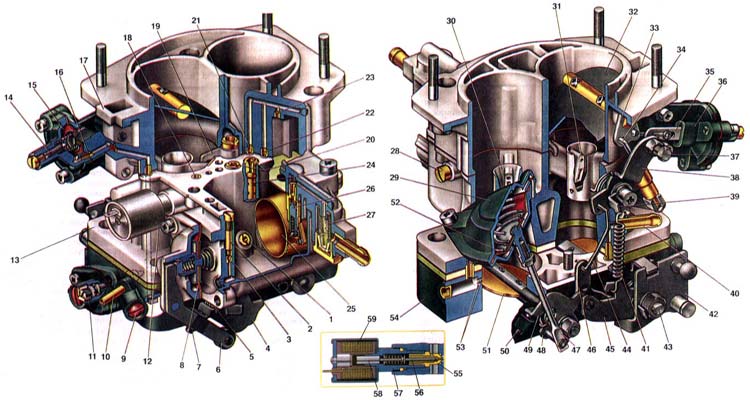

The manufacturer for the VAZ-2106 provides an emulsion carburetor Ozone of the DAA3 2107-1107010-20 series. Structurally, it is made according to a two-chamber scheme and includes the following elements:

- accelerating pump and spray in 1 chamber;

- enrichment device in the 2nd chamber;

- balanced float chamber;

- spool mechanism for venting gases from the crater;

- shut-off solenoid valve;

- pneumatic actuator DZ (throttle valve) in the second chamber;

- 2 main dosing systems;

- system XX (idle).

How does a carburetor work?

Fuel enters the carburetor float chamber through a mesh filter and connected by a flexible rod to the float. Thus, a certain level of gasoline is maintained in the float chamber all the time.

In turn, fuel from the float chamber is supplied through calibrated nozzles to emulsion wells and channels, in which it mixes with air coming from air nozzles. The fuel-air emulsion is then conveyed through the nozzles into the large and small diffusers. Then the mixture enters the inlet duct through a calibrated hole. Its cross section is regulated by a needle, the so-called quantity screw.

The design feature of the carburetor is the presence of two independent systems. The first one ensures the operation of the engine in the XX mode and includes an electric vacuum and vacuum valves with air and fuel jets. The second system comes into operation after opening the remote control by pressing the gas pedal.

The fuel mixture in these systems depends on the fluid level in the float chamber. Therefore, for stable engine operation, first of all, it is necessary to adjust the preset fuel level in the PC.

Setting up the carburetor

Setting up the VAZ-2106 carburetor includes the following operations:

- DZ position adjustment;

- correction of PU;

- testing the performance of the UN;

- control of IC tightness.

By turning the drive and the flap control lever, we set the DZ to the open position. We measure the value of the maximum opening, which should be within 13.0 ± 0.5 mm for the primary chamber and 15.0 ± 0.5 mm for the secondary. Adjustment of the size of the opening of the DZ in the first chamber is made by bending the lower barb of the thrust, and in the second - by twisting or unscrewing the thrust rod.

After that, we measure the distance from the upper tendril of the thrust to the lever limiting the movement of the DZ of the second chamber. If its value goes beyond 6.0 ± 0.1 mm, change it by bending the upper antennae.

Correction of the starting device (PU). By turning the lever counterclockwise to the end, close the DZ of the second camera. We control the position of the end of the rod of the lever, rigidly fixed on the axis of the DZ of the first camera. It should touch the end of the PU rod. If necessary, bend the traction until the required position is reached.

We check the magnitude of the opening of the primary thrust valve when the secondary valve of the second chamber is closed. The size of the open position should be within 0.7-0.8 mm with the extended piston rod by 5.0 ± 0.5 mm.

If the actual value of the extended stem goes beyond these limits, adjust its position by rotating the screw.

