8

Repair of the UAZ engine overhaul restoration bulkhead

The grounds for disassembling and repairing the engine are: a drop in engine power, a decrease in oil pressure, a sharp increase in oil consumption (over 450 g per 100 km of run), engine smoke, increased fuel consumption, a decrease in compression in the cylinders, as well as noise and knocking. When repairing engines, it is necessary to take into account their design features. Engine cylinder block mod. The 4218, unlike the 414, 4178 and 4021.60 engine block with wet, easily removable liners, has a monolithic design with cast liners without seals. The sleeves in it are bored to the size of 100 mm (instead of 92 mm). The dimensions of the pistons, piston pins and rings have been increased accordingly. The pistons have a combustion chamber in the bottom. Piston pins have increased wall thickness, connecting rods - 7 mm longer. When disassembling the engine, carefully check the reusability of each part. The criteria for assessing the possibility of further use of parts are given in table. 2.1.

Engine performance can be restored by replacing worn parts with new nominal sizes or by restoring worn parts and using new oversized parts associated with them. For these purposes, pistons, piston rings, liners for connecting rod and main bearings of the crankshaft, inlet and outlet valve seats, camshaft bushings and a number of other parts and kits of overhaul sizes are produced. The list of parts and kits of nominal and repair sizes is given in table. 2.2.

Values of clearances and tightness in the engine

A decrease or increase in clearances against the recommended ones worsens the lubrication conditions for rubbing surfaces and accelerates wear. Reducing the tightness in stationary (press) landings is also highly undesirable. For parts such as guide bushings and plug-in exhaust valve seats, reducing the interference will impair the transfer of heat from these parts to the cylinder head wall. When repairing the engine, use the data in table. 2.3. (and table 2.3. part 2)

Removal and installation of the engine on cars of the UAZ-31512 family

Before removing the engine from a vehicle installed in an inspection ditch, do the following: 1. Drain the cooling system and the oil from the engine crankcase. 2. Remove the air filter. 3. Disconnect the front exhaust pipe from the engine. 4. Disconnect the cooling system, heater and oil cooler hoses from the engine. 5. Disconnect and remove the cooling system radiator. 6. Disconnect the air and throttle valve rods from the carburetor. 7. Disconnect all electrical wiring from the engine. 8. Disconnect the clutch slave cylinder and the connecting rod from the clutch housing. 9. Remove the bolts securing the cushions of the front engine mounts together with the lower cushions of the supports.

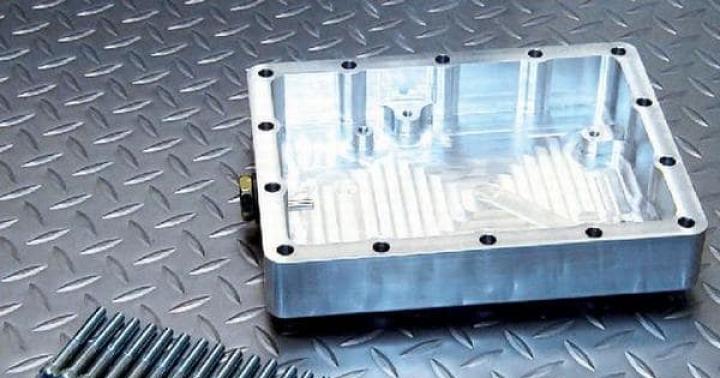

Rice. 2.41. Removing the engine from the vehicle

10. Install a special bracket on the second and fourth pins of the block head (Fig. 2.41), counting from the front end of the block. 11. Lift the engine with a hoist and disconnect the transmission from the engine. 12. Raise the engine and remove it from the vehicle, leaving the transmission with transfer case on the vehicle frame. Install the engine on the vehicle in reverse order. The engine can be removed by lowering it together with the gearbox and transfer case, it is necessary to remove the cross member. This method is much more complicated than the first.

Features of removal and installation of the engine on UAZ cars of wagon layout

To remove the engine, you must: 1. Follow the instructions in p. 1-10 of the section "Removal and installation of the engine on vehicles of the UAZ-31512 family". 2. Remove the seats and the hood cover. 3. Open the hatch in the cab roof, pass the hook with the cable (chain) of the lifting mechanism through it and hook the hook into the shackle. 4. Lift the engine a little and disconnect it from the transmission. 5. To make it easier to remove the engine, install a plank in the doorway that will not bend under the weight of the engine. 6. Lift the engine up to the opening in the hood with a lifting mechanism and, being careful, lift it out through the doorway along the plank. Install the engine in reverse order.

Disassembly and assembly of the engine

Thoroughly clean the engine from dirt and oil before disassembling. Disassemble and assemble the engine on a turntable using tool kits, for example, models 2216-B and 2216-M GARO, as well as special tools and accessories specified in Appendix 2. When using an individual method of repairing an engine, parts suitable for further work should be installed on the former places where they worked. To ensure this, mark the pistons, piston rings, connecting rods, piston pins, liners, valves, rods, rocker arms and pushers when removing in any way that does not cause damage (punching, writing, paint, attaching tags, etc.). With any type of repair, you must not uncomplete the connecting rod caps with connecting rods, rearrange the clutch housing and main bearing caps from one engine to another, or swap the middle main bearing caps in one block, since these parts are processed together. When replacing the clutch housing, check the alignment of the hole that serves to center the gearbox with the crankshaft axis, as well as the perpendicularity of the rear end of the clutch housing relative to the crankshaft axis. When checking, fasten the indicator stand to the crankshaft flange. In this case, the clutch must be removed. The runout of the hole and the end of the crankcase should not exceed 0.08 mm. After disassembling the engine, thoroughly degrease the parts, remove carbon deposits and tarry deposits. Remove carbon deposits from pistons, intake valves and combustion chambers mechanically or chemically. The chemical method for removing carbon deposits consists in keeping the parts in a bath with a solution heated to 80-95 ° C for 2-3 hours. To clean aluminum parts, use the following solution composition (in g per 1 liter of water): Soda ash (Na2CO3) ..... 18.5 Laundry or green soap ..... 10 Liquid glass (Na2SiO3) ..... 8.5 To clean steel parts, use the following solution composition (in g per 1 l of water): Caustic soda (NaOH) ... 25 Soda ash (Na2CO3) ... 33 Laundry or green soap ... .3.5 Liquid glass (Na2SiO3) ..... 1.5

After cleaning the parts, rinse with hot (80-90 ° C) water and blow with compressed air. Do not wash aluminum and zinc alloy parts in solutions containing alkali (NaOH). When assembling the engine, observe the following: 1. Wipe and blow the parts with compressed air, and lubricate all rubbing surfaces with engine oil. 2. Threaded parts (pins, plugs, fittings), if they were turned out or were replaced during the repair process, install on the red lead. 3. One-piece connections (for example, a plug of the cylinder block) should be installed on nitro varnish. 4. Tighten the bolts and nuts with a torque wrench, tightening torque, N · m (kgf · m): Nuts of the cylinder head studs ..... 71.6-76.5 (7.3-7.8) Bolt nuts connecting rod ..... 66.7-73.5 (6.8-7.5) Nuts of studs securing the crankshaft main bearing caps ..... 122.6-133.4 (12.5-13.6 ) Nuts of the flywheel-to-crankshaft bolts ..... 74.5-81.4 (7.6-8.3)

Cylinder block repair

The pairing of the wearing parts is carried out mainly by replaceable parts, which allows you to repair the cylinder block by regrinding or replacing the liners, replacing worn out camshaft bushings with semi-finished ones, followed by processing them to the required size, replacing the crankshaft main bearing shells. The restoration of the operability of a pair of cylinder block bore-pusher due to their insignificant wear is reduced to replacing the pushers.

Repair and replacement of cylinder liners

Rice. 2.42. Puller for extrusion of the liner from the cylinder block: 1 - puller; 2 - sleeve; 3 - block of cylinders

The maximum permissible wear of the cylinder liners should be considered an increase in the clearance between the liner and the piston skirt to 0.3 mm. If there is such wear, press out the liner from the cylinder block using a puller 1 (Fig. 2.42) and bore to the nearest repair size of the piston with a machining tolerance of +0.06 mm. Do not clamp the sleeve into the chuck during machining, as this will deform the sleeve and distort its dimensions. Fasten the sleeve in the tool, which is a sleeve with landing collars with a diameter of 100 and 108 mm. Insert the sleeve into the bushing as far as it will go into the upper shoulder, which is clamped with a cover ring in the axial direction. After processing, the cylinder liner mirror should have the following deviations: 1. Ovality and taper of no more than 0.01 mm, with the larger base of the cone located in the lower part of the liner. 2. Barrel shape and corset - no more than 0.08 mm. 3. The runout of the cylinder mirror relative to the landing belts with a diameter of 100 and 108 mm is not more than 0.01 mm.

