A driver of a VAZ 2110 comes to us and emotionally begins to say: guys, help! In the evening you have to go on a business trip, and the car stalls, the candles are flooded. I put new candles, it works for about 10 minutes and starts to stall again, the carbon deposits on the candles are black. What to do???

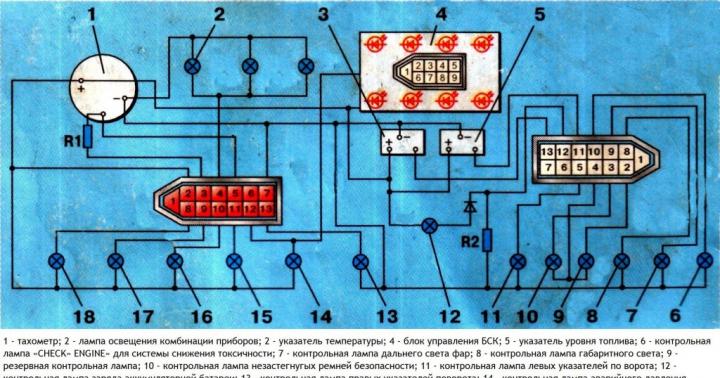

Fig. 1

Well, first, let's introduce you to who is in front of us. We connect the scanner for computer diagnostics and read the errors at the very beginning. Errors(trouble codes) are not in memory, but this does not mean that the car is in good working order, you need to look further. We check what kind of firmware (program) is installed in this electronic control unit (ECU) and what this car is equipped with.

Before us is a VAZ 2110 car, 1.5 liters, 8 valves, an M154 bosch control unit, the M1V13T64 program. This vehicle is not equipped with an oxygen sensor; instead, the mixture composition (CO correction) is corrected from the diagnostic equipment. If a car comes to you with a complaint about increased fuel consumption, then do not be too lazy at the beginning of the diagnosis to look at the readings of the ADC (analog-to-digital converter) MAF (mass air flow sensor).

The readings of the ADC or, more simply, the voltage at the signal output of a serviceable mass air flow sensor (MAF) when the supply voltage is applied to it should correspond to 1.00 volts. If the value is more than 1.06 volts, then it is recommended to replace the mass air flow sensor. How to look at the ADC value of the DMRV sensor? You need to go through the scanner to the tab - "ADC readings".

Fig. 4

Figure 4 shows that the ADC indicator of the DMRV (c) is 1.19 volts. This is very bad, because our DMRV sensor can be thrown into the trash. Its characteristic is so "flew away" that it already shows anything, just not the current air consumption, from that and the client's complaints about excessive fuel consumption.

And how to reject the mass air flow sensor without having a special scanner at hand to check the current parameters of the sensors? You need to pick up a voltmeter (multimeter) and preferably not a Chinese one for 100 rubles, which has an error of plus / minus a kilometer, but at least a semi-professional one. And measure the voltage on pins 3 (sensor mass) and 5 (signal) of the DMRV sensor with the ignition on. See Figure 5. below. By the way, the same (film) sensor is installed on many Mercedes, BMW, Tagaz Tager models, and you can check it in the same way. They have the same pinout.

Fig. 5

As we have already found out, the DMRV readings are 1.19 volts. But before throwing out the sensor, we decided to measure the CO readings in the exhaust gases, to carry out the so-called gas analysis. For gas analysis, the vehicle exhaust system must be completely sealed. To check for leaks, you can plug the exhaust pipe with your hand while the car is running and see if pressure is created. If there is pressure, then you will understand this. You just won't have the strength to hold your hand :). Our vehicle has a fully sealed exhaust system. We install the gas analyzer probe into the exhaust pipe and observe the following picture, Fig. 6.

Fig. 6

What conclusion can be drawn by observing the current performance? To begin with, we will give an example of the composition of the exhaust gases of a serviceable injection engine and compare the typical indicators with our values.

The composition of the exhaust gases (OG) of our faulty vehicle. The catalyst is missing.

CO%= 9.55 (norm 0.7 .... 1.0) the value of carbon monoxide CO (carbon monoxide) in 9 times!

CH= 1228 (norm 200 ... 300) exceeded the value of CH hydrocarbons in Five times!

