The article is based on the materials of the forum, source link

Some information on the karakat, although everything is clear from the photographs, but even so, the kamuto may be interesting. The engine from the motorcycle IZH planet, the left cover with the fan from the disabled woman SZD. The standard electrical equipment has been replaced by Voskhod, which does not need a battery and is much more reliable, since instead of cams there is a hroll sensor.

>

>

Differential UAZ and two long UAZ axle shafts. The half-shafts are shortened because the karakat would be very wide. Native hubs are cut and pressed from the Muscovite ones, since the wheels are made on the basis of lighter Muscovite disks.

>

>

The disc of a motorcycle wheel is halved and a disc for Bel-79 is made on its basis. in general, two sets of wheels were made, one based on Bel - 79 for mud, one based on chambers for swamp. At the end, the unexpected became clear: the chamber wheels turned out to be somewhat heavier. This year the summer was dry and on factory wheels they drove through the swamp without any problems;

>

>

>

>

The frame is reinforced with gussets, at the bottom at the engine mount and in the fork mount area. For strength, a bronze bushing is inserted into the fork mount, since even without such loads as in a swamp at IZH, it breaks the bearings in this place. The body is made of sheet luminescent and riveted luminescent corner:

>

>

The price of a karakat turned out to be very decent, but this is because much had to be redone in the course of work, since there was no experience in making just such devices. various technical problems were solved along the way. In the design, only new parts and materials were mainly used, therefore the price was high. The device is being finalized in the course of operation, it left for summer and half of autumn through mud swamps, etc. so far no problem. Below is a photo of the manufacture of this all-terrain vehicle.

>

>

>

>

>

>

>

>

>

>

The cross-country ability of the karakat is excellent, it rushes through the swamp as it should, the engine is high-torque and even with a load it goes confidently along the complete off-road swamp. Very maneuverable and well-handled certainly not like a regular motorcycle, but quite normal and not heavy. In the north of the Omsk region and in Tyumen it is very rare to see a four-wheeled karakat, three-wheeled karakats are time-tested, and they are simpler in design than four-wheeled ones, less iron and nodes, which means more reliable.

And this karakat, so to speak, is a prototype, and the predecessor of this karakat.

>

>

Checking the buoyancy of the karakat, as seen on the water, it is not bad. There is a current on the river, so I tied it with a rope, we usually have such devices when crossing the river are tied to a motor boat and so they are ferried.

>

>

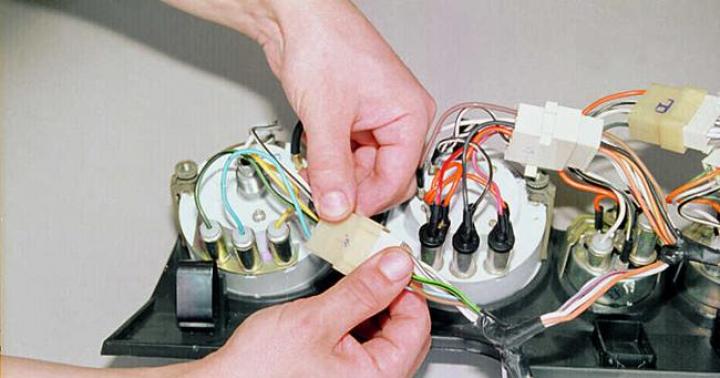

Photo of the rear drive from below

>

>

>

>

It took 63,000 rubles to build and refine this karakat, this price came from the fact that all that we needed to build it was acquired new, even the smallest thing, the work of a turner and stuff. The engine was sorted out, replacing the piston, we bought a left cover with cooling from a disabled woman, and more.

Probably, everyone at least once in his life has seen huge three-wheeled motorcycles, on which no less huge bearded men in leather vests and iron helmets ply the vastness of the roads. And more than once we looked at photos from motorcycle shows or exhibitions, where steel horses flaunt under the flags of their motorcycle clubs. These vehicles are called tricycles or trikes because they have three wheels instead of two.

These motorcycles are specially designed for long and comfortable trips, they have amazing spaciousness and power. The only drawback of these models is that they are rarely found on sale. And if there are any (especially if they are the brainchild of well-known brands), then their cost will be very high. What to do if you want to own such a bike, but there is no big money or purchase opportunities? The only answer is to create it yourself.

How to make a tricycle

To create a homemade trike we will use two other vehicles - a ZAZ-968 car and a heavy Ural motorcycle. As a result, you should get a very powerful and fairly reliable tricycle, on which you can conquer hundreds of kilometers.