Rice. 2.43. Measuring the protrusion of the sleeve above the plane of the block

After pressing the liner into the cylinder block, check the amount of protrusion of the upper end of the liner above the upper plane of the block (Fig. 2.43). The amount of protrusion should be 0.005-0.055 mm. If there is insufficient protrusion (less than 0.005 mm), the head gasket may be punched; in addition, coolant will inevitably enter the combustion chamber due to insufficient sealing of the upper collar of the liner with the cylinder block. When checking the amount of protrusion of the end of the sleeve over the block, it is necessary to remove the rubber O-ring from the sleeve.

Rice. 2.44. Clamp for sleeves: 1 -nut; 2 - washer; 3 - bushing

To prevent the liners from falling out of the slots in the block during repairs, secure them with washers 2 and bushings 3, which are put on the cylinder head mounting studs, as shown in Fig. 2.44. After worn out, replace the cylinder liners bored to the third repair size of the piston with new ones.

Cylinder head repair

The main defects in the cylinder head that can be eliminated by repair include: warpage of the contact plane with the cylinder block, wear of valve seats and valve guides. The non-straightness of the plane of the head in contact with the block, when checking it on the control plate with a probe, should not be more than 0.05 mm. Eliminate slight warpage of the head (up to 0.3 mm) by scraping the plane along the paint. For warpage exceeding 0.3 mm, the head must be sanded.

Replacing the piston rings

Replace the piston rings after 70,000-90,000 km (depending on the operating conditions of the vehicle). Piston rings are installed three on each piston: two compression rings and one oil scraper. Compression rings are made of special cast iron. The outer surface of the upper compression ring is porous chrome plated, and the surface of the second compression ring is tin plated or has a dark phosphate coating.

Rice. 2.45. Installation of rings on the piston: a - piston with rings of the UMZ-4178.10 engine; b, c - piston with rings of the UMZ-4218.10 engine; 1 - piston; 2 - upper compression ring; 3 - lower compression ring; 4 - annular discs; 5 - axial expander; 6 - radial expander

Grooves are provided on the inner cylindrical surfaces of both compression rings (

rice. 2.45, a), due to which the rings turn out somewhat during the downward movement of the piston, which contributes to better removal of excess oil from the surface of the liners. The rings must be installed on the piston with the grooves up, towards the piston crown. The UMZ-4218.10 engine can be equipped with two versions of compression rings (Fig. 2.45, b, c). One version of the upper compression ring 2 (Fig. 2.45, b) has a groove on the inner cylindrical surface. The ring must be installed on the piston with the groove up. Another version of the upper compression ring 2 (Fig. 2.45, c) has a barrel-shaped profile of the outer surface, there is no groove on the inner cylindrical surface of the ring. The position of the ring when installed in the piston groove is indifferent. The lower compression ring 3 (Fig. 2.45, b, c) is of the scraper type, on the lower end surface it has an annular groove, which, together with the tapered outer surface, forms a sharp lower edge ("scraper"). The ring is made in two versions - with a groove on the inner cylindrical surface of the ring (Fig. 2.45, b) and without a groove (Fig. 2.45, c). The ring must be installed on the piston with the sharp edge "scraper" down. The oil scraper ring is composite, has two annular discs, radial and axial expanders. The outer surface of the oil scraper ring disc is hard chrome plated. The lock of the rings is straight. Piston rings of overhaul dimensions (see table 2.2) differ from rings of nominal dimensions only in outer diameter. Oversized rings can be installed in worn-out cylinders with the next smaller oversize by sawing their joints until a gap in the lock of 0.3-0.5 mm is obtained (0.3-0.65 mm for engines mod. 4218).

Rice. 2.46. Selection of piston rings by cylinder (checking the side clearance at the joint of the ring)

Check the side clearance in the joint of the ring as shown in Fig. 2.46. Fit rings to regrind cylinders along the upper part, and to worn ones - along the lower part of the cylinder (within the piston ring stroke). When adjusting the ring, install the ring in the cylinder in the working position, i.e. in a plane perpendicular to the axis of the cylinder, to do this, advance it in the cylinder using the piston head. The planes of the joints when the ring is compressed must be parallel.

Rice. 2.47. Removal and installation of piston rings

Remove and install the rings on the piston using a tool (Fig. 2.47) model 55-1122.

Rice. 2.48. Checking the side clearance between the piston ring and piston groove

After adjusting the rings to the cylinder-frames, check the lateral clearance between the rings and grooves in the piston (Fig. 2.48), which should be: 0.050-0.082 mm for the upper compression ring, 0.035-0.067 mm for the lower compression ring. With large gaps, replacing only the piston rings will not exclude increased oil consumption due to the intensive pumping of oil by the rings into the space above the piston. In this case, replace the pistons at the same time as replacing the rings (see chapter "Replacing the pistons"). Simultaneous replacement of piston rings and pistons dramatically reduces oil consumption.

Rice. 2.49. Cleaning the piston ring grooves from carbon deposits

When replacing only piston rings without replacing pistons, remove carbon deposits from the piston crowns, from the annular grooves in the piston head and from the oil drain holes located in the grooves for the oil scraper rings. Remove carbon deposits from the grooves carefully so as not to damage their side surfaces using a tool (Fig. 2.49). Remove carbon deposits from oil drain holes with a 3 mm drill. When using new or re-sized cylinder liners, the upper compression ring must be chrome plated and the rest of the rings are tin plated or phosphated. If the liner is not repaired, but only the piston rings are changed, then all of them should be tinned or phosphated, since the chrome ring is very badly worn in to the worn liner. Before installing the pistons in the cylinders, spread the joints of the piston rings at an angle of 120 ° to each other. After changing the piston rings, do not exceed the speed of 45-50 km / h on the car within 1000 km of run.

Replacement of UAZ pistons

Replace the pistons when the groove of the upper piston ring or the piston skirt is worn. In partially worn cylinders, install pistons of the same size (nominal or overhaul) as pistons previously used in this engine. However, it is advisable to select a kit with a larger piston size to reduce the clearance between the piston skirt and the cylinder bore. In this case, check the clearance between the piston skirt and the cylinder bore in the lower, least worn part of the cylinder. Do not suppose that the clearance in this part of the cylinder is less than 0.02 mm. Spare parts are supplied with pistons with piston pins and retaining rings matched to them (see table 2.2). For selection, pistons of nominal size are sorted according to the outer diameter of the skirt. On the piston crowns, the letter designations of the size group are stamped, which are indicated in table. 2.4.

The size of their diameter is also knocked out on the pistons of overhaul dimensions. In addition to the selection of pistons to the cylinder liners according to the diameter of the skirt, they are also selected by weight.

The difference in weight between the lightest and the heaviest piston for one engine should not exceed 4 g. When assembling the pistons, install in sleeves of the same group.

Rice. 2.50. Tool for installing piston with rings in a cylinder

Install the pistons into the cylinders using the model 59-85 tool shown in fig. 2.50. When installing pistons in cylinders, the “front” mark, cast on the piston, must face the front of the engine, on the split-skirt piston, the “back” mark should be toward the clutch housing. On all oversized pistons, holes in the piston pin bosses are made of the nominal size with a breakdown into groups. If necessary, these holes are bored or reamed to the nearest repair size with a tolerance of -0.005 -0.015 mm. Taper and ovality of the hole - no more than 0.0025 mm. When machining, ensure that the axis of the hole is perpendicular to the axis of the piston, the permissible deviation is no more than 0.04 mm over a length of 100 mm.

Repair of connecting rods

Repair of connecting rods is reduced to replacing the bushing of the upper head and its subsequent processing under a piston pin of the nominal size or to processing the bushing available in the connecting rod for a pin of repair size. The spare parts are supplied with bushings of the same size, made of 1 mm thick OTsS4-4-2.5 bronze tape. When pressing a new bushing into the connecting rod, ensure that the hole in the bushing aligns with the hole in the upper connecting rod head. The holes are used to supply lubricant to the piston pin. After pressing in the bushing, seal its inner surface with a smooth broach to a diameter of 24.3 + 0.045 mm, and then unfold or bore to the nominal or repair size with a tolerance of +0.007 -0.003 mm. For example, unfold or bore the bushing under a pin of the nominal size to a diameter of 25 +0.007 -0.003 mm or under a pin of an oversized size to a diameter of 25.20 +0.07 -0.003 mm. The distance between the axes of the holes of the lower and upper connecting rod heads should be (168 ± 0.05) mm [(175 ± 0.05) mm for engines of model 4218]; the permissible non-parallelism of the axes in two mutually perpendicular planes over a length of 100 mm should be no more than 0.04 mm; ovality and taper should not exceed 0.005 mm. To maintain the specified dimensions and tolerances, unfold the upper connecting rod bushing in the jig.