To check the performance of the accelerating pump (UH), it is necessary to collect fuel in a beaker, which is supplied during the period of 10 full strokes of the lever that controls the damper. Before that, a preliminary bleeding should be done to fill the pump channels. If the volume of controlled fuel is 5.25-8.75 cm3, the performance is considered normal.

Checking the tightness of the IC (needle valve) is carried out in the laboratory using special equipment. The IC is placed in a control tube for at least 10 seconds. If the pressure does not drop during this time, it means that the valve is working properly.

Do-it-yourself quick carburetor setup

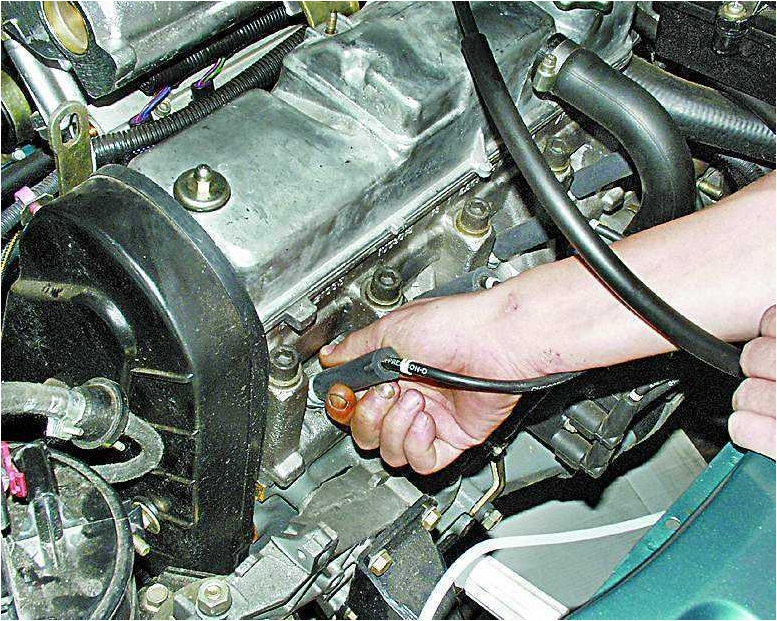

Having previously removed, we measure the distance between the centers of the rod ends. It should be within 80 ± 0.5 mm. If this parameter is outside the specified limits, it is necessary to adjust it in the following order:

- using a screwdriver, remove one of the tips;

- we loosen the lock nut with a wrench of 8 and rotate the tip until the length of the rod is set;

- tighten the lock nut and put the rod in its original place;

- then the assistant must press the gas pedal, after which we control the position of the DZ of the first chamber, if it does not open completely, it is necessary to remove the additional stroke of the lever;

- remove the longitudinal rod tip from the lever;

- we loosen the lock nut, set the predetermined value of the rod length and put it back, tighten the nut;

- re-check the position of the remote sensing;

- after releasing the gas pedal, we control the closing of the remote control;

- if necessary, we make a repeated check and adjustment.

- weaken the damper (choke) drive cable and ask the assistant to completely drown the lever;

- open the air damper by pressing the three-arm lever and tighten the locking screw;

- close the air damper with the lever in the cabin, and then open it again for control.

Possible problems and their elimination

or the engine stalls

- not adjusted XX;

- nozzles and channels are clogged - clean or blow out with air;

- water has entered the carburetor - remove the liquid and drain the sediment from the tank.

The engine cannot be started

- clogged fuel lines - blow out the pipes and flush the tank;

- the carburetor filter is dirty - rinse;

- - rinse the filter.

Weak engine power

- DZ do not open completely - adjust the damper drive;

- the channels and main jets are clogged - clean the carburetor;

- low fuel level in the PC - adjust the position of the float;

- the clearances in the valve assembly are broken - correct the clearances;

Increased consumption

- the air damper does not rise completely - adjust the DZ drives;

- damage or wear of the float - replace the failed part;

- clogged air ducts and nozzles - clean the carburetor.