General construction drawings

Our tricycle will be a single structure made of ZAZ-968 and "Ural". But in order to assemble one, you need to have a drawing, thanks to which you can clearly see the location of all parts and accessories.

1, 2 - front wheel and fender; 3 - front wheel suspension system; 4, 5 - headlight and headlight bracket; 6 - speedometer; 7 - gas tank; 8, 9 - lever and gearbox; 10 - battery; 11 - seat back; 12 - rear lights; 13 - air filter; 14 - engine; 15 - cooler; 16 - oil-air radiator; 17 - mufflers; 18 - rear wheel; 19 - elastic coupling; 20 - brake rod; 21 - brake pedal; 22 - beep; 23 - struts of the rear wing; 24 - shock absorbers; 25 - frame for mounting the radiator and muffler; 26, 27 - rear wing and its attachment console; 28 - front console; 29 - wing bracket; 30 - rear wheel suspension arms; 31, 32 - throttle and brake levers, respectively; 33 - ignition lock; 34, 35 - clutch pedal and clutch rod; 36 - speed switch; 37 - steering wheel.

Design features of the tricycle:

- special kerchiefs are used to strengthen all joints;

- the upper beam is a support for the rear shock absorbers, therefore glasses are welded to it, which are the same in design as automobile ones;

- frames are welded to the kerchiefs and slopes on the central beam, which are necessary for the passenger to have footrests and at the same time act as a support for the suspension bumpers;

- the lower cross member is attached to the frame using brackets and struts, acting as a base for the pedal assemblies;

- the strut on the transverse frame mount is required to support the entire gearshift mechanism.

Features of the tricycle layout differ significantly from the standard motorcycle one. The main difference is that the power unit is located at the back and the balance is shifted back, which gives an extra reason for adrenaline - with a sharp acceleration, the motorcycle rears up.

The engine, like the gearbox, was removed from the ZAZ-968 car and no significant modifications were made to it. Only mufflers, an oil cooler from the car and an air filter have been added to the overall design of the rear of the trike. Everything else completely and completely remained the same as on the ZAZ-968. The engine mount remains the same, the gear lever is on the left (since the driver's right hand is on the throttle control). The linkage of the gearbox mechanism is connected to the gearbox through a conventional hinge, which are installed on domestic cars.

.jpg)

The front suspension fork works on the same principle as in the "Ural". A linkage is used and the front wheel axle is between the wishbones. In general, it is necessary to change a little - it is only necessary to lengthen the borrowed front fork of the "Ural".

DIY assembly

Having a diagram and knowing the individual nuances of the process itself, we begin the step-by-step process of assembling a homemade tricycle.

The end result is a trike, the technical characteristics and appearance of which are in no way inferior to the tricycles that we have seen before.

Video clip about the tricycle IZH

In this video, you can see how a homemade trike based on the IZH Planet 5 motorcycle ultimately looks like.

Below are a few trikes with an interesting and memorable design.

Everyone knows that only three points are needed for good support, but for some reason three-wheeled vehicles are not as common on our roads as four-wheeled vehicles. Although the first tricycles appeared in the 18th century. It was on such steam engines that it was proposed to transport guns and heavy weapons for the army.

Homemade tricycle - transport of many generations.

At one time tricycles were much more common than their own, but today we do not often see three-wheeled vehicles on the roads. Photos of tricycles - this is the second name of tricycles can be seen on the sites of bikers or car enthusiasts. It is worth noting that a tricycle can be both a kind of motorcycle and a kind of car, so if you are thinking of making a tricycle with your own hands, immediately decide what kind of tricycle you imagine.

Of course, before building a trike with your own hands, you should study in detail the principle of operation of such a transport and have drawings. Drawings can be made independently if you have the necessary education and good knowledge of the operation of all units. But if you don't have such skills, but you really want to create a homemade trike, you can find ready-made laid out drawings of homemade trikes that were designed by other craftsmen.

By the way, you can watch a video of tricycles that garage Kulibins made with your own hands on rework sites or YouToube, where a video of testing garage inventions is posted.

DIY trikes: where to start

Donors for a tricycle can be any kind of transport, but most often they collect a tricycle from "Ural" or a tricycle from "IZH".

In this version, you have to redo the least, because the base of the motorcycles is the most suitable for trikes.

Many people make trikes with their own hands "Ural" and "ZAZ" bringing together these two vehicles.