Rice. 2.51. Lapping the hole in the upper head of the connecting rod: 1 - squeezing; 2 - grinding head; 3 - clamp

After deployment, finish the hole on a special grinding head, holding the connecting rod in your hands (Fig. 2.51). Set the grinding stones of the head with a micrometer screw to the required overhaul dimension. Connecting rods, the holes for the inserts in the lower head of which have an ovality of more than 0.05 mm, must be replaced.

Replacement and repair of piston pins

Repair dimensions of piston pins and kit numbers are given in table. 2.2.

To replace piston pins without pre-machining the holes in the piston and in the upper connecting rod head, piston pins increased in diameter by 0.08 mm are used. The use of pins enlarged by 0.12 mm and 0.20 mm requires pre-machining the holes in the piston bosses and in the upper connecting rod head as described above (see chapters "Replacing pistons" and "Repairing connecting rods").

Rice. 2.52. Removing the piston pin retaining ring

Rice. 2.53. A device for pushing out and pushing in the piston pin: 1 - guide; 2 - finger; 3-plunger

Before pressing out the piston pin, remove the piston pin circlips from the piston with pliers, as shown in fig. 2.52. Press out and press in the pin on the device, as shown in Fig. 2.53. Before pressing out the pin, heat the piston in hot water to 70 ° C. Repair of piston pins consists in regrinding them from large repair sizes to smaller ones or in chrome plating, followed by processing to a nominal or repair size. Fingers with kinks, chipping and cracks of any size and location, as well as traces of overheating (tarnishing color) cannot be repaired.

Assembling the connecting rod-piston group

Select the piston pin to the upper head of the connecting rod with a clearance of 0.0045-0.0095 mm. At normal room temperature, the finger should smoothly move in the hole of the upper head of the connecting rod from the effort of the thumb (Fig. 2.54). The piston pin should be lightly greased with lightweight oil. Install the pin into the piston with an interference fit of 0.0025-0.0075 mm. In practice, the piston pin is selected in such a way that at normal room temperature (20 ° C) it would not enter the piston by hand force, and when the piston is heated in hot water to a temperature of 70 ° C, it would enter it freely. Therefore, before assembling the piston, heat it in hot water to 70 ° C. Pressing in the pin without preheating the piston will damage the surface of the holes in the piston bosses, as well as deform the piston itself. Assemble the connecting rod-piston group using the same tool as disassembly (see Fig. 2.53). To ensure correct balancing of the engine, the difference in weight between the pistons and connecting rods installed in the engine must not exceed 8 g. The piston pin circlips must sit in their grooves with a slight interference. Do not use used rings. Fit the piston rings to the piston as described in the chapter "Replacing the piston rings". Considering the complexity of the selection of the piston pin to the piston and connecting rod (to ensure nominal fits), pistons are supplied as spare parts assembled with a piston pin, retaining and piston rings.

And before assembling, it is necessary to make a selection of pistons for the cylinders of the ZMZ-40906 engine. Skirt O.D. pistons and bore cylinders are sorted into five size groups. The pistons are marked with letters on the bottom. The letter of the designation of the size group of the cylinder diameter is applied with paint on the plugs on the left side of the cylinder block.

After repair, the ZMZ-40906 engine can be fitted with pistons with a nominal diameter of 95.5 mm and the first repair size of 96.0 mm (they are marked "AR"). The pistons can be sorted into 2 weight groups. The group of heavier pistons is marked on the bottom. The ZMZ-40906 engine must be fitted with pistons of the same weight group. Pistons to cylinders must be matched group to group, in accordance with the table below.

* - Previously, groups were designated by the letters of the Russian alphabet - "A", "B", "C", "D", "D", respectively.

It is allowed to select pistons to, including working cylinders without processing them, from neighboring groups when the piston passes the check below. It is recommended that the piston be tested for in-cylinder operation as indicated below.

Checking the suitability of the piston for operation in the cylinder of the ZMZ-40906 engine.

1. In an inverted position, the piston should slowly descend along the cylinder under the influence of its own weight or under the influence of light pushes from the fingers of the hand.

2. Measure the pulling force with a dynamometer of a 0.05 mm thick and 10 mm wide probe strip, lowered to a depth of 35 mm between the cylinder wall and the piston inserted into it in an inverted position. The lower edge of the piston skirt should be 10 mm deepened relative to the upper end of the block.

Place the dipstick strip in a plane perpendicular to the axis of the piston pin, that is, along the largest diameter of the piston. The force when pulling the probe strip should be 29-39 N (3-4 kgf) for new cylinders and pistons. Measurement of cylinders, pistons and pulling pistons should be performed at the temperature of the parts plus 20 + -3 degrees.

A selection of fingers for pistons and connecting rods and an assembly of pistons with connecting rods and fingers.

Pistons are sorted into 2 size groups according to the diameter of the pin hole and are marked with a Roman numeral on the bottom. The connecting rods are sorted into 4 size groups according to the diameter of the bore of the bushing for the pin and are marked with paint on the rod in the area of the piston head. Piston pins by outer diameter can be sorted into 5 size groups, which are marked with paint or Latin letters at the end, and into 2 size groups, which are marked with a Roman numeral at the end.

Piston pins with a breakdown into 5 size groups and with a breakdown into 2 size groups must be matched to the pistons and connecting rods separately according to the tables below.

Connecting rods and caps are sorted by weight into four groups and marked with paint on the connecting rod cap. Marking color:

- White - corresponds to the mass of the connecting rod 900-905 g.

- Green - 895-900 g.

- Yellow - 890-895 g.

- Blue - 885-890 g.

For installation in the ZMZ-40906 engine, you should take the connecting rods of the same group by weight. The difference in the mass of the units installed in the engine (piston with connecting rod) should not exceed 22 grams. Before assembly, lubricate the piston pin used on the engine and insert into the piston and connecting rod bores. Connecting rods and pistons, when assembled with a piston pin, must be oriented as follows: the inscription "FRONT" or "FRONT" on the piston, the projection A on the crank head of the connecting rod must point in one direction.

Clean piston crowns and piston ring grooves from carbon deposits. Measure the lateral clearance between the compression rings and the wall of the piston groove with a feeler gauge. For worn rings and pistons, a maximum clearance of not more than 0.15 mm is allowed. Larger clearance will lead to increased oil burnout due to the "pumping" action of the rings. Replace worn ring or piston if necessary.

Slide the piston rings onto the piston using the tool. Install the lower compression ring with the inscription "TOP" (top) or with the manufacturer's trademark towards the bottom (top) of the piston. The rings in the grooves must move freely.

Insert the pistons into the cylinders as follows.

- Orient the piston with the connecting rod so that the inscription "FRONT" or "FRONT" on the piston faces the front end of the cylinder block.

- Wipe the beds of the connecting rods and their caps with a napkin, wipe them and insert the inserts into them.

- Turn the shaft so that the cranks of the first and fourth cylinders take the position corresponding to the BDC.

- Lubricate bearings, piston, connecting rod journal and first cylinder with clean engine oil.

- Open the locks of the piston rings, move the locks of the compression rings 180 degrees relative to each other, set the locks of the annular disc elements of the oil scraper ring to one another at an angle of 180 degrees and at an angle of 90 degrees to the locks of the compression rings. Set the lock of the spring expander at an angle of 45 degrees to the lock of one of the annular disc elements.

- Using a special mandrel with an inner tapered surface, squeeze the rings and insert the piston into the cylinder.

Before installing the piston in the ZMZ-40906 engine block, you should once again check the correct position of the piston and connecting rod in the cylinder. Pull the connecting rod by the crank head to the connecting rod journal and fit the connecting rod cap. The connecting rod cover on the connecting rod must be installed so that the shoulder B on the connecting rod cover and the projection A on the crank head or the grooves for the liners are located on one side.

Tighten the connecting rod bolt nuts with a torque wrench to 68-75 Nm (6.8-7.5 kgcm). In the same order, insert the piston with the connecting rod of the fourth cylinder. Turn the crankshaft 180 degrees and insert the pistons with connecting rods of the second and third cylinders. Turn the crankshaft several times, which should rotate easily with a little effort.

