating any multi-speed bicycle gears, for example, there are 2 stars in front, 11 in the rear, which means that the bicycle has 22 speeds, and so on, etc.

Why do you need a multi-speed transmission on a bicycle?

Why do you need such a large set of stars? 30 gears - isn't that a lot? Passenger cars have everything. This question can be answered in a nutshell; the need for a particular number of gears is directly dictated by the style of skating itself and the scope of their sports application. This wide range of gears allows competitive cyclists to maintain a comfortable pedaling speed (called cadence - the number of revolutions per minute a cyclist makes while riding) regardless of incline or terrain, something that no single-speed chain drive can provide.

High gear, sometimes called “big gear” by cyclists, is most optimal when descending or riding (moving) at high speeds. The highest or largest gear on a bicycle is selected by combining the largest front sprocket with the smallest rear sprocket in terms of the number of teeth. For example, it (transmission) can be expressed by the ratio “53×11”.

And also vice versa, the combination of the smallest size front gear with the largest size rear sprocket gives access to the lowest available gear, which will help you pedal without straining even on very steep climbs.

Let's immediately clarify one thing, namely, that having a large number of gears clearly does not mean that your bike will be faster. More dynamic - definitely yes, faster - no way! A bike with 30 or more gears is not indicative of a machine designed to break land speed records and outspeed a bike with only one gear, and that's assuming the bikes use identical gear ratios.

Having more gears can help you get up and down hills, but they won't make you go any faster.

We are talking specifically about efficiency itself and having a much larger and wider range of gear choices for the specific situation that an athlete-cyclist has to contend with on the track or off-road. Just like cars, bikes benefit from low gear starts when accelerating, from rest, or when climbing a steep hill, while the multi-speed transmission allows you to reach the highest possible speeds without any excessive pedaling. , because, even before reaching maximum speed, you can switch to a higher gear over and over again.

Continuing with our comparison of a bicycle and a car, using too low a gear at high speed usually results in high fuel consumption for the latter (the car). The same goes for pedaling a bicycle. If you pedal too fast, you will quickly run out of steam. From here there is only one conclusion - the more gears in the transmission, the greater the opportunity to find the right gear for a specific situation, that is, speed and cadence for a comfortable and efficient safe ride.

In a broader sense, it all comes down to the fact that during the reign of 5- and 6-speed cassettes, the range of 12 - 25 teeth on the sprockets was usually achieved by adding a significant number of teeth to each subsequent rear gear, which led to a sharp change in loads . Such systems lacked smooth switching and continuity of progression. Modern 10 and 11 speed cassettes today solve this problem. Therefore, riding or moving around on them is much more comfortable and convenient. And also, all these modern systems wear out much slower.

Why do some people choose a single speed bike?

It is interesting that in our modern age, with the development of all kinds of gear shift technologies for a bicycle (we will give examples of them below), some type of people prefer to use only a single-speed transmission, the so-called “singlespeed”. These bikes have only one gear, which is selected by a certain ratio of sprockets - front and rear. The correct selection of the tooth ratio allows you to start quite quickly and accelerate to a maximum speed of 30 - 34 km/h.

Single-speed bicycles are mainly popular among those who live in flat areas and ride their two-wheeled iron horses only around the city, or engage only in extreme types of cycling, on the so-called “stunt bikes”.

Such a single-speed bike also has quite a few advantages:

1. Cheap.-Indeed, it is much cheaper to assemble a single-speed bicycle. How much? Everything will depend on the level of components. If we take really high-quality ones, i.e. racing components of the highest level from the Shimano line - XTR, then you get something like this (calculating the cost of multi-speed bicycle components):

I. The Shimano XTR system with 11 speeds will cost about 25 thousand rubles.

II. High-level carriage (it includes bearings, a housing with threads to fit into the frame) - approx. 3 thousand 500 rubles.