The first stage of work on the trike is the creation of the frame and rear axle. The bridges to the frame can be attached to rods, on the principle of VAZ cars, or they can be put on springs, as is done in Moskvichi. The frame will naturally have to be extended, but this is easy to do with pipes and profiles. If you are planning to make a homemade trike from the "Ural" with your own hands, almost everything will remain native - the fork, brake discs, hydraulics, fender, etc. By the way, these homemade tricycles look good in a chopper style with elongated forks and a low rise. On the Internet you can see photos of tricycles-

Motorcycles produced back in the Soviet era are already considered a rarity. It is unlikely that he will be able to interest any of them in the quality of a vehicle. A museum exhibit, nothing more! Such equipment is sold very cheaply, a little more expensive than scrap metal. Despite the fact that the old "horse" has already served its purpose, it's time, as they say, to retire, but you don't want to part with it. Familiar situation? Often such a vehicle does not have documents, you cannot go far from home on it - trouble from the police is guaranteed.

Not everyone will think that an old motorcycle "Ural", gathering dust idle in the garage, can be turned into a practical unit. Such a homemade product from the Urals does not require huge financial investments, but a certain amount of patience and a few hours of free time will be very useful.

Homemade tricycle from the Urals

The main advantages of a tricycle based on the "Ural":

The predominant part of the component parts belongs to the motorcycle, the engine for the trike is suitable from the ZAZ-968. The most time consuming process is the manufacture of the frame. In the design, it is a kind of connecting link on which all assemblies and parts are installed.

Design features

For inexperienced designers, when assembling a tricycle, the drawing will be an excellent guide to action. It is important to think carefully about sizing.

Rear shock absorbers are mounted on the upper beam, which are similar to automobile counterparts. When driving on a road with irregularities, the shock absorbers will react sensitively to them. Glasses are welded to the beam, which provides the desired comfort. The pipes are welded to the end together with reinforcing kerchiefs - the fastening will be reliable.

Due to the fact that the power unit is installed at the rear, the center of gravity is also there. With a sharp increase in engine speed, the front wheel comes off the road, the tricycle rears up. The elimination of this effect is facilitated by placing the balance closer to the front wheel.

If the engine is slightly tired, it needs to be slightly repaired. The exhaust system in this case is home-made, and the cooling system can be chosen water or oil type.

Since the right hand is busy adjusting the "throttle", then the gear lever, of course, should be on the left side.

Assembly sequence

- The frame is constructed according to the drawing. Everything that is made of ferrous metal must be covered with a layer of primer, and then with paint.

- The rear axle must be in good condition. It can be removed from a Zaporozhets or Moskvich car.

- All major components and assemblies represented by the engine, filters, exhaust system and oil cooler are mounted on the rear axle.

- To have free access to all parts and to ensure ease of assembly, it is recommended to use a jack or lift. The frame must provide a secure connection between the front fork, rear axle and engine.

- When fixing the elements, backlash should not be allowed, there should be no clinking. To avoid vibrations, make the connection with lock nuts.

- The most reliable is considered to be fastening by welding. This must be taken into account when fixing on the frame, rear axle and cross members.

- Attaching the fuel tank, seats, trunk and other accessories is done at the very end of the assembly, when the homemade trike is already on the wheels.

Homemade ATV from the Urals

Heavy motorcycles "Ural" are not very popular. One of the reasons is the huge consumption of gasoline. Many motorcyclists and bikers are not satisfied with the large dimensions of the Urals. Despite this, craftsmen are interested in such motorcycles. Moments such as the presence of a reverse gear, a rather powerful four-stroke engine are very tempting in terms of converting an old Ural into an ATV. As a result, its cost is much lower than that of its European congener, and the engine power is much higher. Such homemade products from the Ural motorcycle will appeal to everyone who loves to create with their own hands.

Design features

Craftsmen from the city of Barnaul received a successful version of a homemade ATV:

- The Ural motorcycle was taken as a basis, in particular, the frame with the engine was left.

- The reinforced gearbox was removed from the motorcycle of another model of the domestic motorcycle - "Dnepr".

- The drive had to be made of a cardan type, due to the fact that the options with sprockets and chains are less reliable.

- Two pairs of wheels fit well from the Gazelle car. At the same time, the appearance of the ATV turned out to be rude, uncouth.

The management of Russian car factories should think about the issue of producing domestic ATVs and tricycles, taking advantage of the excellent experience, for example, of the Barnaul craftsmen. Moreover, most of the components have already left the conveyors of these enterprises in due time!

Homemade Ural motorcycles can look different. In any case, this technique is impressive.