The grounds for disassembling and repairing the engine are: a drop in engine power, a decrease in oil pressure, a sharp increase in oil consumption (over 450 g per 100 km of run), engine smoke, increased fuel consumption, a decrease in compression in the cylinders, as well as noise and knocking.

When repairing engines, it is necessary to take into account their design features. Engine cylinder block mod. The 4218, unlike the 414, 4178 and 4021.60 engine block with wet, easily removable liners, has a monolithic design with cast liners without seals. The sleeves in it are bored to the size of 100 mm (instead of 92 mm). The dimensions of the pistons, piston pins and rings have been increased accordingly. The pistons have a combustion chamber in the bottom. Piston pins have increased wall thickness, connecting rods - 7 mm longer.

When disassembling the engine, carefully check the reusability of each part. Criteria for assessing the possibility of further use of parts are given in

Engine performance can be restored by replacing worn parts with new nominal sizes or by restoring worn parts and using new oversized parts associated with them.

For these purposes, pistons, piston rings, liners for connecting rod and main bearings of the crankshaft, inlet and outlet valve seats, camshaft bushings and a number of other parts and kits of overhaul sizes are produced. The list of parts and kits of nominal and overhaul dimensions is given in

Values of clearances and tightness in the engine

A decrease or increase in clearances against the recommended ones worsens the lubrication conditions for rubbing surfaces and accelerates wear. Reducing the tightness in stationary (press) landings is also highly undesirable. For parts such as guide bushings and plug-in exhaust valve seats, reducing the interference will impair the transfer of heat from these parts to the cylinder head wall. Use the data when repairing the engine. (and )

Removal and installation of the engine on cars of the UAZ-31512 family

Before removing the engine from a vehicle in a viewing ditch, do the following:

1. Drain the cooling system and the oil from the engine crankcase.

2. Remove the air filter.

3. Disconnect the front exhaust pipe from the engine.

4. Disconnect the cooling system, heater and oil cooler hoses from the engine.

5. Disconnect and remove the cooling system radiator.

6. Disconnect the air and throttle valve rods from the carburetor.

7. Disconnect all electrical wiring from the engine.

8. Disconnect the clutch slave cylinder and the connecting rod from the clutch housing.

9. Remove the bolts securing the cushions of the front engine mounts together with the lower cushions of the supports.

10. Install the special bracket on the second and fourth pins of the block head (), counting from the front end of the block.

11. Lift the engine with a hoist and disconnect the transmission from the engine.

12. Raise the engine and remove it from the vehicle, leaving the transmission with transfer case on the vehicle frame.

Install the engine on the vehicle in reverse order.

The engine can be removed by lowering it together with the gearbox and transfer case, it is necessary to remove the cross member. This method is much more complicated than the first.

Features of removal and installation of the engine on UAZ cars of wagon layout

To remove the engine, you must:

1. Follow the instructions of p. 1–10 of the section "Removal and installation of the engine on vehicles of the UAZ-31512 family".

2. Remove the seats and the hood cover.

3. Open the hatch in the cab roof, pass the hook with the cable (chain) of the lifting mechanism through it and hook the hook into the shackle.

4. Lift the engine a little and disconnect it from the transmission.

5. To make it easier to remove the engine, install a plank in the doorway that will not bend under the weight of the engine.

6. Lift the engine up to the opening in the hood with a lifting mechanism and, being careful, lift it out through the doorway along the plank.

Install the engine in reverse order.

Disassembly and assembly of the engine

Thoroughly clean the engine from dirt and oil before disassembling.

Disassemble and assemble the engine on a turntable using tool kits, for example, models 2216-B and 2216-M GARO, as well as special tools and accessories specified in Appendix 2.

With an individual method of repairing the engine, parts suitable for further work should be installed in the same places where they were worn in. To ensure this, mark the pistons, piston rings, connecting rods, piston pins, liners, valves, rods, rocker arms and pushers when removing in any way that does not cause damage (punching, writing, paint, attaching tags, etc.).

With any type of repair, you must not uncomplete the connecting rod caps with connecting rods, rearrange the clutch housing and main bearing caps from one engine to another, or swap the middle main bearing caps in one block, since these parts are processed together.

When replacing the clutch housing, check the alignment of the hole that serves to center the gearbox with the crankshaft axis, as well as the perpendicularity of the rear end of the clutch housing relative to the crankshaft axis. When checking, fasten the indicator stand to the crankshaft flange. In this case, the clutch must be removed. The runout of the hole and the end of the crankcase should not exceed 0.08 mm.

After disassembling the engine, thoroughly degrease the parts, remove carbon deposits and tarry deposits.

Remove carbon deposits from pistons, intake valves and combustion chambers mechanically or chemically.

The chemical method for removing carbon deposits consists in keeping the parts in a bath with a solution heated to 80–95 ° С for 2–3 hours.

To clean aluminum parts, use the following solution composition (in g per 1 liter of water):

Soda ash (Na2CO3) ..... 18.5

Laundry or green soap ..... 10

Liquid glass (Na2SiO3) ..... 8.5

To clean steel parts, use the following solution composition (in grams per liter of water):

Caustic soda (NaOH) ..... 25

Soda ash (Na2CO3) ..... 33

Laundry or green soap ..... 3.5

Liquid glass (Na2SiO3) ..... 1.5

After cleaning, rinse the parts with hot (80–90 ° C) water and blow them off with compressed air.

Do not wash aluminum and zinc alloy parts in solutions containing alkali (NaOH).

Observe the following when assembling the engine:

1. Wipe and blow the parts with compressed air, and lubricate all rubbing surfaces with engine oil.

2. Threaded parts (pins, plugs, fittings), if they were turned out or were replaced during the repair process, install on the red lead.

3. One-piece connections (for example, a plug of the cylinder block) should be installed on nitro varnish.

4. Tighten the bolts and nuts with a torque wrench, tightening torque, N · m (kgf · m):

Cylinder head stud nuts ..... 71.6–76.5 (7.3–7.8)

Connecting rod bolt nuts ... 66.7-73.5 (6.8-7.5)

Crankshaft main bearing cap stud nuts ... 122.6-133.4 (12.5-13.6)

Flywheel-to-crankshaft bolt nuts ..... 74.5-81.4 (7.6-8.3)

Cylinder block repair

The pairing of the wearing parts is carried out mainly by replaceable parts, which allows you to repair the cylinder block by regrinding or replacing the liners, replacing worn out camshaft bushings with semi-finished ones, followed by processing them to the required size, replacing the crankshaft main bearing shells. The restoration of the operability of a pair of cylinder block bore-pusher due to their insignificant wear is reduced to replacing the pushers.

Repair and replacement of cylinder liners

The maximum permissible wear of the cylinder liners should be considered an increase in the clearance between the liner and the piston skirt to 0.3 mm. If there is such wear, press the liner out of the cylinder block using a puller 1 () and re-bore to the next piston oversize with a machining tolerance of +0.06 mm.

Do not clamp the sleeve into the chuck during machining, as this will deform the sleeve and distort its dimensions.

Fasten the sleeve in the tool, which is a sleeve with landing collars with a diameter of 100 and 108 mm. Insert the sleeve into the bushing as far as it will go into the upper shoulder, which is clamped with a cover ring in the axial direction. After processing, the cylinder liner mirror should have the following deviations:

1. Ovality and taper not more than 0.01 mm, and the larger base of the cone should be located in the lower part of the sleeve.

2. Barrel shape and corset - no more than 0.08 mm.

3. The runout of the cylinder mirror relative to the landing belts with a diameter of 100 and 108 mm is not more than 0.01 mm.

After pressing the liner into the cylinder block, check the protrusion of the upper end of the liner above the upper plane of the block (). The amount of protrusion should be 0.005–0.055 mm. If there is insufficient protrusion (less than 0.005 mm), the head gasket may be punched; in addition, coolant will inevitably enter the combustion chamber due to insufficient sealing of the upper collar of the liner with the cylinder block. When checking the amount of protrusion of the end of the sleeve over the block, it is necessary to remove the rubber O-ring from the sleeve.

To prevent the liners from falling out of the slots in the block during repairs, secure them with washers 2 and bushings 3, which are put on the cylinder head mounting studs, as shown in.

After worn out, replace the cylinder liners bored to the third repair size of the piston with new ones.

Cylinder head repair

The main defects in the cylinder head that can be eliminated by repair include: warpage of the contact plane with the cylinder block, wear of valve seats and valve guides.