III. Front sprocket (Shimano XTR) - 5 thousand rubles.

IV. XTR level chain for 11 speeds - 3 thousand rubles.

V. Shimano XTR rear derailleur - 15 thousand rubles(at discounts), the cost without them during the cycling season can reach up to 22 thousand rubles.

VI. But you also need a so-called “shifter” - a speed switch (about 6 thousand 500 rubles), cables, shirts and of course the rear cassette, which is also not cheap - 5 thousand rubles.

In total, just one transmission will take about 63 thousand rubles! Yes, at the moment this is the price list for really high-quality racing-level components (parts). They will be strong, light, work great, and so on. But for the same money you can buy a complete stunt bike with one gear, and with equally high-quality and more durable components. Do you feel the difference?

2. Reliability.-Do you know what captivates many people with the Kalashnikov assault rifle? No, they didn’t guess, not with their long-range shooting accuracy. It is practically considered simply trouble-free in any difficult operating conditions. The same goes for single speed bikes. There's simply nothing to break there! Remember the old Soviet bicycles that you probably saw at least once in the outback. They serve their owners for decades... It’s not for nothing that extreme sports enthusiasts around the world almost always use singlespeed bicycles for their stunts.

3. Maintainability.-It is not difficult to repair a bicycle with one gear. And spare parts for it are inexpensive. The same cannot be said about “multispeed”. Even if we take an approximately average price range of components that are acceptable in terms of reliability, such as Shimano XT or SRAM X9, then it is still not cheap. For one rear derailleur from one of these manufacturers you will pay approximately 6 thousand rubles.

4. Racing ambitions.-You will be surprised, but even the racers themselves sometimes use a single-speed transmission. They do this to reduce the weight of the bike itself (all additional attachments, no matter how light they are, still have weight) and to eliminate the risk of problems with gear shifting. In this case, choosing the correct gear ratio is critical.

5. And finally the last thing, A track bike initially has only one gear. This is not an advantage - it's just a fact.

As a result, with the correct ratio, the cyclist receives smoother and more accurate pedaling, without any difficulty when the chain jumps to a larger or smaller sprocket. This means that pedaling in certain driving modes will be more efficient.

Some win and some lose

If you have never been interested in cycling, you will probably be surprised by the fact that despite such a large number of gears, it turns out that not all of them are necessary and can be ridden.

The reality of this multispeed transmission is that overlapping some ranges with a certain combination of sprockets is almost inevitable. For example, if there are 33 gears, sprocket combinations such as 53×19 and 39×14 are actually gears with the same ratio. That is, their (gears) will be identical, as will their maximum speed.

In addition, you cannot use, at least constantly, the outer rows of stars diagonally. For example, the leftmost front sprocket and the small sprocket, i.e. the rightmost sprocket on the cassette. Such a misalignment will create excessive tension on the chain, which will increase the wear of the teeth on the sprockets, overload the spring of the rear derailleur leg, and the expensive transmission on your bike will wear out more.

The old advice from the seasoned ones is still relevant: - Avoid “crossing the chain.” (See the left picture illustrating this - you can’t do this):

Also, one more tip that will help you preserve an expensive component (segment) for as long as possible: - Do not shift gears in the middle of an incline, this creates a very strong load on the transmission itself, on the derailleurs and on the chain. To avoid this problem, downshift early before starting a grade.

As you can now see, you do not have all 33 gears at your disposal and will not always be able to use them. It’s probably impossible to call this a marketing ploy by the bike manufacturers, or some other kind of deception, it’s just that such a technological flaw already lies initially in the very gear shifting scheme of the bike and there’s no getting around it now.

Moreover, a large (total) number is not an end in itself; what is much more important is that the transmission has a continuous progression in load, which can only be achieved by an extremely minimal discrepancy between the number of sprocket teeth on the rear cassette.

What are the types of gears?

These days there are tons (many) options for bicycle transmissions, so choosing the right one for your cycling activities will not be difficult. Let's go over the main types of transmissions.

Standard double

The two stars at the front are paired with 11 stars at the back. The standard double layout is usually the preferred choice for racing bikes, offering the largest chainrings at the front to maintain high speed.