Homemade snowmobile from the Urals

Most craftsmen who have tried to design a snowmobile with their own hands are faced with the problem of choosing a light engine with high power. It is also difficult to find a track track.

Important criteria a homemade snowmobile must meet:

- I would like to simplify the scheme as much as possible so that the manufacture of the unit at home is not accompanied by difficulties. The product should be as cheap as possible, otherwise it is more profitable to buy a ready-made factory analogue.

- The inventor is accountable to customers by offering them a hazardous vehicle.

- Minimize the naming of parts that require processing on a lathe or other machine. Otherwise, the process of manufacturing the unit becomes more complicated, because in modern conditions, finding the necessary machine and a specialist who knows how to handle it is not easy.

Features of a homemade snowmobile

- When choosing and modifying the chassis, you can use the Buran snowmobile diagram. The track system is in the form of rollers, but only one of them was needed for the homemade unit.

- The implementation of the power train from the gearbox to the drive shaft is made possible by means of a chain.

- In the front there are a pair of racks that are designed to have skis instead of wheels. The struts are equipped with springs from the rear shock absorbers of the Izh-Planeta motorcycle.

- The run of the homemade snowmobile over 3 thousand km did not affect the engine's operation - there was no overheating. Traveling a distance of 90 km, the snowmobile consumes almost 10 liters of gasoline.

This is my second attempt to build a tricycle with my own hands. Due to the fact that my tricycle was supposed to correspond to the ideology of a classic chopper, I did it with great care.

Installed engine ZAZ-968

I must say right away that the front fork with a large angle of inclination negatively affected the handling and maneuverability of the device. This is especially noticeable at speeds over 100 km / h. In addition, at this speed, if you hit a serious pothole, there is a danger of destruction of the levers.

The machine is based on a spatial welded frame made of tubular elements. The combination of curved side members and cross beams makes the structure quite robust. The lower and upper side members are connected in pairs at the rear.

The central beam is combined with the upper spar into one unit and reinforced with a special box, and in the rear part it is connected to the side spars through struts.

Tricycle design

The side members are vertically interconnected by means of a lower arch and internal lugs, into which the rear suspension arms are installed. All joints are reinforced with kerchiefs. The upper beam serves as a support for the rear shock absorbers, for which glasses are welded to it, the design of which is similar to automobile ones.

General design

1 - front wheel; 2 - front fender (from the Yamaha motorcycle); 3 - front wheel suspension, lever; 4 - headlight; 5 - headlight bracket; 6 - speedometer body (Steel st3, chrome plating); 7 - fuel tank; 8 - gear change lever; 9 - gearbox; 10 - battery; 11 - seat back; 12 - a block of rear lights; 13 - air filter; 14 - engine; 15 - fan; 16 - oil-air radiator; 17 - mufflers (from the Yamaha motorcycle); 18 - rear wheel (295x50x15); 19 - elastic coupling; 20 - brake rod (Steel X18H9T, pipe 12 × 1); 21 - brake pedal; 22 - horn; 23 - rear wing strut (Steel st3, pipe 15 × 1.5, chrome plating); 24 - shock absorber (from the ZAZ-968 car); 25 - frame for attaching mufflers and radiator (Steel Х18Н9Т, pipe 18 × 1.5); 26 - rear wing; 27 - wing mounting console (Steel st3, pipe 28 × 1.5); 28 - front console (Steel Х18Н9Т, pipe 12 × 1); 29 - wing bracket (Steel Х18Н9Т, sheet s1.5); 30 - rear wheel suspension arm (from ZAZ-968); 31 - gas handle; 32 - front brake lever; 33 - ignition lock case (St3, chrome plating); 34 - clutch pedal; 35 - clutch rod (Steel Х18Н9Т, pipe 12 × 1); 36 - gearshift mechanism; 37 - steering wheel (Steel Х18Н9Т, pipe 25 × 3)

Tubular frames are welded to the kerchiefs and struts of the central beam. These units are sheathed on both sides with steel sheet, and have several purposes. Firstly, they have passenger footpegs similar to motorcycle footboards. Secondly, they support the suspension bumpers. Thirdly, struts are attached to them, on which the rear empennage consoles are supported.

The lower cross member is attached to the frame with brackets and a brace and serves as the basis for the pedal assembly. It includes an axle, levers, stems and footrests. The crossframe support also supports the gearshift guide.