The non-straightness of the plane of the head in contact with the block, when checking it on the control plate with a probe, should not be more than 0.05 mm. Eliminate slight warpage of the head (up to 0.3 mm) by scraping the plane along the paint. For warpage exceeding 0.3 mm, the head must be sanded.

Replacing the piston rings

Replace the piston rings after 70,000–90,000 km (depending on the operating conditions of the vehicle).

Piston rings are installed three on each piston:

two compression and one oil scraper. Compression rings are made of special cast iron. The outer surface of the upper compression ring is porous chrome plated, and the surface of the second compression ring is tin plated or has a dark phosphate coating.

On the inner cylindrical surfaces of both compression rings, grooves (, a) are provided, due to which the rings are slightly twisted when the piston moves downward, which contributes to better removal of excess oil from the surface of the sleeves. The rings must be installed on the piston with the grooves up, towards the piston crown.

The UMZ – 4218.10 engine can be equipped with two versions of compression rings (, b, c).

One version of the upper compression ring 2 (b) has a groove on the inner cylindrical surface. The ring must be installed on the piston with the groove up.

Another version of the upper compression ring 2 (c) has a barrel-shaped profile of the outer surface, there is no groove on the inner cylindrical surface of the ring. The position of the ring when installed in the piston groove is indifferent.

The lower compression ring 3 (, b, c) is of the scraper type; it has an annular groove on the lower end surface, which, together with the tapered outer surface, forms a sharp lower edge ("scraper"). The ring is made in two versions - with a groove on the inner cylindrical surface of the ring (, b) and without a groove (, c). The ring must be installed on the piston with the sharp edge "scraper" down.

The oil scraper ring is composite, has two annular discs, radial and axial expanders. The outer surface of the oil scraper ring disc is hard chrome plated.

The lock of the rings is straight.

Piston rings of repair sizes (see) differ from rings of nominal sizes only in outer diameter.

Oversized rings can be installed in worn-out cylinders with the next smaller oversize by sawing their joints until a gap in the lock of 0.3–0.5 mm is obtained (0.3–0.65 mm for engines mod. 4218).

Check the side clearance in the ring joint as shown in. Fit rings to regrind cylinders along the upper part, and to worn ones - along the lower part of the cylinder (within the piston ring stroke). When adjusting the ring, install the ring in the cylinder in the working position, i.e. in a plane perpendicular to the axis of the cylinder, to do this, advance it in the cylinder using the piston head. The planes of the joints when the ring is compressed must be parallel.

After adjusting the rings to the cylinder-frames, check the lateral clearance between the rings and grooves in the piston (), which should be: 0.050–0.082 mm for the upper compression ring, 0.035–0.067 mm for the lower compression ring. With large gaps, replacing only the piston rings will not exclude increased oil consumption due to the intensive pumping of oil by the rings into the space above the piston. In this case, replace the pistons at the same time as replacing the rings (see chapter "Replacing the pistons"). Simultaneous replacement of piston rings and pistons dramatically reduces oil consumption.

When replacing only piston rings without replacing pistons, remove carbon deposits from the piston crowns, from the annular grooves in the piston head and from the oil drain holes located in the grooves for the oil scraper rings. Carefully remove carbon deposits from the grooves so as not to damage their lateral surfaces using the tool ().

Remove carbon deposits from oil drain holes with a 3 mm drill.

When using new or re-sized cylinder liners, the upper compression ring must be chrome plated and the rest of the rings are tin plated or phosphated. If the liner is not repaired, but only the piston rings are changed, then all of them should be tinned or phosphated, since the chrome ring is very badly worn in to the worn liner.

Before installing the pistons in the cylinders, spread the joints of the piston rings at an angle of 120 ° to each other.

After changing the piston rings, do not exceed the speed of 45-50 km / h on the vehicle within 1000 km of run.

Replacing pistons

Replace the pistons when the groove of the upper piston ring or the piston skirt is worn.

In partially worn cylinders, install pistons of the same size (nominal or overhaul) as pistons previously used in this engine. However, it is advisable to select a kit with a larger piston size to reduce the clearance between the piston skirt and the cylinder bore.

In this case, check the clearance between the piston skirt and the cylinder bore in the lower, least worn part of the cylinder.

Do not suppose that the clearance in this part of the cylinder is less than 0.02 mm.

The spare parts are supplied with pistons with piston pins and retaining rings matched to them (see).

For selection, pistons of nominal size are sorted according to the outer diameter of the skirt. On the piston crowns, the letter designations of the size group are stamped, which are indicated in

The size of their diameter is also knocked out on the pistons of overhaul dimensions.

In addition to the selection of pistons to the cylinder liners according to the diameter of the skirt, they are also selected by weight. The difference in weight between the lightest and the heaviest piston for one engine must not exceed 4 g.

When assembling, install the pistons in the sleeves of the same group.

When installing pistons in cylinders, the "front" mark, cast on the piston, must face the front of the engine, on the split-skirt piston, the "back" mark - toward the clutch housing.

On all oversized pistons, holes in the piston pin bosses are made of the nominal size with a breakdown into groups. If necessary, these holes are bored or reamed to the nearest repair dimension with a tolerance of –0.005 –0.015 mm. Taper and ovality of the hole - no more than 0.0025 mm. When machining, ensure that the axis of the hole is perpendicular to the axis of the piston, the permissible deviation is no more than 0.04 mm over a length of 100 mm.

Repair of connecting rods

Repair of connecting rods is reduced to replacing the bushing of the upper head and its subsequent processing under a piston pin of the nominal size or to processing the bushing available in the connecting rod for a pin of repair size.

The spare parts are supplied with bushings of the same size, made of 1 mm thick OTsS4-4-2.5 bronze tape.

When pressing a new bushing into the connecting rod, ensure that the hole in the bushing aligns with the hole in the upper connecting rod head.

The holes are used to supply lubricant to the piston pin.

After pressing in the bushing, seal its inner surface with a smooth broach to a diameter of 24.3 + 0.045 mm, and then unfold or bore to the nominal or repair size with a tolerance of +0.007 –0.003 mm.

For example, unfold or bore the sleeve under a pin of the nominal size to a diameter of 25 +0.007 –0.003 mm or under a pin of an oversized size to a diameter of 25.20 +0.07 –0.003 mm.

The distance between the axes of the holes of the lower and upper connecting rod heads should be (168 ± 0.05) mm [(175 ± 0.05) mm for engines of model 4218]; the permissible non-parallelism of the axes in two mutually perpendicular planes over a length of 100 mm should be no more than 0.04 mm; ovality and taper should not exceed 0.005 mm. To maintain the specified dimensions and tolerances, unfold the upper connecting rod bushing in the jig.

After deployment, finish the hole on a special grinding head, holding the connecting rod in your hands (). Set the grinding stones of the head with a micrometer screw to the required overhaul dimension.

Connecting rods, the holes for the inserts in the lower head of which have an ovality of more than 0.05 mm, must be replaced.

Replacement and repair of piston pins

To replace piston pins without pre-machining the holes in the piston and in the upper connecting rod head, piston pins increased in diameter by 0.08 mm are used. The use of pins enlarged by 0.12 mm and 0.20 mm requires pre-machining the holes in the piston bosses and in the upper connecting rod head as described above (see chapters "Replacing pistons" and "Repairing connecting rods").

Before pressing out the gudgeon pin, remove the gudgeon pin circlips from the piston with pliers as shown in. Press out and press in the pin on the tool, as shown on. Before pressing out the pin, heat the piston in hot water to 70 ° C.

Repair of piston pins consists in regrinding them from large repair sizes to smaller ones or in chrome plating, followed by processing to a nominal or repair size.

Fingers with kinks, chipping and cracks of any size and location, as well as traces of overheating (tarnishing color) cannot be repaired.

Assembling the connecting rod-piston group

Select the piston pin to the upper connecting rod head with a clearance of 0.0045–0.0095 mm. At normal room temperature, the finger should slide smoothly into the bore of the upper crank arm with the force of the thumb (). The piston pin should be lightly greased with lightweight oil.

Install the pin into the piston with an interference fit of 0.0025–0.0075 mm.

In practice, the piston pin is selected in such a way that at normal room temperature (20 ° C) it would not enter the piston by hand force, and when the piston is heated in hot water to a temperature of 70 ° C, it would enter it freely. Therefore, before assembling the piston, heat it in hot water to 70 ° C. Pressing in the pin without preheating the piston will damage the surface of the holes in the piston bosses, as well as deform the piston itself. Assemble the connecting rod-piston group using the same tool as disassembly (see).

To ensure correct engine balancing, the difference in weight between pistons and connecting rods installed in the engine must not exceed 8 g.