Triple scheme

Once you have three chainrings, you have the option of shifting to a small chainring. By throwing the chain over the large rear sprocket, you get an all-terrain bike that can climb very steep hills.

Compact

Compact version of the first type transmission. Here both chainrings are reduced in size. Usually the internal one is represented by 34 - 36 teeth, respectively, the external one - 48 - 50 teeth. A very popular scheme today, mainly for amateur athletes, which allows you not to reduce your cadence even on steep climbs.

Singlespeed

Everything is clear here. Two stars and one gear. No switches or other “extra” parts.

Planetary hub

Technically complex, heavy and difficult to maintain (however, it does not require frequent servicing), it is an expensive transmission element, most similar to . Switching occurs without external “switches” or any other auxiliary mechanisms. Currently on the market there are two, four, seven, eight, nine and twelve-speed planetary hubs from the companies SRAM, Shimano and Sturmey-Archer. There are even 14-speed planetary gearboxes from Rohloff. The cost of one such bushing will unpleasantly surprise you - about 90 thousand rubles.

Suitable for touring bikes rather than racing bikes.

Dictionary of cycling terms

"Chainring" (front sprocket): a toothed ring on the front of a chain drive, attached by rivets or bolts to the drive connecting rod.

Cassette: a group of stars on the rear of the transmission. It may contain a different number of sprockets, mainly from 7 to 11, of various sizes (differing in diameter and number of teeth). Slide onto the rear hub drum.

Star block with ratchet: another term for a rear sprocket assembly. It actually refers to an older technology in which the ratchet drum sits in a cassette and, in turn, is screwed onto the hub axle.

Switches: The front and rear derailleurs do all the hard work of moving the chain from one sprocket to the next.

Star: refers to a single gear in a cassette/ratchet.

Coefficient: describes the relationship between the rear cassette sprockets and the front sprockets. For example, "53×12", or the stars on the cassette (11-25).

« t": an abbreviation for the word “teeth” - teeth (located on an asterisk). Used to indicate the number of teeth on a star, for example - “23t’.

Effective use of bicycle gears will help you go uphill easily and safely

Transmission: a term that groups into a single system all the moving parts that combine the cranks with the rear wheel, and therefore drive the entire bicycle through the front sprockets, chain, cassette and derailleur.

Cadence (pedaling): pedaling speed per unit of time, measured by the number of revolutions of the crank arms per minute.

STI lever: short for "Shimano Total Integration" is the term for Shimano's design of integrated brakes and shifters for road bikes. The term is sometimes applied to shifters/brake levers regardless of brand.

Ergolever: The brand name of Campagnolo, a company specializing in the production of attachments for road bicycles. Brand version of integrated gear shift and brake levers.

DoubleTap lever: SRAM's piece of the shifting technology pie uses the same lever for upshifts and downshifts.

Progress does not stand still and certain innovations in the bicycle market appear on the market with equal frequency. Somewhere such inventions find their buyer and remain. And some new parts or even entire systems do not gain popularity and distribution and disappear back into oblivion. Now a new miracle has appeared on the bicycle market - an automatic transmission for a bicycle. But how necessary is it at all?

Automatic transmission - is it really necessary?

The main idea of such a box was initially an attempt to protect gear shifting from dirt, debris, dust, mechanical damage and metal corrosion. There is already a planetary hub, but it is designed in such a way that the entire weight distribution of the bicycle is strongly pulled towards the rear wheel of the bicycle.

In the case of automatic shifting, the center of gravity is exactly in the center of the bike, improving its maneuverability and appearance.

The main disadvantage of such an attribute on a bicycle will be the appearance of additional excess weight of the device - gearboxes weigh about 2.5-3 kilograms, increasing the weight of the iron friend by an average of a quarter. If you do not take into account the heavy mountain options, downhill and cross-country, where 3 kilograms does not matter so much, then the average bike has 9-13 kilograms.