CO2%= 7.88 (norm 12.5 ... 14) the value of carbon dioxide CO2 is underestimated in 1.5 times!

02%

= 1.42 (normal 1 ... 1.5) oxygen readings are normal.

Lambda= 0.762 (norm 0.98 ... 1.08) low lambda value. The mixture is very rich.

And so, let's consider each parameter separately:

CO- Carbon monoxide (carbon monoxide), a product of incomplete combustion of fuel. Necessarily present in the composition of exhaust gases (exhaust gases). With a properly running engine, concentration CO in waste gas is 0.7...1.0 %. In practice, CO values can be 0.5...1.2 %. If the CO reading in the flue gas exceeds the 1.5 %, then it is definitely worth sounding the alarm, with such a CO reading, an increased fuel consumption is observed.

In our case, the CO concentration is 9.55 % this is a lot, and it is not surprising that the owner complains about excessive fuel consumption.

CH- Hydrocarbons are fuel molecules that did not take part in combustion. The norm of hydrocarbons in exhaust gases is 200 ... 300 particles. Exceeding this value indicates that the fuel simply flies into the pipe and the mixture burns poorly.

In our case, the CH concentration is 1228 particles. The fuel simply does not burn.

CO2- Carbon dioxide. By this indicator, one can judge how well the mixture burns. The higher this indicator, the better and better the mixture burns. If this indicator is within 13...14 % then the rest of the values are most likely closer to the reference values. If the indicator is lower 10 %, the mixture burns very badly and there are serious malfunctions in the engine.

In our case, the CO2 concentration is 7.88 %. This is not surprising, because the engine is unstable, the consumption is frantic. The mixture burns very badly.

O2- Oxygen. The oxygen concentration in the exhaust gases is 1...1.5 %. In our case, the oxygen concentration is 1.42%. What's within tolerance.

Lambda- this can be said to be the main parameter of the composition of the mixture. Complete combustion occurs when stoichiometric composition of the mixture and corresponds to the value 14.7 hours air / 1 part fuel is a theoretical value.

If more air is supplied to the engine than is needed for complete combustion of the mixture (air 15 ... 19 parts), or air is supplied to the norm (14.7), but less fuel is supplied (less than 1 part, 0.7 ... 0.9), then " lambda "is within = 1.1...1.3

... This mixture is poor.

If less air enters the engine than is needed for complete combustion of the mixture (air is 10 ... 13 parts), or air is supplied to the norm (14.7), but more fuel is supplied (more than 1 part, 2 ... 3), then " lambda" is in the range = 0.7 ... 0.98. This mixture is rich.

Let's clarify again:

If "lambda"> 1 (1.1 ... 1.3), then we have a mixture poor... A lot of air (suction), or little gasoline.

If the lambda is rich. There is little air or a lot of gasoline (excessive fuel pressure, incorrect readings of the mass air flow sensor).

In our case, the "lambda" indicator is 0.762 , indicating a very rich mixture.

Conclusion from the readings of the gas analyzer. So, what conclusion can be drawn from our gas analyzer readings? And the only conclusion is that our mixture is very rich and indeed, with such readings, the fuel consumption will be frantic.

How to return the composition of the mixture to the desired parameters? What to tweak, tweak, and return the indicators to normal values?

And so, remember, what does the air-fuel mixture consist of? These are two components: fuel and air... Since we have a rich mixture, it means either there is not enough air, or too much fuel gets into the cylinders. Or maybe the sensor is lying, which measures the air flow and overestimates the values? Well, of course, we have already rejected such a sensor - this is a mass air flow sensor. In order to test this theory in reality, you must, of course, check all the parameters on a computer.

We start the engine, warm it up and at idle we observe the following parameters.