The gudgeon pin circlips should fit slightly in their grooves. Do not use used rings.

Fit the piston rings to the piston as described in the chapter "Replacing the piston rings".

Considering the complexity of the selection of the piston pin to the piston and connecting rod (to ensure nominal fits), pistons are supplied as spare parts assembled with a piston pin, retaining and piston rings.

Crankshaft repair

Repair of the crankshaft consists in regrinding the main and connecting rod journals to the next repair size.

The repair dimensions of the connecting rod and main journals are determined by the dimensions of the connecting rod and main bearing kits supplied in the spare parts, which are given in

The radial clearances in the connecting rod and main bearings of the crankshaft should be 0.020–0.049 mm and 0.020–0.066 mm, respectively. Re-grind the necks with a tolerance of 0.013 mm.

If the dimensions of the connecting rod and main journals do not coincide with each other, they must be re-grinded to the same repair size.

The chamfers and holes of the front and rear ends of the crankshaft are not suitable for installation in a grinding machine. To do this, make removable glass centers. Press the front center onto the neck with a diameter of 38 mm, and center the rear center on the outer diameter of the flange (Ж122 mm) of the shaft and fasten to it with bolts. When making transition centers, ensure that the centering and locating holes are concentric. Without observing this condition, it is impossible to ensure the necessary concentricity of the seats of the flywheel and gear to the axes of the main journals.

When grinding the connecting rod journals, install the shaft on additional centers coaxial with the connecting rod journal axes. To do this, you can use the centers-cups, providing them with flanges with two additional center holes, spaced from the middle hole by 46 ± 0.05 mm.

For the front end, it is better to make a new center-flange, which is installed on a neck with a diameter of 40 mm (on a key) and additionally secured with a bolt (ratchet) screwed into a threaded hole.

Before grinding the necks, deepen the chamfers on the edges of the oil channels so that their width after removing the entire grinding allowance is 0.8–1.2 mm. Do this with an emery stone with a 60–90 ° apex angle driven by an electric drill.

When grinding the connecting rod journals, do not touch the side surfaces of the journals with the grinding wheel so as not to disturb the axial play of the connecting rods. Maintain the radius of transition to the lateral surface 3.5 mm. Grind with plenty of emulsion cooling.

During the regrinding process, observe:

1. The distance between the axes of the main and connecting rod journals is 46 ± 0.05 mm.

2. Taper, barrel, saddle, ovality and neck cut not more than 0.005 mm.

3. Angular arrangement of connecting rod journals ± 0 ° 10 ".

4. The non-parallelism of the connecting rod journal axes with the main journal axis is not more than 0.012 mm over the entire length of the connecting rod journal.

5. Runout (when installing the shaft with extreme main journals on prisms) of the middle main journals is not more than 0.02 mm, journals for the camshaft gear up to 0.03 mm, and journals for the pulley hub and rear oil seal up to 0.04 mm.

After grinding the journals, flush the crankshaft, and clean the oil channels from abrasive and resinous deposits. Unscrew the dirt trap plugs. After cleaning the dirt traps and channels, screw the plugs back into place and secure each of them against spontaneous twisting.

Clean the oil passages also during maintenance repairs of the engine, when the crankshaft is removed from the block.

After repair, re-assemble the crankshaft with the same flywheel and clutch that were in place before the repair. Install the clutch on the flywheel according to the factory marks "O" printed on both parts one against the other near one of the clutch cover bolts to the flywheel ().

Dynamically balance the crankshaft with clutch assembly on a special machine before installing the clutch assembly on the engine. Pre-center the clutch disc using the gearbox shaft or a special mandrel.

Eliminate imbalance by drilling metal in the flywheel rim at a radius of 158 mm with a 12 mm drill. The drilling depth should not exceed 12 mm. The permissible imbalance is not more than 70 gf cm.

Replacing the crankshaft main and connecting rod bearings

The spare parts are supplied with shells of main and connecting rod bearings of nominal and seven overhaul sizes, which are given in. Repair size inserts differ from nominal size inserts with an inner diameter reduced by 0.05; 0.25; 0.50; 0.75; 1.0; 1.25 and 1.50 mm.

Replace main and connecting rod bearing shells without any adjustment.

Depending on the wear of the journals, when changing the liners for the first time, use liners of the nominal or, in extreme cases, the first repair size (reduced by 0.05 mm).

Install the liners of the second and subsequent overhaul sizes into the engine only after regrinding the crankshaft journals.

If, as a result of repeated regrinding, the diameters of the crankshaft journals are reduced so much that the liners of the last repair size are unsuitable for it, then assemble the engine with a new shaft.

The radial clearance in the connecting rod and main bearings of the crankshaft should be 0.020–0.049 mm and 0.020–0.066 mm, respectively.

Check the magnitude of the radial clearances using a set of control probes made of copper foil 0.025 thick; 0.05; 0.075 and 0.1 mm, cut into strips 6–7 mm wide and slightly shorter than the liner width. The edges of the probes should be cleaned to prevent damage to the liner surface.

Check the radial clearance in the following order:

1. Remove the cap with the liner from the neck to be checked and place a pre-oiled 0.025 mm dipstick across the liner.

2. Reinstall the cover with insert and tighten with the bolts, while the bolts of the remaining covers must be loosened.

3. Rotate the crankshaft by hand through an angle of no more than 60–90 ° to avoid damaging the liner surface with the feeler gauge.

If the shaft turns too easily, then the clearance is greater than 0.025 mm. In this case, repeat the check with the 0.05 probes; 0.075 mm, etc. until it becomes impossible to turn the crankshaft.

The thickness of the stylus, at which the shaft turns with a noticeable effort, is considered equal to the actual clearance between the liner and the crankshaft journal.

Observe the following when replacing earbuds:

1. Replace liners without adjusting operations.

2. Make sure that the locking lugs at the joints of the liners freely (with the help of hand force) enter the grooves in the shaft beds.

3. At the same time when replacing the bearing shells, clean the dirt traps in the connecting rod journals.

The connecting rod bushings can be replaced without removing the engine from the vehicle chassis. Replace the main bearing shells with the engine removed from the vehicle chassis.

After replacing the liners, run the engine in as described in the "Engine Break-In After Repair" section.

If, when replacing the liners, the engine was not removed from the car, then during the first 1000 km of run the speed should not exceed 50 km / h.

Simultaneously with replacing the liners, check the axial clearance in the thrust bearing of the crankshaft, which should be 0.075–0.175 mm. If the axial clearance is more than 0.175 mm, replace washers 7 () and 8 with new ones. The front washer is made in four thicknesses: 2.350–2.375; 2.375-2.400; 2,400-2,425; 2.425-2.450 mm.

To check the thrust bearing clearance, place a screwdriver () between the first crank of the shaft and the front wall of the block and press the shaft towards the rear end of the motor. Then, with a feeler gauge, determine the clearance between the end face of the thrust bearing rear washer and the shoulder plane of the first main journal.

Before installing the liners, check the alignment of the crankshaft main journals (deflection boom). To do this, place the crankshaft in the centers and check the position of the axles of the main journals according to the indicator readings.

Repair of the camshaft and replacement of its bushings

Restore the required gaps in the camshaft bushings by regrinding the bearing journals, reducing their size by no more than 0.75 mm, and replacing the worn out bushings with semi-finished ones, followed by their boring to the size of the regrind journals.

On engines without bushings, restore the required clearances by boring holes in the block for bushings, guided by the data. (and), and subsequent pressing in of bushings of nominal or repair size.

Before regrinding the camshaft journals, deepen the grooves on the first and last journals by the amount of reduction in the diameter of these journals in order to ensure that after regrinding the journals, the lubricant flows to the camshaft gears and to the rocker arm axis. Grind the necks in the centers with a tolerance of 0.02 mm. After grinding the neck, polish it.

It is more convenient to press out and press-in bushings using threaded rods (of the appropriate length) with nuts and washers.

The semi-machined camshaft bushings, supplied as a single engine kit, have the same outer diameter as the nominal bushings, so they are pressed into the bores of the block without pre-machining.

To ensure a sufficient thickness of the babbitt layer (antifriction material), the repair reduction of the inner diameter of all bushings must be the same.