Frame design

All frame parts are made of CT3 steel. 1 - steering column; 2 - kerchiefs (sheet s5); 3 - main spar, upper (pipe 60 × 3); 4 - brace (pipe 34 × 2); 5 - reinforcing box (sheet s3); 6 - platform bracket for the battery (corner 50 × 50); 7 - upper side members (pipe 34 × 2); 8 - lower arc (pipe 34 × 2); 9 - passenger footrest frame (pipe 22 × 1.5); 10 - struts of the central beam (pipe 52 × 3); 11 - shock absorber glasses; 12 - arc of the passenger seat (pipe 28 × 1, chrome plating); 13 - lugs for fastening the levers of the rear suspension (sheet s5); 14 - shelf for fastening the checkpoint (strip 80 × 5); 15 - gusset plate for installing the hinge of the gear lever (sheet s3); 16 - outlets for mounting pedals (pipe 28 × 2, chrome plating); 17 - pedal lever (sheet s5, 2 pcs., Chrome plating); 18 - main spars, lower (pipe 34 × 2); 19 - horn mounting bracket (corner 50 × 50); 20 - central beam (pipe 60 × 3); 21 - upper beam (pipe 52 × 3); 22 - engine mounting unit (sheet s5); 23 - jumper (corner 50 × 50); 24 - frame sewing (sheet s3 on both sides); 25 - footboard (Х18Н9Т, pipe 36 × 4); 26 - axis (X18H9T, bar 028); 27 - plug (X18H9T); 28 - bracket (sheet s3); 29 - lower cross member (pipe 34 × 2); 30 - guide of the shank of the gear shifting mechanism (pipe 28 × 1.5); 31 - base of the passenger seat (tube 20 × 1, chrome plating)

The layout of a home-made tricycle differs significantly from a motorcycle one, primarily in the location of the power unit. It is located outside the base behind the rear axle, which does not in the best way affect the stability of the car, but it provides an experienced driver with an additional opportunity to generate adrenaline. With a sharp acceleration, the tricycle can be easily “reared up”, which delivers an unforgettable experience.

Engine

The power unit, including the gearbox, was taken from the Zaporozhets car. No special modifications were made. It is worth noting only the installation of an oil cooler from the helicopter, the manufacture of a chrome-plated housing of the air filter and mufflers from Honda, and a separate one is installed for each cylinder.

All other units are from ZAZ-968. The mount of the power unit also has not undergone any changes. The two attachment points are located at the corners of the arch, which is where the upper beam and the side members join. The third is located between the lower side members flush with the front of the gearbox. The shift lever is on the left as the driver's right hand is busy controlling the throttle. The rod of the gearshift mechanism is connected to the box shank through a hinge similar to the Zhiguli one.

Suspension

The front wheel suspension design deserves a separate description. It is made according to a lever scheme, which is quite rare. The suspension consists of two pairs of consoles and two pairs of springs. The consoles are made of titanium and are interconnected by wishbones. The front wheel axle runs through the wishbones.

Suspension scheme

1 and 11 - thrust cones (Steel Kh18N9T); 2 - special nut М12 (Steel Х18Н9Т); 3 - main traverse, upper (AK4); 4 - main console (VTZ-1, bar 40); 5 - main traverse, lower (AK4); 6 - transverse lever (X18H9T, sheet s10); 7 - lower traverse (AK4); 8 - movable console (VTZ-1, bar 28); 9 - upper traverse (AK4); 10, 15, 18 - bushings (Steel Х18Н9Т); 12, 13, 16, 17 - compression springs; 14 - thrust washers; 19 - nut М12; 20 - spherical support; 21 - stock (Х18Н9Т); 22 - axis (bolt M12); 23 - bushings (bronze); 24 - nut with a spherical head

The springs are used from the IZH motorcycle and helicopter units. The suspension works in such a way that the upward movement of the wheel is compensated by the lower springs, and when moving in the opposite direction, the upper springs, which have a significantly lower rigidity, enter into action.

The battery is installed behind the driver's seat on a special frame above the engine. The passenger seat mounts are also mounted here, on which leather trunks are hung with the help of lacing. The latter not only serve to transport things, but also cover the engine, and most importantly, give the car a complete "chopper" look.

Exhaust system

The gas tank, steering wheel, instrument cluster and front suspension are made in the same style. The rear wing consists of two interconnected wings from the Ural motorcycle. Like the gas tank, the rear fenders are painted black.

Then the surface is properly prepared, and a drawing with cosmic images performed by a professional artist is applied to it by the method of airbrushing. The last stage of finishing was the application of several coats of clear varnish and polishing.