Advantages of the box

Such gearboxes require a frame built specifically for them, which has not yet been invented. The existing box looks wrong, and the frame itself looks less stable. Unfinished triangles make you think that such a frame will more easily crack at the most inopportune moment. But everything is not as bad as it might seem at first glance. Automatic transmissions were not invented out of idleness and they are not at all useless. Among the obvious and undeniable advantages are:

- More security. The maximum closed box protects the owner from falling as a result of trying to change gear with a twig stuck in the star.

- Only the exposed parts of the transmission need to be serviced. Anything that is locked in a box may not be opened or serviced for years. The manufacturer himself states that you will only need to add oil to it once a year.

- Parts need to be replaced much less frequently.

- Properly distributed weight.

- It is easy to adjust to exclusive chain replacements - belts, ropes and other eye-catching things.

- In this case, the chain or its replacement will definitely not dangle.

- Switching gears is possible without pedaling, in any weather and in any contamination of the chain.

- The gear shift scale is intuitive and gears are not repeated.

- The weight of the rear wheel has been reduced as much as possible and unnecessary equipment that could easily break has been removed from it.

- It can be repaired, moreover, this bike has a 70-kilometer warranty. You can always return a defective product.

However, do not forget about the significantly higher price compared to conventional bicycles. To ride such an exclusive, you will have to pay a decent amount. In addition, such devices have worse efficiency, but this becomes noticeable only in big sports. A person who took a bicycle for riding with friends or for an independent long journey will not even notice this difference, since it is up to 7%.

How it works

The operating principle of automatic switching is not very different from a similar unit in a car. The box is assembled using three shafts. The gears have straight teeth, which ensures better gear shifting. The lower shaft is responsible for the pedals, the gears of the upper shaft are rigidly attached to it along with the star. Between them there is a third shaft, which moves freely and is needed to connect the remaining parts together.

There is also no rear derailleur, so the chain is tensioned well enough and will not fly off-road. The transmission is completely open - chain, drive and driven stars. They will have to be regularly maintained, monitored for condition and readiness for work. But this must be done in any bike, there is nothing surprising about it. But at the same time, the transmission is performed in a broader form - its goal is no longer flexibility, only the transfer of forces to increase speed.

Different models usually have from 9 to 18 speeds. The speeds are switched sequentially, one after another the necessary gears are connected and disconnected, fixing the desired one on the middle shaft. But the speeds correspond to those declared by the manufacturer; if 9 is specified, then that’s exactly how many there will be. Planetary bushings cannot achieve this result.

Why might you need it?

Despite the fact that such bicycles appeared relatively recently, they have already found their buyer, entered a small market niche and are gradually being modernized. If the owner of such a device is a fan of riding on large off-road or mountain slopes, then a bicycle with automatic gear shifting is ideal for him. They look great when you need to quickly change gears. In addition, there is no additional structure on the rear wheel that could come off.

They are easily combined with any type of brake, leaving the rider to make his own choice.

In this case, the steering wheel does not have a large number of switches, shifters and other unaesthetic loading of the steering part. Of course, there is still work to be done.

First of all, it is necessary to achieve complete closure of the transmission in order to ensure the safety of the owner’s health, continuous operation of the bicycle itself and the planetary bushings. It is necessary to cover the chain and components with a casing or similar structure. This will completely prevent dirt from getting into inappropriate places, and will prevent chain links from breaking, breaking off, or compromising the integrity of the lubricant. There are developments in which the entire gear shift structure is located inside a carbon frame and is completely protected from possible mechanical damage.

Another regulated issue remains the price of the issue. Such models are more expensive than their usual mechanical counterparts. However, with an increase in demand for a similar product and its mass production, the price will decrease, and the absence of the need for constant maintenance of the bicycle will contribute to an increase in sales. In the end, riding such a device will be much more comfortable, especially for those who are accustomed to off-road terrain, hilly terrain and small mountain slopes. There such technology will be simply irreplaceable.