When pressing in the bushings, make sure that their side holes coincide with the oil channels in the block. Boring the bushings, reducing the diameter of each subsequent bushing, starting from the front end of the block, by 1 mm. Bore with a tolerance of +0.050 +0.025 mm so that the clearances in the bushings after installing the shaft correspond to the data

When boring bushings and holes in the bushing block, keep the distance between the axes of the crankshaft and camshaft holes (118 ± 0.025) mm. Check this dimension at the front end of the block. The deviation from the alignment of the holes in the bushings should be no more than 0.04 mm, and the deviation from the parallelism of the crankshaft and camshafts should be no more than 0.04 mm along the entire length of the block. To ensure the alignment of the bushings within the specified limits, process them at the same time using a long and sufficiently rigid boring bar with cutters or reamers attached to it according to the number of supports. Install the boring bar based on the main bearing shell holes.

With slight wear and tear, clean the camshaft cams with abrasive paper: first coarse, then fine. In this case, the sandpaper should cover at least half of the cam profile and have some tension, which will ensure the least distortion of the cam profile.

If the cams are worn in height by more than 0.5 mm, replace the camshaft with a new one.

Check the camshaft bent with an indicator on the backs of the heads (on the cylindrical surface) of the intake and exhaust cams of the second and third cylinders. At the same time, install the shaft in the centers. If the shaft runout exceeds 0.03 mm, then straighten or replace the shaft.

Restoration of valve tightness and replacement of valve sleeves

Violation of the tightness of the valves with the correct gaps between the valve stems and rocker arms, as well as with the correct operation of the carburetor and the ignition system, is detected by the characteristic pops from the muffler and carburetor. At the same time, the engine runs intermittently and does not develop full power.

Restore the tightness of the valves by lapping the working chamfers of the valves to their seats. If there are sinks on the working chamfers and seats, ring workings or scratches that cannot be removed by lapping, grind the chamfers, followed by lapping the valves to the seats. Replace warped-head valves.

Grind the valve chamfers with a pneumatic or electric drill model 2213, 2447 GARO or manually using a rotary wheel. Perform lapping in a back-and-forth motion, in which the valve turns slightly more in one direction than in the other. When lapping under the valve, install a release spring with a slight elasticity. The inner diameter of the spring should be about 10 mm. The spring should lift the valve slightly above the seat, and when pressed lightly, the valve should sit on the seat. The connection between the instrument and the valve is carried out by a rubber suction device, as shown in. For better adhesion of the suction cup to the valve, their surfaces must be dry and clean.

To speed up lapping, use a lapping paste made up of one part of M20 micro-powder and two parts of engine oil. Stir the mixture thoroughly before use. Lapping until a uniform matte chamfer appears on the working surfaces of the seat and valve disc around the entire circumference. At the end of lapping, reduce the amount of micro-powder in the lapping paste. Finish lapping in one clean oil. Instead of lapping paste, you can use # 00 emery powder mixed with engine oil.

For grinding the working chamfers of the valves, it is recommended to use grinding machines of the R-108 or OPR-1841 GARO type. At the same time, clamp the valve stem in the centering chuck of the headstock, which is installed at an angle of 44 ° 30 "to the working surface of the grinding stone. A 30" decrease in the angle of inclination of the working chamfer of the valve head compared to the chamfer angle of the seats accelerates the running-in and improves the tightness of the valves. Chamfer the valve head with a minimum amount of metal when grinding. The height of the cylindrical shoulder of the working chamfer of the valve head after grinding should be at least 0.7 mm, and the alignment of the working chamfer relative to the rod within 0.03 mm of the total indicator readings. Valve stem runout - no more than 0.02 mm. Replace valves with large runout with new ones. Do not re-grind valve stems to a smaller size, as it will be necessary to make new valve spring plate craters.

Grind the seat chamfers at a 45 ° angle coaxial with the bore in the bushing. The chamfer width should be 1.6–2.4 mm. It is recommended to use the tool shown on the right for grinding the seats. Grind the saddle without lapping paste or oil until the stone is on the entire working surface.

Change the stone to a fine-grained stone after coarse cutting and fine-sand the seat. The runout of the chamfer relative to the axis of the bore of the valve sleeve should not exceed 0.03 mm. Replace worn seats with new ones. Spare parts are supplied with valve seats with an outer diameter greater than the nominal by 0.25 mm. Remove worn seats from the head using a countersink.

After removing the seats, bore in the head of the socket for the outlet valve to a diameter of 38.75 + 0.025 mm and for the inlet valve to a diameter of 49.25 + 0.25 mm. Before pressing the seats, heat the cylinder head to a temperature of 170 ° C, and cool the seats with dry ice. Press in quickly, without allowing the seats to heat up. The cooled head tightly wraps around the saddles. To increase the seating strength of the seats, hammer the OD with a flat mandrel to fill the seat chamfer. Then grind to the required size and grind.

If the wear of the valve stem and the guide sleeve is so great that the clearance in their joint exceeds 0.25 mm, then restore the valve tightness only after replacing the valve and its sleeve. Spare parts are supplied with valves of nominal sizes only, and guide bushings with an inner diameter reduced by 0.3 mm for their subsequent reaming to the final size after being pressed into the cylinder head.

Expand the pressed-in sleeves to a diameter of 9 + 0.022 mm. The inlet valve stem has a diameter of 9 –0.050 –0.075 mm, the diameter of the outlet valve 9 –0.075 –0.095 mm, therefore, the clearances between the inlet and outlet valve stems and bushings should be equal to 0.050–0.097 mm and 0.075–0.117 mm, respectively.

Press out the worn guide bushings from the cylinder head using a punch shown in fig. ...

Press in the new bushing from the side of the rocker arms using the same punch as far as it will go into the retaining ring on the bushing. In this case, as in the case of pressing in the valve seats, heat the cylinder head to a temperature of 170 ° C, and cool the sleeve with dry ice.

After replacing the valve bushings, grind the seats (centering on the holes in the bushings) and then grind the valves to them. After grinding the seats and lapping in the valves, thoroughly rinse all channels and places where abrasive could get into and blow with compressed air.

Valve sleeves are porous sintered metal. Soak them in oil after finishing and rinsing. To do this, insert a felt wick soaked in spindle oil into each sleeve for several hours. Before assembling, lubricate the valve stems with a thin layer of a mixture prepared from seven parts of an oil colloidal graphite preparation and three parts of engine oil.

Replacing valve springs

Possible valve springs failures that appear during operation can be: a decrease in elasticity, breakage or cracks on the turns.

Check the tightness of the valve springs when disassembling the valve train. The force required to compress the new valve spring up to 46 mm in height should be 267-310 N (27.3-31.7 kgf), and up to 37 mm - 686-784 N (70-80 kgf). If the compression force of the spring up to 46 mm in height is less than 235 N (24 kgf), and up to 37 mm is less than 558.6 N

(57 kgf), then replace such a spring with a new one.

Replace springs with breakage, cracks and traces of corrosion with new ones.

Replacement of pushers

The pilot holes in the block for the pushers are slightly worn out, therefore, restore the nominal clearance in this mating by replacing the worn pushers with new ones. Only the nominal size pushers are supplied with spare parts.

Match the pushers to the holes with a gap of 0.040–0.015 mm. Pushers, depending on the size of the outer diameter, are divided into two groups and are marked with stamping: number 1 - with a pusher diameter of 25 –0.008 –0.015 mm and number 2 - with a pusher diameter

25 –0.015 –0.022 mm. A properly selected pusher, lubricated with liquid mineral oil, should smoothly descend under its own weight into the block socket and rotate easily in it.

Replace pushers with radial scuffs, wear or chipping of the working surface at the ends of the plates.

Distributor drive repair

|

|

Rice. 2.62. The drive of the oil pump and the ignition distributor: the position of the groove of the roller A - on the drive installed on the engine; B - on the drive before installing it on the engine; B - on the oil pump shaft before installing the drive on the engine; 1 - oil pump roller; 2 - bushing; 3 - intermediate roller; 4 - pin; 5 - drive gear; 6 - camshaft gear; 7 - thrust washer; 8 - block of cylinders; 9 - gasket; 10 - drive roller; 11 - drive body; 12 - ignition distributor drive |

The roller 10 () of the distributor drive, worn out in diameter, is restored by chrome plating followed by grinding to a diameter of 13–0.011 mm.

Replace the pinion gear 5 of the distributor drive, which has breaks, staining or significant wear on the surface of the teeth, as well as wear of the hole for the pin to a size of more than 4.2 mm, with a new one.

To replace the roller or the distributor drive gear, remove the gear from the roller by first removing the pin of the gear using a 3 mm diameter bit. When removing the gear from the roller, place the drive housing 11 with its upper end on a support with a hole in it for the passage of the drive roller assembly with a thrust bushing.