Fig. 8

From the experience of carrying out diagnostics, we can immediately say that we have overestimated the indicator (JAIR) of the air consumption and the opening time of the nozzle (INJ_TIME). We have JAIR shows 14.3 kg / h, and INJ_TIME is 3.1 ms. At idle engine speed 800 ... 900 rpm. with a volume of 1.5 liters and a working mass air flow sensor, the JAIR parameter should be within 9...10 kg / h., and the injection time INJ_TIME (with non-phased injection, as in our case) must correspond to the value 2...2,5 ms. Since our sensor is faulty, it overestimates the air flow rate by about 4..5 kilogram. It turns out that our idling engine really sucks in 9 kilogram of air, DMRV lies and shows 14 kilogram, the computer thinks that there is no air 9 , a 14 and adds fuel injection (increases injector opening time) to 3.1 ms respectively enriching the mixture. Hence such readings of the gas analyzer.

Our car is equipped with a mass air flow sensor of the company Bosch 0 280 218 037 and we recommended the client to purchase a sensor from Bosch. But the owner of the car decided to save money and bought a DMRV from another manufacturer (let's call it DMRV-37), because the price for it was more attractive. What came of it? And so, we install the DMRV-37 sensor ...

Fig. 9

We look at the readings of the ADC on a muffled engine, with the ignition on ...

Fig. 10

The readings of the DMRV-37 ADC are 0.98 volts, well, not 1.0 volts, but closer to the ideal. We start the engine, warm it up and begin to adjust the CO coefficient ( CO_Koeff).

Fig. 11

The CO factor is adjusted between -0.25 before +0.25 , i.e. the mixture is either leaner (reduced injection time), or enriched (increased injection time). And we know that if the engine and other sensors and actuators are in good working order, then the correction factor is usually in the range of -0.008 ... + 0.004. In order for our gas analyzer readings (mixture composition) to come to more or less reference readings, we set the CO coefficient to almost the maximum CO_Koeff = +0.242... But at the same time the air consumption became too low JAIR = 7.2 kg / h., and the readings of the gas analyzer became as follows.

Fig. 12

Well, in principle, we almost got the readings we wanted, but the idle air flow parameter JAIR = 7.2 kg / h., clearly underestimated, hence such a high CO correction factor (CO_Koeff = +0.242). Well, of course, even though the DMRV-37 is new and the readings with the ignition on are about 1.00 volts (0.98 volts according to the readings), it still underestimates the air flow readings, and instead of the real 9 kg. shows only 7 kg. Naturally, with the CO correction factor, we have to increase the fuel supply to obtain the optimal mixture composition. But no one knows how this sensor will behave during further operation. If the engine runs on a lean mixture, then this can lead to sad consequences and complete engine failure. After explaining to the client what the savings on parts could lead to, we installed the company's proven mass air flow sensor Bosch 0 280 218 037

Fig. 13

And we decided to check what the computer and the gas analyzer will show us at the current CO correction factor (+0.242) but already with the sensor installed Bosch... Let's see.

And so, first we check the readings of the ADC DMRV Bosch 0 280 218 037 when the engine is not running, but the ignition is on.

Fig. 14

Well, the readings of the ADC DMRV Bosch 0 280 218 037 ideal (Fig. 14.), 1.00 volts. We start the engine and look at the engine parameters and the mixture composition according to the gas analyzer with a correction factor (+0.242) which we set with the DMRV-37 sensor.

Fig. 15

Air flow readings (Fig. 15.) finally began to show real values, JAIR = 8.8...9 kg / hour. At the same time, in comparison with Fig 11., the injection time also increased by 0.2 ms and began to be 2.4 ms. as the air flow rate has increased. But what about the composition of the mixture? What will the gas analyzer show at the current (overestimated) CO coefficient CO_Koeff (+0.242). Most likely, our mixture will again become rich and we will have to reduce this coefficient.

Fig. 16

It is, as we expected. With the current correction factor with a properly working mass air flow sensor, the mixture turned out to be enriched (Fig. 16.), CO = 5.34 %. To adjust the mixture to the operating values, reduce CO_Koeff to 0 and, observing the readings of the gas analyzer, adjust the mixture composition by reducing (in our case) the CO_Koeff coefficient to -0.008 .

These are the parameters we got with the DMRV sensor Bosch 0 280 218 037 Fig. 17.

Fig. 17

Well, these parameters can be considered as reference (Fig. 17.). And pay attention to the JQT indicator (l / h) - 0.7 ... This parameter shows the instantaneous current fuel consumption, you can navigate by it and roughly estimate what the consumption will be when driving.