Assemble the drive taking into account the following:

1. When installing the roller (assembled with the thrust bush) in the distributor drive housing, lubricate the roller with engine oil.

2. Having connected the drive shaft 10 with the drive intermediate roller-plate 3 and putting on the thrust washer 7, press the gear wheel onto the roller, maintaining the gap between the thrust washer and the drive gear 0.25 –0.15 –0.10 mm ().

In this case, it is necessary that the O – O axis passing through the middle of the depressions between the two teeth on the end B was displaced relative to the B – C axis of the roller spline by 5 ° 30 "± 1.

3. Drill a hole in the pinion and pin roller with a diameter of (4 ± 0.037) mm, maintaining the distance from the axis of the hole to the end of the pinion (18.8 ± 0.15) mm.

When drilling a hole and when setting the gap between the thrust washer and the gear, the distributor drive shaft assembly with the thrust sleeve must be pressed against the drive housing in the direction of the oil pump. The pin connecting the pinion to the pinion should be 4–0.025 mm in diameter and 22 mm long.

In the assembled distributor drive, its roller should turn freely by hand.

Oil pump repair

With heavy wear of the oil pump parts, the pressure in the lubrication system decreases and noise appears. When disassembling the pump, check the elasticity of the pressure relief valve spring. The elasticity of the spring is considered sufficient if a force (54 ± 2.45) N [(5.5 ± 0.25) kgf] is required to compress it up to 24 mm in height.

Repairing an oil pump usually consists of grinding the end caps, replacing gears and gaskets.

When disassembling the pump, pre-drill the riveted head of the bushing fixing pin 2 (see) on its roller 1, knock out the pin, remove the bushing and the pump cover. After that, remove the pump shaft together with the drive gear from the housing towards its cover.

In the case of disassembling the pinion gear and roller, drill the pin with a 3 mm drill.

Replace the drive and driven gears with chipped teeth, as well as with noticeable deformations of the surface of the teeth with new ones. Installed in the pump housing, the drive and driven gears should be easily turned by hand by the drive shaft.

If there is a significant (more than 0.05 mm) depletion from the ends of the gears on the inner plane of the cover, grind it.

Paronite gaskets 0.3–0.4 mm thick are installed between the cover, plate and pump casing.

The use of shellac, paint or other sealing substances when installing the gasket, or installing a thicker gasket, is not allowed, as this will reduce the pump flow.

Assemble the pump taking into account the following:

1. Press the bushing onto the drive shaft, keeping a 8 mm (8 mm) dimension between the end of the drive shaft and the end of the sleeve (). In this case, the gap between the pump casing and the other end of the sleeve must be at least 0.5 mm.

2. Drill in the drive roller

and in the sleeve a hole with a diameter

4 + 0.03–0.05 mm, keeping the dimension (20 ± 0.25) mm.

3. Countersink the hole on both sides to a depth of 0.5 mm at an angle of 90 °, press in a pin with a diameter of 4-0.048 mm and a length of 19 mm and rivet it on both sides.

If it is impossible to restore the pump performance by repair, then replace it with a new one.

Install the oil pump drive and ignition distributor on the block in the following order:

1. Remove the spark plug from the first cylinder.

2. Install a compressor in the hole for the spark plug and turn the crankshaft with the starting handle until the arrow starts moving. This will happen at the beginning of the compression stroke in the first cylinder. You can plug the candle hole with a paper wad or your thumb. In this case, during the compression stroke, a wad will pop out or air will be felt from under the finger.

3. After making sure that compression has started, carefully rotate the crankshaft until the hole on the crankshaft pulley rim aligns with the pointer (pin) on the timing gear cover.

4. Turn the drive shaft so that the slot on its end for the distributor awl is positioned as indicated in B, and using a screwdriver, turn the oil pump shaft to the position indicated in C.

5. Carefully, without touching the gear wheels on the block walls, insert the drive into the block. Once the drive is in place, the roller should be in the position shown in A.

To reduce wear on the drive pivots, align the pump with the drive bore. To do this, use a mandrel () that fits snugly into the drive hole in the block and has a 13 mm diameter cylindrical shank. Center the pump on the arbor shank and secure in this position.

Cooling pump repair

|

|

Rice. 2.66. Engine cooling system pump: a - cooling system pump 21-1307010-52; b - cooling system pump 421-1307010-01; 1 - nut; 2 - roller; 3 - pump casing; 4 - control hole for the lubricant outlet; 5 - press lubricator; 6 - spacer sleeve; 7 - sealing washer; 8 - rubber cuff; 9 - spring; 10 - impeller; 11 - impeller mounting bolt; 12 - retaining ring; 13 - bearings; 14 - fan pulley hub; 15 - belt; 16 - pulley; 17 - fan; 18 - bolt; 19 - roller-ball bearing assembled with a roller; 20 - retainer; 21 - stuffing box; 22 - pump casing cover |

Possible pump malfunctions () may be: fluid flow through the impeller oil seal as a result of wear of the sealing washer or destruction of the rubber seal of the oil seal, wear of bearings, breakage and cracks of the impeller.

Repair of the pump 21–1307010–52 of the cooling system

Eliminate fluid leakage from the pump by replacing the sealing washer and rubber cuff. To replace, remove the pump from the engine, disconnect it from the bracket, remove the impeller () with special tool 71-1769, remove the sealing washer and the gland seal.

To assemble the impeller seal, first insert the rubber gland assembly into the gland holder located on the pump housing, then the sealing washer and retaining ring. In this case, lubricate the part of the pump shaft, coupled with the rubber cuff, with soap before installing the oil seal and pressing the impeller, and the end of the impeller, which is in contact with the sealing washer, with a thin layer of graphite grease.

Before installing the gland, check its end (the end of the sealing washer) for paint: when the gland is compressed to a height of 13 mm, the end imprint should have at least two completely closed circles without breaks.

Press the impeller onto the roller on a hand press until its hub stops against the flat end. In this case, the pump should rest on the table with the front end of the roller, and the force should be applied to the impeller hub.

To replace the bearings or pump shaft, disassemble the pump completely in the following order:

1. Remove the impeller from the pump shaft and remove the sealing washer and rubber lip.

|

|

Rice. 2.68. Removing the pump pulley hub |

2. Unscrew the pulley hub retaining nut and remove it using the tool as shown in.

3. Remove the bearing retaining ring from the pump housing 1 () and press out or knock out the roller 2 with bearings from the housing with a copper hammer using a press, resting the front end of the housing on the support 3 with a hole for the passage of the bearings.

We assemble the pump in the reverse order. In this case, press the new bearing onto the roller 1 () and into the housing 2 at the same time using a hand press and a mandrel 3. The felt bearing gland must face the retaining ring. Putting the spacer sleeve on the shaft, press the second bearing out with the felt gland.

After replacing the retaining ring, press the pulley hub onto the front end of the roller, resting the roller against the rear end of the ring. Press the pulley hub onto the pump shaft of the 4218 engine after installing the retainer 19 (see, b). When pressing on the hub, make sure there is no play between the bearing and the circlip.

Rice. 2.66, b). Press out the oil seal.

Assemble the pump in reverse order. In this case, press-in the fan pulley hub until it stops in the shoulder, and press-in the impeller - to the size 117.4 +0.925 –1.035 (see, b).

Before assembly, lubricate the part of the roller of the roller-ball bearing, mated with the oil seal, with soap, and the end of the impeller, which is in contact with the oil seal, with graphite grease.

When installing the assembled pump on the motor, pay attention to the suitability of a paronite gasket between the cover and the pump housing.

Repair of fuel tanks

A possible malfunction of the tanks can be a leakage due to the formation of cracks, holes or other damage that occurs during operation. For repair, remove the tank from the car, clean it from dirt and rinse the outside.

To identify a malfunction, immerse the tank in a bath of water and supply compressed air inside the tank at a pressure of 30 kPa (0.3 kgf / cm2). All tank openings must be pre-sealed. In places where the tightness is broken, air bubbles will come out of the tank. Mark all damage with paint.

Then disassemble the tank completely, thoroughly rinse it from the inside with hot water to remove gasoline vapors and blow it with compressed air. Solder small cracks with soft solder. Apply metal patches to large cracks and holes. It is possible to seal cracks with epoxy pastes and layered fiberglass patches. After repair, test the tank for leaks.

Repair small cracks in the fuel tank cap caused by impacts. Seal cracks with epoxy paste. After the paste has hardened, check the function of the plug valves.

Fuel pump repair

Possible pump malfunctions can be: violation of the tightness of the diaphragm and valves, reduced elasticity or breakdown of the diaphragm spring, wear of pump drive parts.